Foam insulation board manufacturing system

A foam insulation board and manufacturing system technology, applied in the field of insulation board manufacturing, can solve the problems of reducing the combination degree of tailings and other raw materials, the inability to control and disperse granite tailings, and the inclusion of debris in granite tailings, so as to avoid cleaning Effects of incompleteness, increased work steps, and increased purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

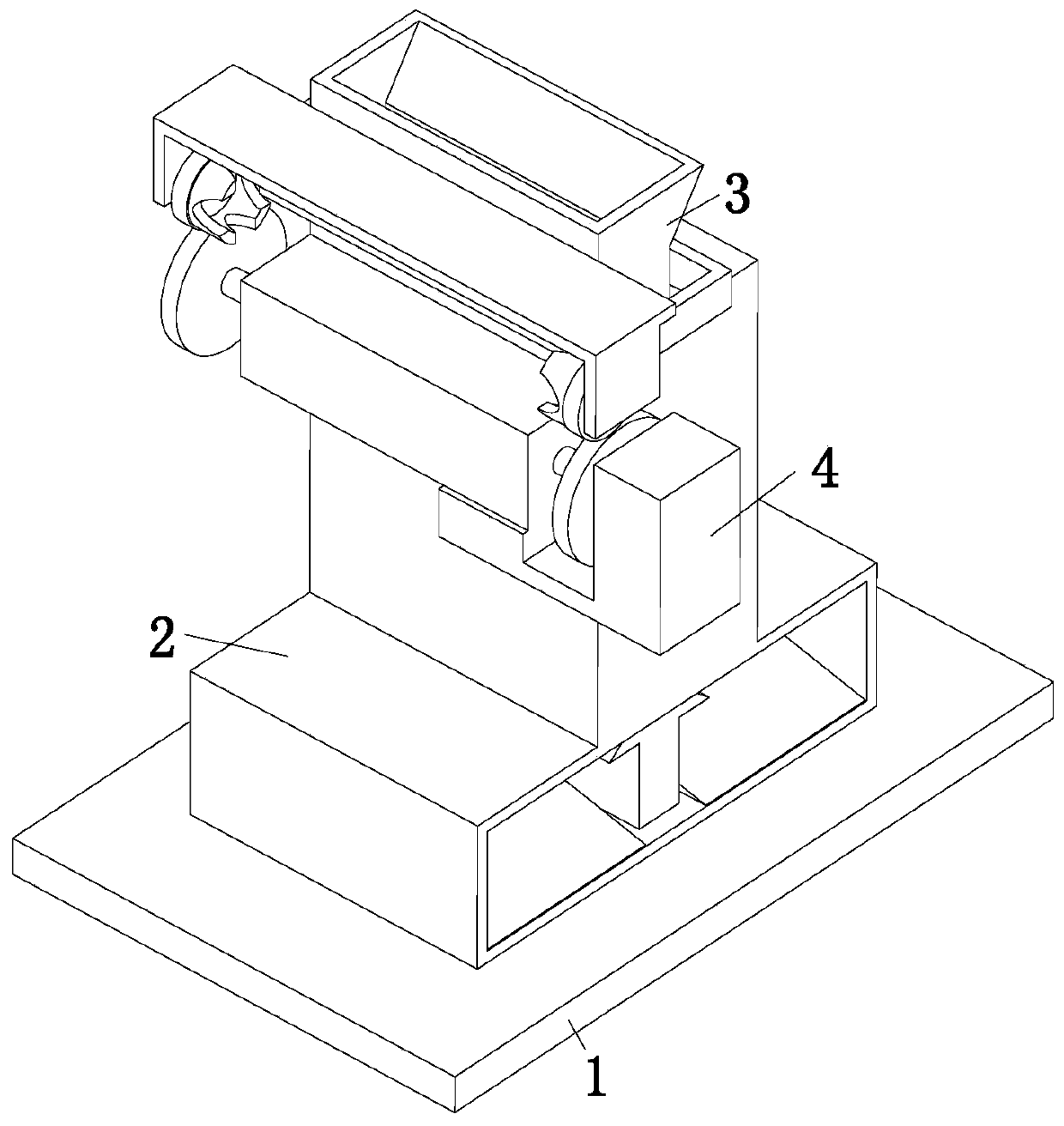

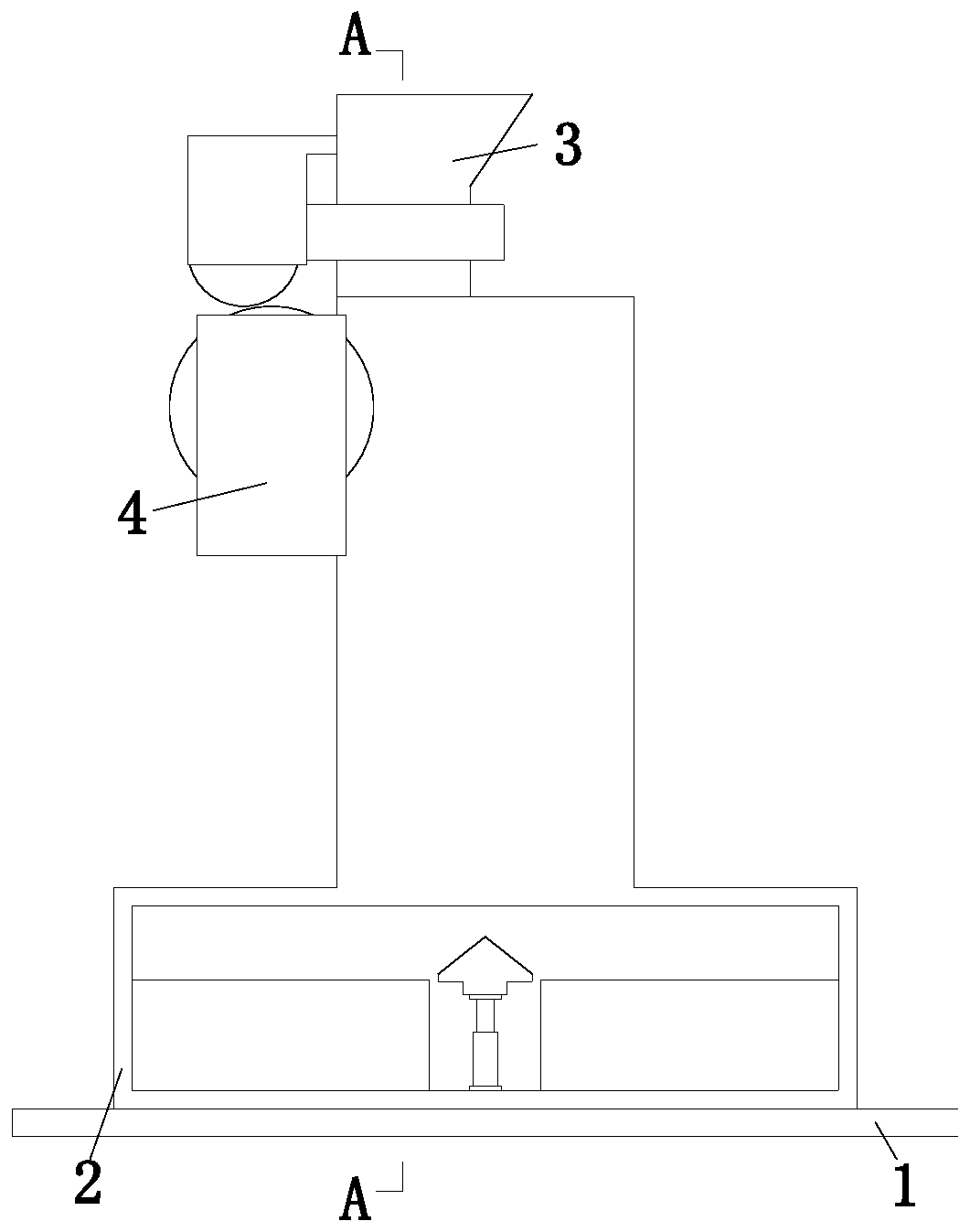

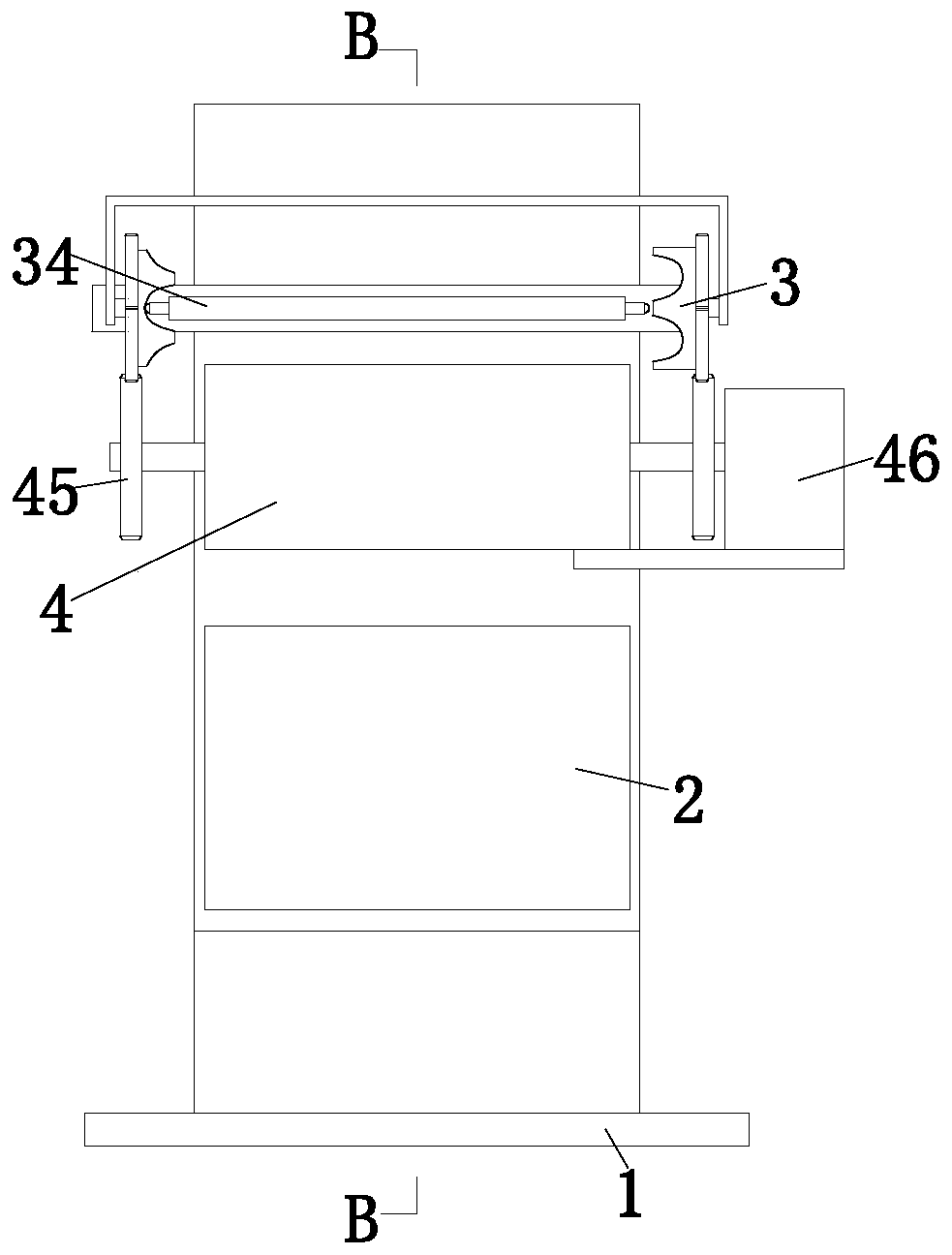

[0028] Such as Figure 1 to Figure 6 As shown, in order to achieve the above object, the present invention adopts the following technical scheme, a foam insulation board manufacturing system, including a base plate 1, a receiving device 2, a feeding device 3 and a dispersion device 4, and a receiving device is installed on the upper end of the base plate 1 2. A feeding device 3 is installed on the upper end of the receiving device 2, and a dispersing device 4 is installed below the feeding device 3, and the dispersing device 4 is installed on the left end surface of the receiving device 2.

[0029] The receiving device 2 includes a receiving frame 21, a connecting plate 22, an air inlet pipe 23, a protective net 24, a cylinder 25, a limit mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com