Patents

Literature

170results about How to "Avoid incomplete cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

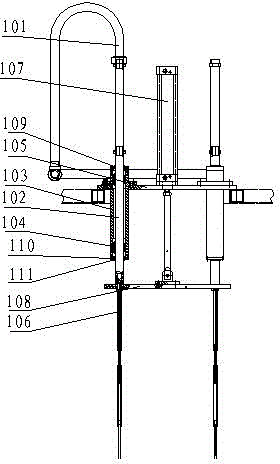

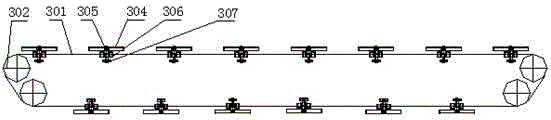

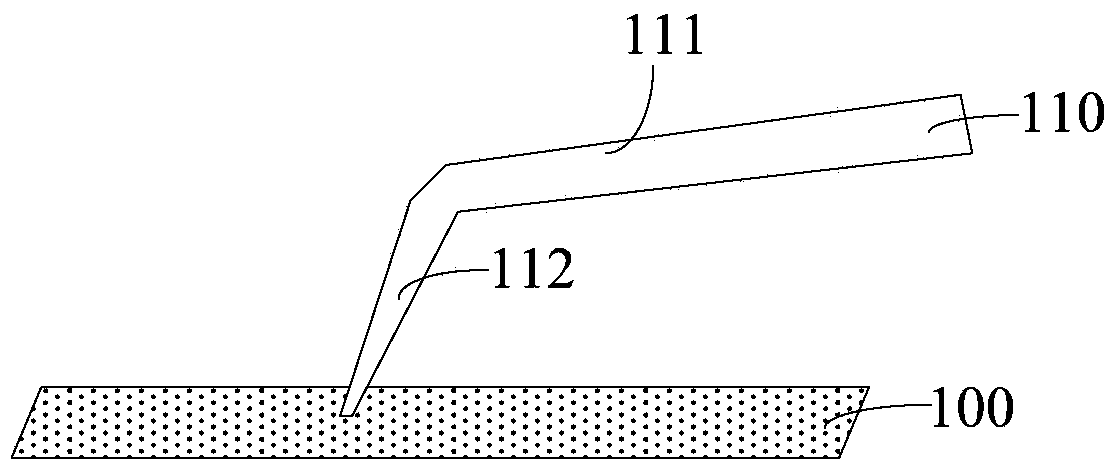

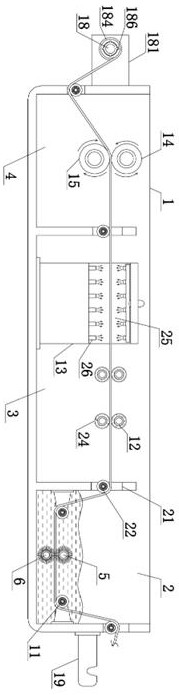

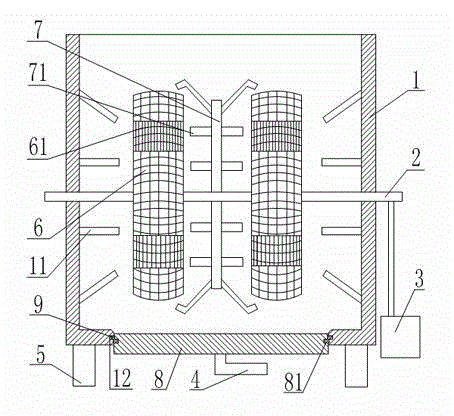

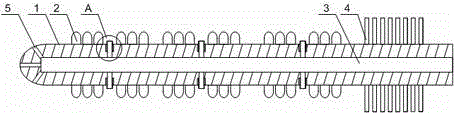

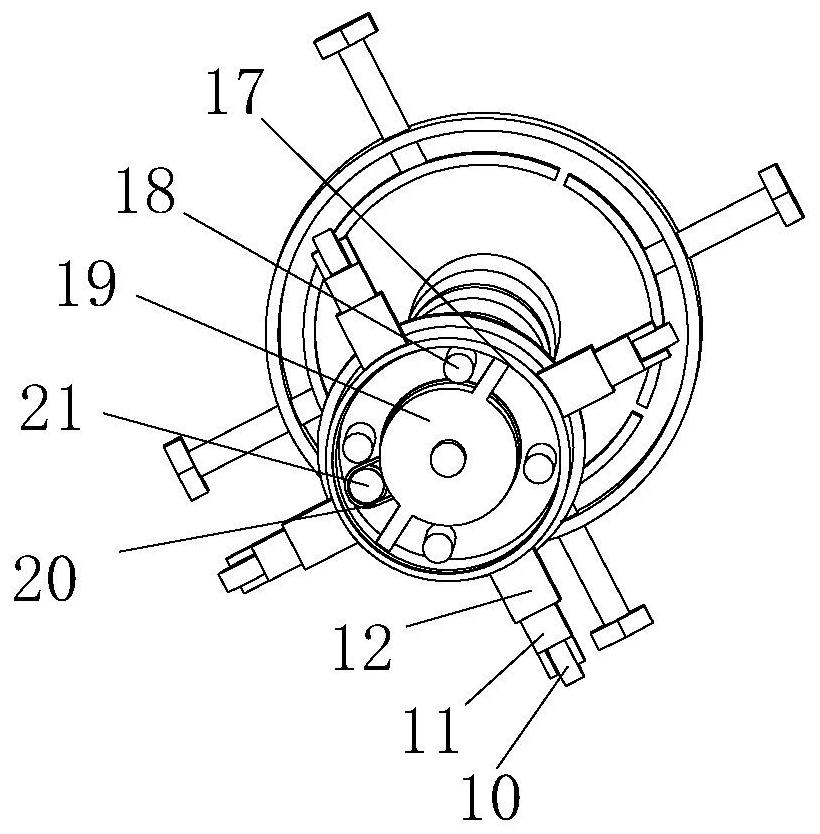

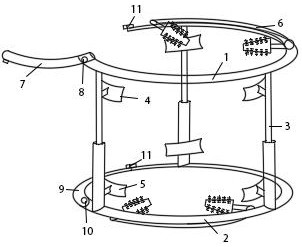

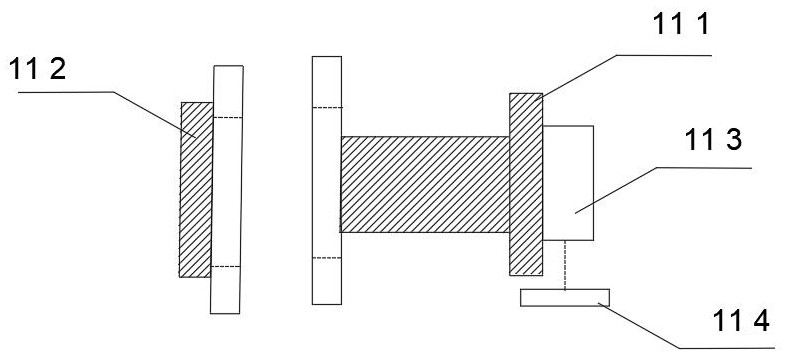

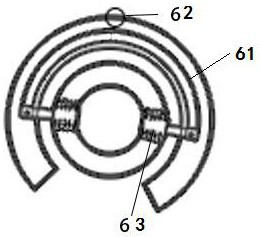

Stepping all-directional valve cleaner

ActiveCN104368547AEasy to liftEasy to useConveyorsDrying gas arrangementsEngineeringMechanical engineering

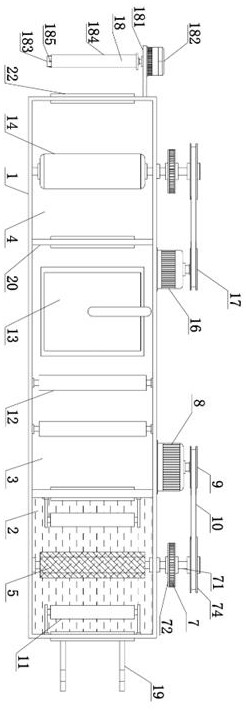

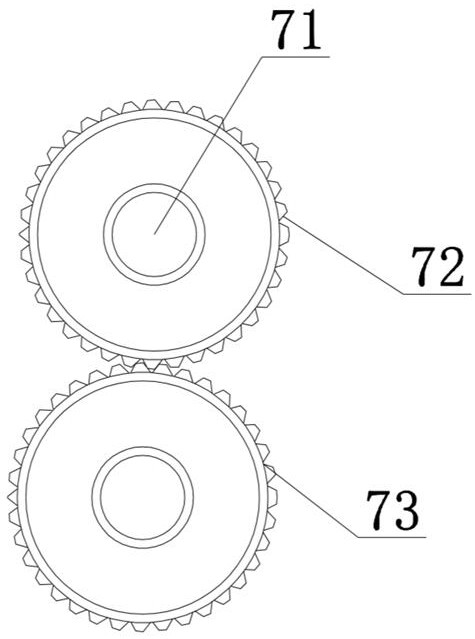

The invention provides a stepping all-directional valve cleaner comprising a conveying mechanism, a cleaning device, a rinsing device, a blow-drying deice and a drying device. The conveying mechanism is used for moving a workpiece. The cleaning device is used for removing impurities on the surface of the workpiece; the rinsing device is used for removing oil stain on the surface of the workpiece; the blow-drying device is used for removing water on the surface of the rinsed workpiece; the drying device is used for removing the water on the surface of the workpiece. The cleaning device, the rinsing device, the blow-drying device and the drying device are disposed in order; both the cleaning device and the rinsing device comprise spraying units. According to the stepping all-directional valve cleaner, the conveying mechanism conveys the workpiece to pass the cleaning device, the rinsing device, the blow-drying device and the drying device in order; when passing the cleaning device and the rising device, the spraying units above clean and rinse the workpiece; during cleaning and rinsing, the conveying mechanism allows the workpiece to be driven to rotate by a rotating gear, cleaning and rinsing effect of the workpiece is guaranteed, and all-directional thorough cleaning of the workpiece is achieved.

Owner:安徽宝辉清洗设备制造有限公司

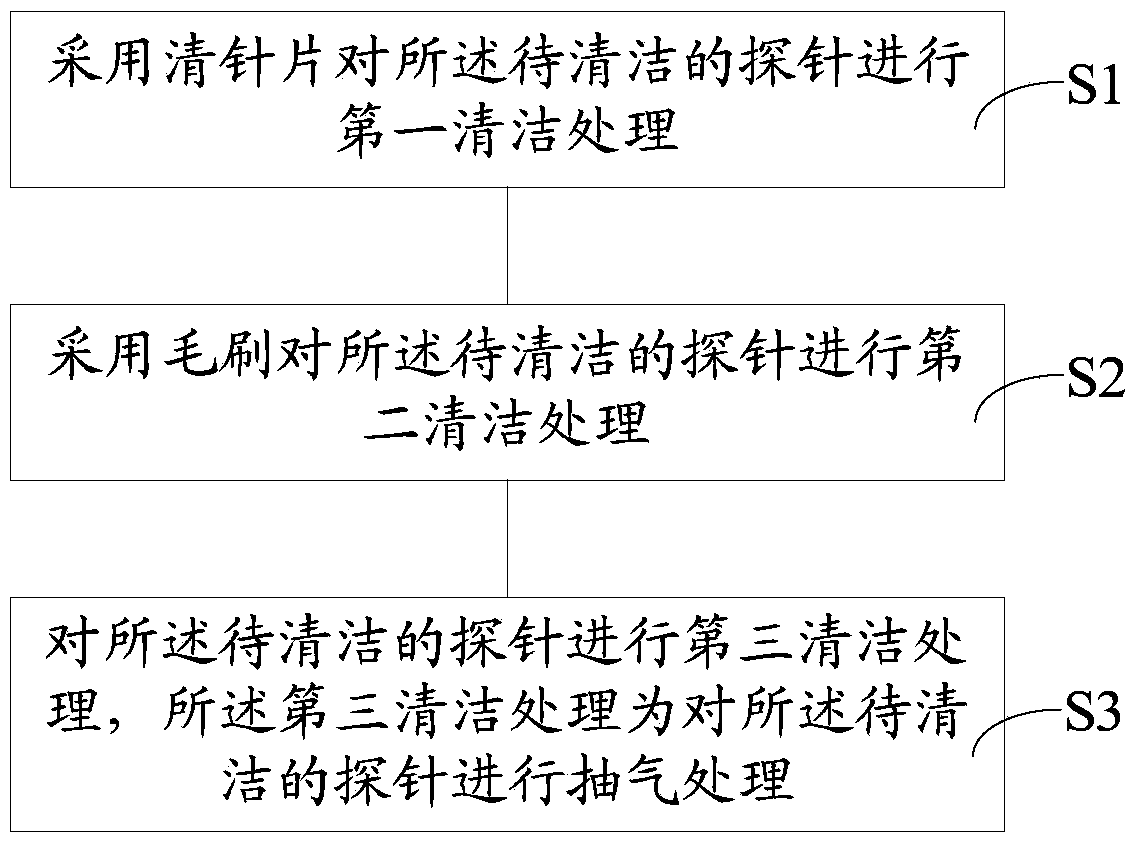

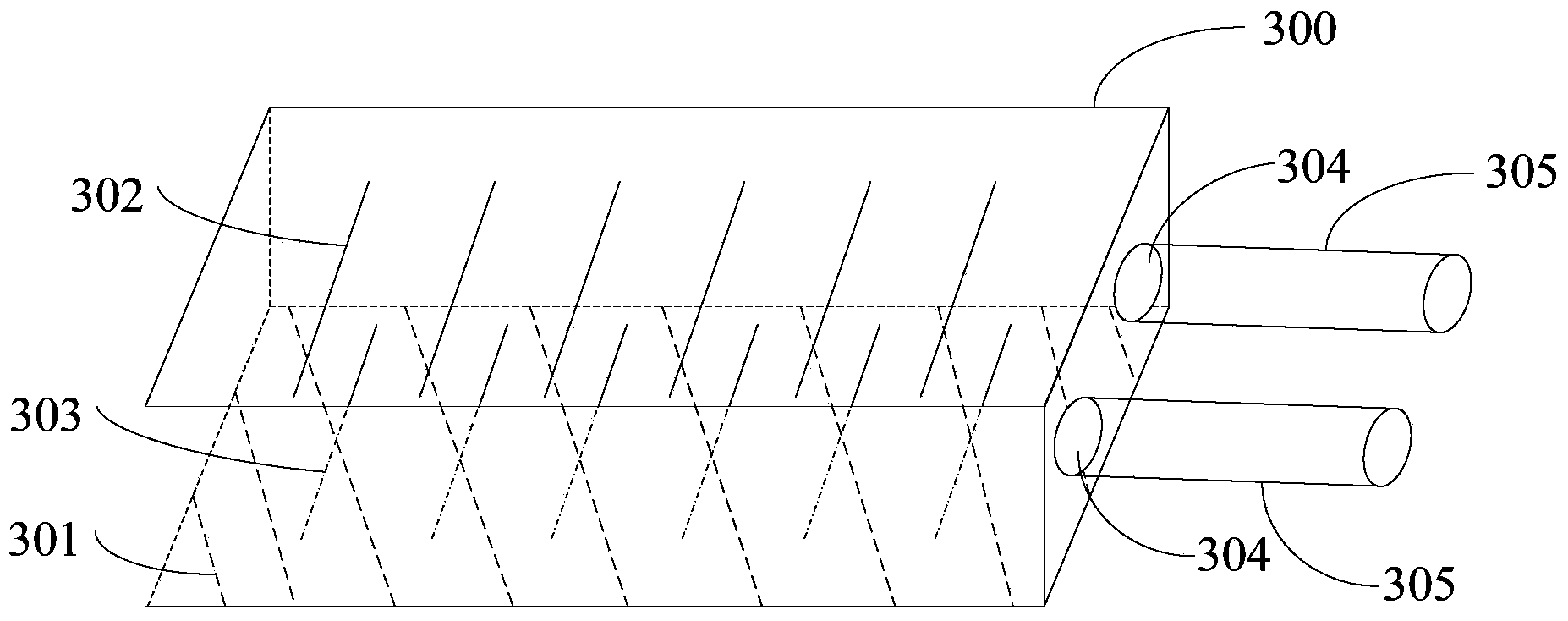

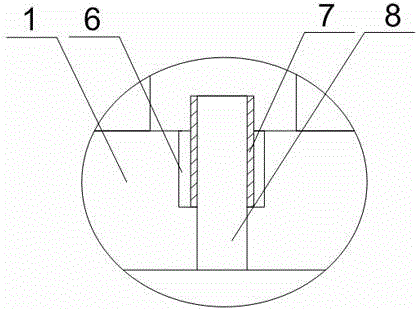

Probe cleaning method and probe cleaning device

ActiveCN103878150AImprove reliabilityImprove accuracyDirt cleaningCleaning using toolsCleaning methodsBiomedical engineering

The invention provides a probe cleaning method and a probe cleaning device. The probe cleaning method comprises the steps of providing a probe to be cleaned, adopting a probe cleaning piece to primarily clean the probe to be cleaned, adopting a brush to secondarily clean the probe to be cleaned, thirdly cleaning the probe to be cleaned, namely extracting air of the probe to be cleaned in the third cleaning process, and carrying out the first cleaning process, the second cleaning process and the third cleaning process at the same time. According to the probe cleaning method and the probe cleaning device, probe cleaning efficiency is improved, impurity removing ability is enhanced, probe cleaning time is shortened, accuracy and reliability of wafer testing results are improved, wafer testing time is shortened, and production efficiency is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

