Patents

Literature

162results about How to "Reduce cleaning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent cleaning robot and path planning method thereof

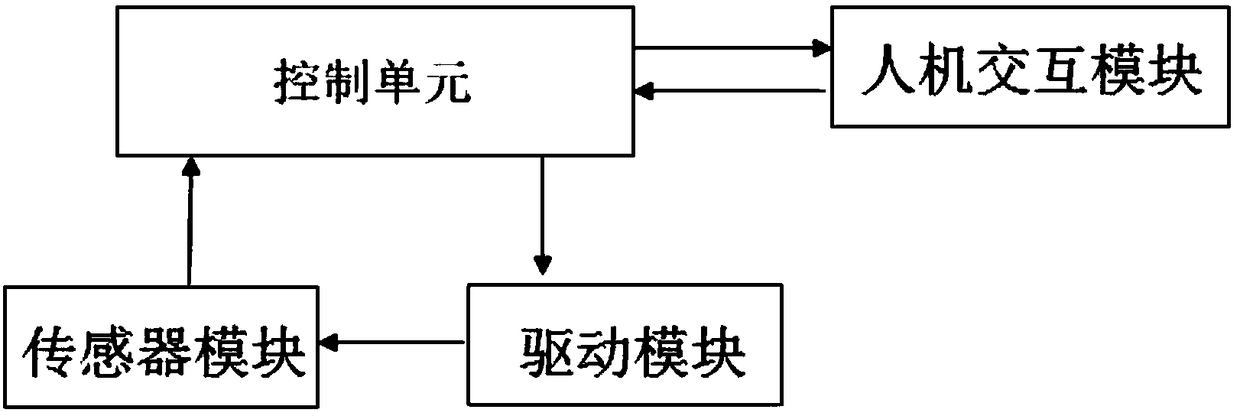

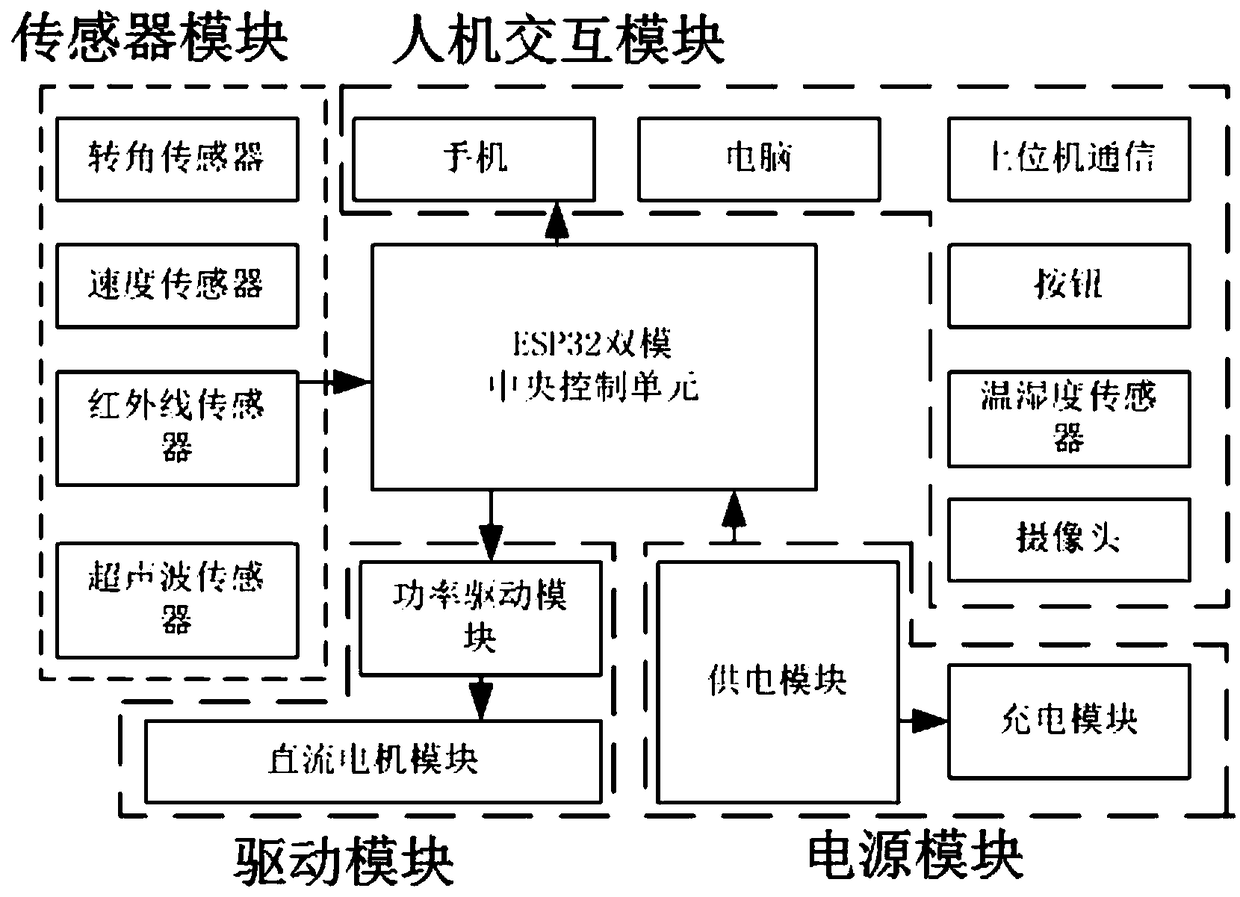

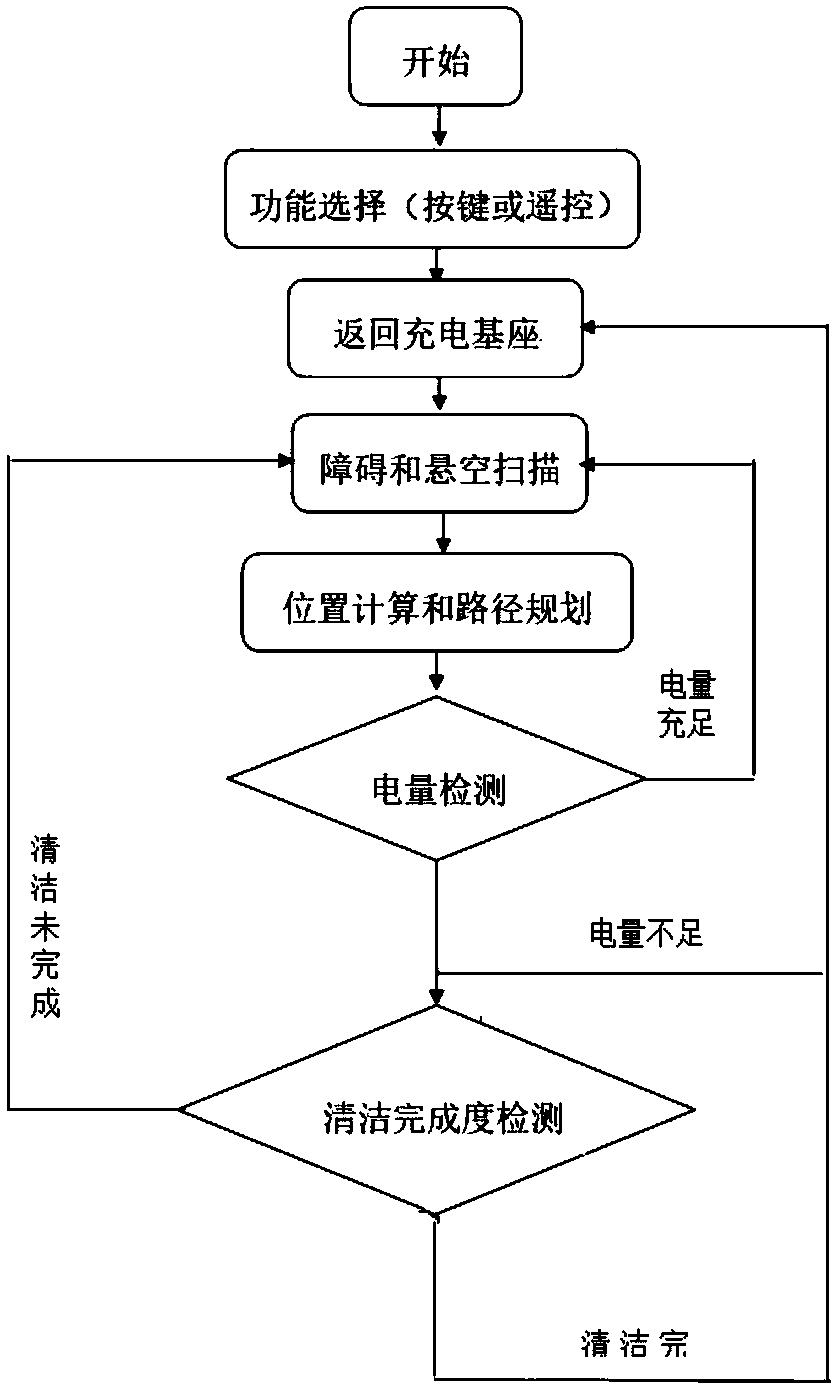

ActiveCN109144067AAchieve maximum coverageAchieving cleanlinessPosition/course control in two dimensionsVehiclesReal time analysisRemote control

The invention discloses an intelligent cleaning robot and a path planning method thereof. A sensor module is used for analyzing and feeding back real-time cleaning environment information; an accuratepositioning module is used for acquiring the position of the current intelligent cleaning robot on the environment map which is established through a geometric-topological hybrid map technology, andthe environment map and the real-time position are combined, the optimal sweeping path is planned by using an advanced path planning algorithm, and the data is uploaded to a cloud platform for realizing the real-time analysis, recording, and control; a driving module is used for driving the intelligent cleaning robot to run according to the planned optimal path and carrying out cleaning operation;a man-machine interaction module can be used for displaying the working state and performance of the intelligent cleaning robot by combining the temperature and humidity sensor with the camera, and the remote control and reservation functions of the intelligent cleaning robot can be completed through wifi / Bluetooth technology. According to the invention, the labor intensity is reduced, the laborefficiency is improved, and the robot is suitable for hotels, libraries, office places and public families.

