Tenon connection processing method for producing and processing solid wood furniture

A processing method and tenon technology, applied in the direction of wood processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the efficiency of grinding, increasing the working steps, and not being able to grind, so as to improve the efficiency of grinding, reduce the working steps, Avoid over-sanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

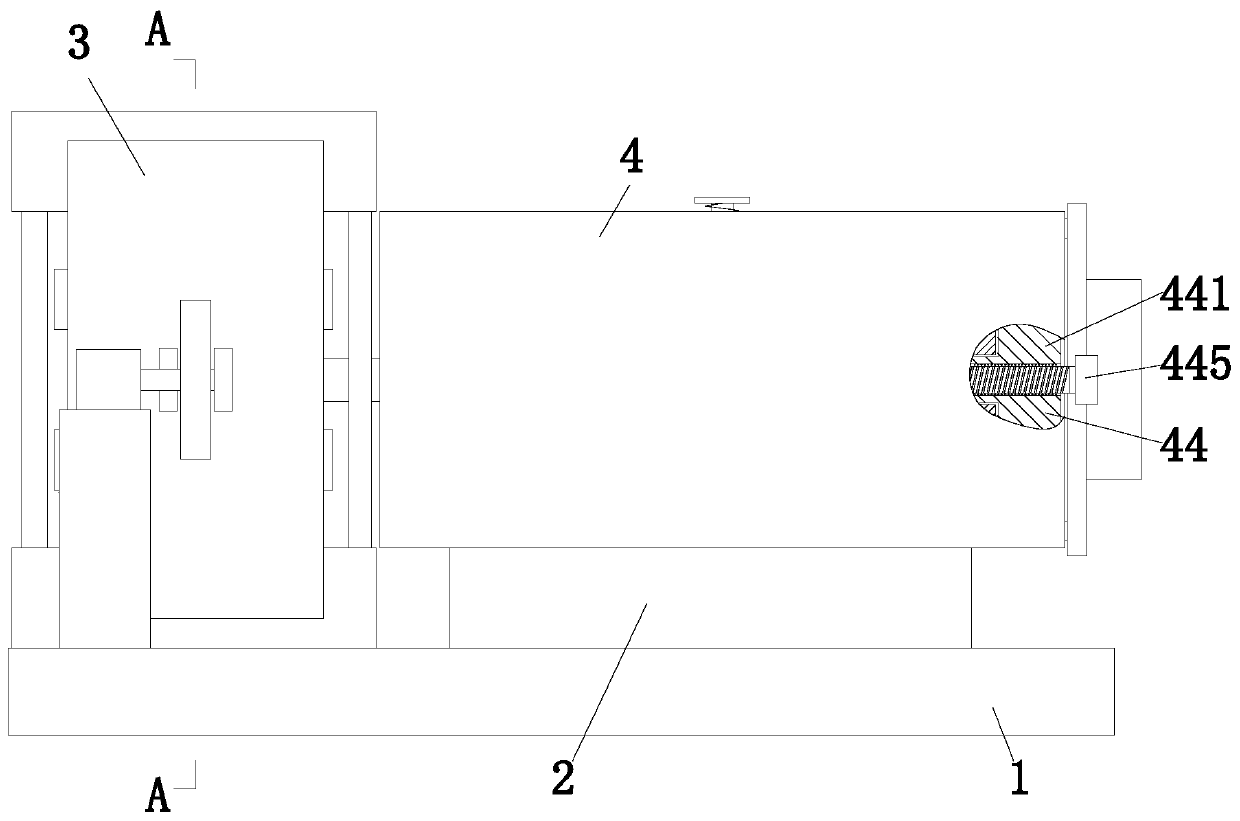

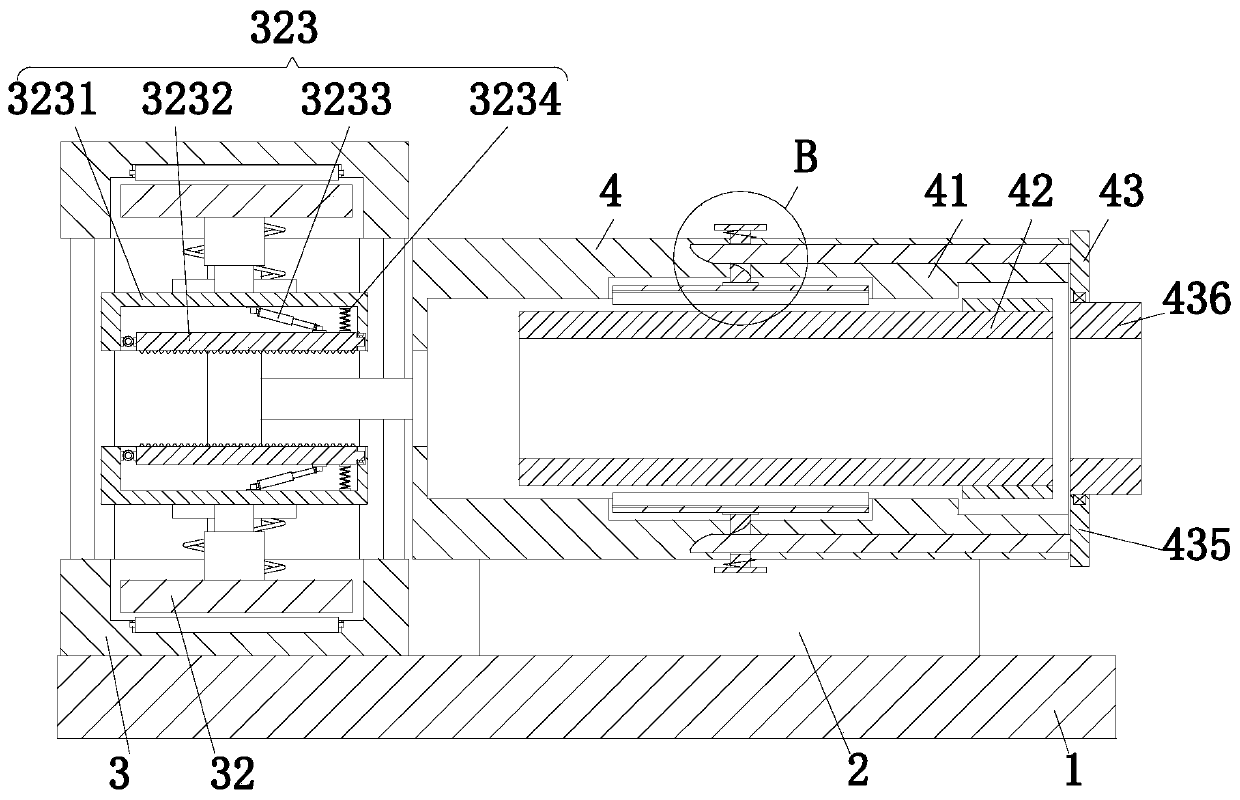

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

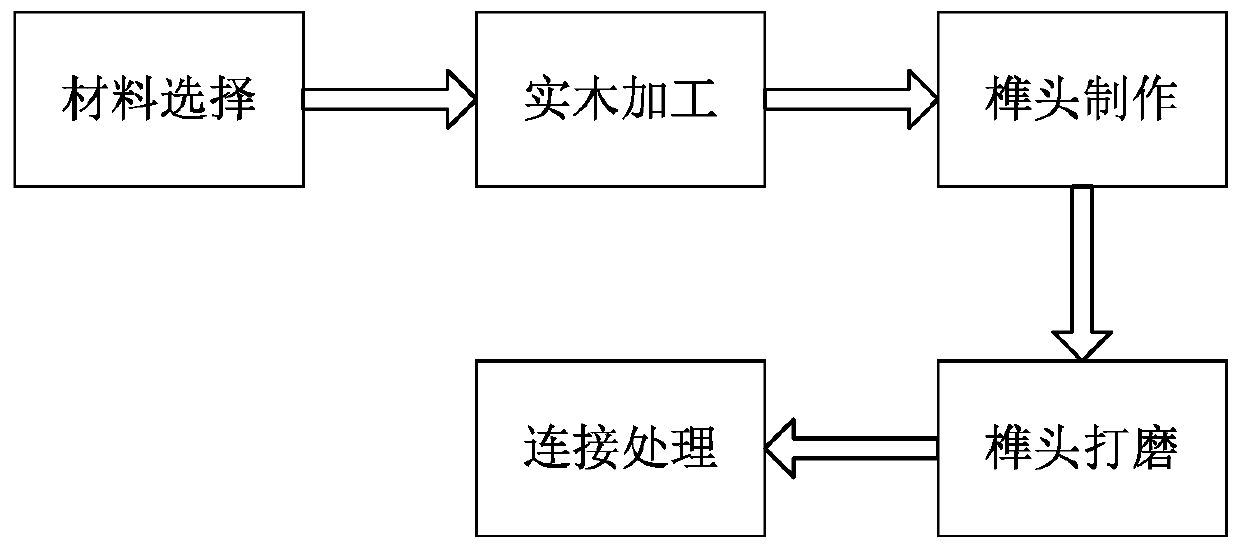

[0034] Such as Figure 1 to Figure 5 As shown, a method for processing tenon joints in the production and processing of solid wood furniture comprises the following steps:

[0035] S1. Material selection: manually select the wood required for the production of furniture;

[0036] S2, solid wood processing: manually place the wood selected in step S1 on the wood cutting machine, the wood cutting machine cuts the wood, removes the skin on its surface, and processes the wood into square wooden strips;

[0037] S3, tenon making: place the square wooden strips processed in step S2 on the tenoning machine, and the tenoning machine performs tenon processing on the square wooden strips to make a dovetail tenon;

[0038] S4. Grinding the tenon: manually plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com