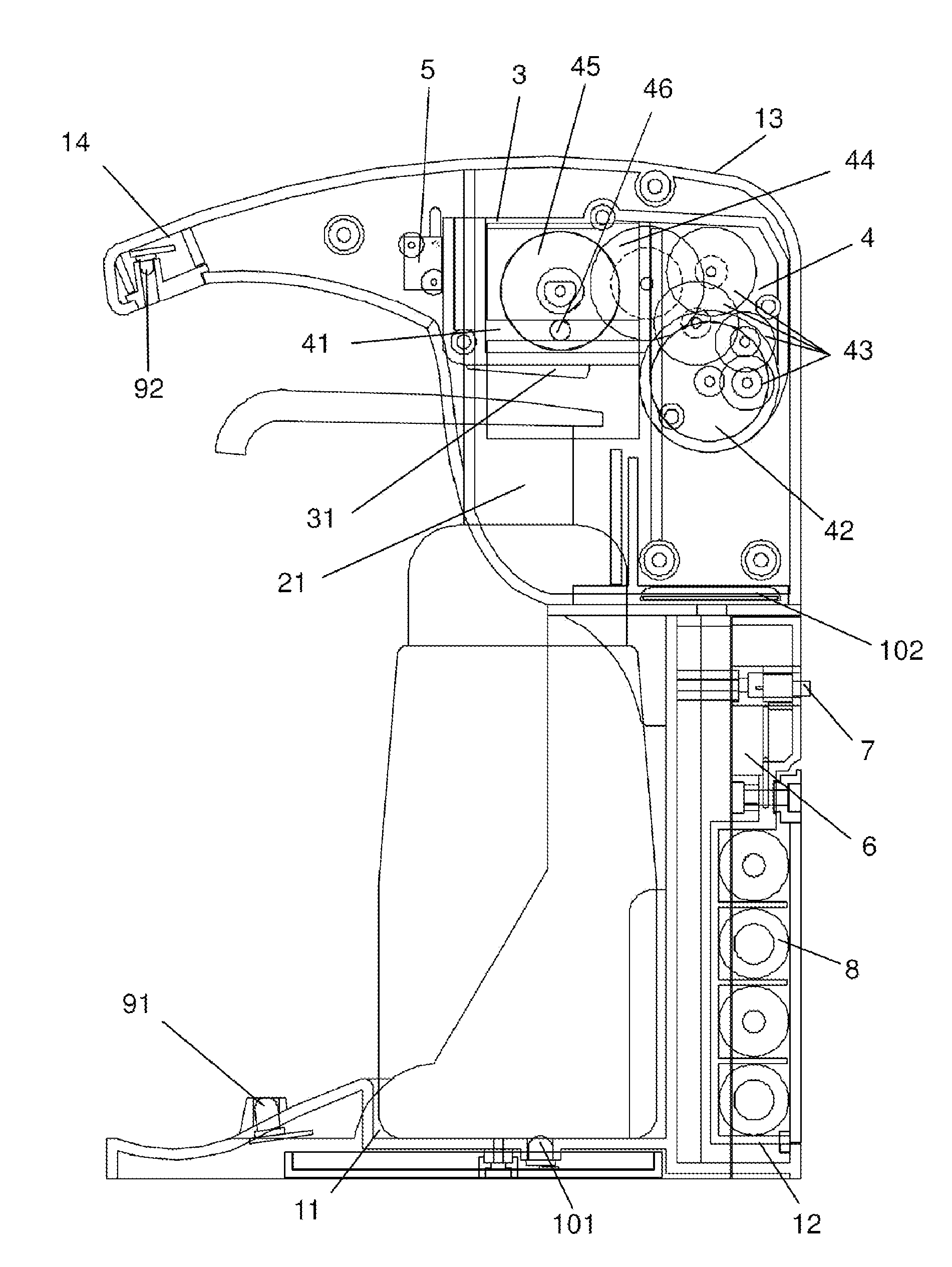

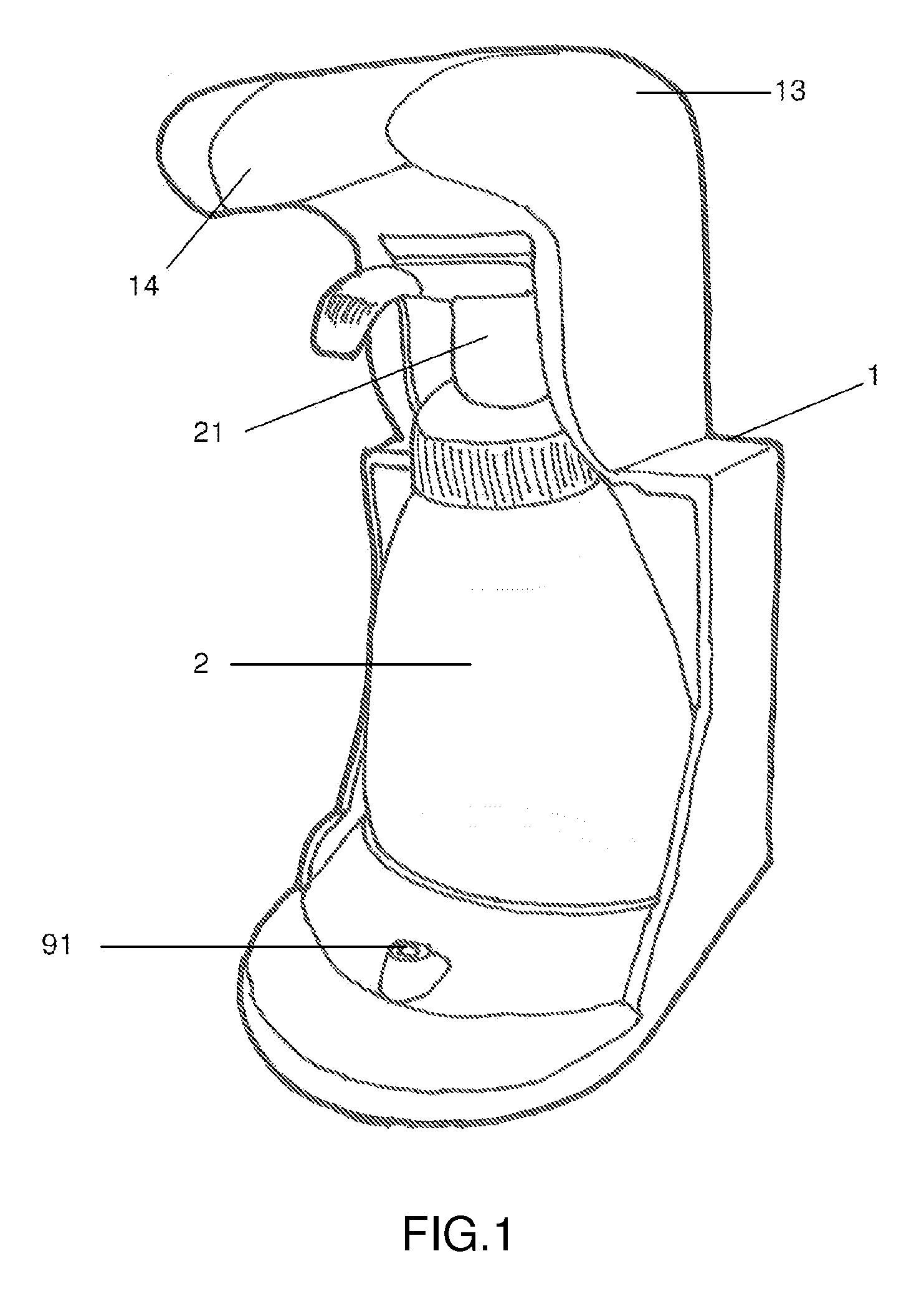

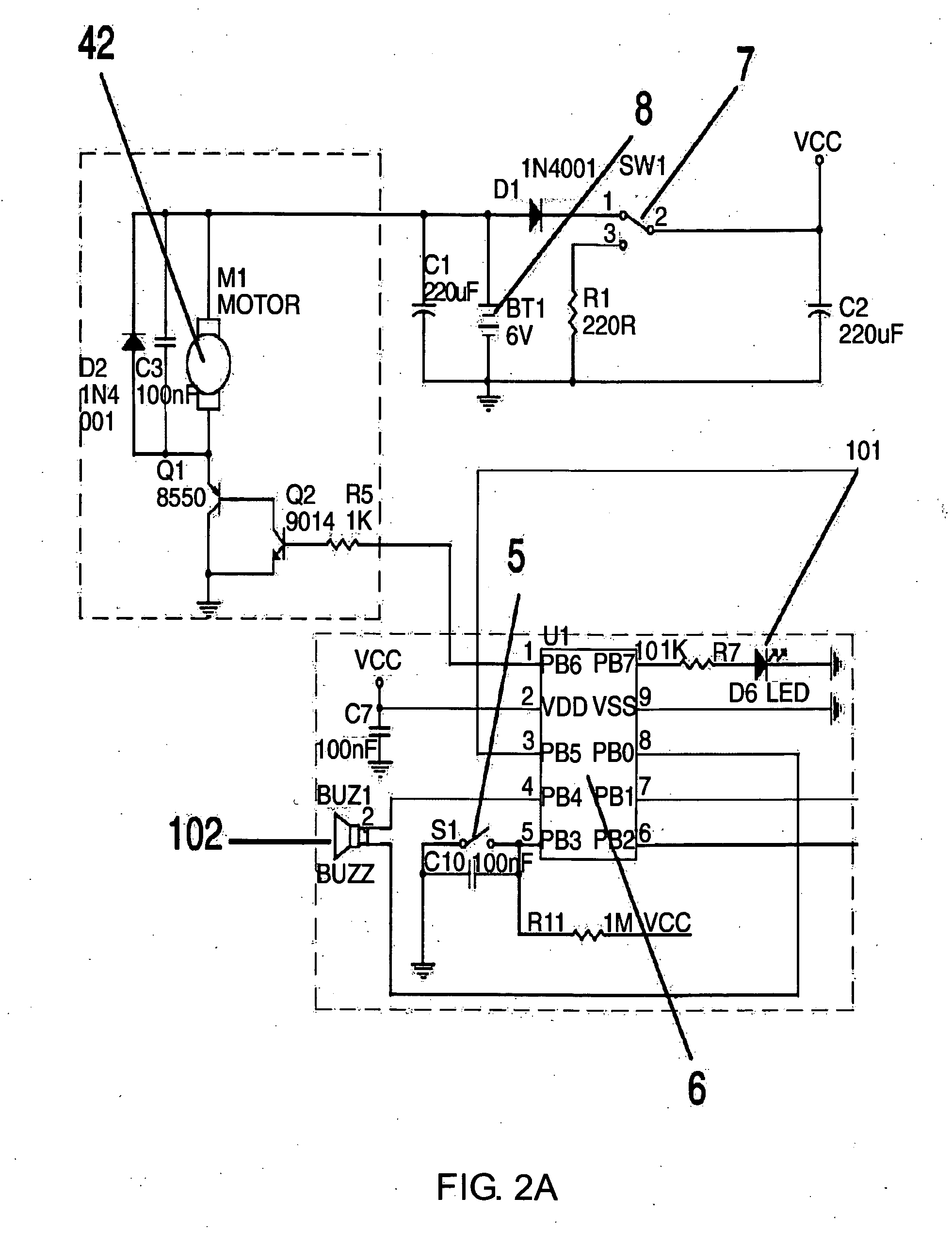

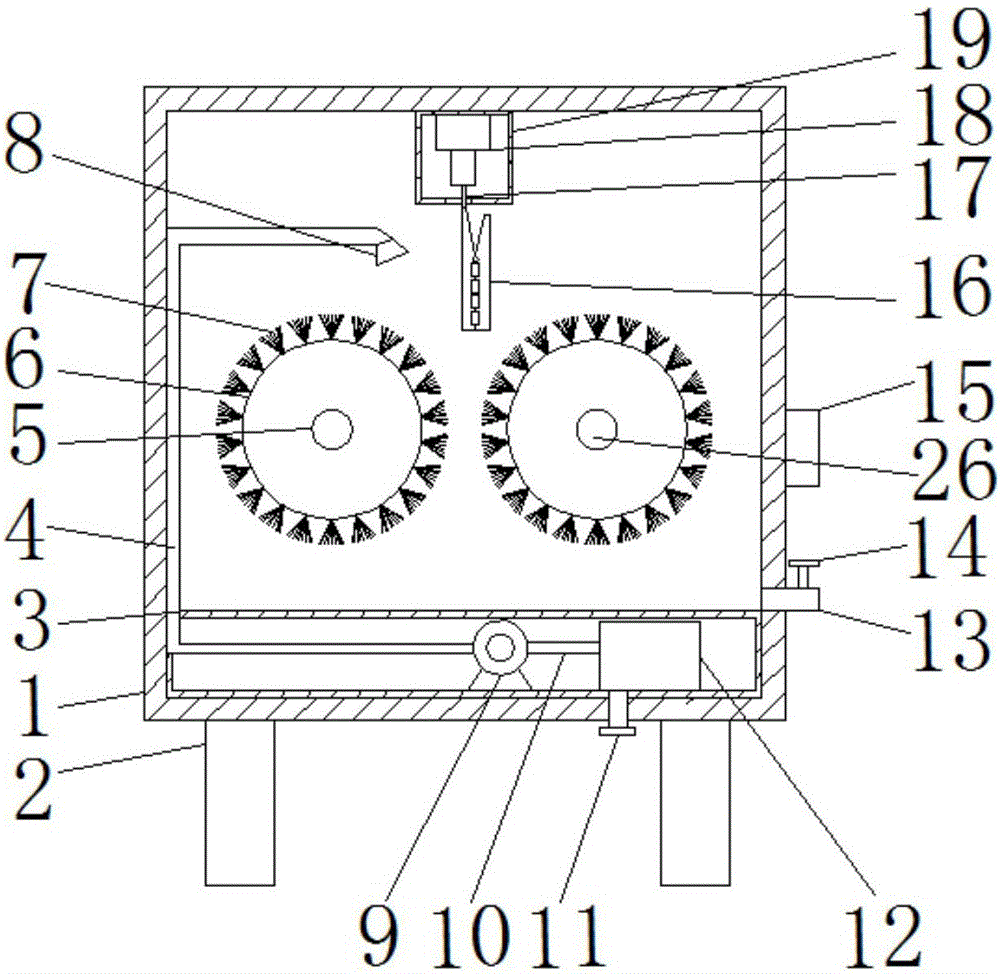

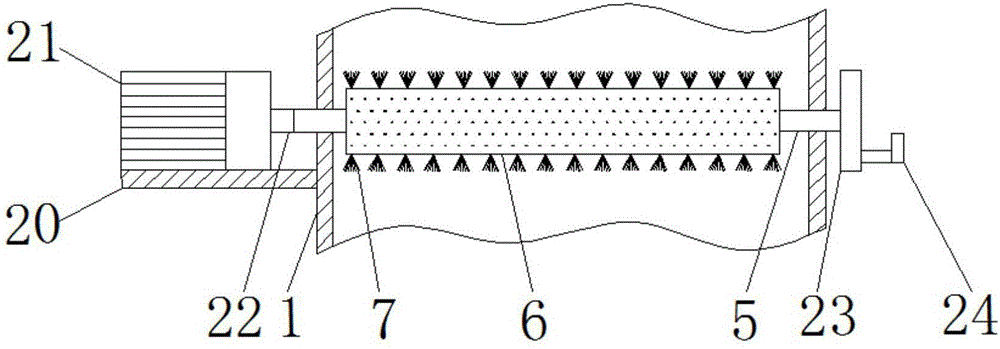

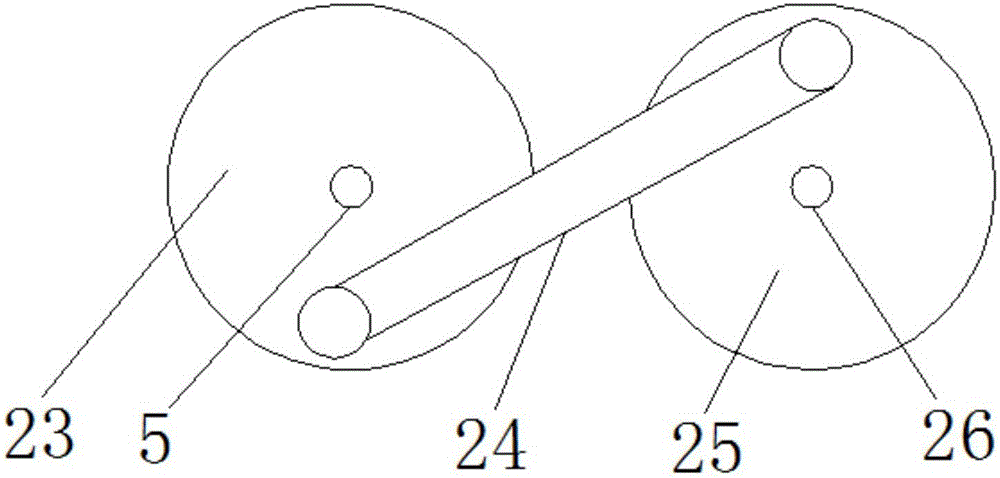

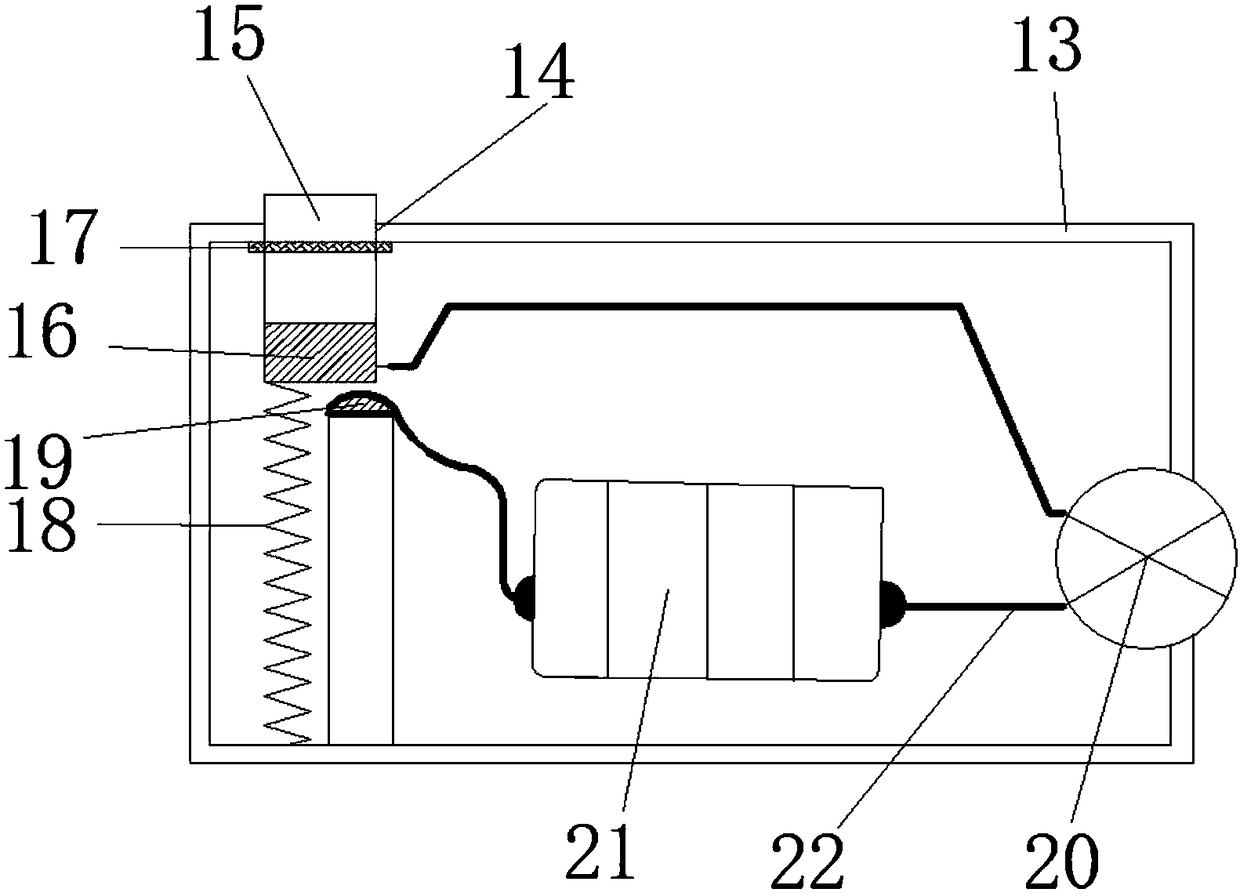

Automatic soap dispenser with notification function

InactiveUS20120111884A1Avoid incomplete cleaningReduce chanceTime indicationDiagnosticsEngineeringSoap dispenser

The present invention is an automatic soap dispenser with notification function, which comprises an outer casing; a soap container; a plunger driven by a plunger driving means to move up and down between a default position and a dispensing position where the pump dispensing means is depressed to dispense liquid soap; a plunger position sensor which is configured to be triggered when the plunger is at the default position; and an integrated circuit with timing function which is programmed to operate in such a way that when the user sensing means is triggered, the integrated circuit activates the plunger driving means and initiates the timing function in order to activate the notification means after a predetermined period of time has elapsed, and when the plunger position sensor is triggered, the integrated circuit deactivates the plunger driving means.

Owner:CHOI CHUN KWONG

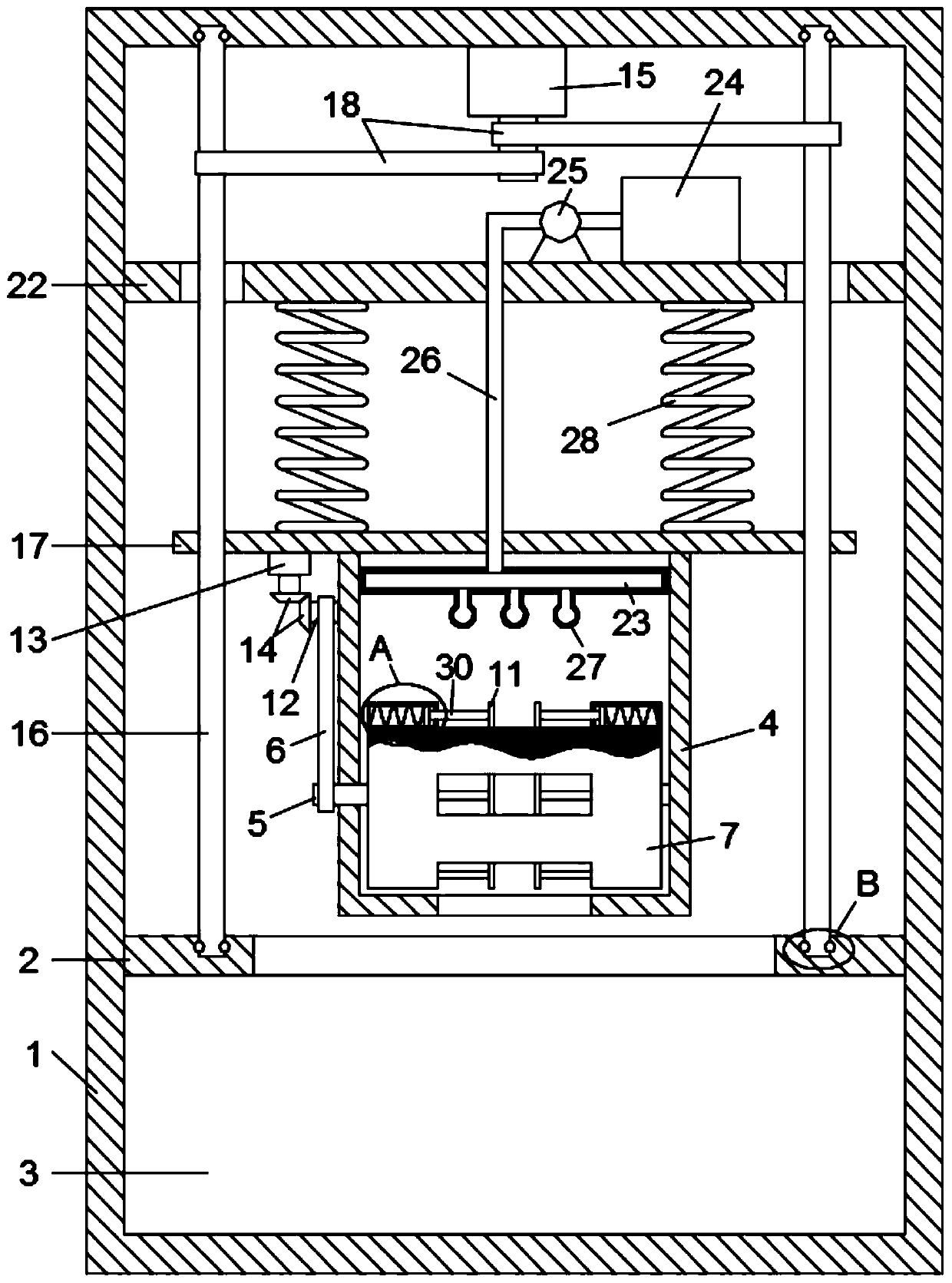

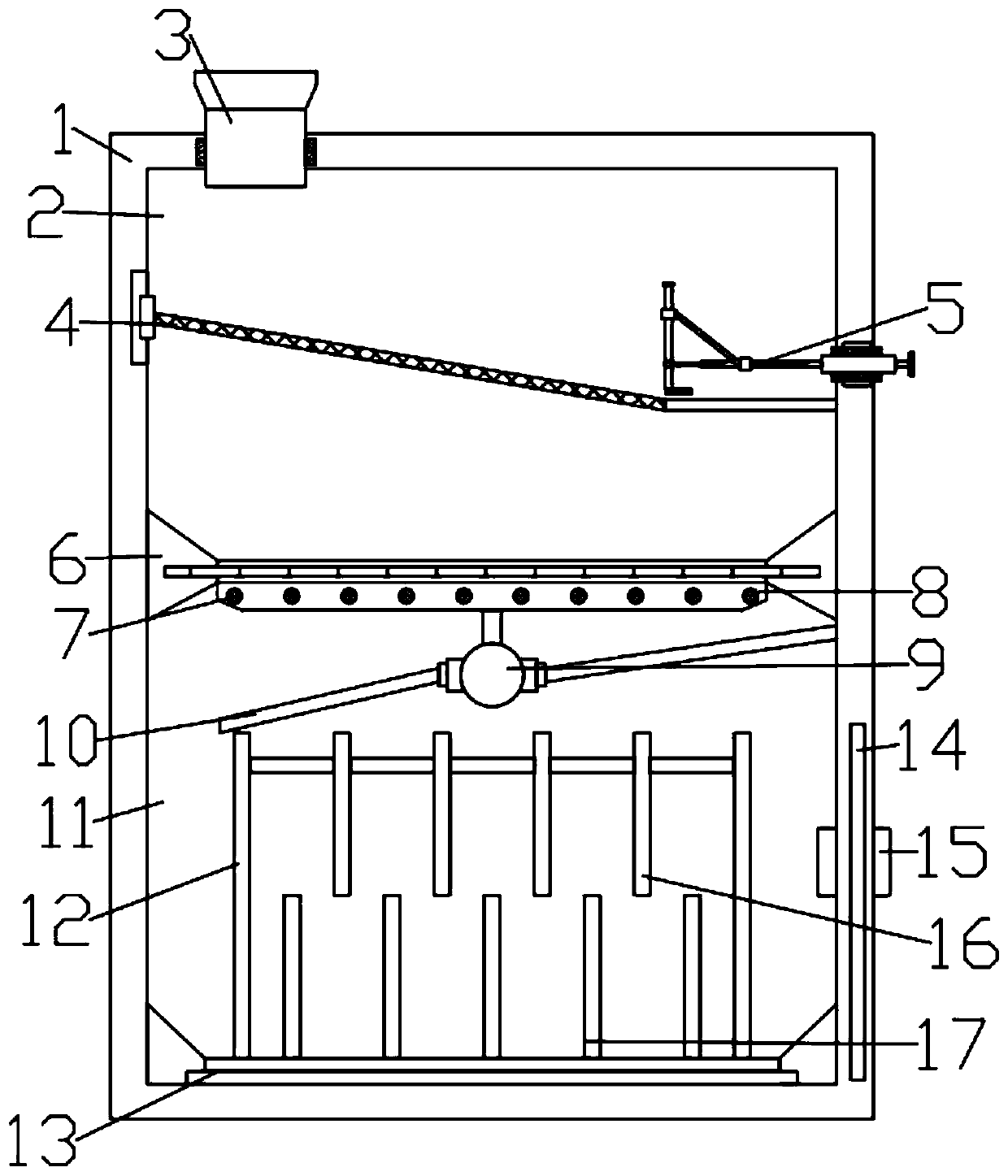

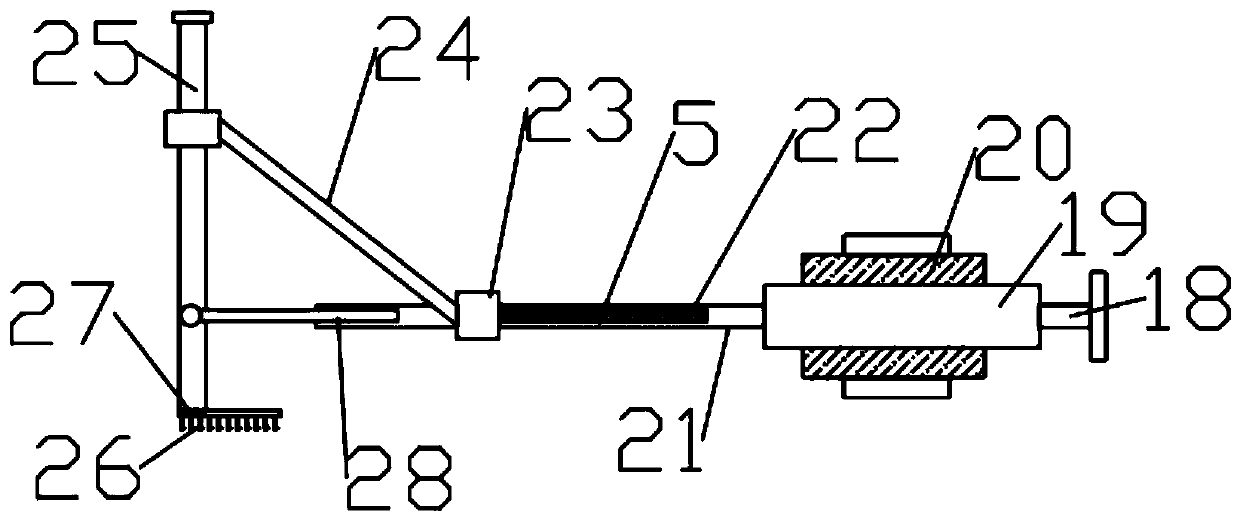

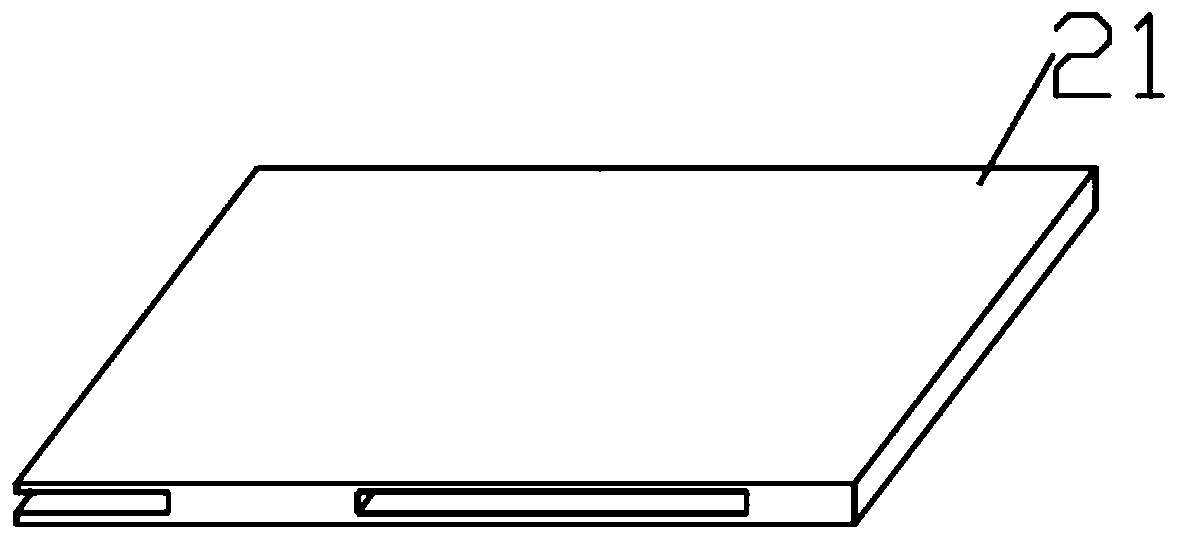

Medical apparatus cleaning device

InactiveCN106623161AGood cleaning effectImprove work efficiencyCleaning using toolsCleaning using liquidsWater pipeWater tanks

The invention discloses a medical apparatus cleaning device. The medical apparatus cleaning device includes a box; a first protection case is fixedly connected to the bottom of the inner wall of the box; a water pump and a water tank are successively and fixedly connected to the bottom of the inner wall of the first protection case from left to right; two sides of the water pump communicate with a first water pipe and a second water pipe respectively; the right side of the second water pipe communicates with the water tank; the left side of the bottom of the water tank communicates with a water injection pipe; the bottom of the water injection pipe successively passes through the protection case and the box, and extends to the bottom of the box; and one end, away from the water pump, of the first water pipe, passes through the first protection box and extends to an inner cavity of the box. According to the invention, a clamp can move vertically through an air cylinder, and the cleaning effect of medical apparatuses is good; the problem that the medical apparatuses are not completely cleaned due to insufficient contact between a brush and the medical apparatuses in cleaning of the medical apparatuses can be avoided; and a support plate can support a motor.