Owner:CHECC DATA CO LTD +1

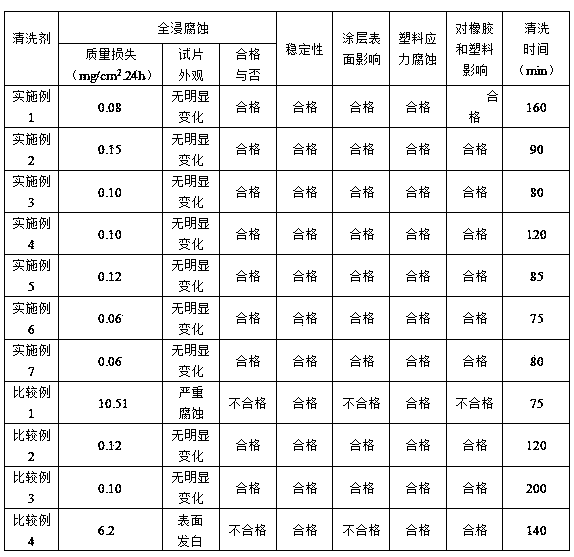

Cleaning agent for aircraft pipelines and preparation method thereof

ActiveCN103642612AGood synergyKeep efficientSurface-active non-soap compounds and soap mixture detergentsOrganic acidChemistry

The invention relates to the field of aviation and specifically relates to a cleaning agent for aircraft pipelines and a preparation method thereof. The cleaning agent comprises an organic acid, a corrosion inhibitor, a surfactant, auxiliaries and deionized water, wherein the organic acid is a complex organic acid, the complex organic acid comprises an aminosulfonic acid and an organic acid with a low pH buffer value, and the complex organic acid accounts for 8-20% by weight of the total cleaning agent; in order to further improve the pH buffer capacity of the cleaning agent and improve the proportion of the organic acid with the buffer function in the complex organic acid to keep the high efficiency in descaling of the cleaning agent, the proportion of the complex organic acid to the aminosulfonic acid in parts by weight is (25-50): (75-50). By adding the high-efficient corrosion inhibitor in the formula, the corrosion to metal materials caused by the acid is greatly reduced, so that the safety of aircraft materials is ensured.

Owner:成都民航六维航化有限责任公司

Veterinary foam cleaning agent and preparation method thereof

ActiveCN105925395AImprove decontamination abilityGood emulsifying effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansing AgentsBiological membrane

The invention relates to a veterinary foam cleaning agent and a preparation method thereof which are applicable to animal stalls, hatching houses, farm utensils, vehicles passing in and out and the like. The veterinary foam cleaning agent is prepared from, by mass, 20%-32% of surfactant compound components, 2%-3% of detergent assistant, 4%-6% of chelating agent, 1.5%-2% of corrosion inhibitor, 3%-4% of foam stabilizer, 0.5%-2% of dispersing agent, 5%-6% of solubilizer and the balance purified water, and the sum of the contents of the components is 100%; the surfactant compound components are prepared from 3%-5% of anionic surfactant I, 2%-5% of anionic surfactant II, 8%-12% of nonionic surfactant I and 7%-10% of nonionic surfactant II. According to the veterinary foam cleaning agent, it is finally proved through the foaming effect and decontamination effect of a breeding field that the foaming effect is good, and foam is rich, exquisite, high in adhesivity and long in adhesive time; meanwhile, the decontamination effect is excellent, and stubborn stains such as hard stool, grease, the blood and biological membranes can be effectively removed.

