Iron drum renovation treatment system

A processing system and iron bucket technology, applied in the direction of cleaning hollow objects, measuring devices, instruments, etc., can solve the problems of emitting odor, unsatisfactory treatment effect, and harmful health of staff, and achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

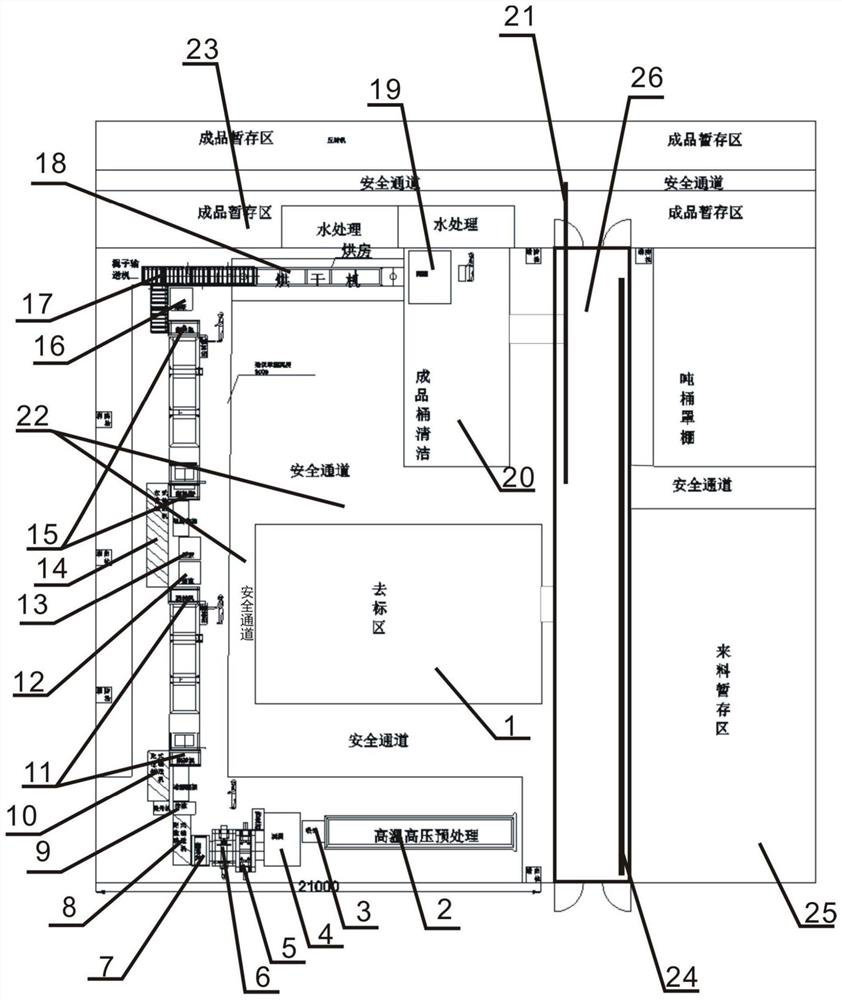

[0136] Before unloading, manually or automatically scan and read the source, nature, receiving time and other information of the material, classify according to the type of different residual liquid, and put the iron drums of different types through the main import and export, and transfer the different types of iron drums through the conveyor belt unloaded in different districts.

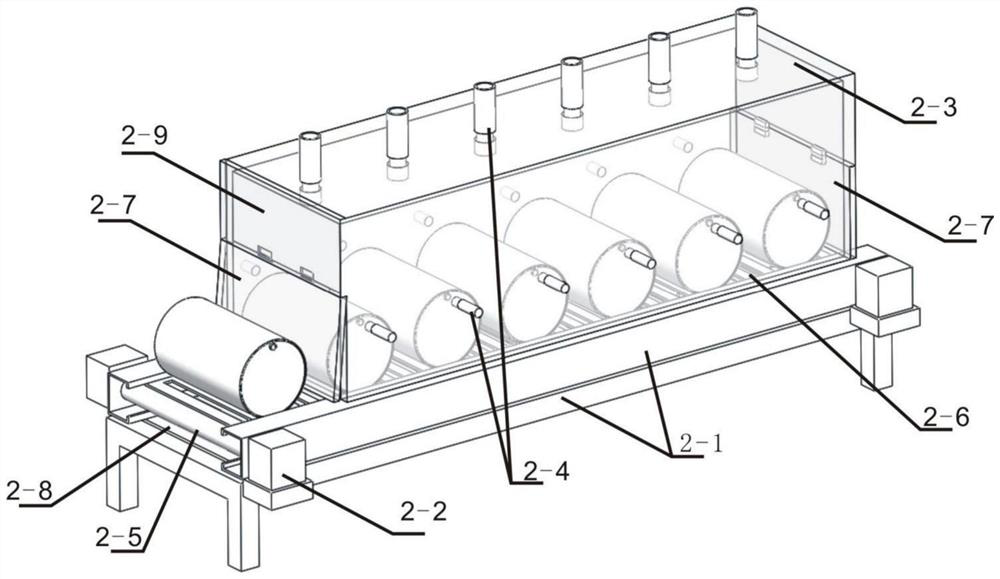

[0137] First of all, the material once contained in the iron drum to be processed is oil. When processing, the iron drum is placed on the conveyor belt I24 from the community, and the conveyor belt I24 is sent to the demarking machine 1, and the iron drum on the conveyor belt I24 is processed. The process is:

[0138] 1 pretreatment period

[0139] Step 1: Unmark

[0140] The oil drum is placed in the demarking machine 1 to remove the label on the surface of the iron drum; the time for the iron drum to be processed in the demarking machine 1 is 1 minute;

[0141] The second step: remove the slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com