Owner:佛山市翠微自动化科技有限公司

Chemical scrubbing method of the flat-plate film

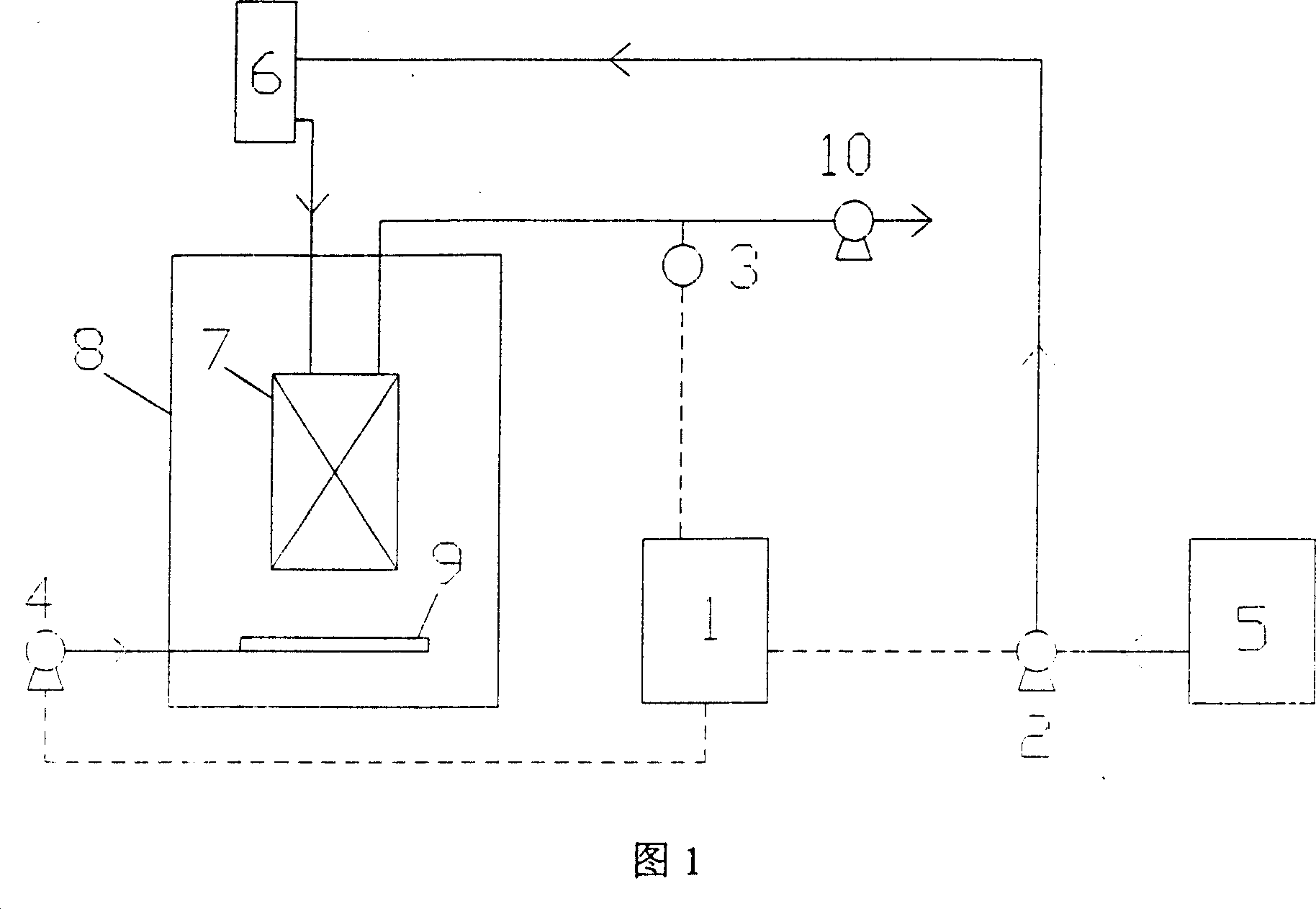

InactiveCN101116797AEasy to cleanGuaranteed flushSemi-permeable membranesAutomatic controlControl system

The present invention relates to a chemical washing technology for diaphragm, which is applicable to the washing process of plate diaphragm in plate diaphragm biologic reactor; the present invention can detect through the operation pressure in the running process of the plate diaphragm; when the pressure is more than certain degree, an automatic control system can adjust the aeration quantity of the plate diaphragm, meanwhile, a washing liquid is added into the plate diaphragm through a medicine adding system, after for a while, the washing liquid is discharged from the plate diaphragm, the described steps is repeated by once at least; the washing chemical agent added in the present invention can effectively wash the inside of the plate diaphragm, the control on the staying time can assure the medicine to penetrate from the inside to the outside of the diaphragm in order to wash a diaphragm hole and the outside of the diaphragm; a continuous aeration process can assure the air to flush on the external surface of the diaphragm to remove a pollutant outside the washed diaphragm in time, a repetitive washing process can avoid the incomplete washing effect from the first washing process, and improve the effectiveness of diaphragm washing; the invention has the advantages of an easy operation, a high automatic degree and so forth.