Owner:SHANDONG SINDER TECH

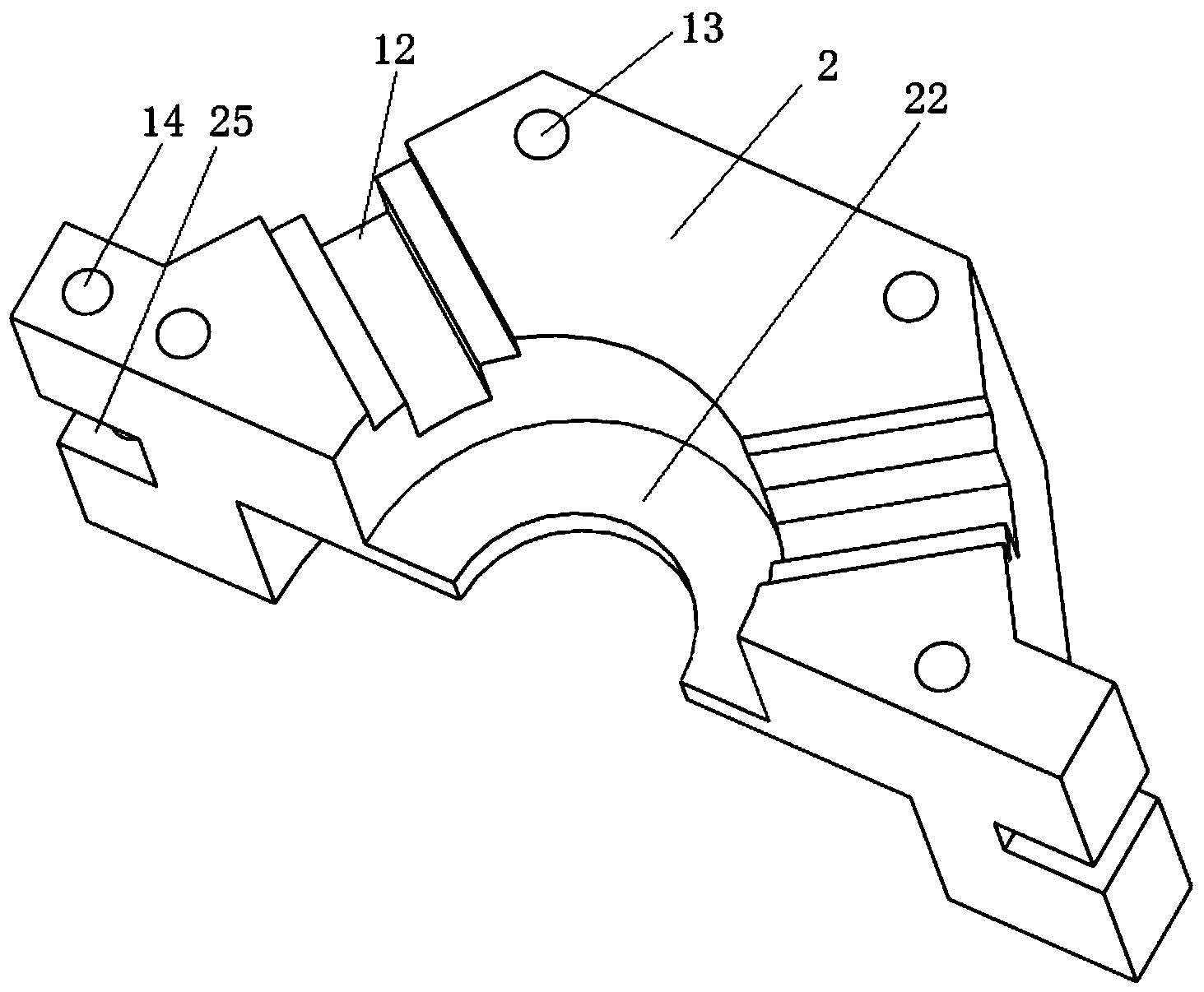

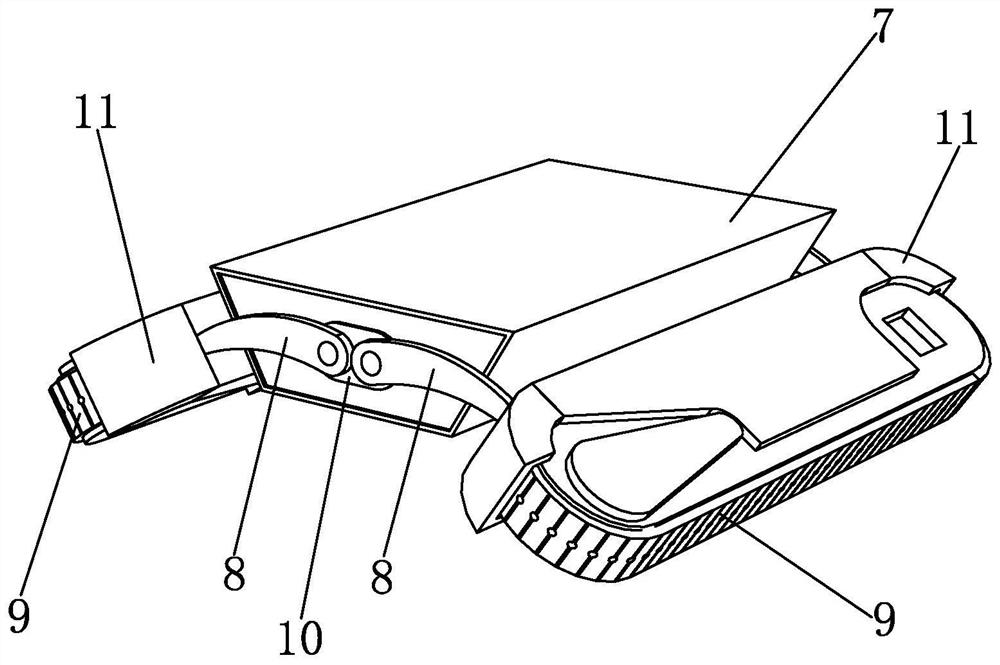

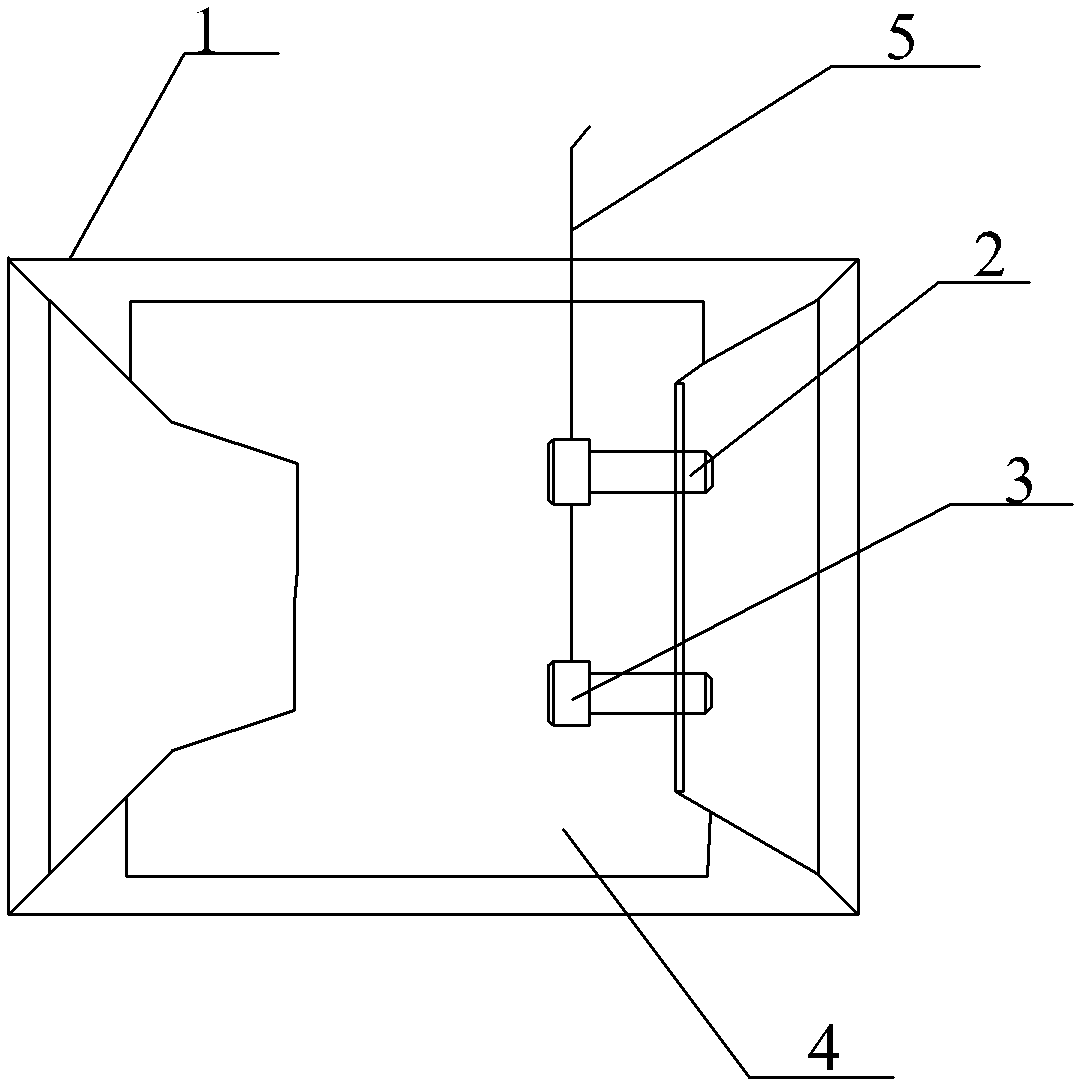

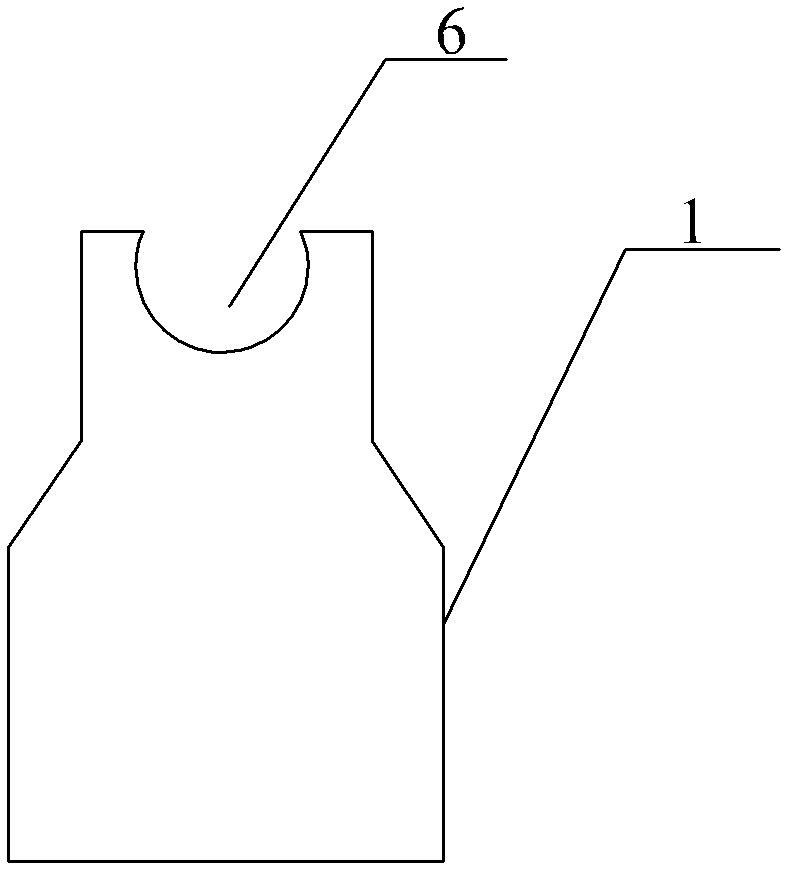

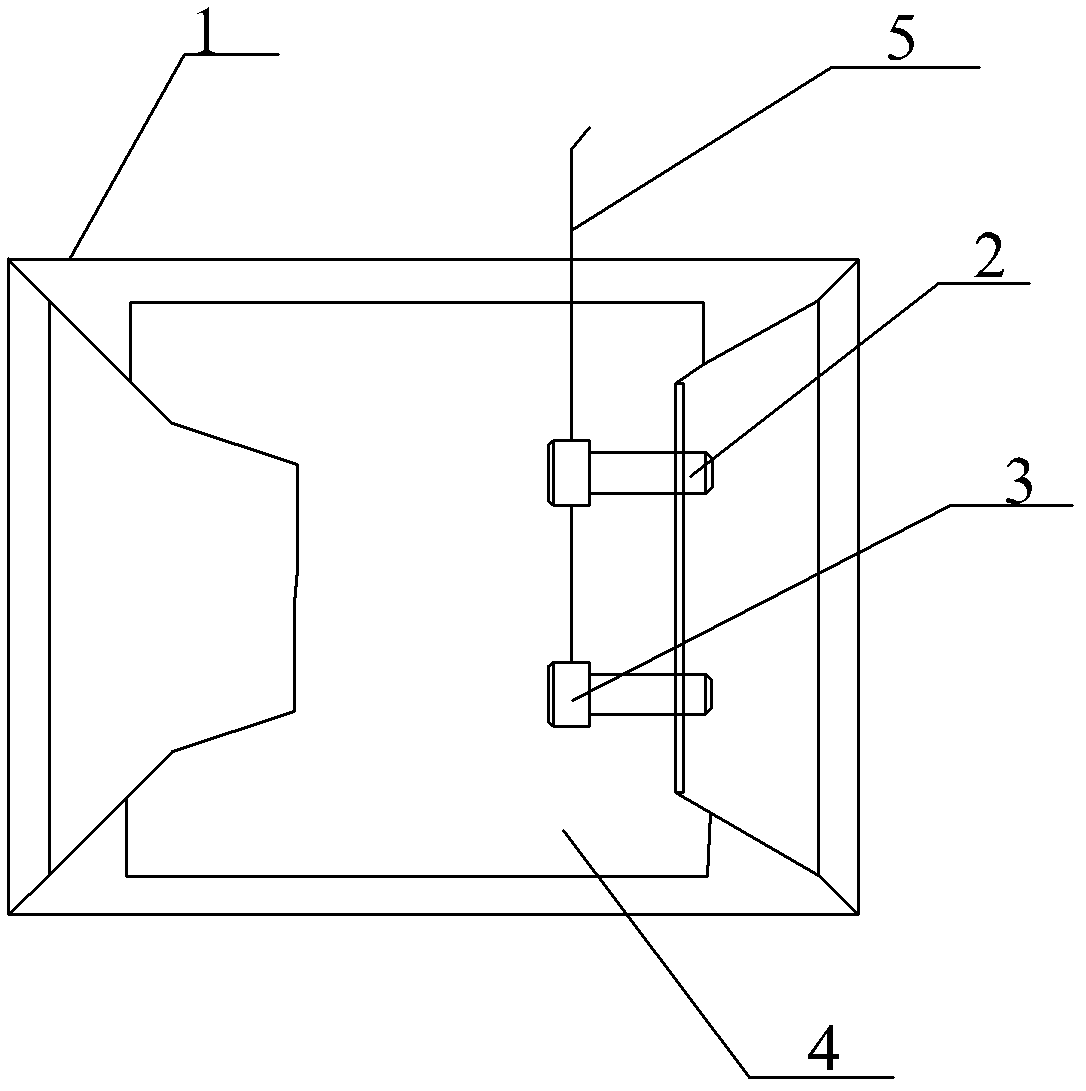

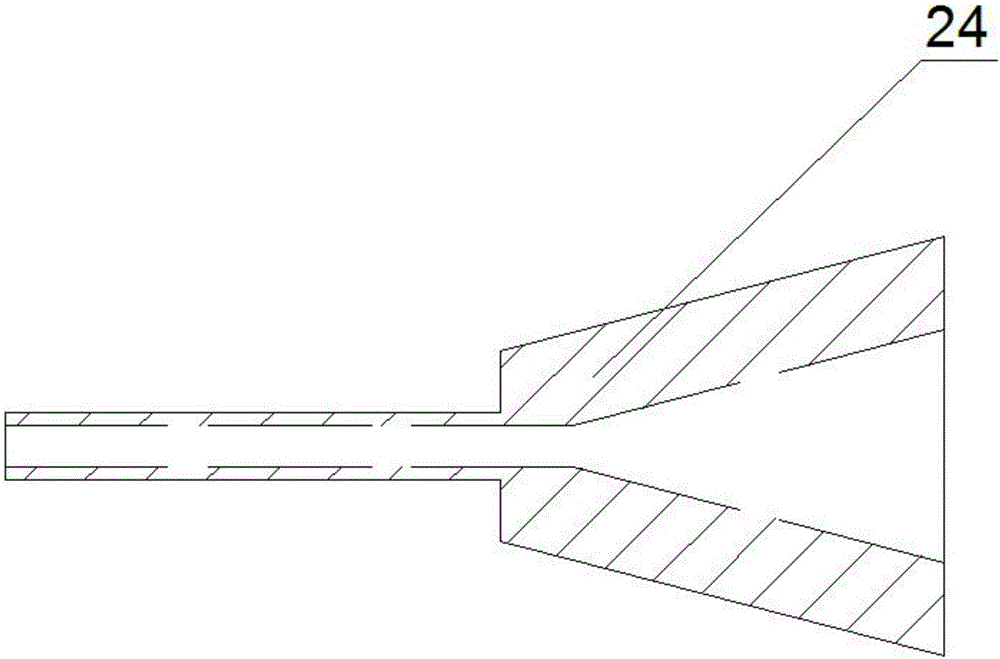

