Sewage sedimentation tank for waste incineration power plant

A technology for waste incineration and power plants, which is applied in filtration and separation, separation methods, fixed filter element filters, etc., can solve the problems of increasing screening costs, inability to classify and screen impurities, etc., to avoid incomplete cleaning, improve filtration efficiency, and avoid stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

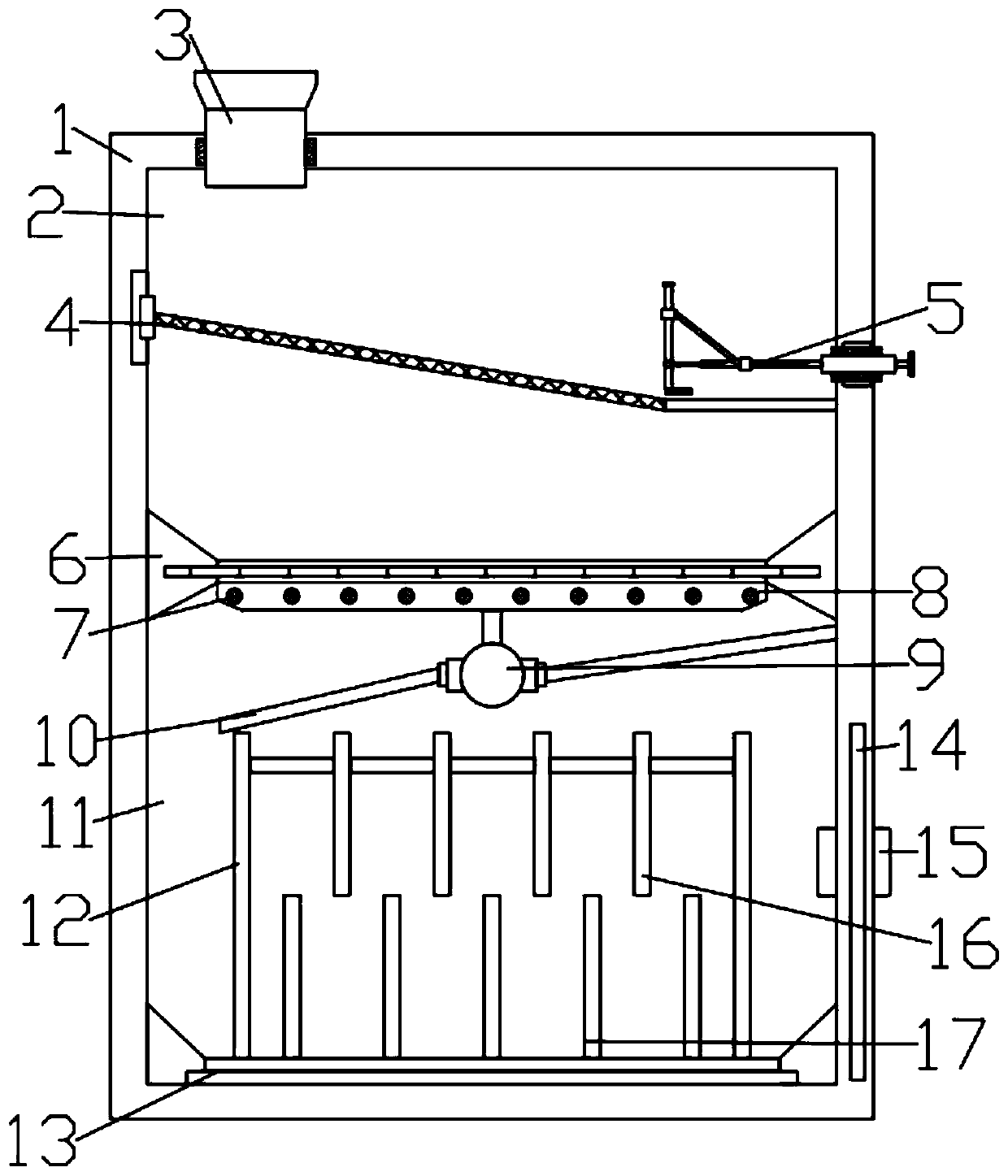

[0023] Such as figure 1 As shown, in the embodiment of the present invention, a sewage settling tank for a waste incineration power plant includes a tank body 1, a filter cavity 2 and a settling cavity 11 are provided inside the tank body 1, and a settling cavity 11 is provided on the upper part of the filter cavity 2 , the filter chamber 2 communicates with the settling chamber 11, the settling chamber 11 is provided with a settling assembly, the filter chamber 2 is provided with a filter assembly, the upper surface of the pool body 1 is fixedly installed with a water injection port 3, and the water injection port 3 communicates with the filter chamber 2;

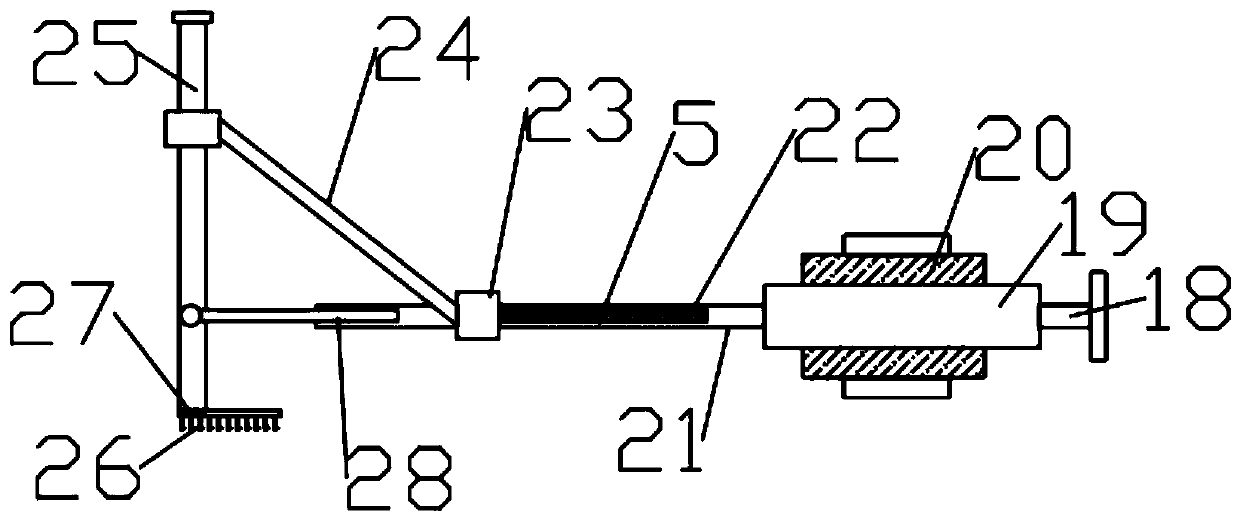

[0024] The filter assembly comprises a first filter screen 4 and a second filter screen 6, the first filter screen 4 is arranged above the second filter screen 6, and the mesh aperture of the first filter screen 4 is greater than the mesh aperture of the second filter screen 6, The first filter screen 4 is inclined, and th...

Embodiment 2

[0032] Such as figure 1 As shown, in the embodiment of the present invention, a sewage settling tank for a waste incineration power plant includes a tank body 1, a filter cavity 2 and a settling cavity 11 are provided inside the tank body 1, and a settling cavity 11 is provided on the upper part of the filter cavity 2 , the filter chamber 2 communicates with the settling chamber 11, the settling chamber 11 is provided with a settling assembly, the filter chamber 2 is provided with a filter assembly, the upper surface of the pool body 1 is fixedly installed with a water injection port 3, and the water injection port 3 communicates with the filter chamber 2;

[0033] The filter assembly comprises a first filter screen 4 and a second filter screen 6, the first filter screen 4 is arranged above the second filter screen 6, and the mesh aperture of the first filter screen 4 is greater than the mesh aperture of the second filter screen 6, The first filter screen 4 is inclined, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com