Owner:TORAY FIBER RES INST(CHINA) CO LTD +1

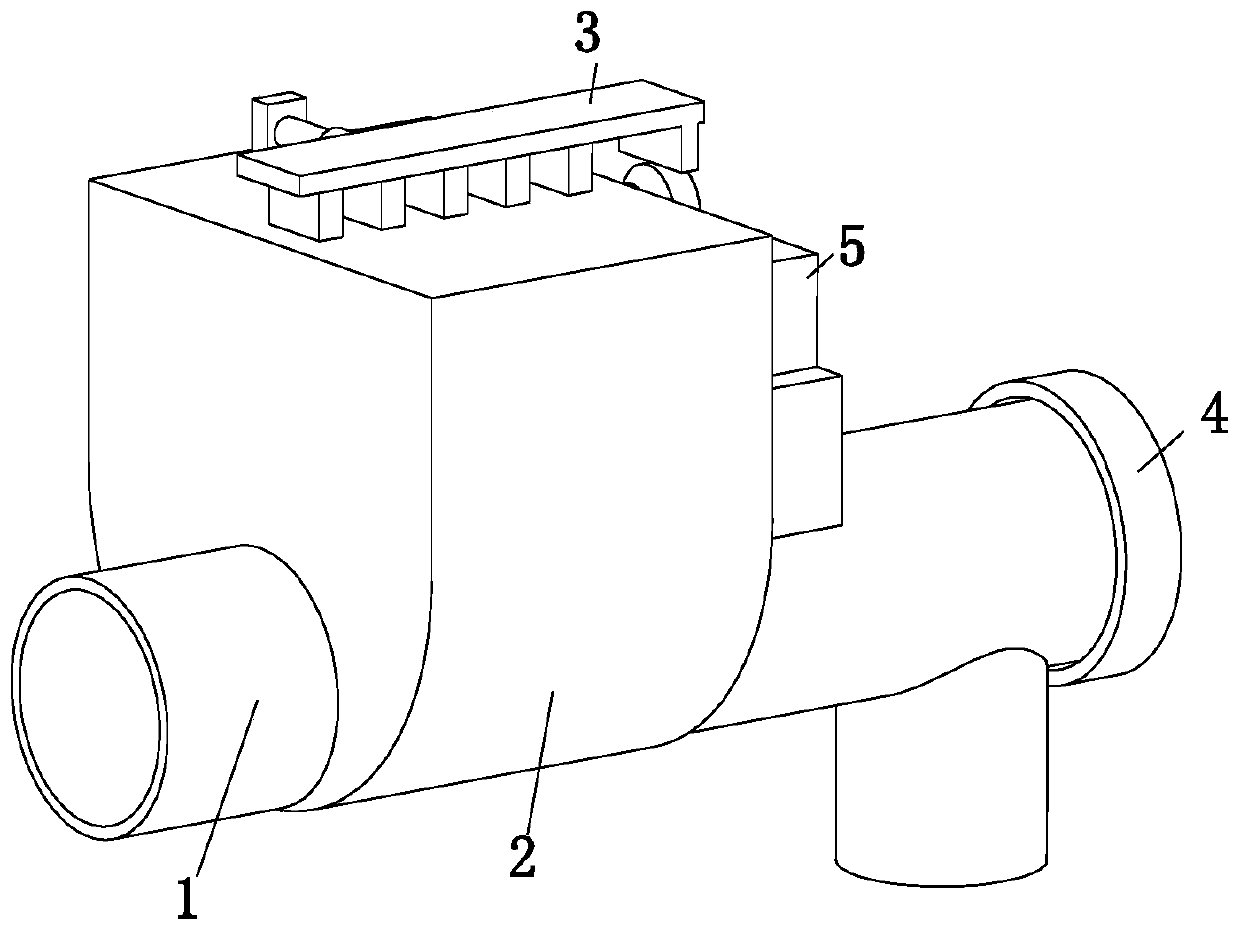

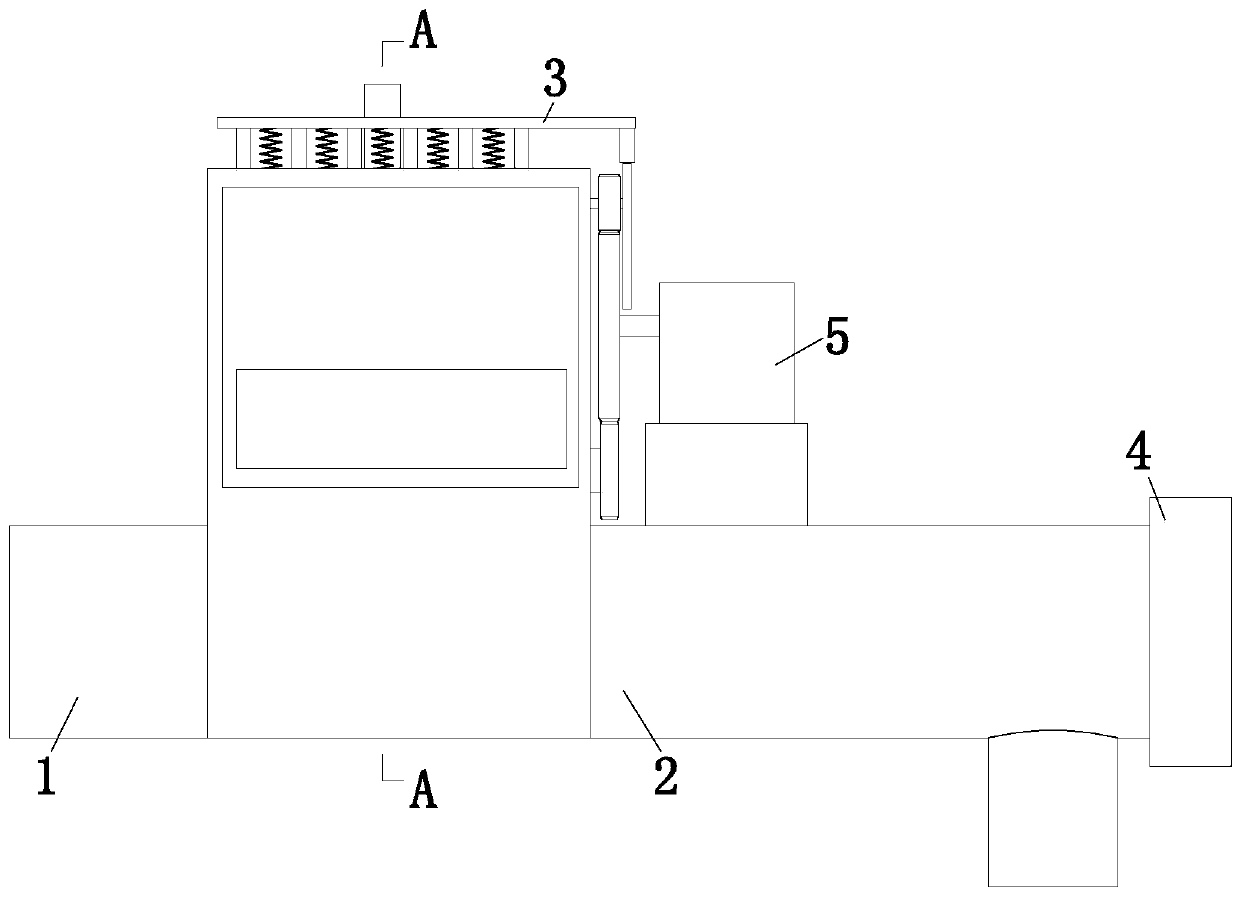

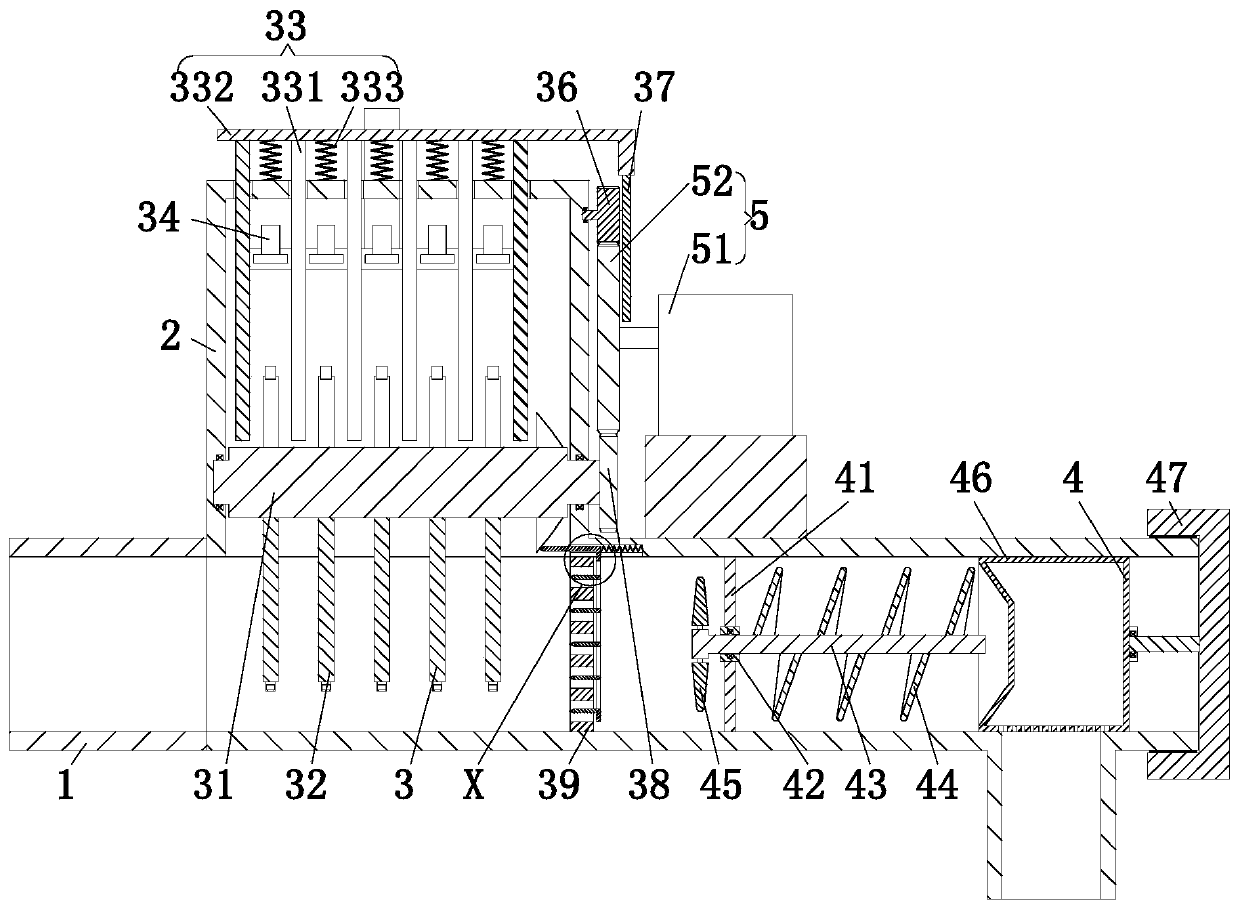

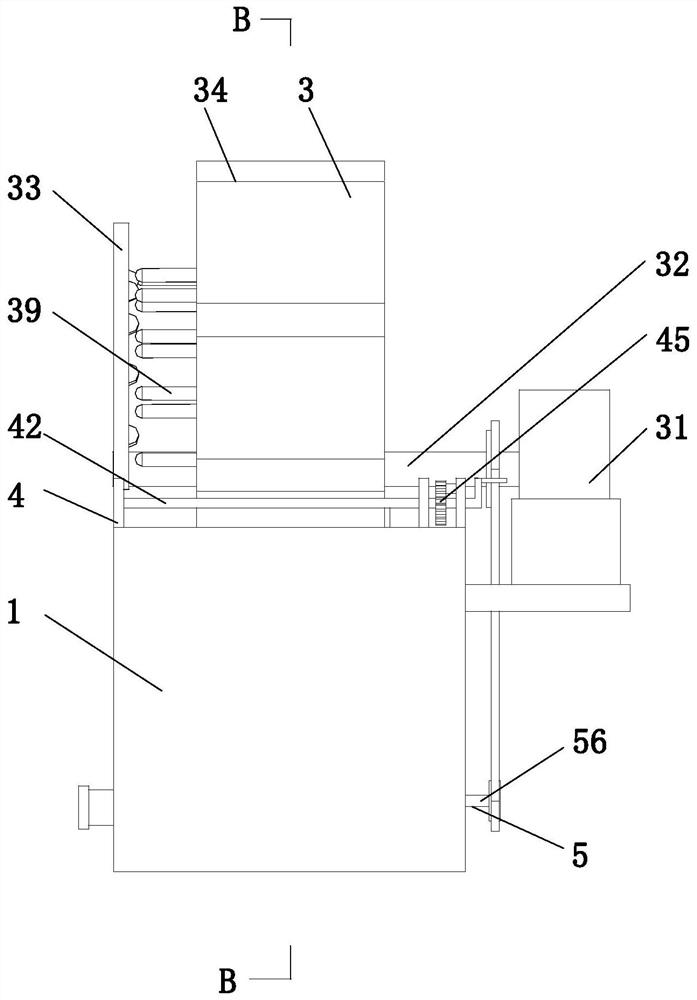

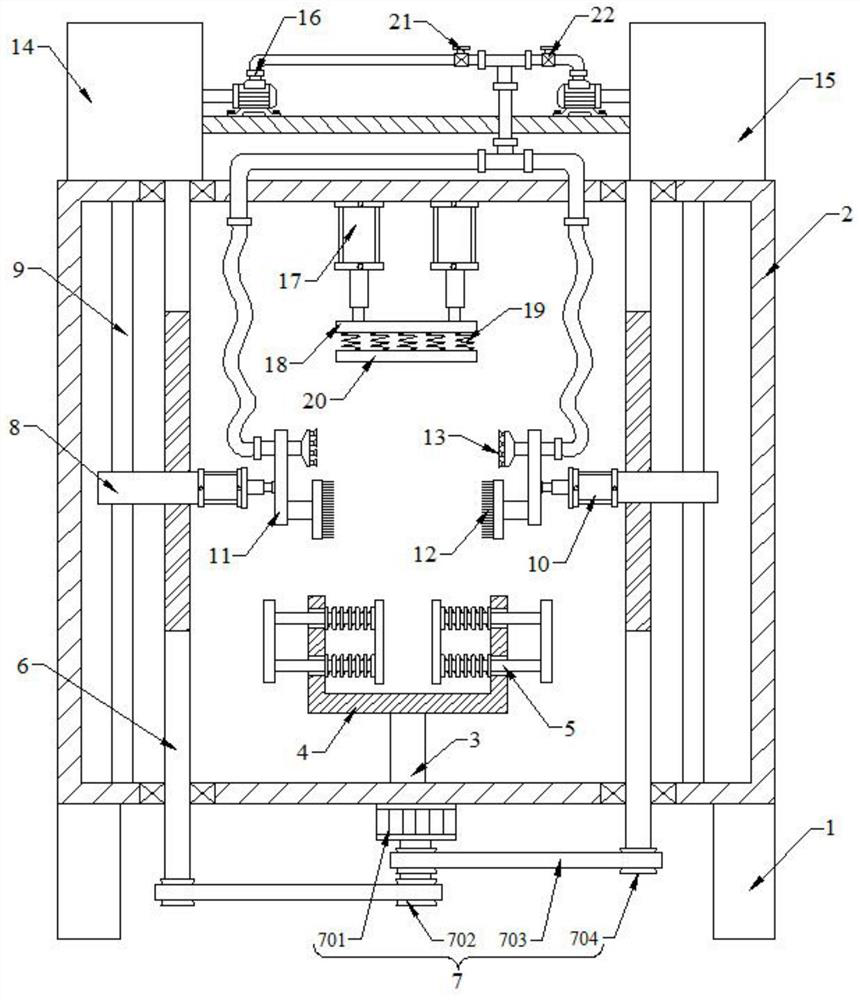

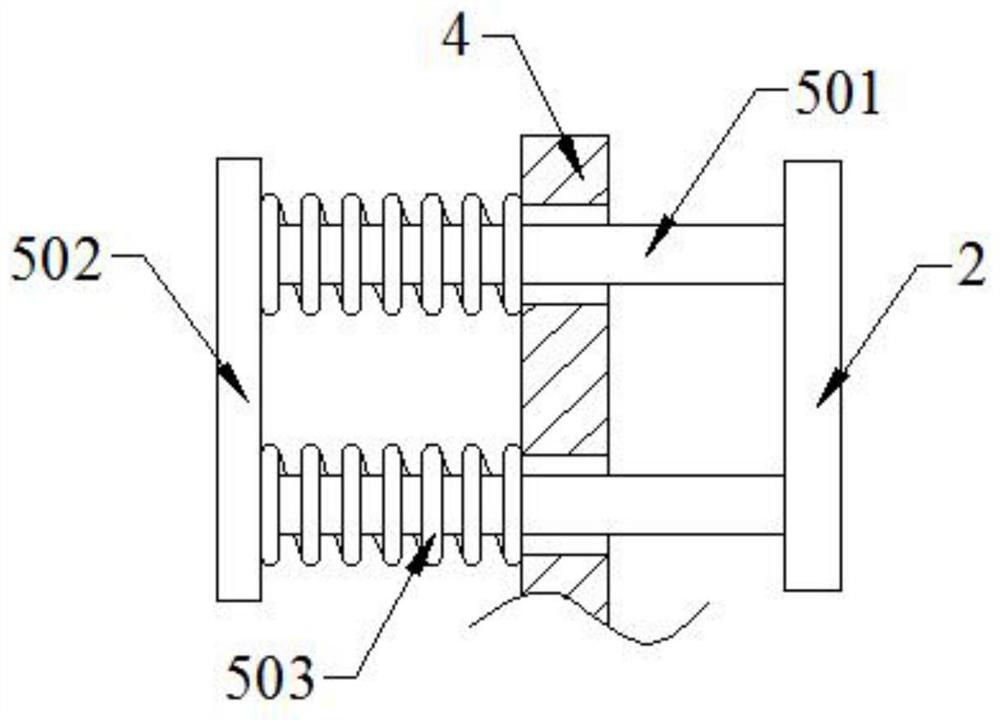

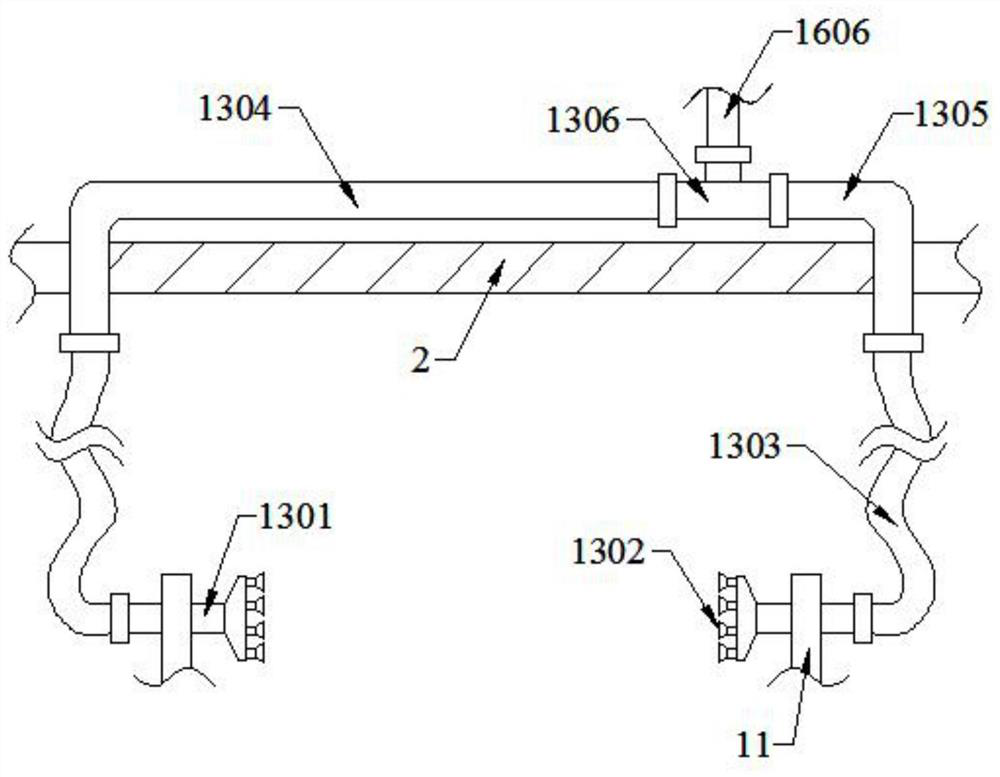

Central air-conditioner cleaning device

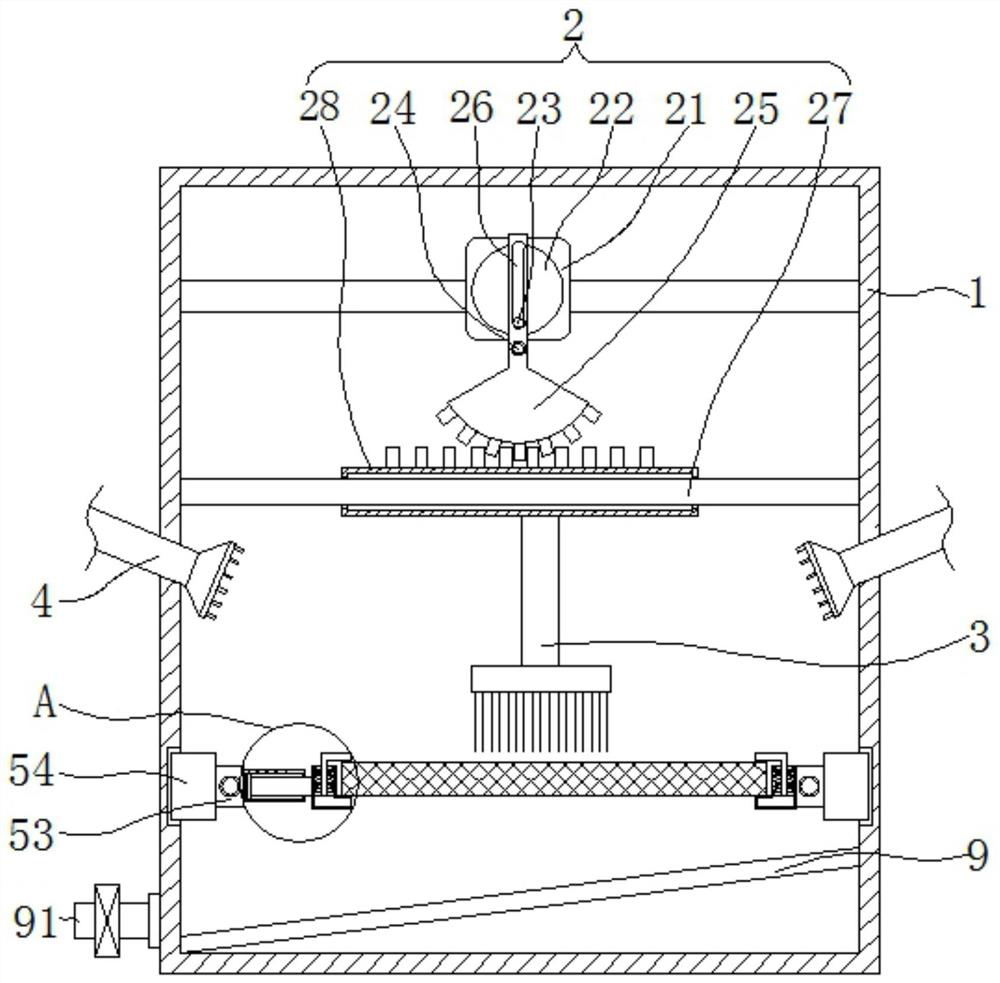

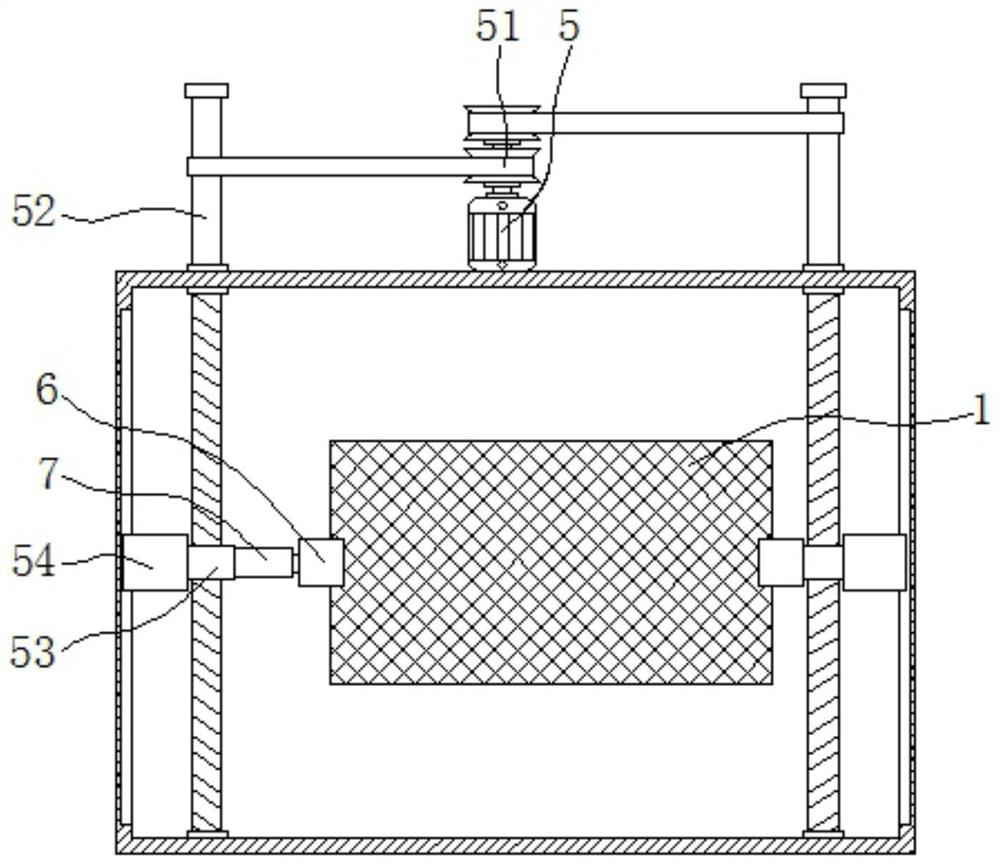

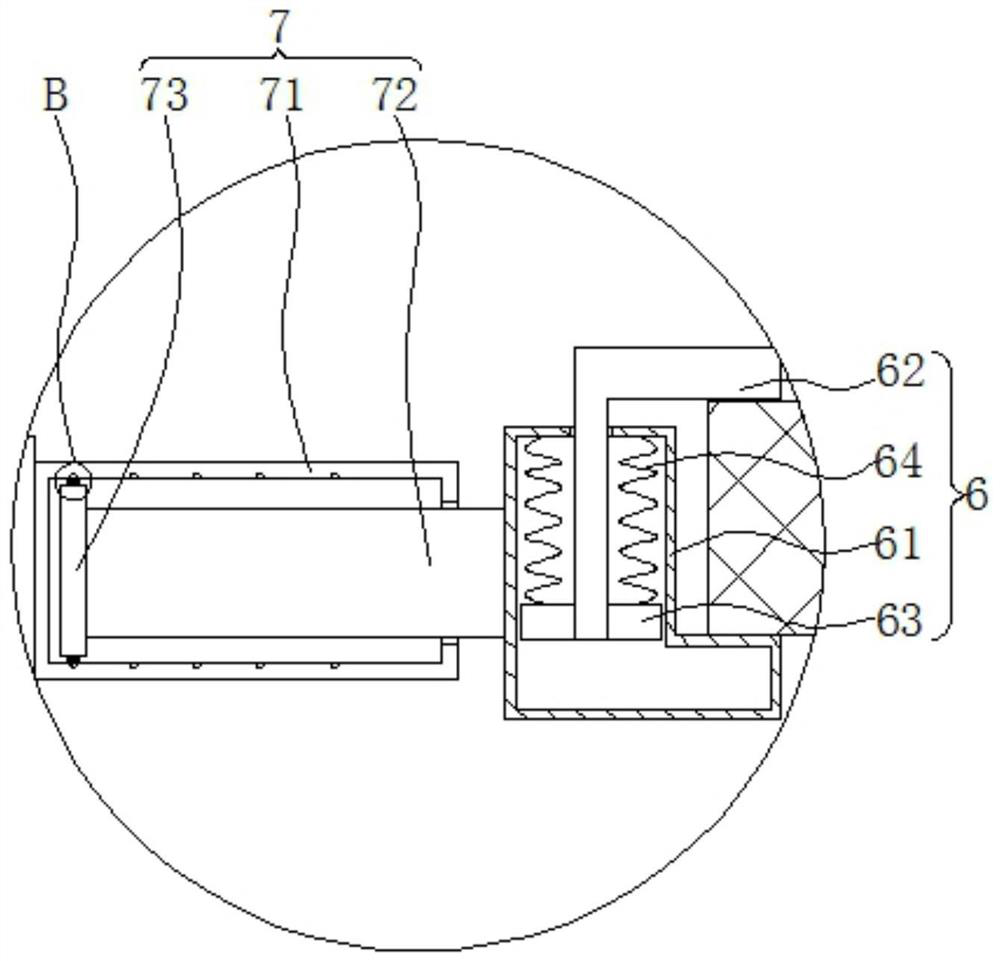

InactiveCN111889418AEasy to cleanAvoid incomplete cleaningCleaning using toolsCleaning using liquidsPhysicsCentral air conditioning

The invention discloses a central air-conditioner cleaning device. The central air-conditioner cleaning device comprises a box body and a reciprocating device, wherein the reciprocating device is arranged in the box body, the reciprocating device comprises a first motor, the first motor is arranged in the box body, a disc is fixedly connected to an output shaft of the first motor, a cylindrical plate is fixedly connected to the front side of the disc, a fixing rod is fixedly connected to the inner wall of the box body, a swinging tooth plate is movably connected to the fixing rod, a sliding groove is formed in the swinging tooth plate, and the cylindrical plate is slidably connected with the sliding groove. According to the central air-conditioner cleaning device, filter screens are fixedthrough a fixing device and a stretching assembly, the filter screens with different sizes are conveniently cleaned, the incomplete cleaning of the filter screens caused by unfixing is avoided, the filter screens are driven to move forward and backward through a second motor, meanwhile a brush moves left and right to clean the filter screens, and thus the filter screens are cleaned more completely.

Owner:快住智能科技(苏州)有限公司

Surrounding type blowing dust removal device

ActiveCN103961943AExtended service lifeGood effectDispersed particle filtrationEngineeringDust control

The invention discloses a surrounding type blowing dust removal device. The surrounding type blowing dust removal device comprises a blowing gas delivery pipe, a control valve, a rotating joint and a blowing pipe, wherein a plurality of nozzles are arranged on the blowing pipe; the control valve is arranged at the lower part of a filter element of a dust collector through the rotating joint. The heat-expansion and cold-contraction characteristic of metal is utilized, dusty gas is taken as gas for dust removal, and gas back spraying rotation is adopted, so that dust removing is well realized, the cost is low, the equipment is safe and reliable and long in operation cycle, the dust removal efficiency of the filter element is improved by more than 5%, and the operating cost is reduced by 10%; the surrounding type blowing dust removal device has excellent economic benefit, develops a new way in the aspect of dust removal for the filter element, and has excellent popularization and application value.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Aluminium strip anode oxidized surface pre-treatment equipment

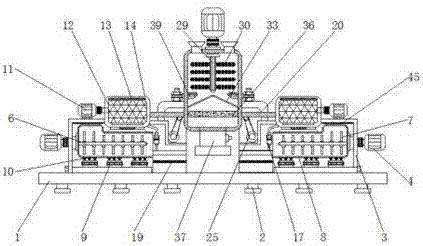

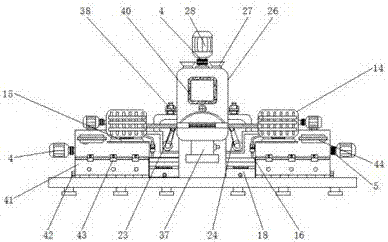

InactiveCN111809212AEasy to cleanImprove oxidation capacityPolishing machinesGrinding drivesElectric machineryPre treatment

The invention discloses aluminium strip anode oxidized surface pre-treatment equipment and belongs to aluminium strip anode oxidization. The aluminium strip anode oxidized surface pre-treatment equipment comprises a device body; an oil removing chamber, a drying chamber and a polishing chamber are formed in the device body; the oil removing chamber in the device body removes oil from an aluminiumstrip first; a first washing roll and a second washing roll in the oil removing chamber are driven by a first motor to rotate to wash off oil stains on the surface of the aluminium strip so that the aluminium strip is conveniently cleaned; the washed aluminium strip is driven into the drying chamber; an adsorption liquid in the drying chamber adsorbs liquid, brought from the oil removing chamber,on the surface of the aluminium strip; and then the aluminium strip passes through the interior of the drying chamber to be dried for the second time so as to prevent the surface of the aluminium strip from being wet to affect oxidization; the dried aluminium strip enters into the polishing chamber to be polished so that the surface of the aluminium strip is clean and smooth; during the follow-upoxidization of the aluminium strip anode, the aluminium strip oxidization effect is improved to avoid flaws.

Owner:王东亮

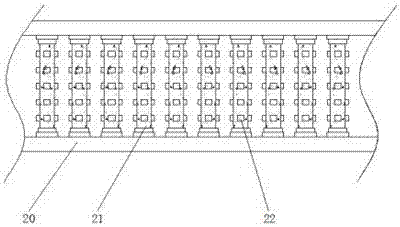

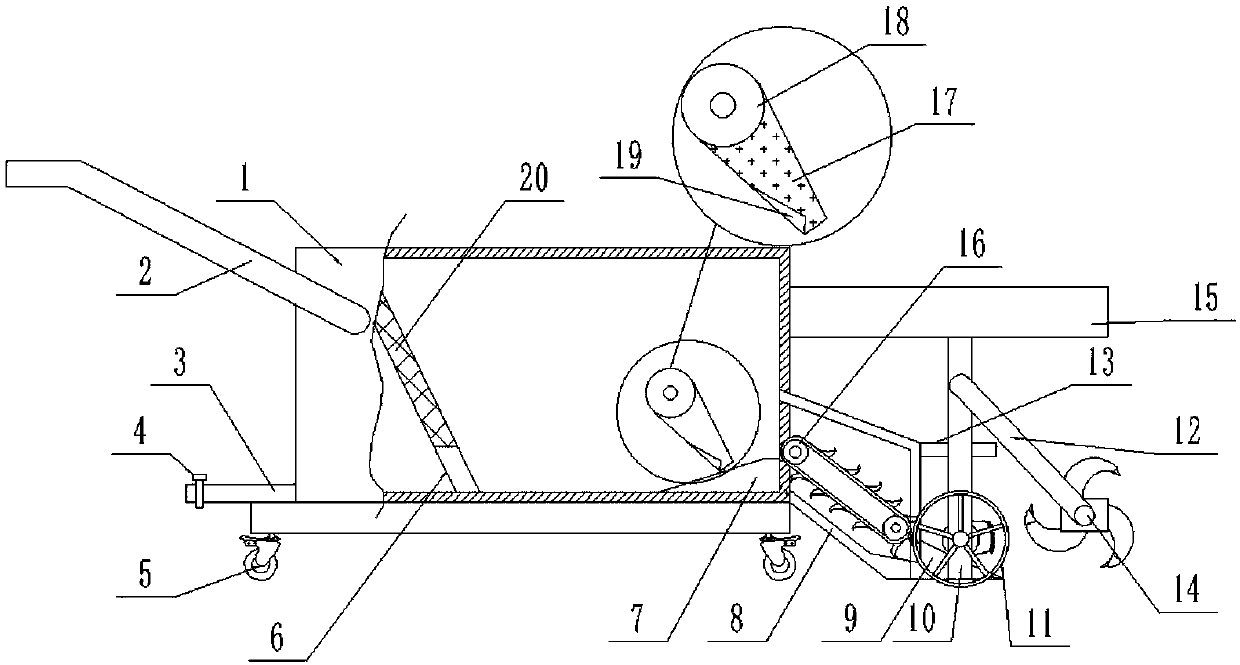

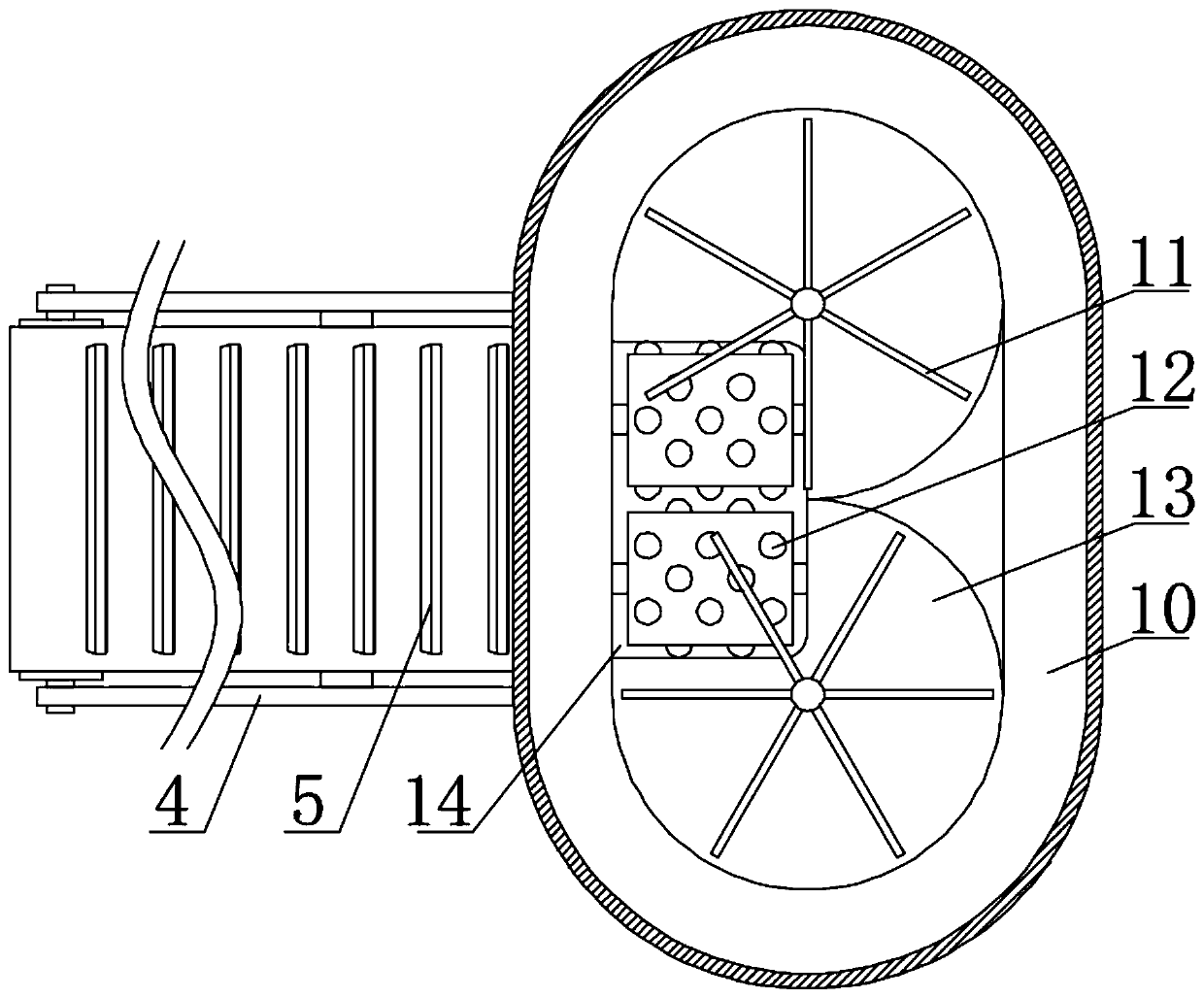

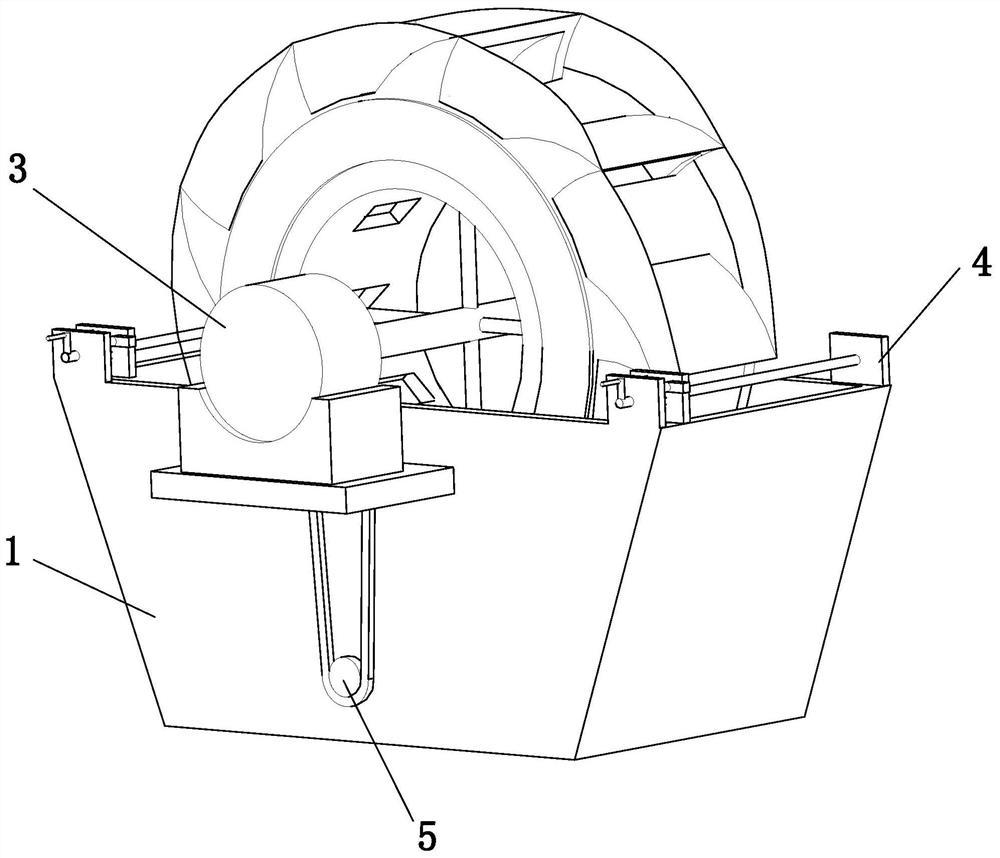

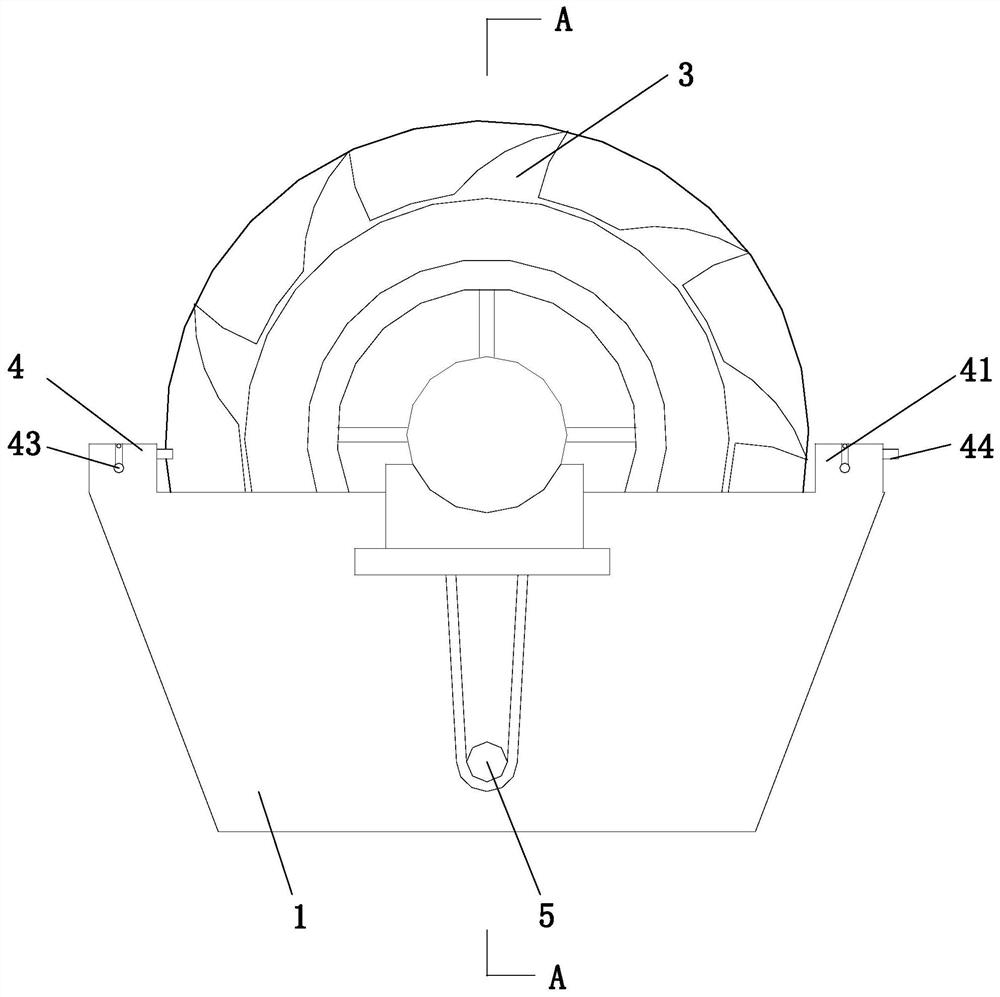

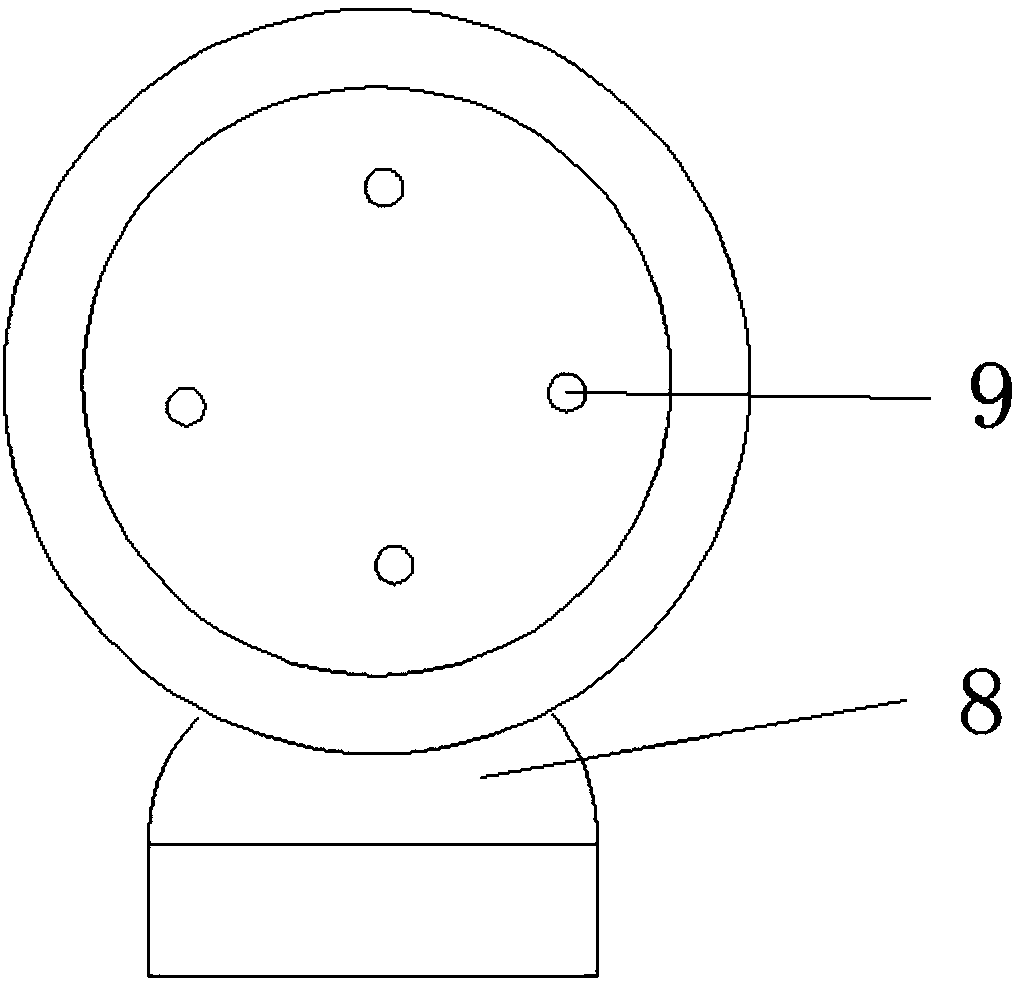

Radix pseudostellariae cleaning and drying integrated machine

ActiveCN107470208ASo as not to damageImprove anti-corrosion performanceDrying gas arrangementsCleaning using toolsWater filterAgricultural engineering

The invention discloses a radix pseudostellariae cleaning and drying integrated machine. The radix pseudostellariae cleaning and drying integrated machine comprises a supporting frame, a first rotating shaft, a drying machine, baffles, a cleaning barrel, a first filter plate, a sewage outlet, an observation window, a clamping cover and a heater; a damping mat is arranged at the bottom end of the supporting frame, a first motor is arranged on the outer side of a drying box, the first rotating shaft is connected with the first motor through a transmission, the drying machine is located at the bottom end of an isolation net, filter nets are connected through a first rotating device, and one end of the baffle is connected with a water filtering box; and the two sides of the cleaning barrel are connected with the baffles, the first filter plate is located below a second rotating shaft, the observation window is located on the outer surface of the cleaning barrel, and the clamping cover and the heater are located on the outer side of the drying box; and a heat conduction pipe is arranged on the outer side of the heater. By means of the radix pseudostellariae cleaning and drying integrated machine, radix pseudostellariae can be quickly and effectively cleaned and dried, the product quality is good, the mechanical body stability is good, and use is convenient.