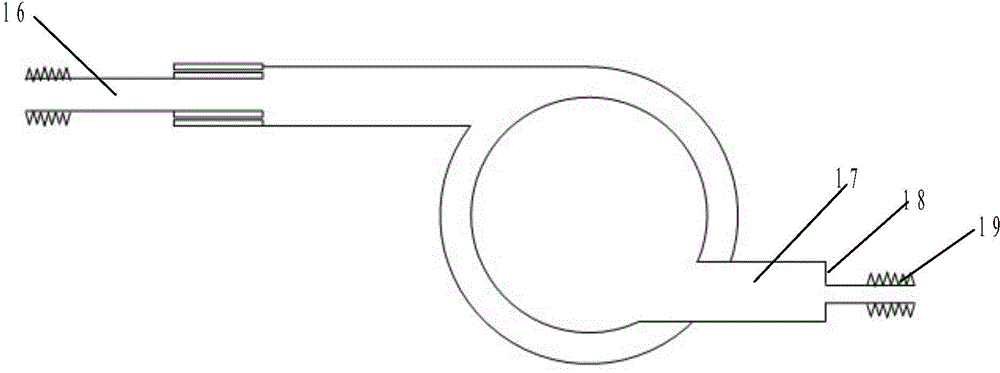

Atomizing cleaning head for overhead transmission line

ActiveCN104226623AEfficient cleaning functionEasy to replaceCleaning using liquidsApparatus for overhead lines/cablesComputer modulePotential harm

