High-strength and high-performance mineral admixture for concrete and production method thereof

A technology of mineral admixture and production method, applied in the field of building materials, can solve the problems of reduced concrete performance and low Portland cement ratio, and achieve the effects of improving filling, reducing bleeding and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

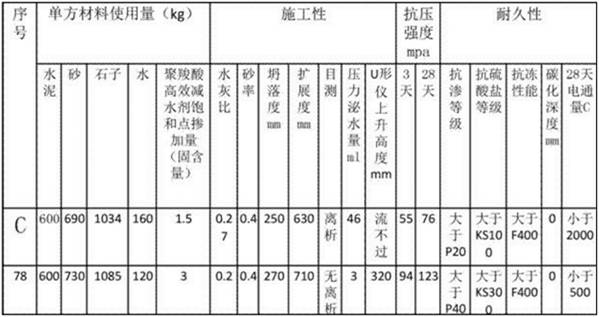

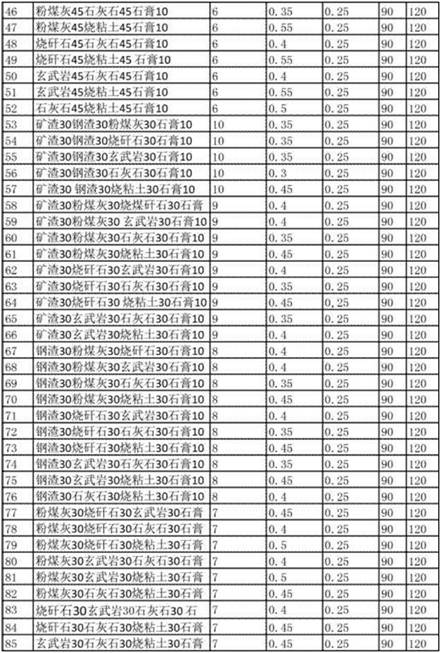

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments.

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

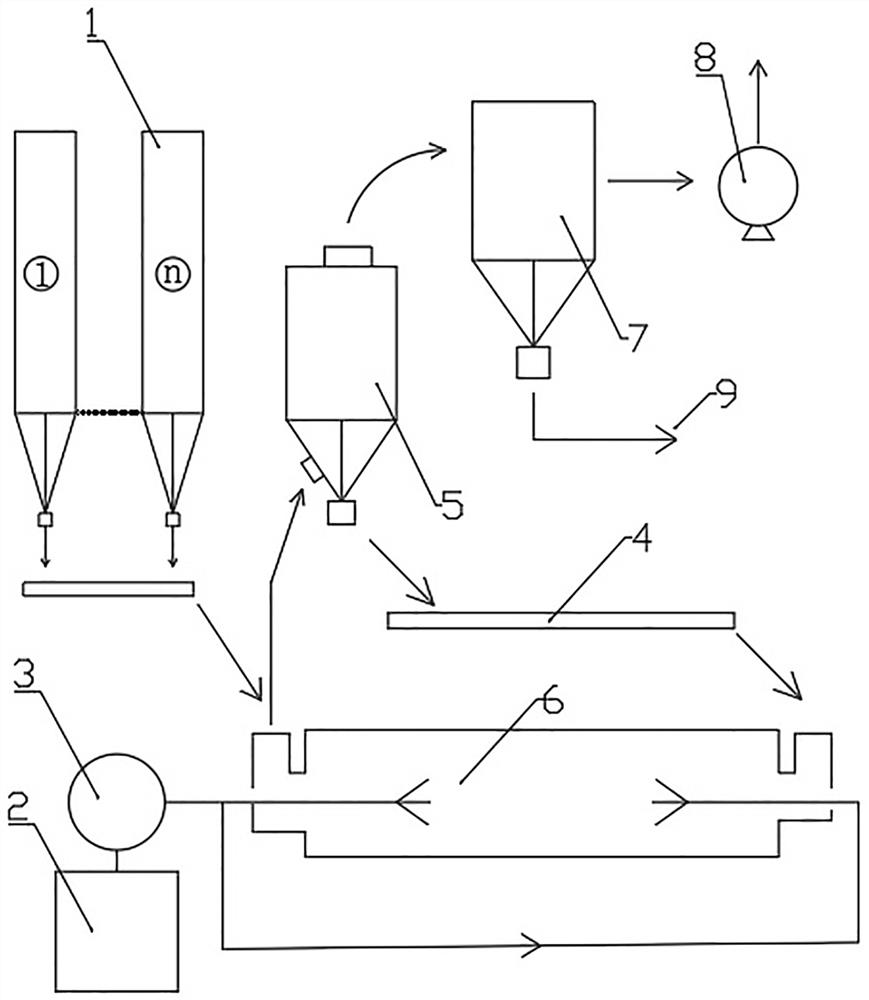

[0020] With regard to Figure 1 of the accompanying drawing in the above description, the following explanations need to be made:

[0021] In the drawings of the instruction manual - 1, 1-n is the storage tank below n kinds of mineral admixture raw material grinding materials (K97=100 microns), 2 is the polycarboxylic acid high-efficiency water-reducing grinding aid water storage tank, and 3 is the metering high pressure Spray device, 4 is the powder return metering conveyor, 5 is the tube mill, the tube mill is equipped with (steel or ceramic) microspheres or microforgings or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com