Owner:ZHANJIANG EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

Sweet potato cleaning device

InactiveCN109567231AImprove cleaning efficiencyEasy to cleanClimate change adaptationFiltration separationActivated carbon filtrationWater resources

The invention discloses a sweet potato cleaning device. The sweet potato cleaning device comprises a cleaning box; vibrating springs are respectively arranged at the two ends of the upper part of thecleaning box; a vibrating box body is welded at the upper parts of the vibrating springs; the vibrating box body is connected with the cleaning box through the vibrating springs; and vibrating motorsare respectively arranged at the two ends of the bottom of the vibrating box body. According to the invention, under the combined action of the vibration motors and the vibrating springs, the sweet potato cleaning device effectively enables soil particles on the surfaces of sweet potatoes to drop due to the vibration force of the vibrating box body, and large pieces of soil dust on the surfaces ofthe sweet potatoes can be shaken off; a brush can contact the surfaces of the sweet potatoes; the sweet potatoes are brushed with the brush while being washed, and the sweet potato skin is not damaged; damping shock absorbers play a role of shock absorption, and damping plates are in contact with each other so as to increase the friction force, so that the shock absorption effect is improved; anactivated carbon filter is used for filtering sewage in the cleaning box, thus effectively saving water resource, and promoting the recycling of the water resource; and re-cleaning is performed by means of ultrasonic waves, so that the cleaning effect of the sweet potatoes is enhanced.

Owner:颍上县绿地食品有限公司

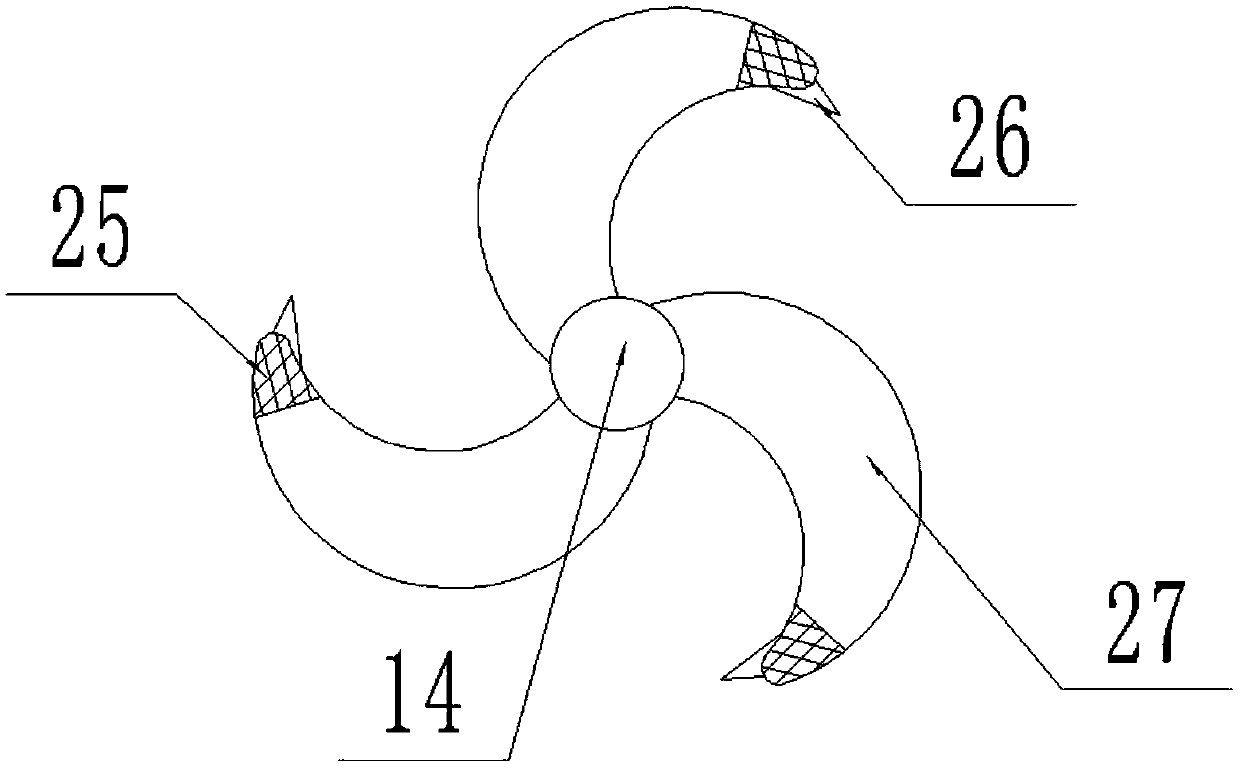

Cleaning device convenient for collecting water surface waste

The invention discloses a cleaning device convenient for collecting water surface waste, including floating plates, a water tank, tailboards and poking strips, the floating plates are internally provided with brushless motors, vertical shafts are arranged under the brushless motors, first leaf plates are installed on each sleeve rod, the first leaf plates are connected with the vertical shafts through the sleeve rods separately, first bevel gears are positioned inside the tailboards, mounting grooves inside which the poking strips are positioned are formed in the tailboards, the poking stripsare positioned outside sleeves, openings are formed in the tailboards, and the tailboards are externally provided with hooks. According to the cleaning device convenient for collecting water surface waste, driving devices composed of the brushless motors, the vertical shafts, the sleeve rods and the first leaf plates separately can not only drive the cleaning device to move, but also poke the water from the outside of the cleaning device into the water tank, thereby facilitating the water to be discharged to the rear of the cleaning device to form pushing force, and simultaneously facilitatingthe collection and poking of the water surface waste.

Owner:江苏源泉泵业股份有限公司

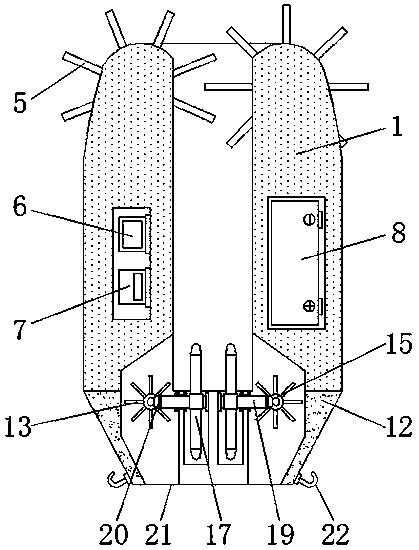

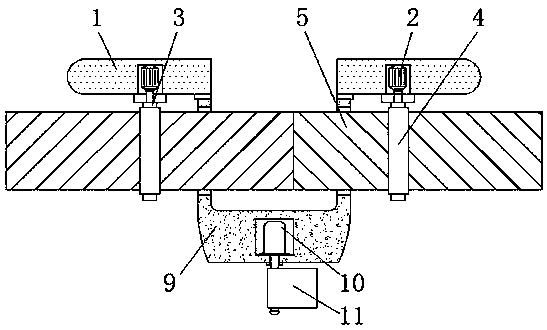

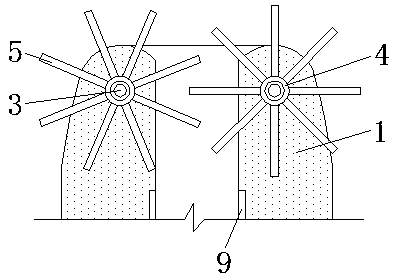

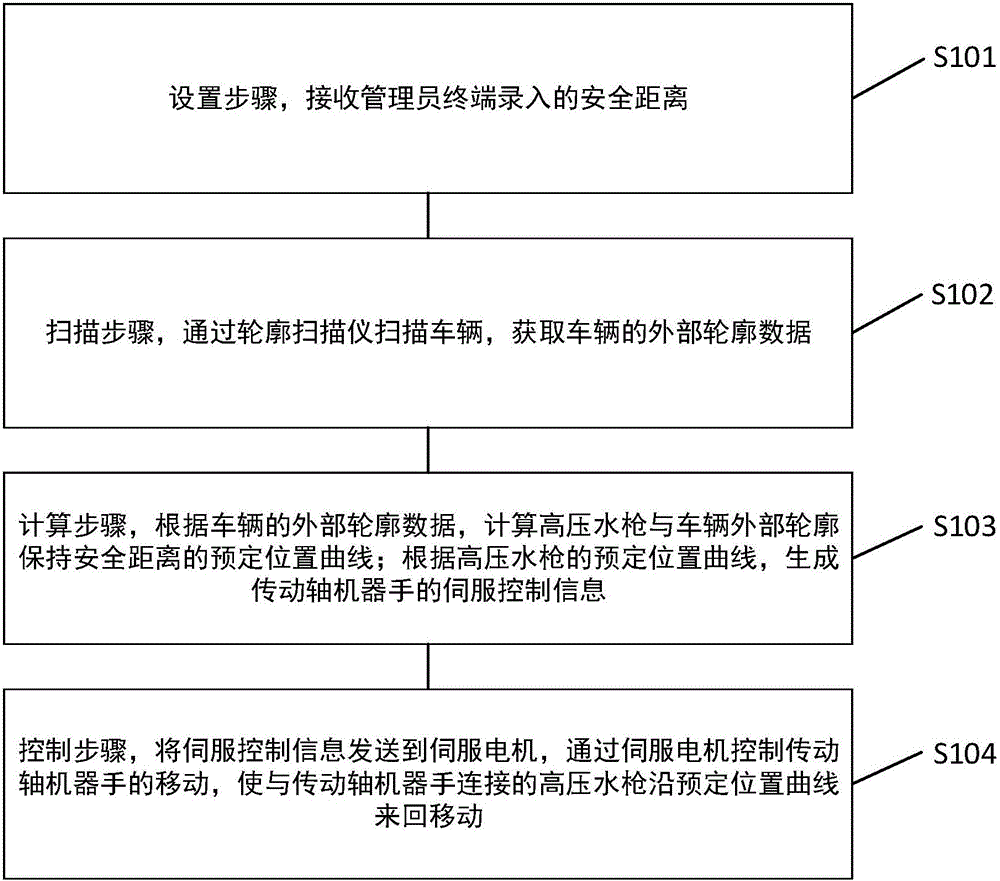

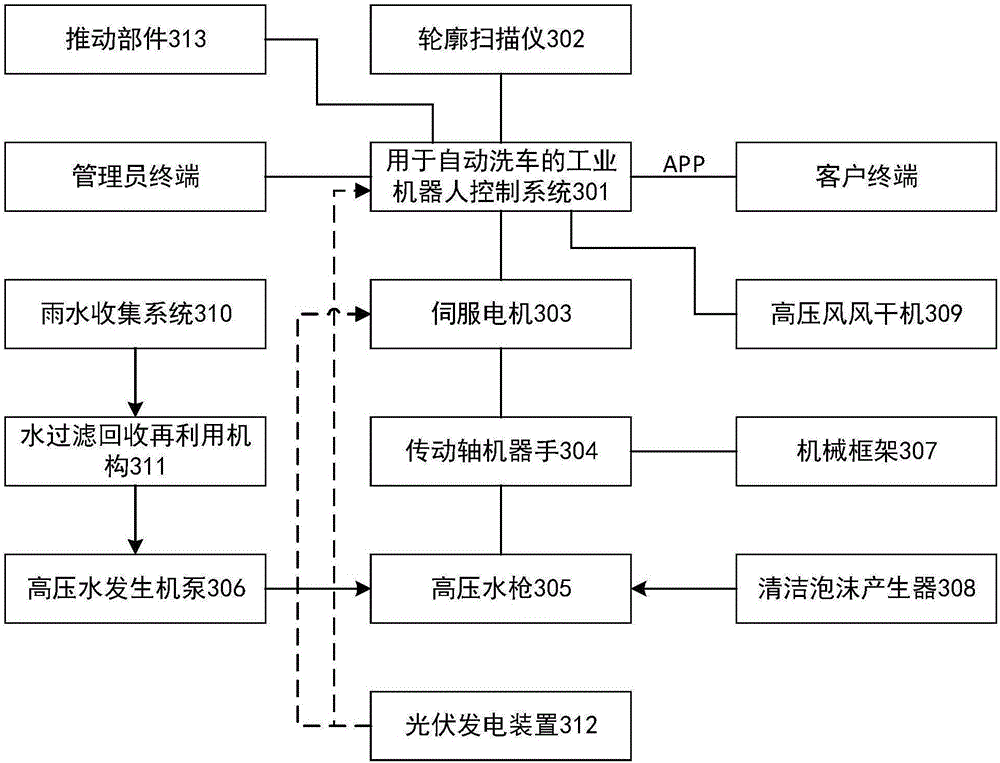

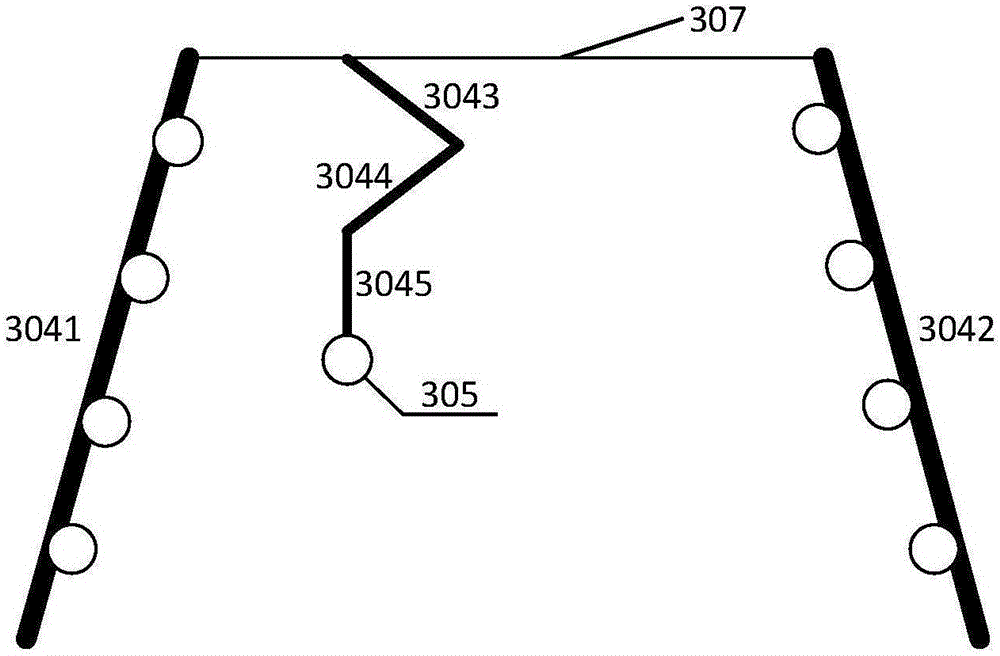

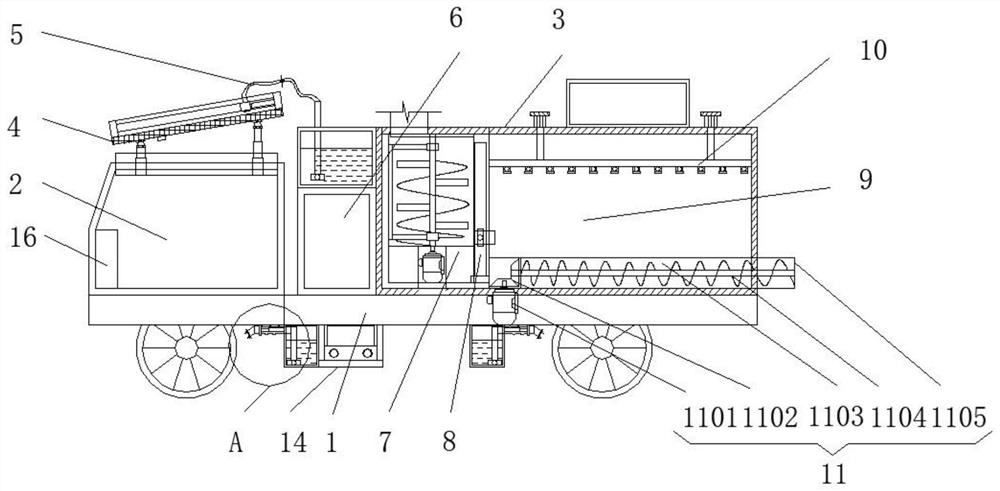

Industrial robot control method used for automatic car washing and automatic car washing machine

PendingCN107179747AReduce labor costsAvoid damageCleaning apparatus for vehicle exteriorsNumerical controlDrive shaftIndustrial robotics

The invention provides an industrial robot control method used for automatic car washing and an automatic car washing machine. The method comprises steps of firstly scanning a vehicle and acquiring external profile data of the vehicle; according to the profile of the vehicle, determining a preset position curve of a high pressure water gun under the condition that a safe distance is kept between the vehicle and the high pressure water gun; according to the to-be-achieved preset position curve of the high pressure water gun, acquiring servo control information of a mechanical hand of a transmission shaft; controlling movement of the mechanical arm of the transmission shaft through a servo motor so as to drive the high pressure water gun to reciprocate along the preset position curve; and spraying high pressure liquid to the vehicle through the high pressure water gun so as to clean the vehicle. According to the invention, position curves of the high pressure water gun in a moving process can be automatically adjusted according to the external size of the vehicle, and the high pressure water gun and the external profile of the vehicle are kept in the preset safe distance, so vehicle is prevented from being damaged caused by the too small cleaning distance, and a condition that the vehicle is not thoroughly cleaned caused by the too big cleaning distance can be avoided. Furthermore, the invention provides an online ordering function.

Owner:刘万祥

Cleaning tool suitable for complete cleaning of dwarf lilyturf tuber

ActiveCN104475384AAvoid damageAvoid excessive labor intensitySievingScreeningEngineeringPlant Tubers