The invention discloses an atomizing cleaning head for an overhead transmission line. The atomizing cleaning head comprises a cylindrical member formed by connecting a plurality of module structures, wherein two sealing elements which are arranged longitudinally in parallel are fixed on the middle part of the inner cavity of the cylindrical member; a hole through which the transmission line needing to be cleaned passes and which is hermetically formed in the transmission line in a sleeving manner is formed in the center of each sealing element; a cavity is formed between the two sealing elements; a plurality of atomizing nozzles which are communicated to the outside of the cylindrical member are arranged along the circumferential direction of the cavity; a recycling nozzle which is communicated to the outside of the cylindrical member is arranged at the bottom of the cavity; compression walking mechanisms which can be compressed onto the transmission line and can move along the transmission line are arranged in the inner cavities at the two ends of the cylindrical member. Through adoption of a modular structural design form, the atomizing cleaning head is simple in overall structure, is reliable, is convenient to replace, and is low in manufacturing cost; during cleaning, the atomizing cleaning head is not in direct physical contact with the transmission line, so that potential damage to the surface of the transmission line is avoided, residual cleaning liquid can be recycled while atomizing cleaning is realized, and potential harm to the environment is avoided.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

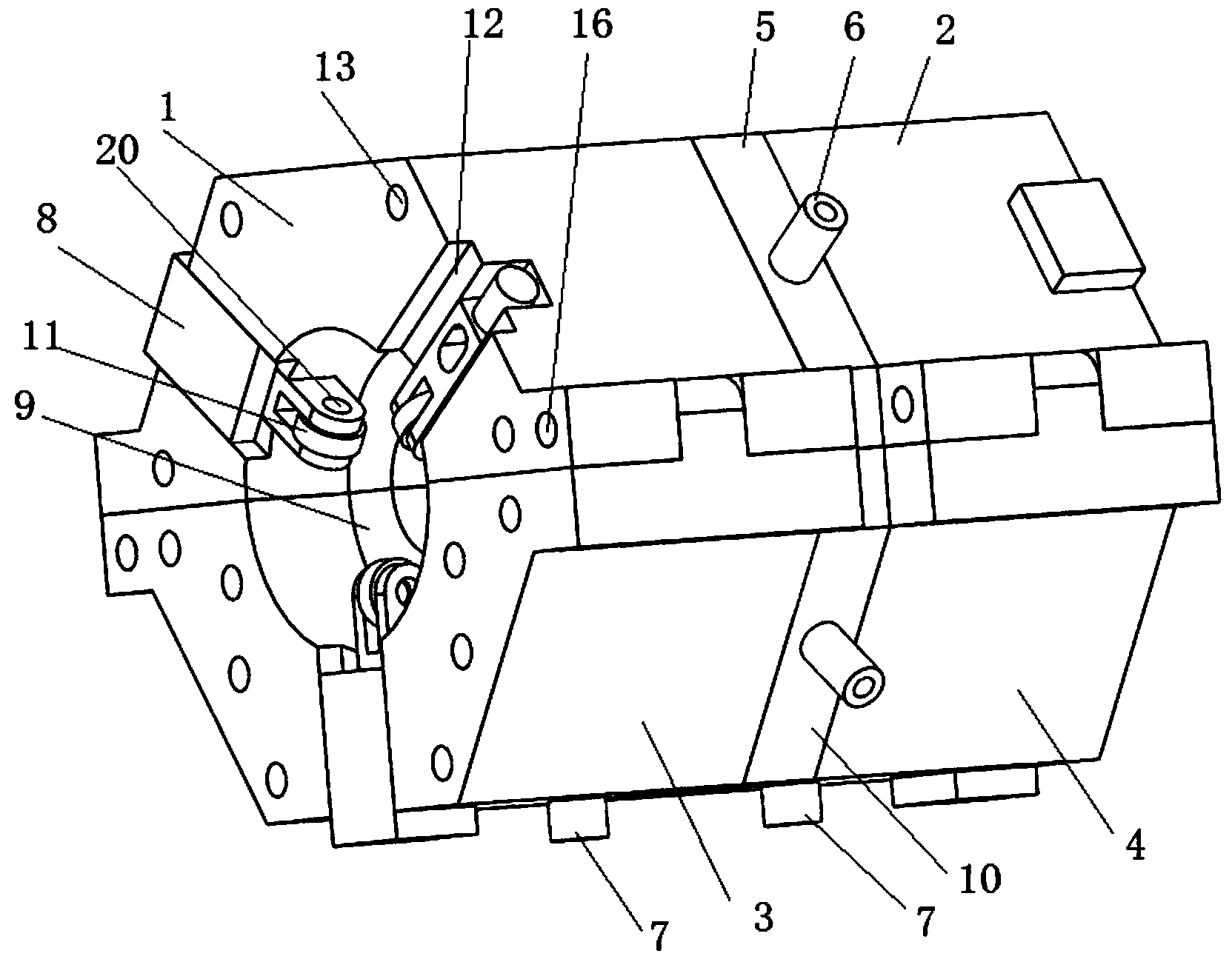

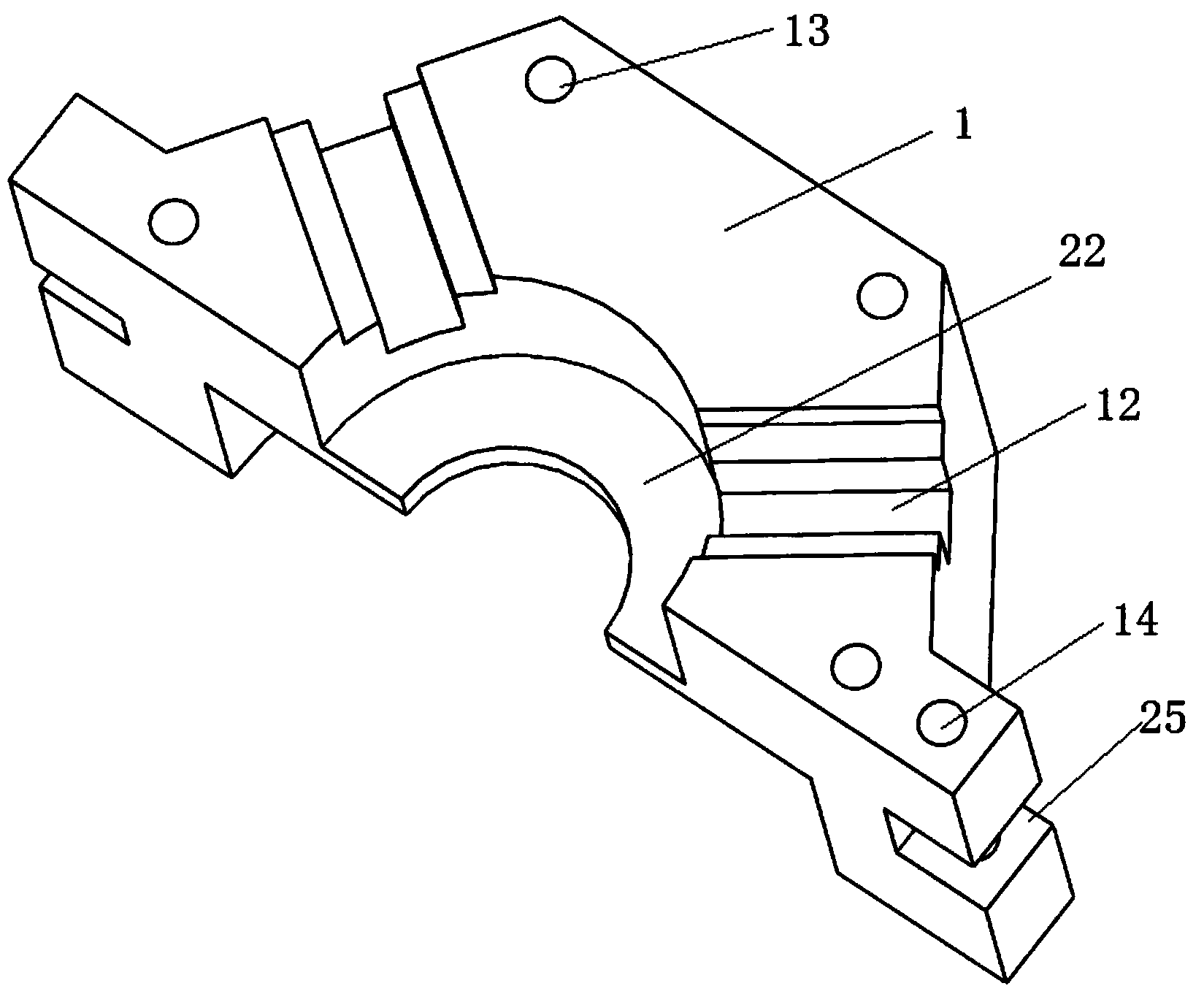

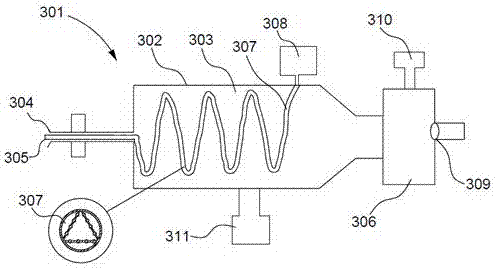

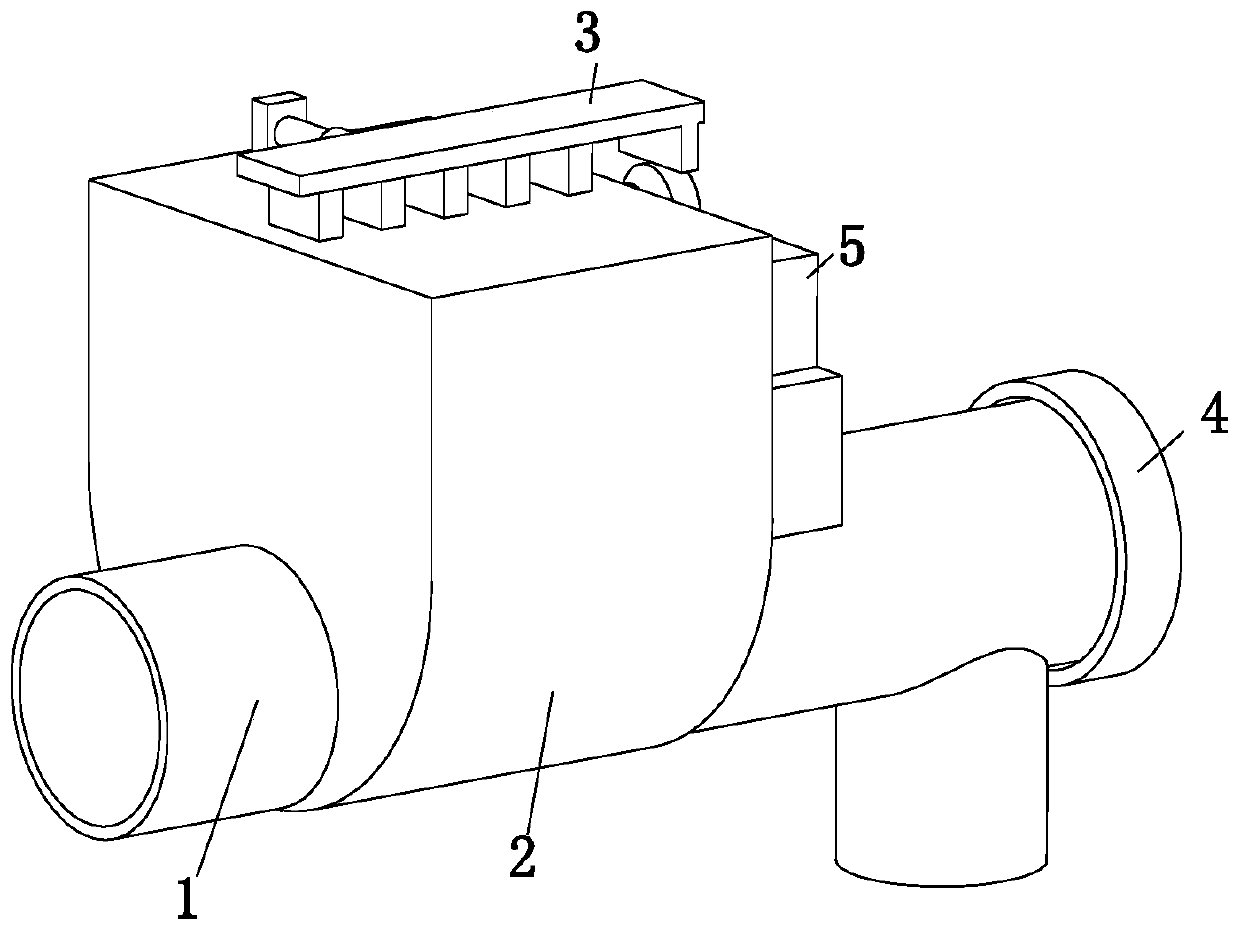

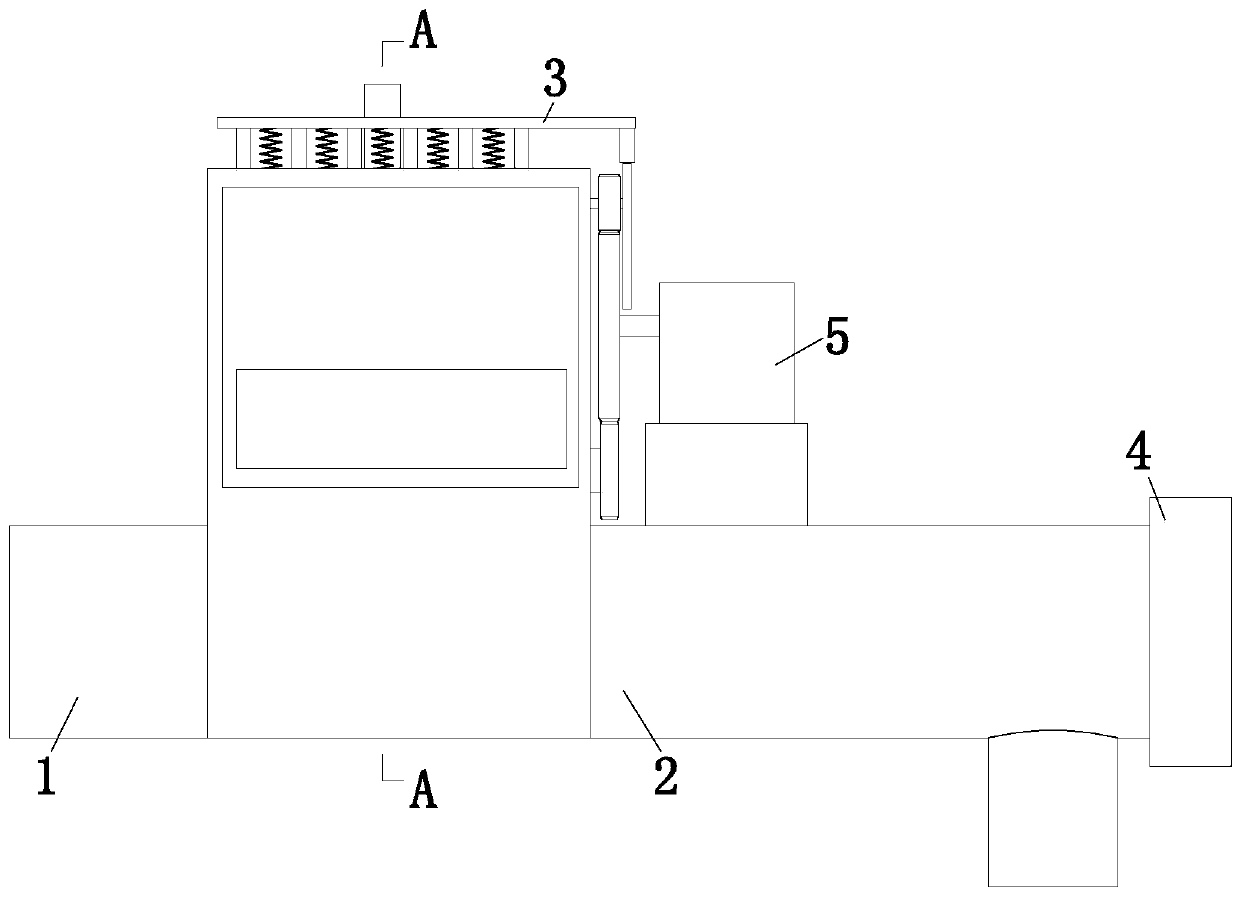

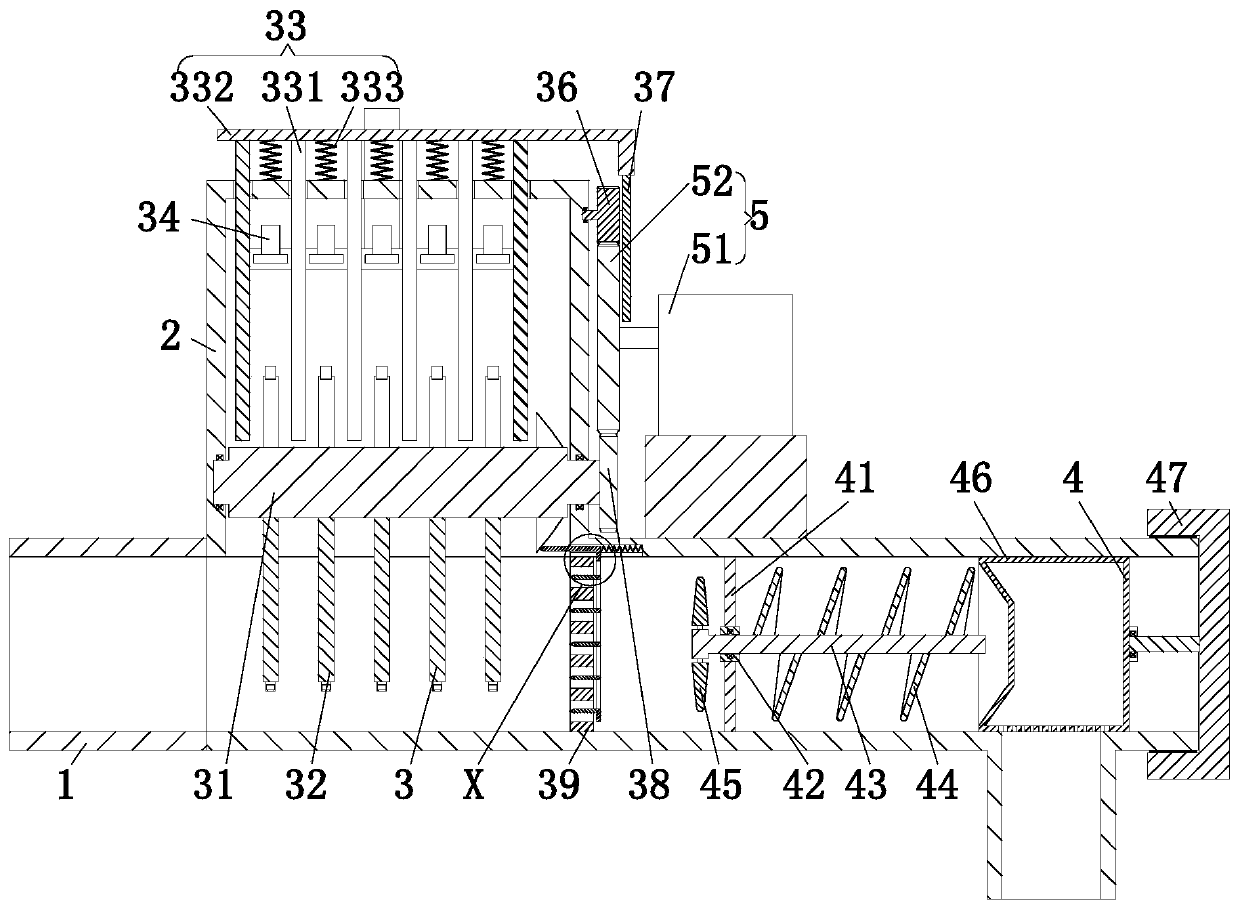

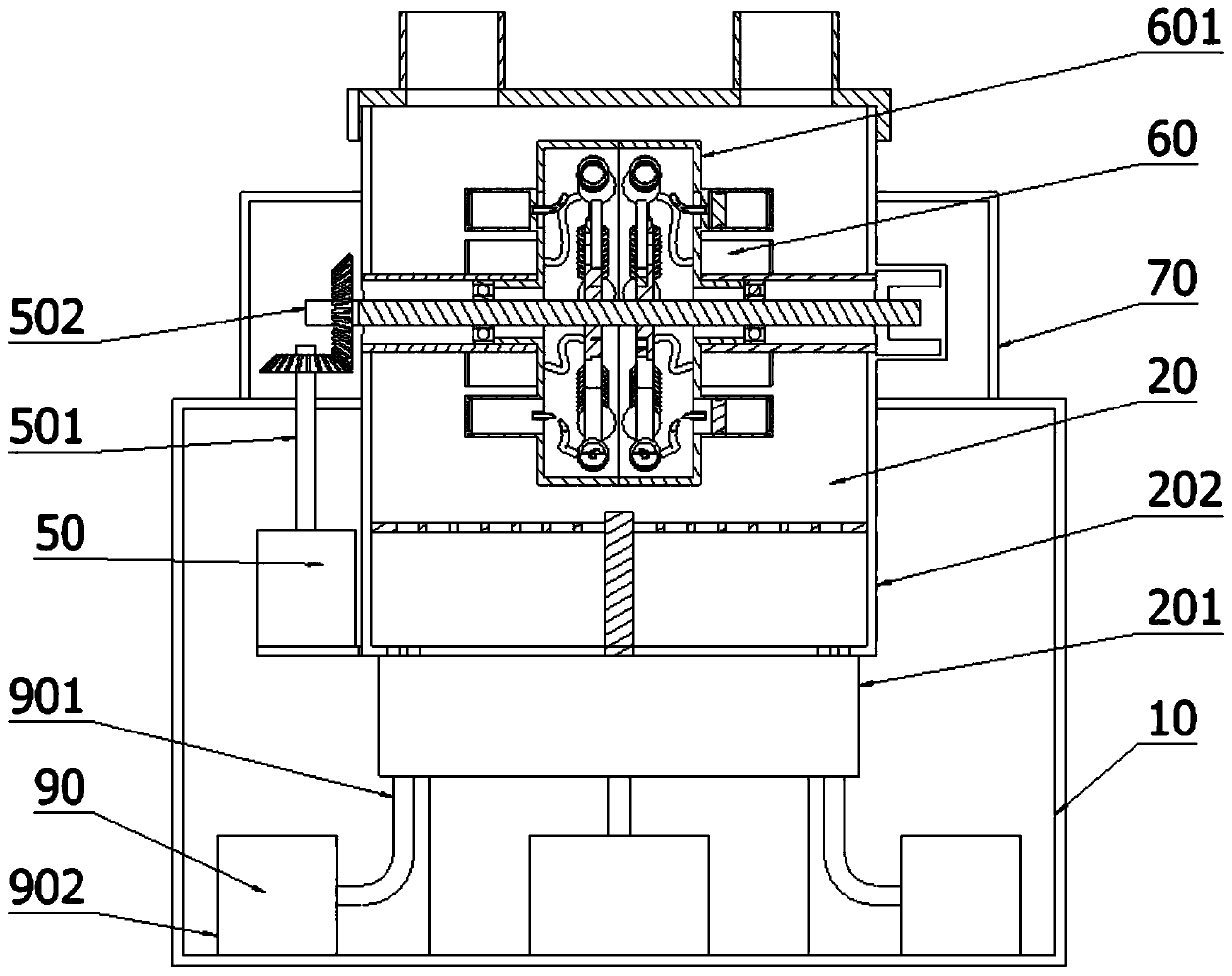

Cleaning device for die waterway

ActiveCN103406299AExtended service lifeFast heat conductionCleaning using liquidsEngineeringMechanical engineering

