Floating type uniform load planet grinding head

A planetary grinding and floating technology, applied in the direction of grinding tools, etc., can solve the problems of low usage rate of sandpaper, high processing difficulty of planetary grinding head, uneven pressure distribution, etc. Even pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the patent of the present invention clearer, the implementation of the patent of the present invention will be further described in detail below in conjunction with the accompanying drawings.

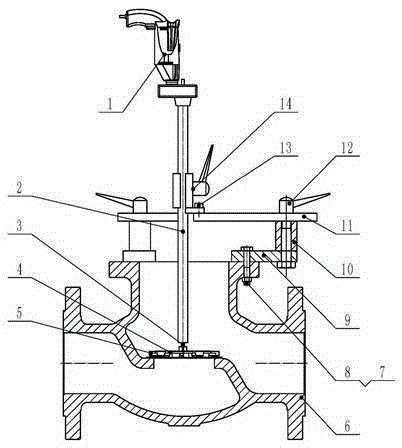

[0023] Take grinding the sealing surface of globe valve as an example, see figure 1 , Before grinding, the fixing plate 9 is fixed to the shut-off valve 6 through the nut 7 and the bolt 8, and the supporting block 10 and the adjusting plate 11 are fixed with the locking device 12. The fixing device 14 is fixedly connected with the adjustment plate 11 through the locking screw 13, and the fixing device 14 remains in a loose state. Wherein, the number of nuts 7 , bolts 8 , fixing plates 9 , supporting blocks 10 , adjusting plates 11 , locking devices 12 and locking screws 13 is three.

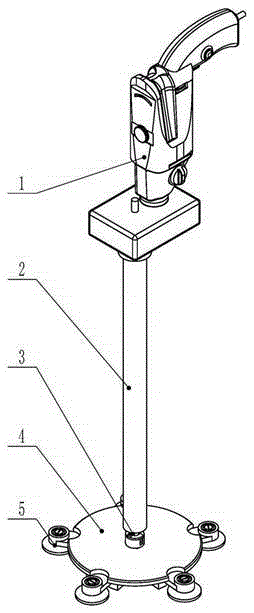

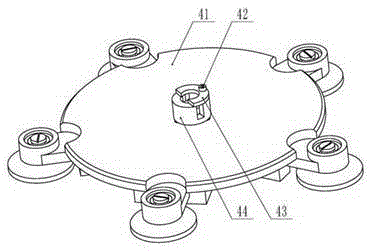

[0024] see Figure 1-Figure 4 , the planetary grinding head assembly 5 is fixedly connected with the sun disk assembly 4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com