Owner:SICHUAN DAIDAIWEIBEN AGRI TECH

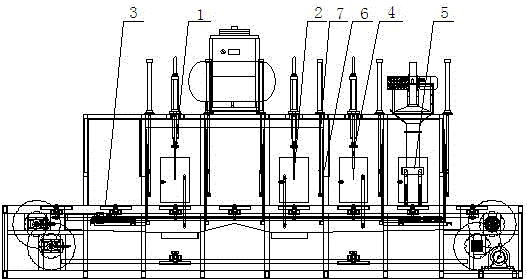

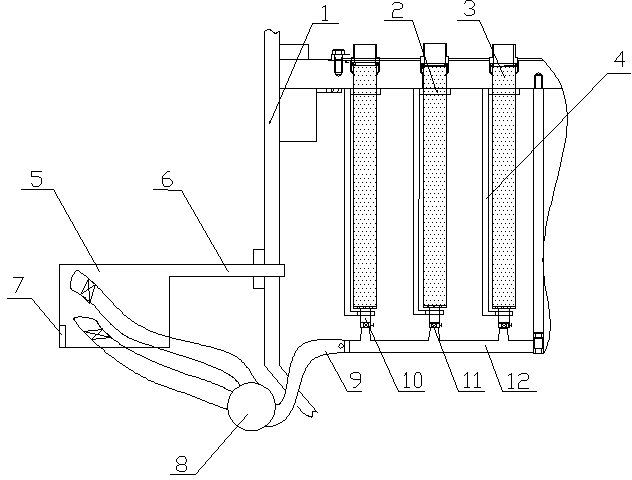

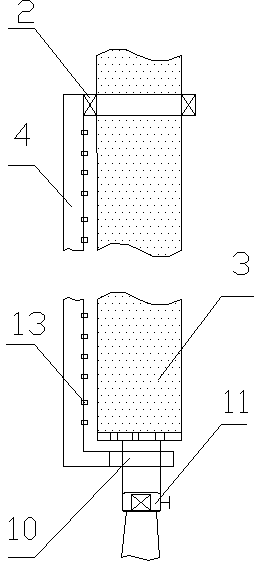

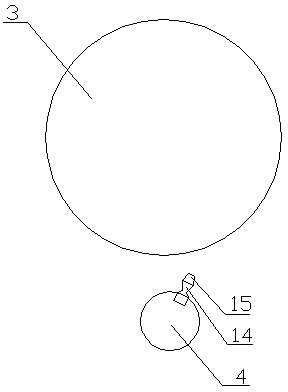

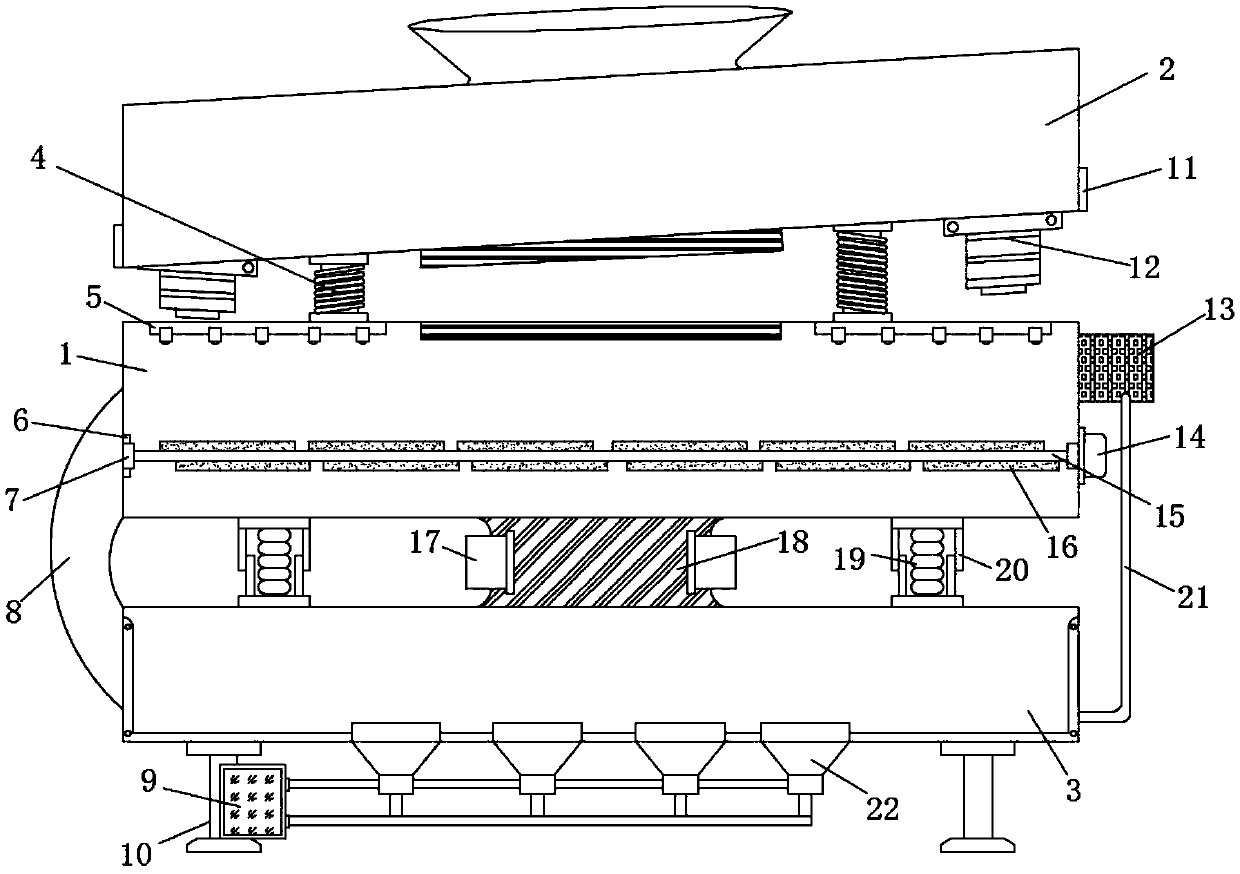

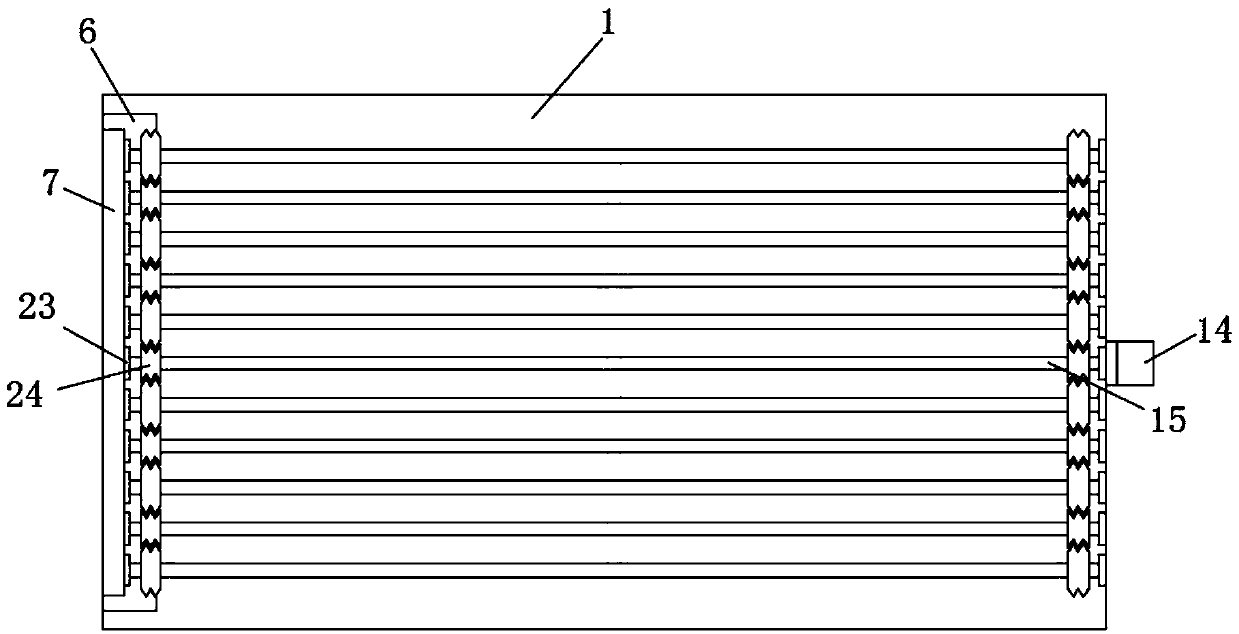

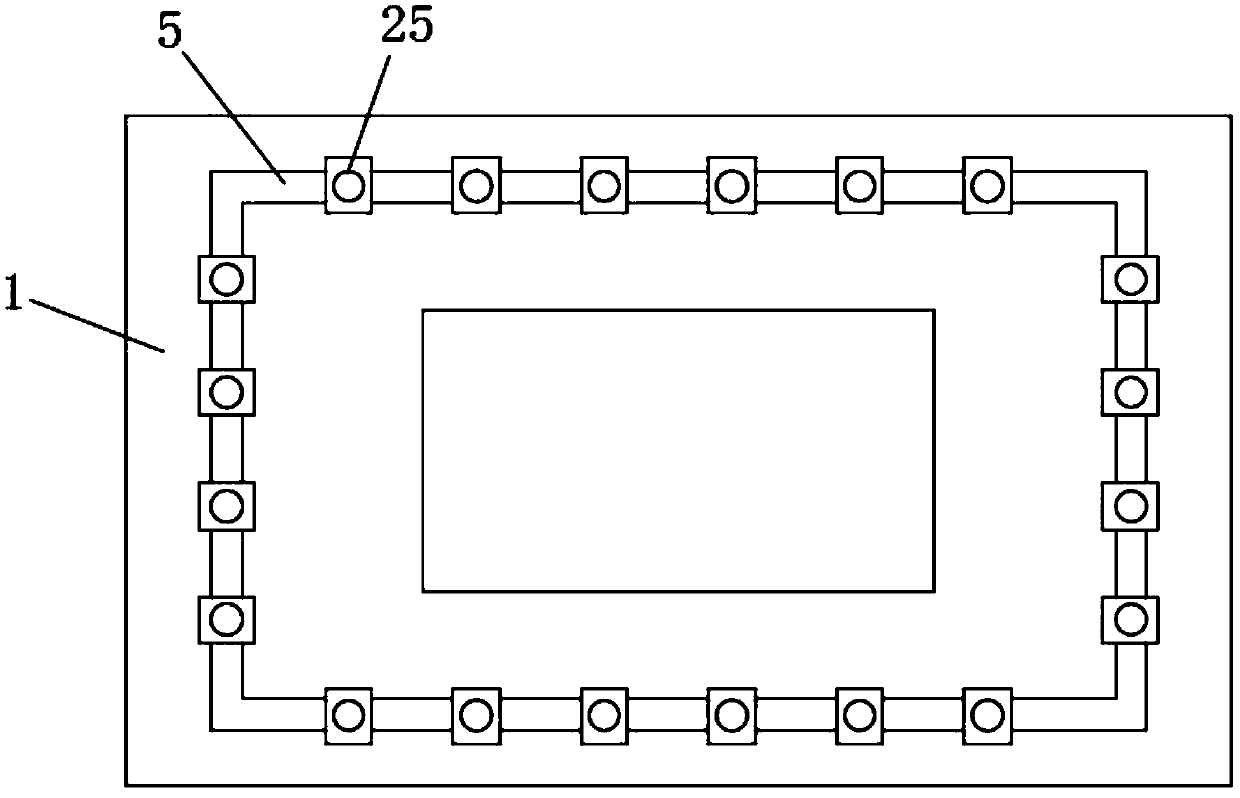

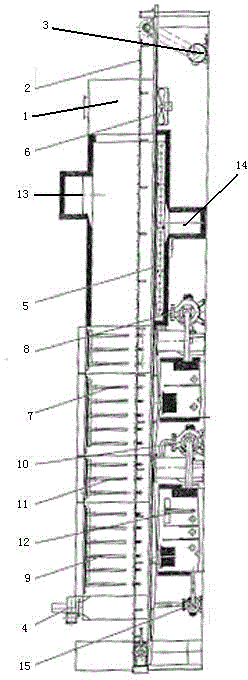

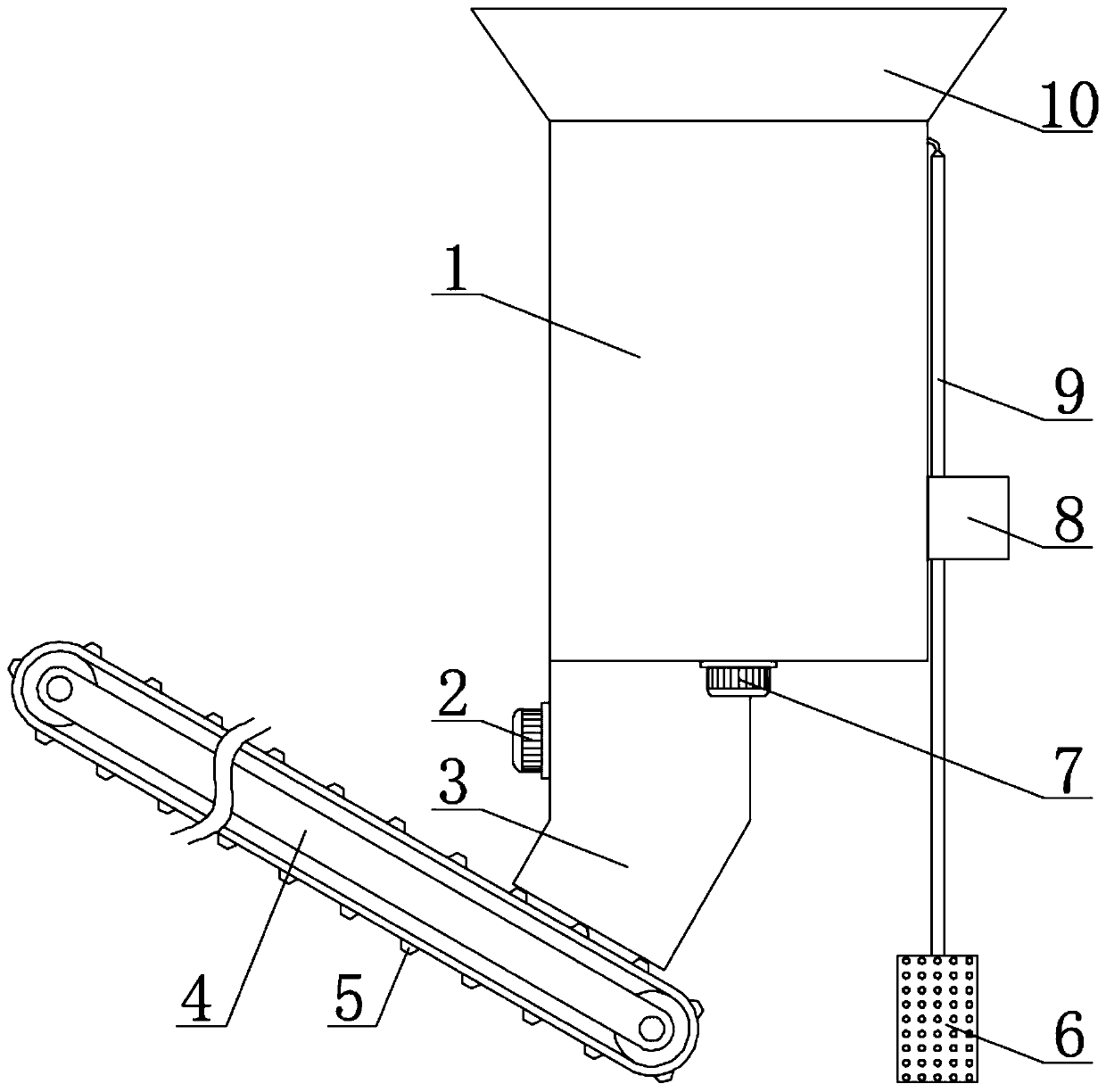

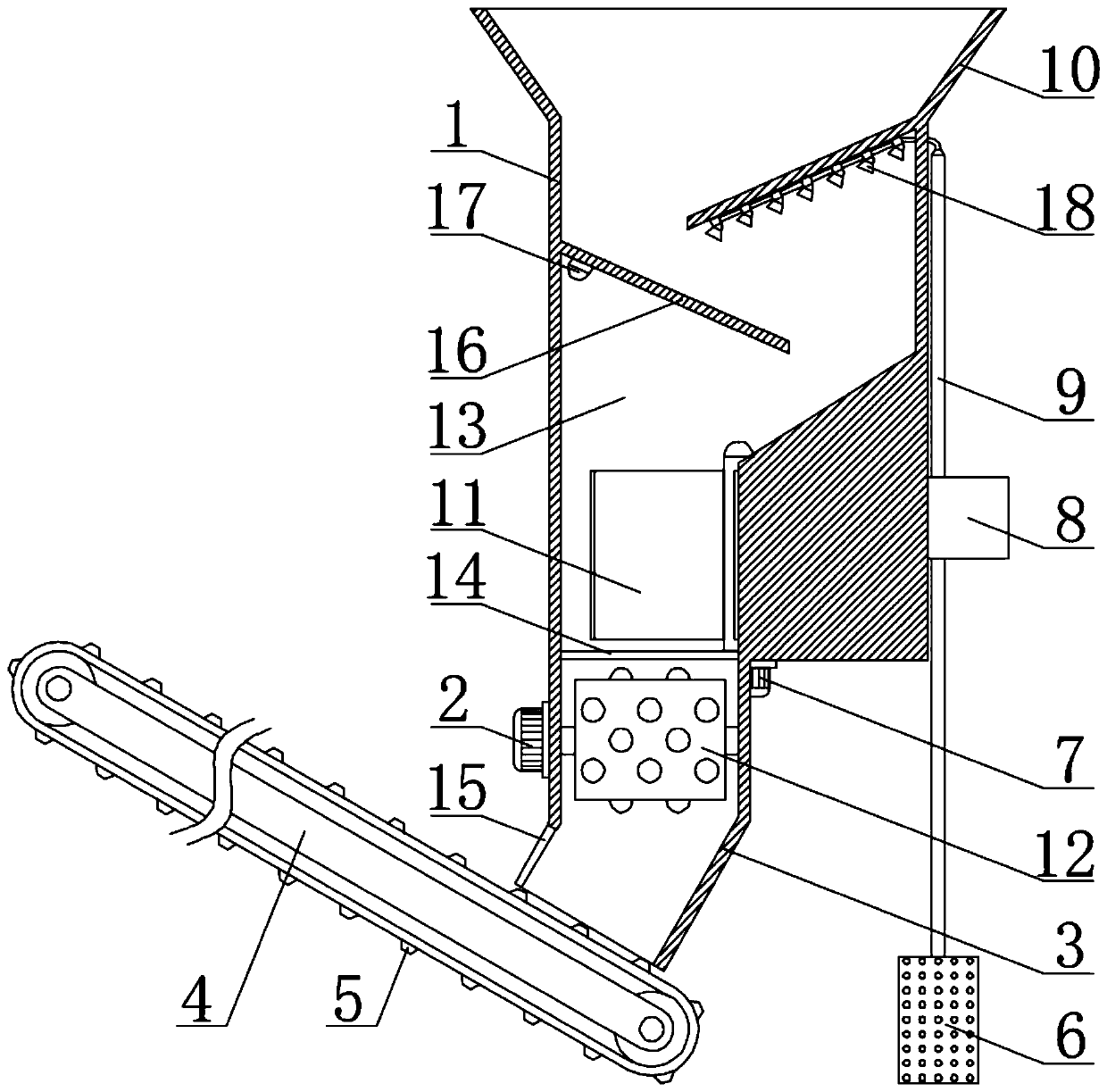

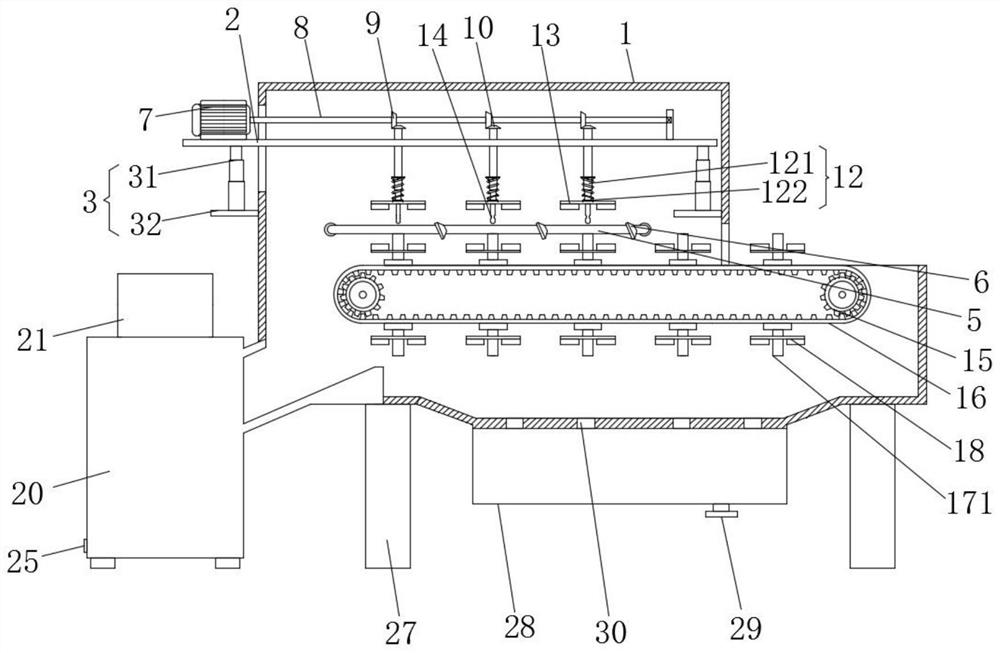

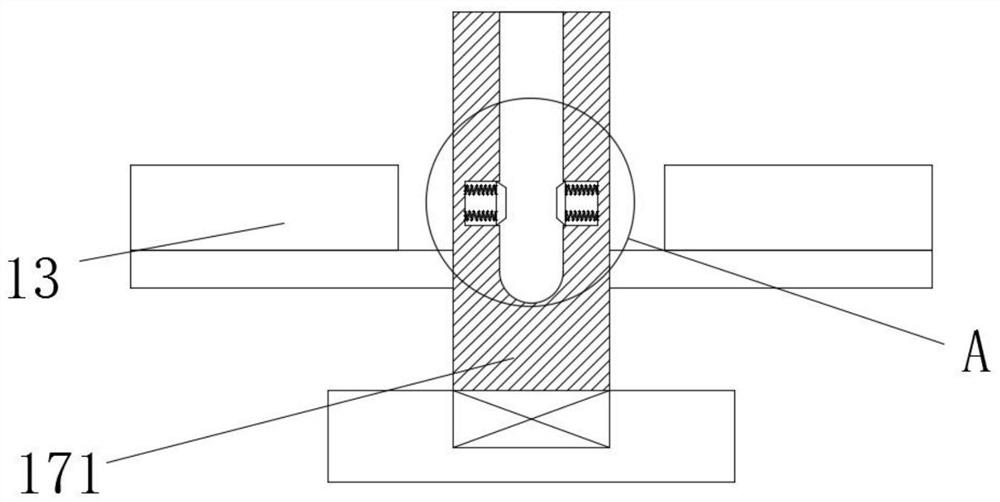

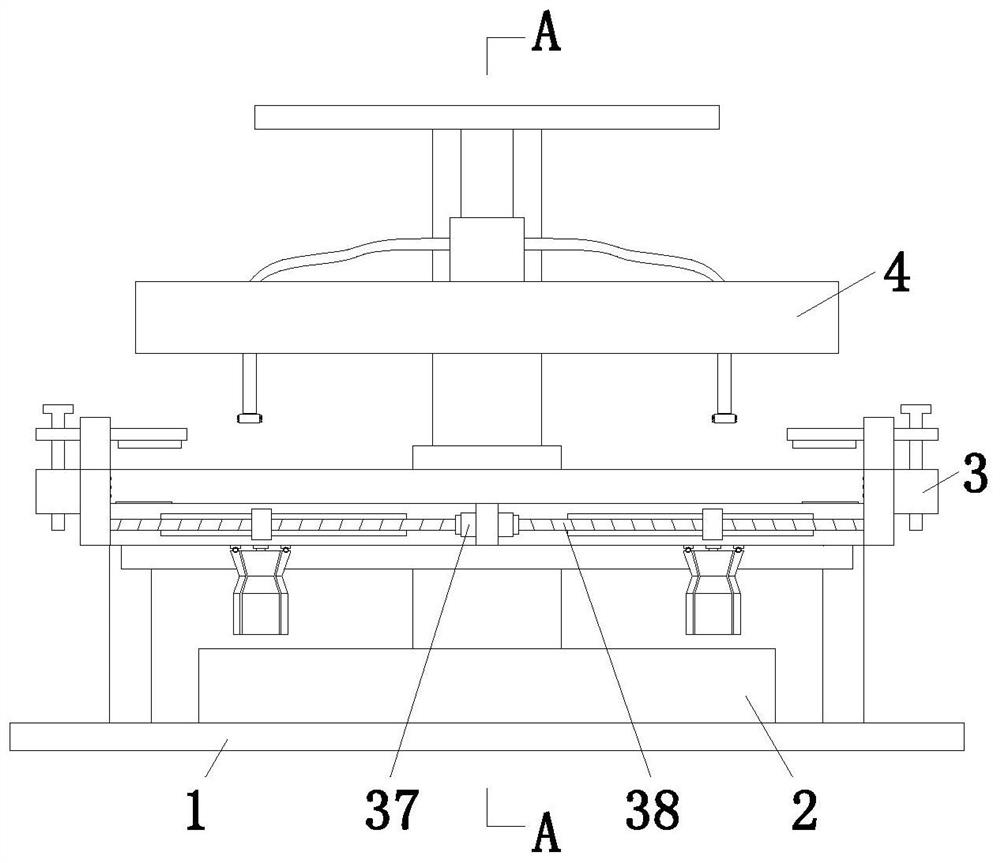

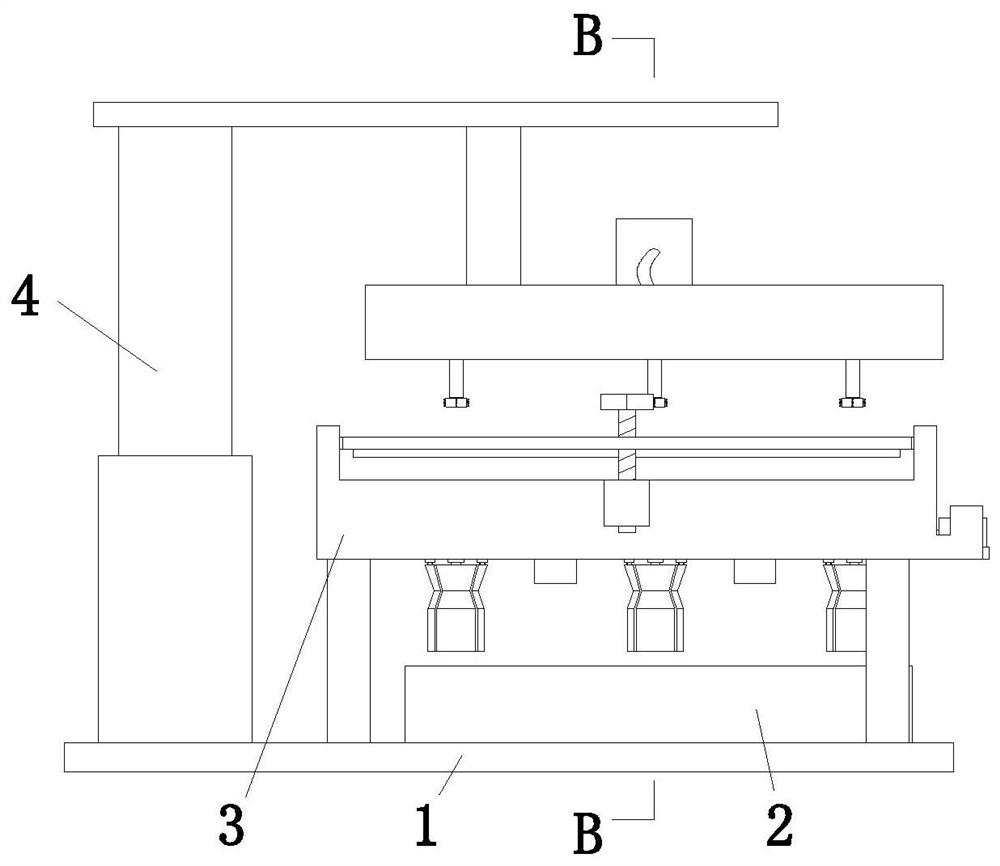

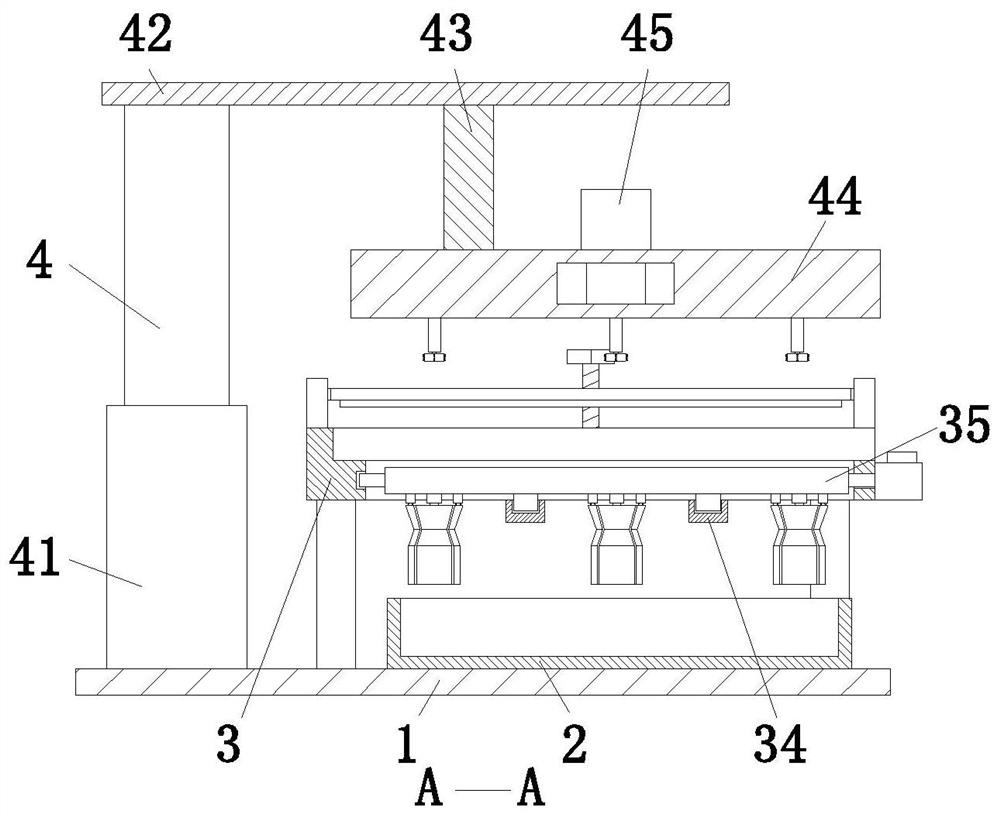

Continuously-passing type cleaning machine

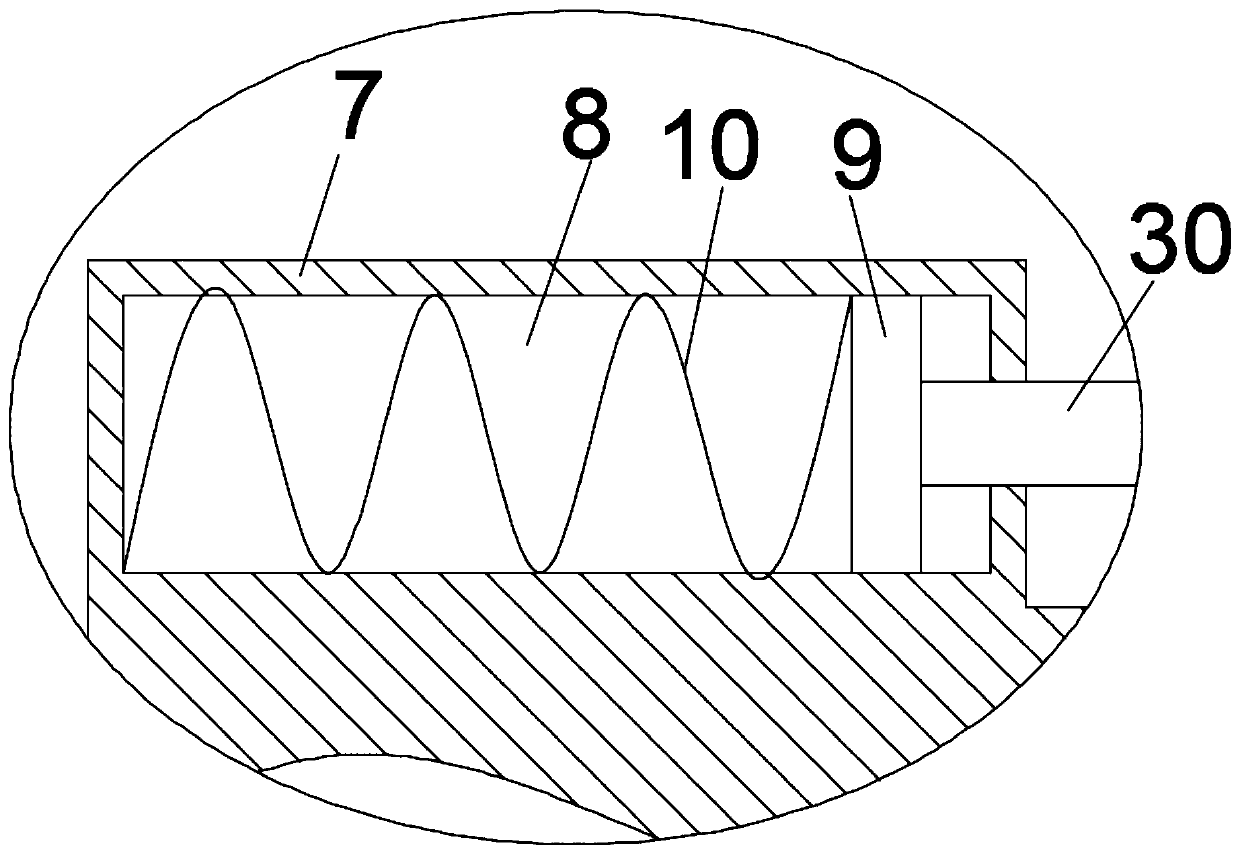

InactiveCN104874561AAvoid incomplete cleaningImprove work efficiencyDrying gas arrangementsCleaning using gasesEngineeringMechanical engineering

The invention provides a continuously-passing type cleaning machine. The cleaning machine comprises a shell, a conveyor chain is arranged inside the shell, the conveyor chain is driven to work through a motor, a cleaning device is arranged inside the shell, the cleaning device is divided into a rinsing part and a spray-washing part, a mist absorbing draft fan is further arranged at the left side of the cleaning device, the mist absorbing draft fan is arranged outside the shell and conducts mist absorbing treatment on the interior of the shell, an air heating device is arranged at the right side of the cleaning device, and a cooling fan is further arranged at the right side of the air heating device. A bearing is cleaned through the cleaning device, oil stains are removed and recycled through an oil stain collecting device, the bearing is heated by means of the air heating device, the cooling fan is arranged so that the bearing obtained after heating can be cooled, the work of cleaning the bearing and the work of drying the bearing are completed in one time, the working efficiency is improved, mist inside equipment is discharged through the mist absorbing draft fan, and it is avoided that the cleaning is not completed due to the fact that after drying, residual mist in the equipment is left on the bearing.