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

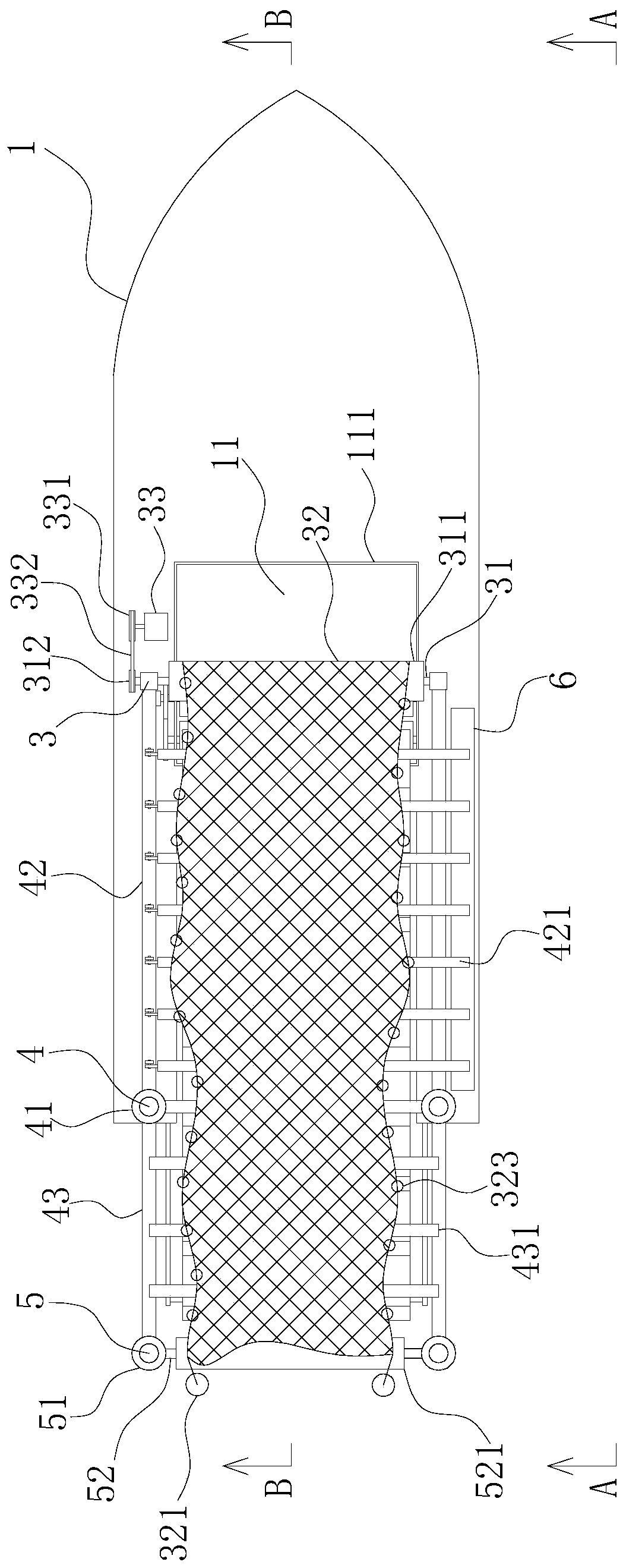

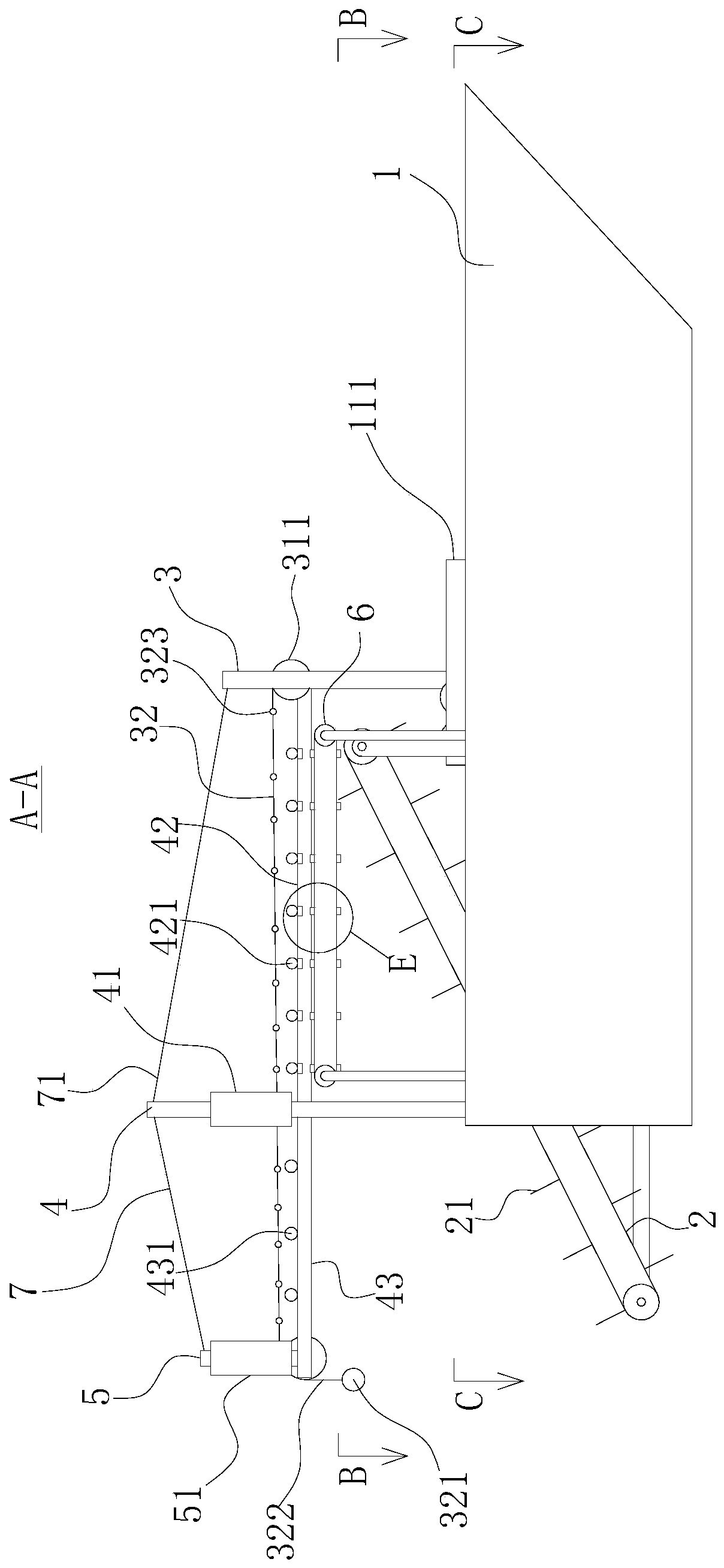

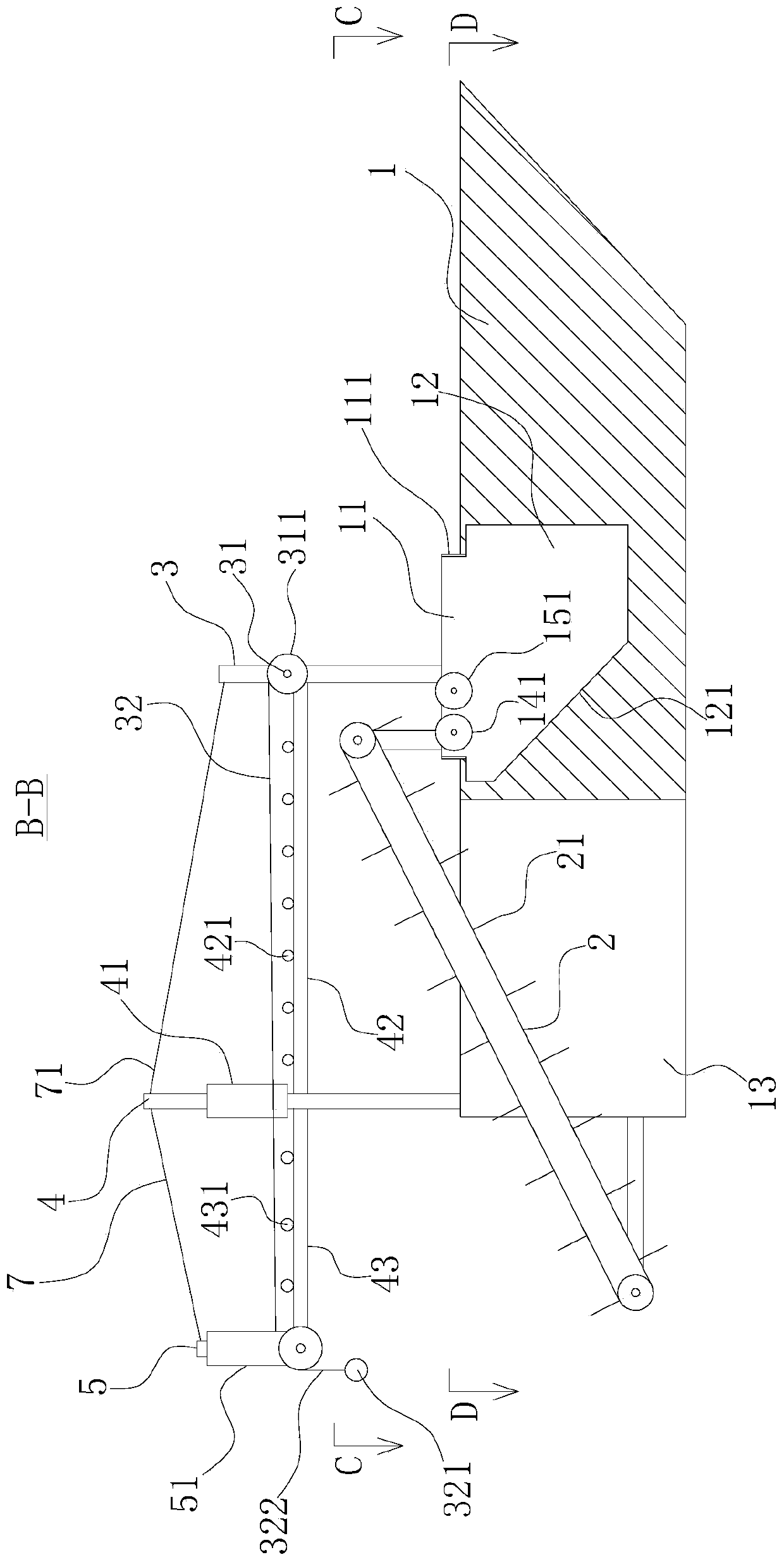

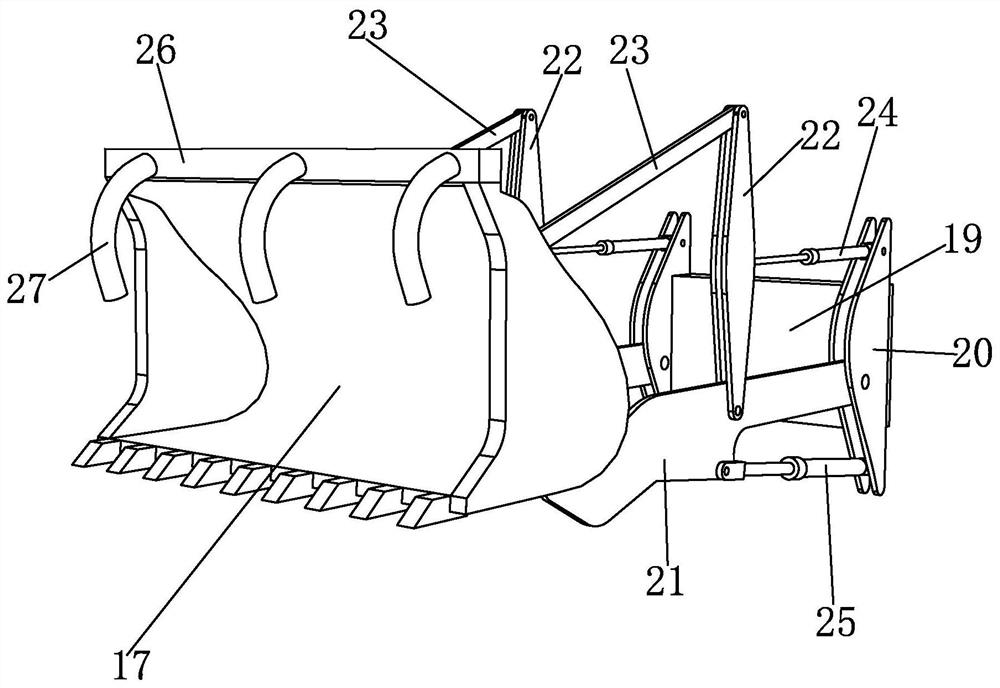

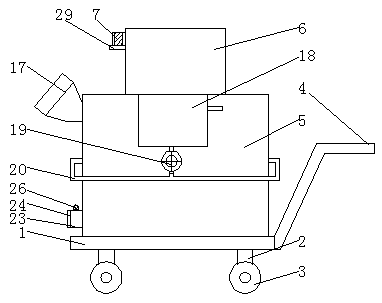

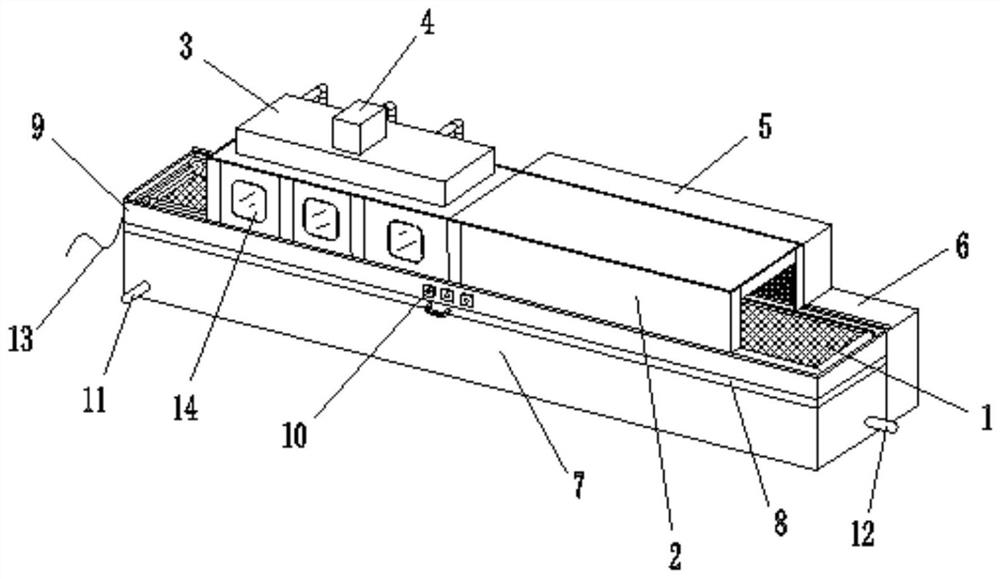

Trawl type garbage cleaning ship

PendingCN111152895AImprove cleaning efficiencyReduce the hassle of manual operationWater cleaningWaterborne vesselsHull structureRefuse collection

The invention provides a trawl type garbage cleaning ship, and belongs to the technical field of garbage cleaning ships. The ship comprises a ship body structure, a first conveying belt and a collecting mechanism. A notch is formed in the tail part of the ship body structure; a collecting cabin is arranged in the ship body structure; an opening is formed in the deck surface of the ship body structure; the opening is communicated with the collecting cabin; the first conveying belt is obliquely arranged in the notch; the right end of the first conveying belt obliquely extends upwards out of thedeck surface of the ship body structure, and the end part is positioned above the opening; the left end of the first conveying belt obliquely extends out of the tail of the ship body structure downwards, a push plate is perpendicularly arranged on the belt face of the first conveying belt, the collecting mechanism is arranged at the tail of the ship body structure, and the collecting mechanism cancollect garbage on the water surface around the ship body structure to the first conveying belt. The cleaning area of garbage on the water surface can be increased, and the garbage cleaning efficiency is improved.

Owner:ZHEJIANG OCEAN UNIV

Novel submersible aerator

PendingCN108849710AAvoid enteringReduces the possibility of access to the inside of the pressure cylinderPisciculture and aquariaEngineering

Owner:HUZHOU GAOYUANJIN MACHINERY

High-efficient dust removal device

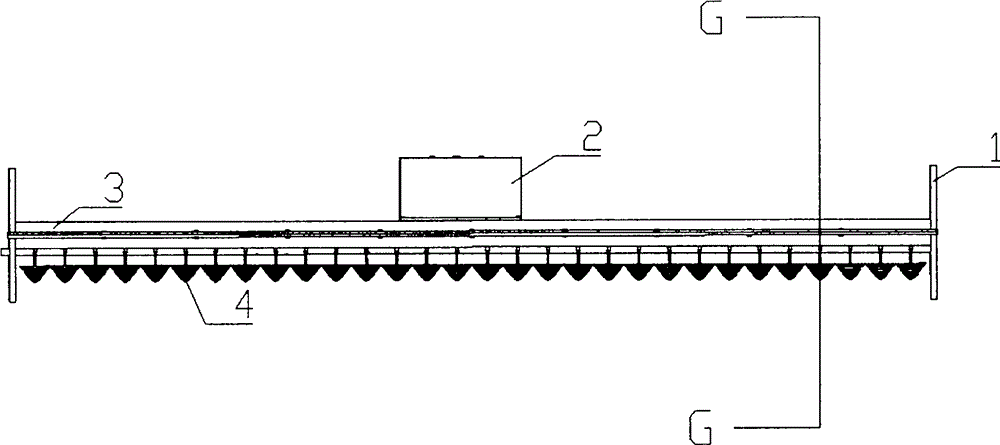

InactiveCN107486427AAvoid wastingComprehensive cleaningDrying gas arrangementsPhotovoltaicsEngineeringWater pipe

The invention discloses a high-efficient dust removal device. The dust removal device comprises a photovoltaic panel; a spray head support is connected with a first edge of the photovoltaic panel, a water pipe is arranged on the spray head support, and uniformly-distributed spray heads are arranged on the lower part of the water pipe; a water collecting groove is connected behind the spray head support, one end of the water collecting groove is connected with a water pump, the water pump is connected with a rotating shaft through a hose, and the rotating shaft is connected with a first motor; the water collecting groove and the water pump are connected with a support; a first slide rail is arranged beside the side part of a second edge of the photovoltaic panel, and the first slide rail is in sliding connection with the spray head support; and the spray head support is further connected with an air cylinder. According to the dust removal device, the photovoltaic panel can be washed and dried, and most of cleaning water adopts rainwater stored in rainy days so that resources can be saved; and rust-proof coatings coat the positions of the spray head and the spray head support so that corrosion affects cleaning effect can be effectively avoided, and therefore the service life of cleaning equipment can be prolonged.