Owner:NEXTEER LINGYUN DRIVELINE WUHU

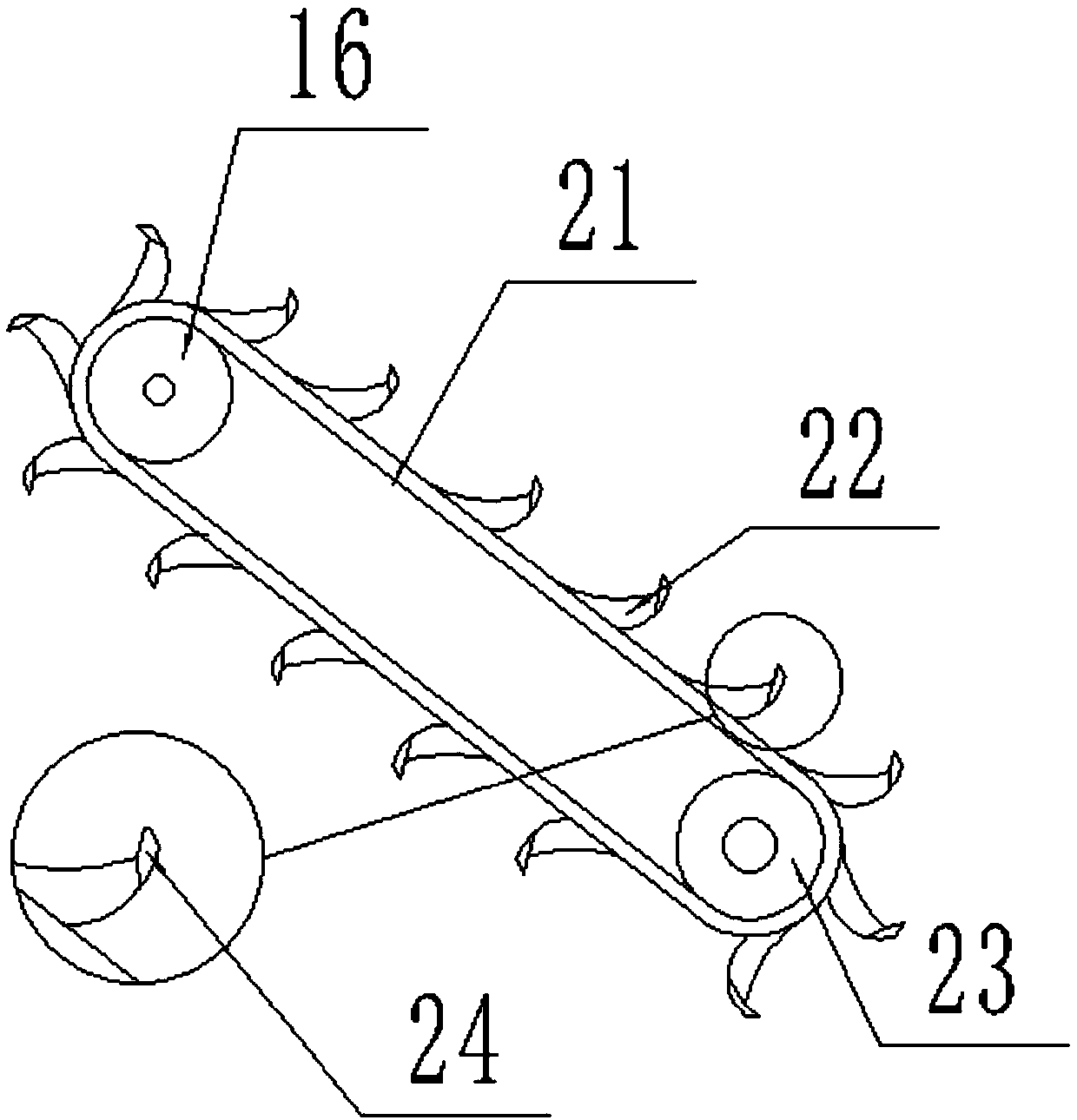

Chicken manure cleaning device for henhouse

ActiveCN109526794AReduce wearImprove loose effectBird housingsStationary filtering element filtersFecesEngineering

The invention belongs to the technical field of poultry breeding, specifically relates to a chicken manure cleaning device for a henhouse, and aims to solve the problems that the cost of a conventional chicken manure cleaning device is high, and the cleaning effect is not good. The provided chicken manure cleaning device comprises a box. A base plate is arranged on the outer wall of the bottom ofthe box. Four corners of the outer wall of the bottom of the base plate are all provided with a universal wheel. One side of each outer wall of two sides of the box is provided with a handle. Rubber sleeves sleeve the outer walls of the handles. The outer wall of the side, which is far away from the handles, of the box is provided with a material inlet. The inner wall of the material inlet is provided with a feed hopper. The inner wall of the feed hopper is provided with a conveying mechanism. By providing a road holding pad and a rubber pawl, manure that is compacted by chicken can be loosened, the phenomenon that chicken manure is not completely cleaned is avoided; the inner mechanisms are driven to rotate without a plurality of motors, the mechanical cost and electricity cost are reduced, the manures are intermittently shoveled and placed on a conveying belt, and the accumulated manures can be cleaned at a time.

Owner:奉节县银青生态农业有限公司

Pediatric medical instrument cleaning device

InactiveCN110976381AAvoid holdingGuaranteed pollutionLavatory sanitoryCleaning using liquidsMedicineApparatus instruments

The invention discloses a pediatric medical instrument cleaning device. The device comprises a cleaning box body, a partition plate integrally formed with the cleaning box body is arranged in the lower portion in the cleaning box body. An instrument disinfecting and cleaning box is formed between the partition plate and the cleaning box body; an instrument clamping device, a power assembly and a lifting device are arranged above the partition plate, the instrument clamping device comprises a rotating roller and a support, a rotating shaft is rotationally installed on the support, the rotatingshaft and the power assembly are in connection transmission through a belt, and a plurality of instrument clamping assemblies are evenly distributed on the rotating roller in the circumferential direction. The rotating shaft and the rotating roller are arranged; under the driving of the power assembly, the rotating shaft is driven to rotate, the rotating roller is driven to rotate, the instrumentsclamped on the rotating roller are driven to rotate, under the action of the lifting device, the rotating roller is driven to enter the instrument disinfecting and cleaning box, incomplete cleaning caused by instrument accumulation is avoided, the cleaning effect is effectively improved through dynamic cleaning, and the instruments are ensured to be safe and free of pollution.

Owner:孙灵梅

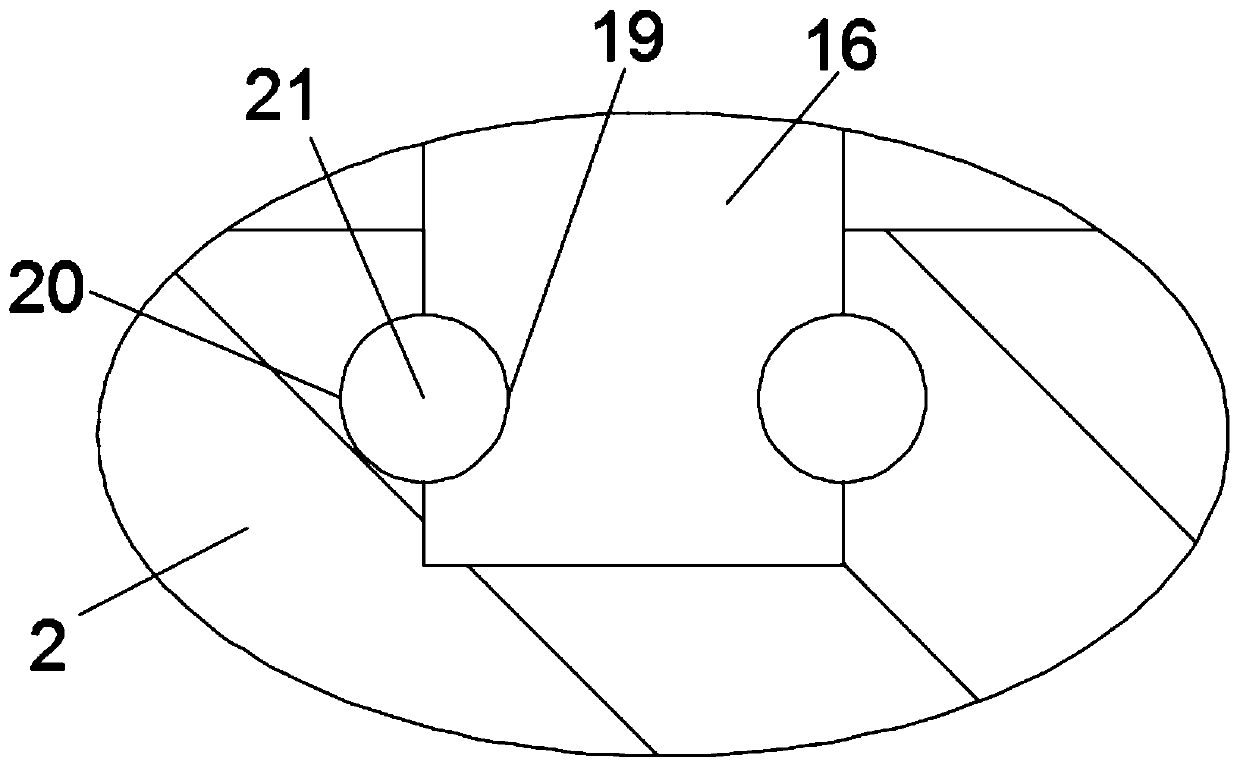

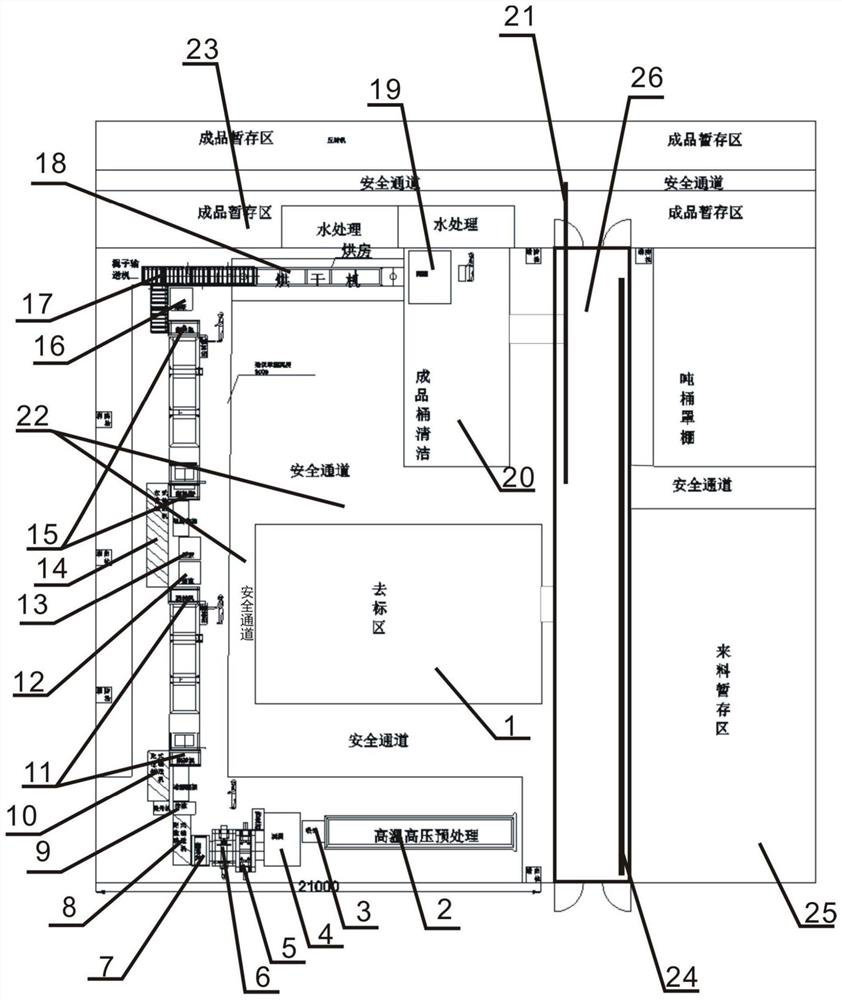

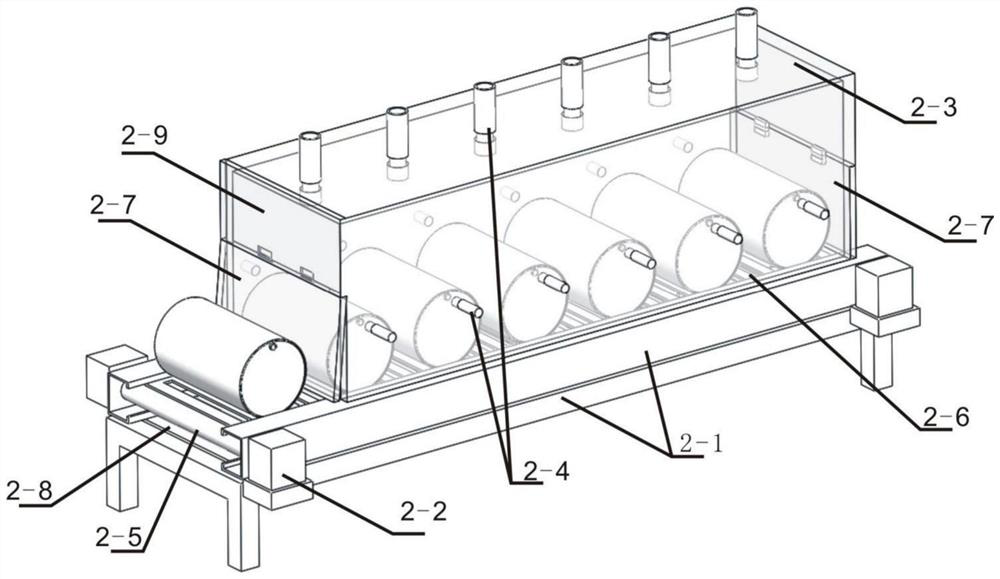

Iron drum renovation treatment system

InactiveCN111842379APromote prolapseEnsure safetyHollow article cleaningFluid-tightness measurementThermodynamicsAfter treatment

The invention provides an iron drum renovation treatment system, and relates to the field of resource recycling. The iron drum renovation treatment system involves a pre-treatment module, a cleaning module I, a cleaning module II and a post-treatment module which are arranged in sequence; the pre-treatment module comprises a label removing machine, a high-temperature high-pressure pretreatment machine, a residue suction machine, a leak detector I, an edge trimming machine, a shaping machine and an overturning machine I which are arranged in sequence; the cleaning module I comprises a liquid injection machine I, an overturning machine II and a liquid pumping machine I which are arranged in sequence, and the cleaning module II comprises a liquid injection machine II, an overturning machine III and a liquid pumping machine II which are arranged in sequence; and the post-treatment module sequentially comprises a dryer and a leak detector II. The iron drum renovation treatment system has the beneficial effects that a conventional mode that cleaning is carried out only through cleaning fluid is broken through, high-temperature and high-pressure steam is adopted for earlier-stage treatment, and two cleaning procedures are combined after residues and residual liquid are evaporated and gasified, so that an iron drum is cleaned more thoroughly, the treatment area is standardized, and thesafety before, during and after treatment is fully guaranteed.

Owner:天津绿展环保科技有限公司

Domestic sewage discharging and filtering system

ActiveCN111467864AReduce cleaning efficiencyReduce the efficiency of exclusionStationary filtering element filtersFilter systemMechanical engineering

The invention relates to a domestic sewage discharging and filtering system which comprises a connecting pipe, a cleaning pipe, a removing device, a cleaning device and a driving device, wherein the cleaning pipe is installed at the right end of the connecting pipe, the removing device is installed in the cleaning pipe, the cleaning device is arranged on the right side of the removing device, andthe cleaning device is installed on the inner wall of the cleaning pipe. According to the system, the problems that when existing equipment is used for filtering garbage in domestic sewage, garbage inthe sewage cannot be cleaned in a multi-stage filtering manner, garbage with different volumes cannot be cleaned respectively, the phenomenon that the garbage is incompletely cleaned easily occurs, so that the garbage cleaning effect is reduced, meanwhile, the garbage cannot be blocked in the garbage cleaning process, the phenomenon that the garbage falls easily occurs in the cleaning process, the garbage cleaning efficiency is reduced, the phenomenon that a pipeline is blocked easily occurs, and the sewage discharging efficiency is reduced are solved.

Owner:浙江湾北建设有限公司

Coal cinder cleaning device for thermal power plant

ActiveCN110173703AAvoid incomplete cleaningLighting and heating apparatusGrain treatmentsCoalMicroprocessor

The invention discloses a coal cinder cleaning device for a thermal power plant. The coal cinder cleaning device comprises a coal cinder collecting shell, a discharging shell, crushing rollers and a microprocessor. Two cylindrical collecting cavities are fixedly formed in the coal cinder collecting shell and used for collecting coal cinder waste. Discharging outlets used for discharging coal cinder are formed in the sides, located at the bottoms of the collecting cavities, of the coal cinder collecting shell. Two receiving motors are fixedly installed on the lower surface of the coal cinder collecting shell through screw spikes, the receiving motors are electrically connected with the signal end of the microprocessor, and the power output ends of the receiving motors are fixedly welded with receiving plates. The coal cinder can be concentrated in the collecting cavities and then pushed into the discharging outlets by means of the receiving plates in the collecting cavities, because thecollecting cavities are cylindrical and the receiving plates can be exactly matched with the inner walls of the collecting cavities during rotation, the receiving plates can clean all the coal cinderin the collecting cavities, and incomplete cleaning o the coal cinder is avoided.

Owner:大唐东营发电有限公司

Polishing tool for scale in oil tube

InactiveCN104785477ASolve the trouble of cleaningImprove cutting efficiencyHollow article cleaningScrub brushesCalcium carbonate

The invention discloses a polishing tool for scale in an oil tube. The polishing tool comprises a supporting cylinder and a scrubbing brush. A plurality of cutter sets are arranged on the supporting cylinder at intervals, gaps are reserved in the middles of the cutter sets, the supporting cylinder is provided with a swinging cavity concaved inwards, the top end of the swinging cavity is provided with radial water spraying holes communicated with a water injection channel, the top ends of the radial water spraying holes are fixedly provided with water spraying hoses which can freely move in the swinging cavity, and the moving ends of the water spraying hoses protrude out of the upper end of the swinging cavity and are arranged in the gaps. To solve the problem that in the prior art, the effect of cleaning the scale in the oil tube through the methods such as high-pressure water jetting washing, acid pickling and other chemical cleaning modes is not good, water-jetting washing and physical cutting modes are combined to conduct deep cleaning on mass compact hard calcium carbonate and sulfate scale in the oil tube to guarantee that the oil tube can be used again, and the problems that originally, the oil tube is washed difficultly, cost is high and washing is not thorough are solved.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

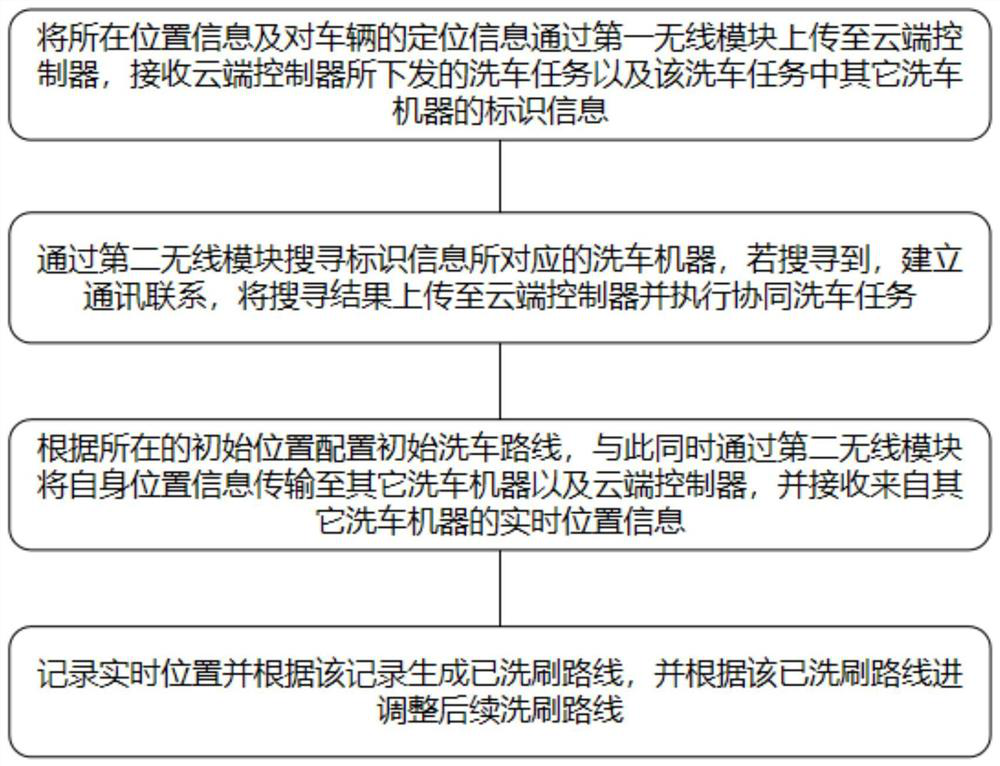

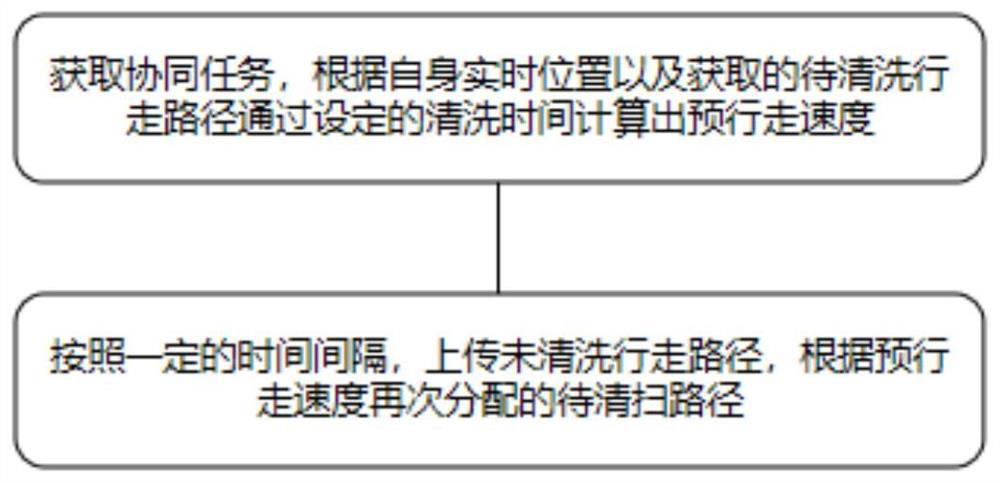

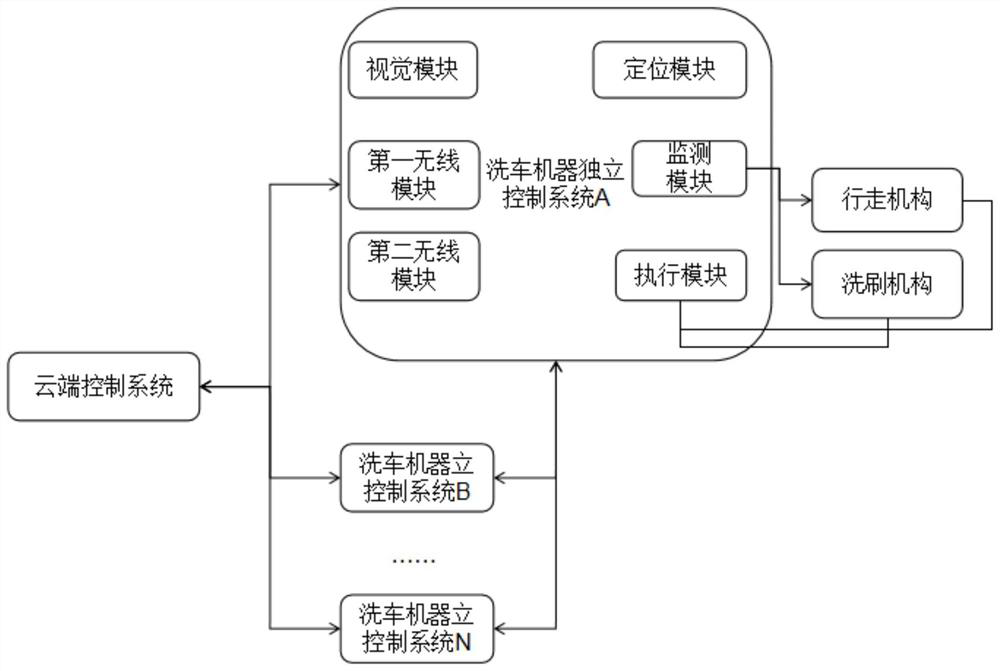

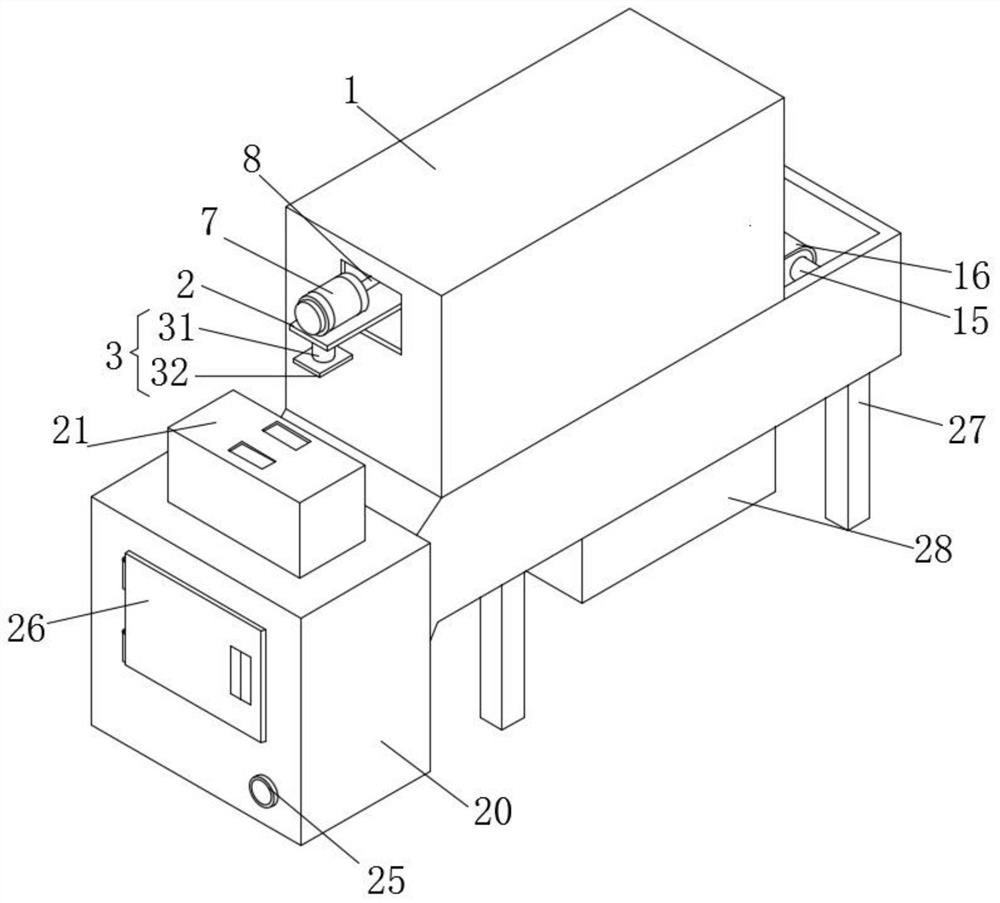

Walking vehicle washing method based on walking unmanned vehicle washing equipment and control system

ActiveCN111661010AHigh speedReduce total car wash timeCleaning apparatus for vehicle exteriorsTransmissionControl systemControl engineering

The invention discloses a walking vehicle washing method based on walking unmanned vehicle washing equipment and a control system, and relates to the technical field of vehicle washing machines. The control system comprises a cloud control system which is used for collecting, analyzing and processing position information and monitoring information sent by a vehicle washing machine independent system and sending task information to the vehicle washing machine independent system, the vehicle washing machine independent system which uploads the position information to the cloud control system, and receives and executes an instruction issued by the cloud control system and carries out information interaction with other vehicle washing machine independent control systems, wherein the interaction information comprises real-time position information and control information of an instruction executed by a hairbrush at the position; and vehicle washing machines are controlled to carry out cooperative vehicle washing through the above systems. According to the method and control system of the invention, a cloud controller issues a cooperative task to the plurality of vehicle washing machinesfor cooperative vehicle washing, so that vehicle washing speed is improved.

Owner:ZHEJIANG YI GONG LI INTELLIGENT TECH CO LTD

Mechanical gear cleaning device and operation method thereof

InactiveCN113305061AAvoid Incomplete CleaningImprove cleaning diversityDrying gas arrangementsCleaning using toolsGear wheelElectric machinery

The invention discloses a mechanical gear cleaning device and an operation method thereof. The mechanical gear cleaning device comprises a cleaning box, one side of the cleaning box is slidably connected with a lifting plate, and the two sides of the bottom of the lifting plate are in bolted connection with lifting mechanisms. To-be-cleaned gears are placed on the surface of a cylinder, the lifting mechanisms are started to drive a guide pipe at the bottom of an upper cleaning plate to be fixed to a clamping mechanism, a first motor is started to drive a rotating rod to rotate, and the rotating rod drives a second bevel gear to rotate through a first bevel gear, so that the rotating rod drives a clamped mechanism to rotate; the upper cleaning plate and a lower cleaning plate are used for washing the surfaces of the gears, so that incomplete cleaning is avoided, and the cleaning diversity is improved; and a washing mechanism is started to wash the gears, a second motor is started, the second motor drives a roller to rotate, the roller drives a conveying belt to move, the multiple gears on the conveying belt are cleaned, and therefore the multiple gears can be cleaned together, and convenience is improved.

Owner:WENZHOU POLYTECHNIC

Sand washing robot for gravel mining

The invention relates to a sand washing robot for gravel mining, which comprises a bottom box, a rubber plate, a sand washing device, contraction devices and a vibration device; the rubber plate is arranged in the bottom box; the four corners of the rubber plate are fixed to the front inner end face and the rear inner end face of the bottom box correspondingly; the sand washing device is installed in the middle of the upper end of the bottom box; and the contraction devices are symmetrically installed on the upper end face of the bottom box in the length direction of the bottom box, and the vibration device is installed at the bottom end in the bottom box. The sand washing robot for the gravel mining provided by the invention can solve the problems that when an existing sand washing machine washes sand, in order to improve the sand discharging speed of sand washing, the sand washing amount of each time can be increased, however, in the sand washing process, sand and stones are accumulated together, soil and dust on the surfaces of the sand and stones cannot be effectively cleaned away, meanwhile, the sand and stones at the bottom of the sand washing machine cannot be cleaned away, and consequently the sand and stones cannot be cleaned away completely; and during sand discharging, the sand and stones at the corners of the bottom of the sand washing machine cannot be taken out, and waste of the sand and stones is caused.

Owner:韩寒

Combined type automatic cleaning machine for vehicle evaporation box

InactiveCN112264417AReasonable structural designPracticalHollow article cleaningCleaning using liquidsWater storage tankEvaporator

A combined type automatic cleaning machine for a vehicle evaporation box comprises two groups of supporting columns, cleaning boxes are fixedly connected to the upper ends of the supporting columns, fixing assemblies are arranged on the left wall and the right wall of a fixing seat, a linkage assembly is connected to the lower end of a rotating shaft, a cleaning brush is installed at the other endof a connecting plate, a flushing assembly is connected with the upper side of the connecting plate, a liquid storage tank and a clear water tank are arranged at the upper ends of the cleaning boxes,and a liquid inlet assembly is connected between the liquid storage tank and the clear water tank. According to the combined type automatic cleaning machine, two evaporation boxes can be fixed through the fixing assemblies, the situation that the cleaning effect of the evaporation boxes is affected due to movement of the evaporators in the cleaning process is prevented, the cleaning brush is driven by the linkage assembly to move up and down, and the cleaning brush can be driven to comprehensively and thoroughly clean the evaporators up and down; and the liquid inlet assembly and the flushingassembly are matched to spray cleaning liquid to the two side faces of the evaporation boxes to be cleaned, meanwhile, clean water cleans the evaporator again finally, the cleaning effect is improved, the evaporation boxes are pressed through pressing plates, and the fixing effect of the evaporation boxes is improved.

Owner:安徽省玉环清洗设备制造有限公司

Sewage sedimentation tank for waste incineration power plant

InactiveCN111359303AAchieve cleanupImprove filtration efficiencyFiltration circuitsStationary filtering element filtersAir pumpEngineering

The invention discloses a sewage sedimentation tank for a waste incineration power plant, belongs to the technical field of waste treatment, and solves the problems that an existing device cannot classify and screen impurities in a sedimentation tank, and the later screening cost is increased. The sewage sedimentation tank is technically characterized by comprising a tank body, a filtering cavityand a settling cavity are formed in the tank body, the upper part of the filtering cavity is provided with the settling cavity, the filtering cavity is communicated with the settling cavity, a settling assembly is arranged in the settling cavity, a filtering assembly is arranged in the filtering cavity, and a water injection port is fixedly formed in the upper surface of the tank body and communicated with the filtering cavity. A cleaning assembly is arranged; due to the arrangement of the cleaning assembly, impurities are cleaned, and the sewage filtering efficiency is improved. Meanwhile, due to the arranged setting assembly, sedimentation of the sewage is facilitated, the phenomenon that impurities are not cleaned thoroughly is avoided, an air pump is started to blow air into an aeration pipe, the air is released through an aeration spray head, accumulation of impurities on a second filter screen can be effectively avoided, and the filtering efficiency is improved.

Owner:汕头市汕联水处理设备有限公司

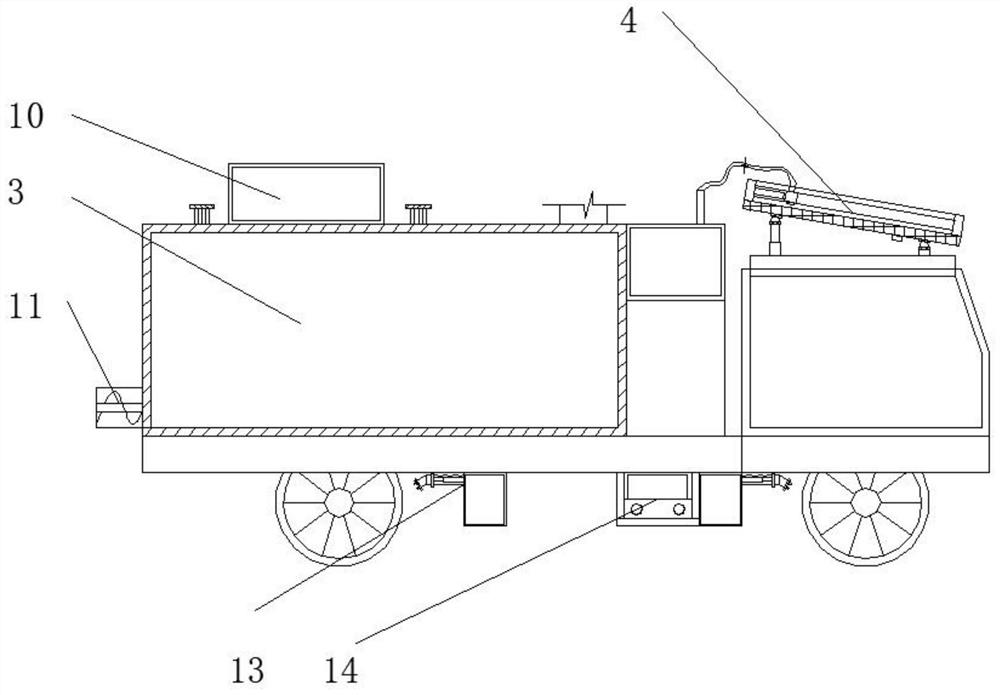

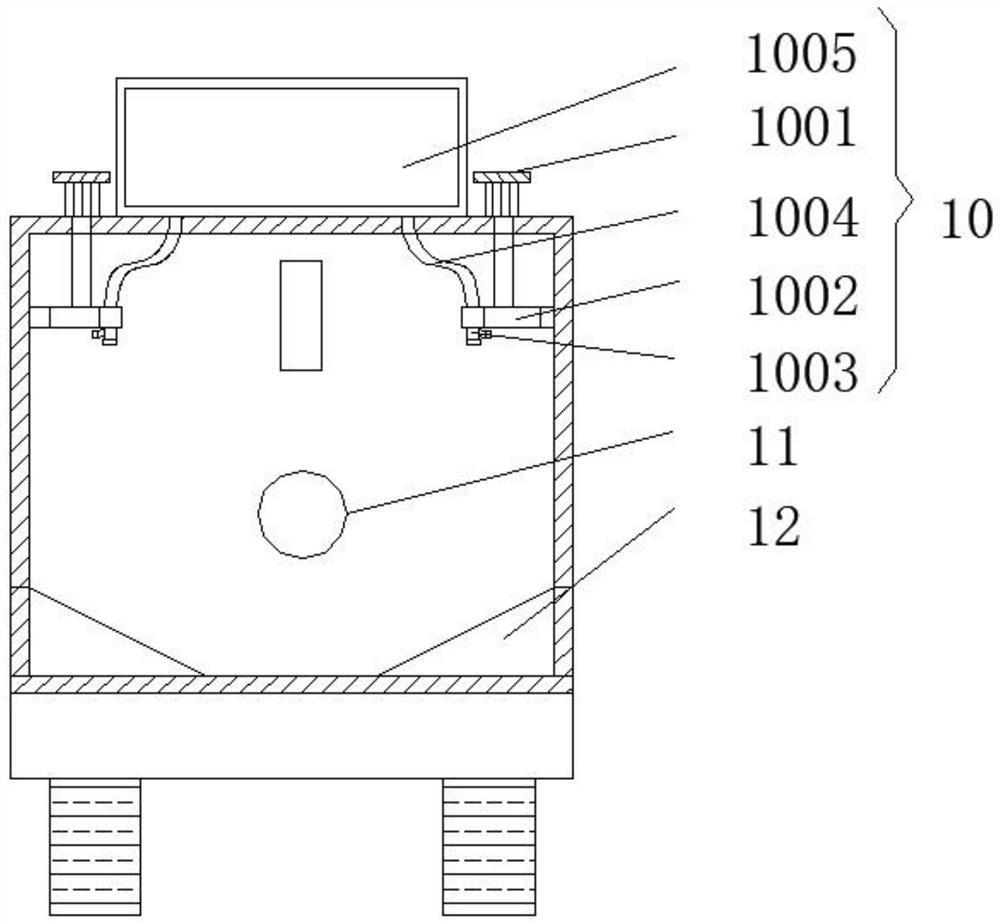

Energy-saving new energy electric mud truck

InactiveCN112874420AComplete dischargeAvoid stickingVehicle cleaningItem transportation vehiclesNew energyEngineering

The invention discloses an energy-saving new energy electric mud vehicle which comprises a base, a first storage battery, a wheel cleaning assembly and a control box, wherein a control chamber and a storage box are fixed to the upper side of the base, the storage box is located on the right side of the control chamber, meanwhile, a new energy energy-saving assembly and a photovoltaic panel cleaning assembly are fixed to the upper side of the control chamber, the photovoltaic panel cleaning assembly is fixed to the upper side of the new energy energy-saving assembly, the first storage battery is located on the left side of a smashing, stirring and scraping assembly, the smashing, stirring and scraping assembly is communicated with the slurry storage box through a first conveying pipe, the cleaning and scraping assembly is located on the upper side of a guide plate, the discharging assembly is fixed to the lower side of the interior of the slurry storage box, and the wheel cleaning assembly and the limiting assembly are fixed to the lower side of the base. The energy-saving new energy electric slurry truck has the advantages that the energy-saving effect can be achieved, cement slurry can be pretreated, it can be ensured that slurry adhering to the storage box is discharged thoroughly, and tires can be cleaned.

Owner:徐州新智动智能化科技有限公司

Rod type automatic moving bent pipe inner wall cleaning device

ActiveCN112643418AEasy to cleanArc automatically adaptsRevolution surface grinding machinesGrinding drivesPipeMechanics

The invention relates to the technical field of steel pipe machining, and discloses a rod type automatic moving bent pipe inner wall cleaning device. The device comprises a base and four outer rods, a fixing device is arranged in the base, a water inlet pipe is fixedly connected to the bottom of the base, and extendable rods are arranged in the outer rods. According to the rod type automatic moving bent pipe inner wall cleaning device, when a bent pipe is cleaned and the cleaning device enters the bent pipe, an inner ball can rotate in an outer ball, the interior of the bent pipe can be cleaned conveniently, bending can be conducted according to the radian of the bent pipe, then the inner wall of a steel pipe can be cleaned, the situation that the interior of the bent pipe is inconvenient to clean is avoided, it is guaranteed that the device can automatically adapt to the radian of the bent pipe, then steel pipes with different bent radians can be cleaned conveniently, and when the steel pipes with the excessively-large bent radians are cleaned, the length of the extendable rod with the proper length should be changed.

Owner:杭州新元素医疗科技有限公司

Wood composite board finish machining treatment system and finish machining treatment technology

ActiveCN111822400AAvoid incomplete cleaningImprove cleaning efficiencyBrush bodiesBristle carriersComposite plateMechanical engineering

The invention relates to a wood composite board finish machining treatment system and finish machining treatment technology. The system comprises a bottom plate, a collecting frame, a storing device and a clearing device. The collecting frame is installed at the upper end of the bottom plate. The storing device is arranged above the collecting frame. The storing device is installed on the bottom plate. The clearing device is arranged above the storing device. The clearing device is installed on the bottom plate. The system can solve the problems that when the hole wall of a perforated wood composite board is cleared at present, in the clearing process of the hole wall, close attaching to the hole wall cannot be achieved, the phenomenon of incomplete clearing of the hole wall occurs easily,thus the clearing efficiency is reduced, moreover, through holes in different shapes cannot be cleared on one equipment, thus applicability of the equipment is lowered, meanwhile, after the wood composite board is cleared, a clearing mechanism cannot be cleared, next clearing of the clearing mechanism is influenced easily, and the effect of continuous clearing is reduced.

Owner:赣州市南康区金源家具有限公司

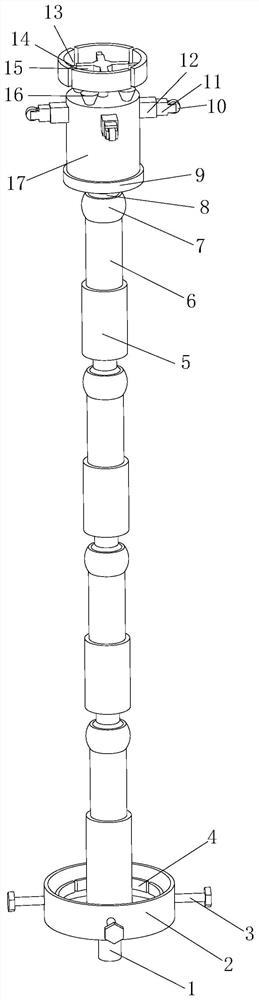

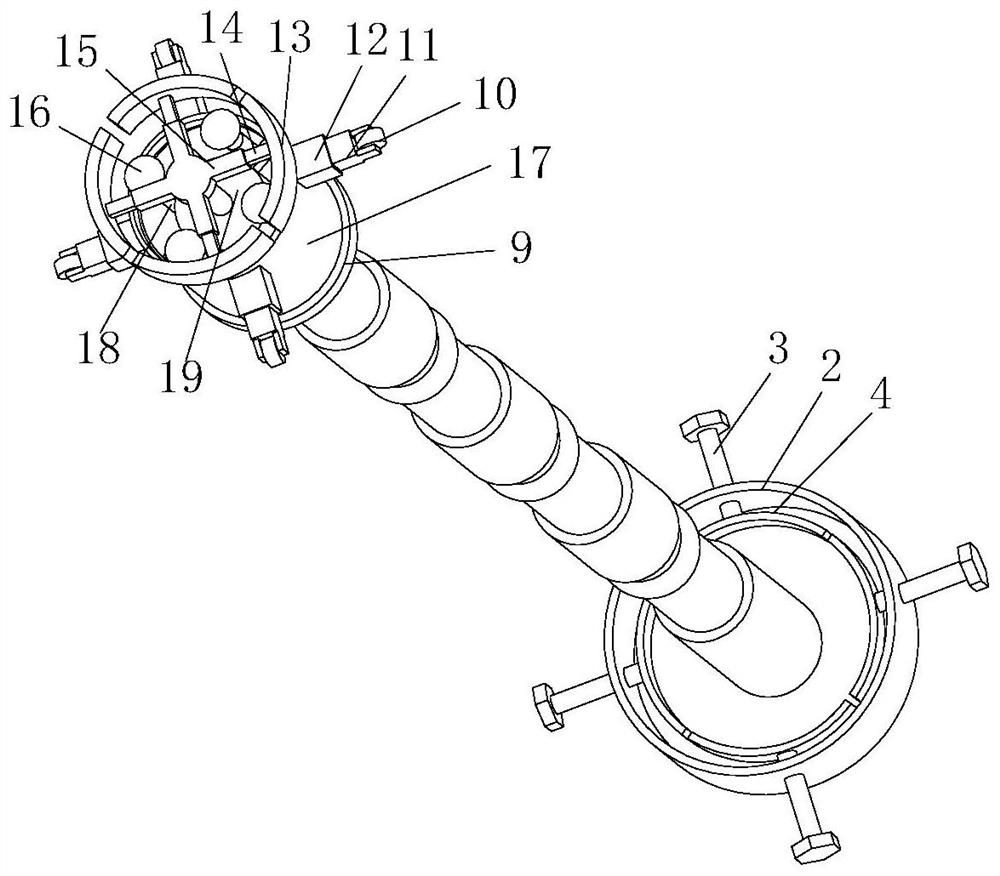

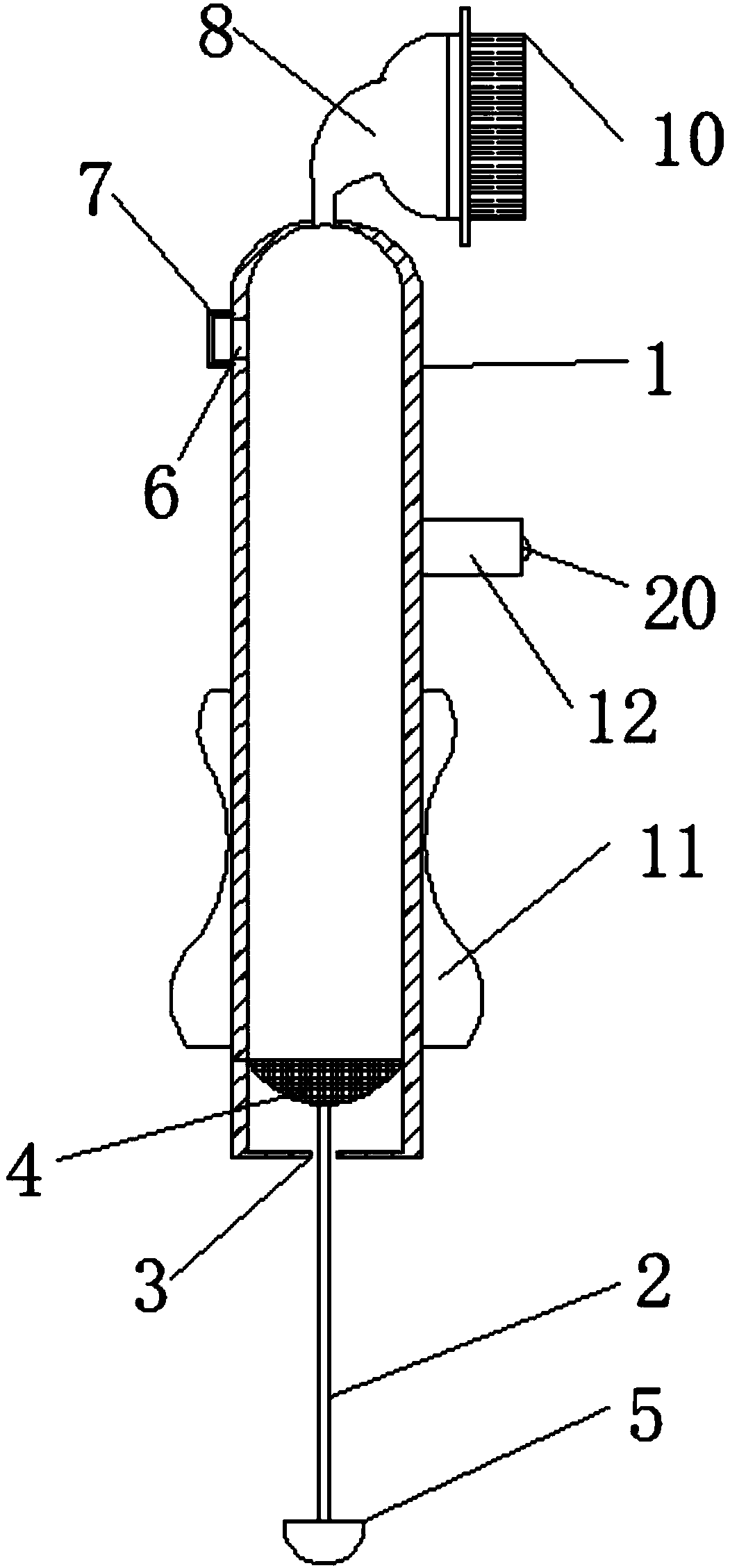

Power transmission line insulator cleaning robot and method

InactiveCN112044835AAvoid deformationAvoid offsetDrying gas arrangementsDirt cleaningMechanical engineeringRoboty

The invention provides a power transmission line insulator cleaning robot and method, and belongs to the technical field of insulator cleaning. The power transmission line insulator cleaning robot comprises an upper-layer support and a lower-layer support connected with the upper-layer support through an electric push rod; an upper clamping component which is arranged in a surrounding manner to clamp an insulator steel cap is arranged in the position, close to the upper-layer support, of the electric push rod; a lower clamping component which is arranged in a surrounding manner to clamp the insulator steel cap is arranged in the position, close to the lower-layer support, of the electric push rod; and the upper-layer support and the lower-layer support are provided with sweeping mechanismsused for sweeping the insulators. According to the power transmission line insulator cleaning robot and method, the steel caps of the insulators are clamped by using clamping jaws, so that large clamping force is achieved and crawling is stable; and as the whole frame is of a symmetrical structure, the center of the robot is prevented from deviating; The structure is simple, and the dead weight is low; a worker can easily assemble, disassemble and carry the robot through an insulating rod; alternate operation on different insulator chains is facilitated; the power transmission line insulatorcleaning robot can be used for cleaning with bristles, cleaning with liquid and blow-drying, can clean stubborn stains, and thoroughly cleans dirt on the surface of the insulator.

Owner:国网河南省电力公司西峡县供电公司

Dust collecting device for capacitor shell

InactiveCN108246665AAchieve cleaningAvoid incomplete cleaningLighting elementsCleaning using toolsEngineeringCleansing Agents

The invention discloses a dust collecting device for a capacitor shell. The dust collecting device comprises a cleaning agent pipe and a piston rod, wherein an opening is formed in the lower wall of the cleaning agent pipe; the piston rod penetrates through the opening but is not in contact with the opening; the upper end of the piston rod is fixedly connected to a piston block, and a piston blockis slidably connected to the inner wall of the cleaning agent pipe; the bottom end of the piston rod is fixedly connected to a pushing handle; a liquid injection opening is formed in the side wall ofthe upper end of the cleaning agent pipe; a liquid injection pipe is fixedly connected to the outer wall of the upper end of the cleaning agent pipe, and the position of the liquid injection pipe corresponds to the liquid injection opening. An effect of cleaning dust of the capacitor shell is achieved by means of the dust collecting device which is capable of injecting a cleaning liquid and is provided with a brush head. By additionally arranging an illuminating device, the condition of incomplete cleaning due to insufficient rays is avoided when dust in the capacitor shell in an electric appliance is collected, and an effect of serving dust collecting work is better achieved.

Owner:四川恒科伟科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com