Owner:浦江县顺光科技有限公司

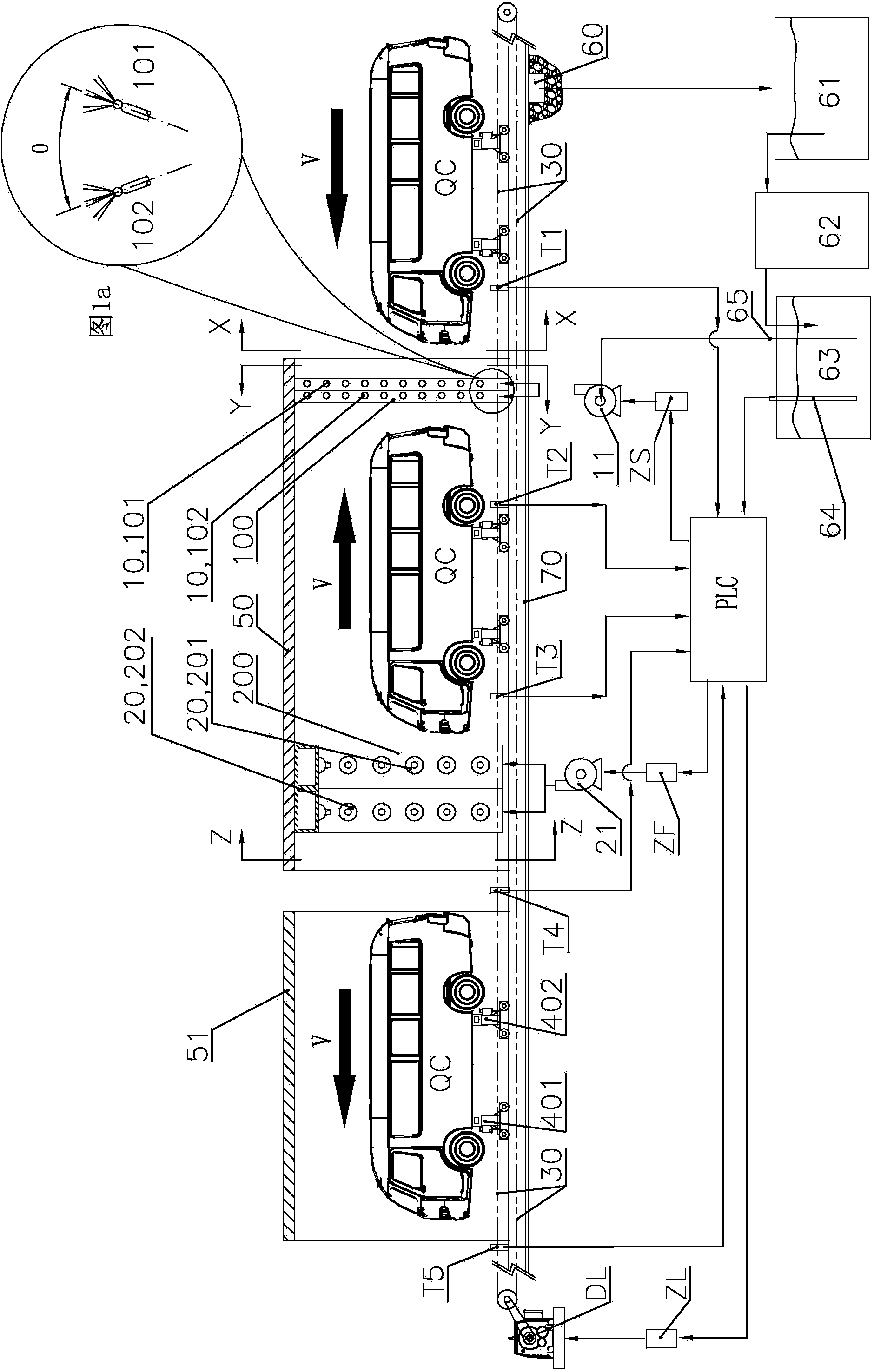

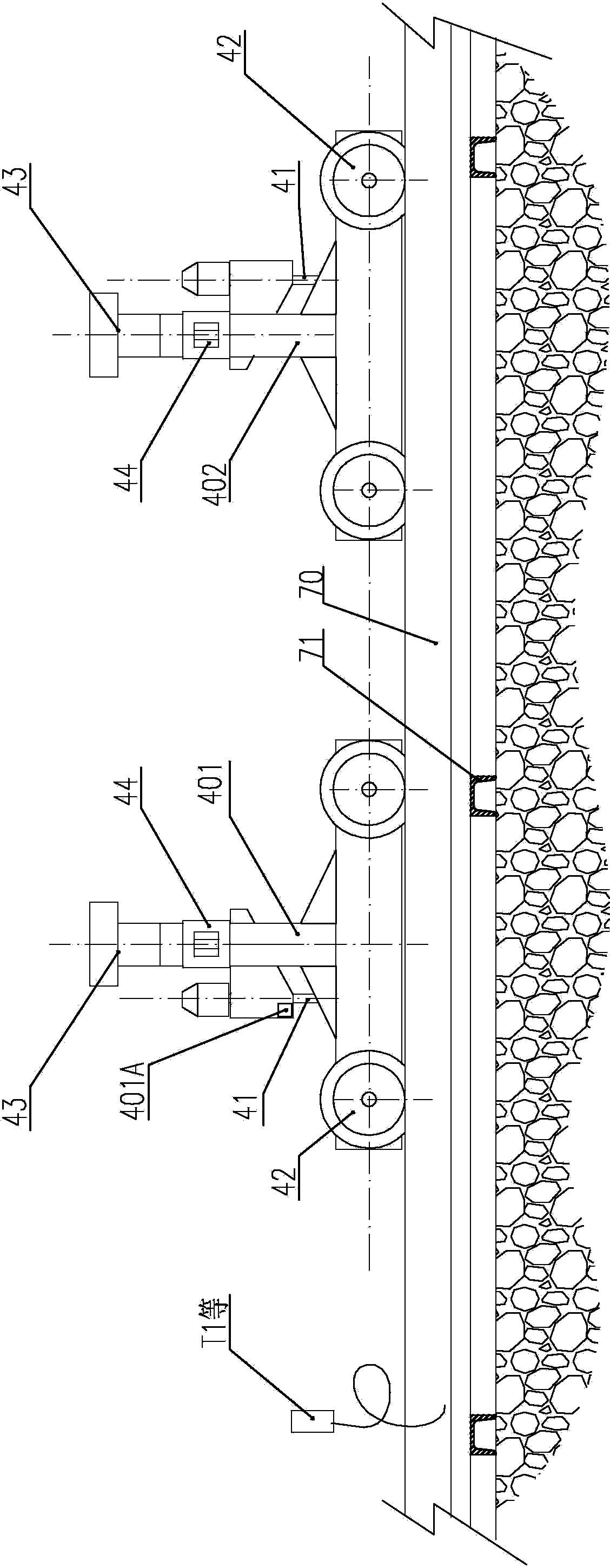

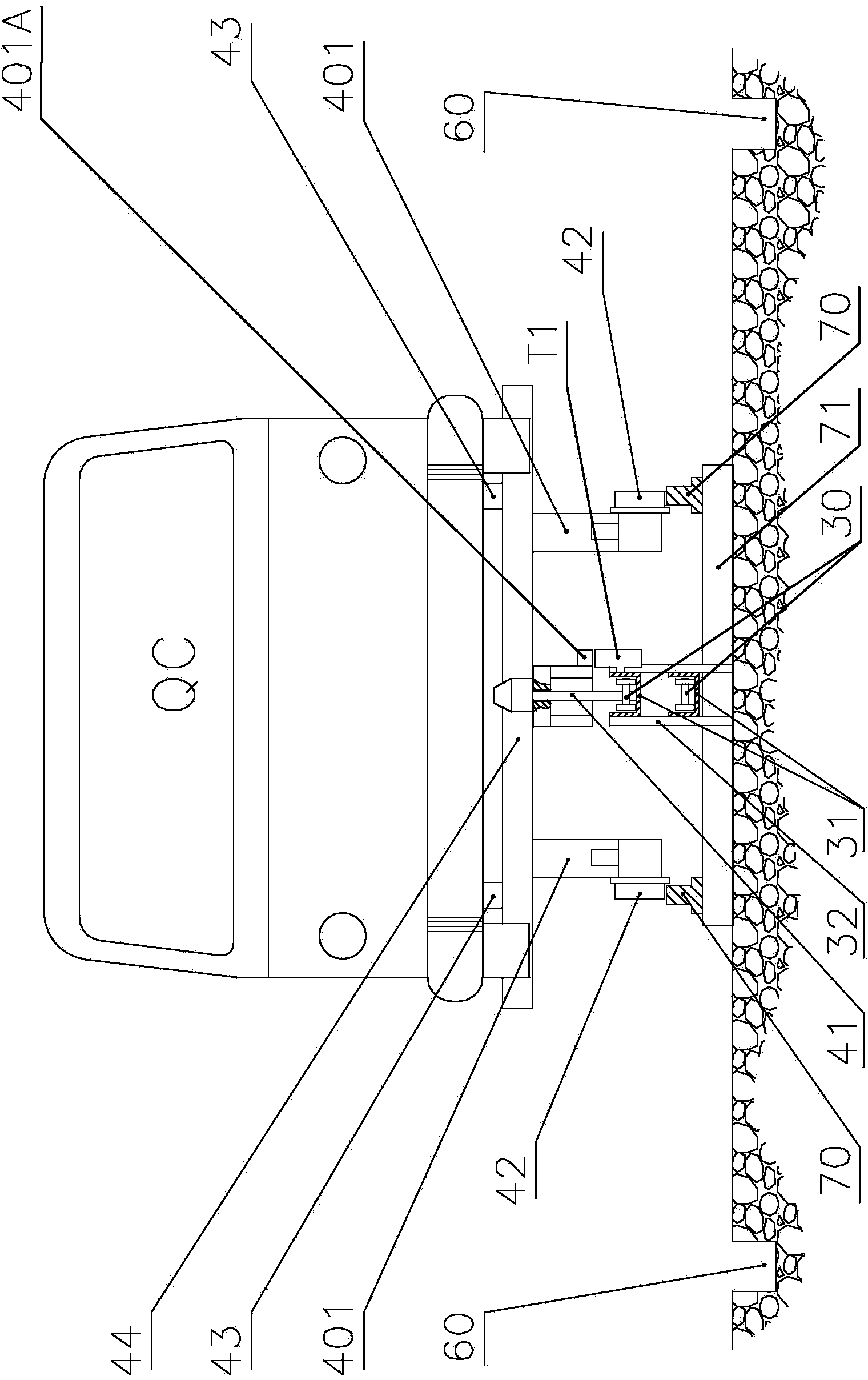

Automatic cleaning method and automatic cleaning device of scraped car

ActiveCN104029659AGuaranteed cleaning efficiencyReduce cleaning efficiencyCleaning apparatus for vehicle exteriorsWash waterBackup

The invention relates to an automatic cleaning method and automatic cleaning device of a scraped car. The method comprises the steps that a front sensor T1 and a rear sensor T2 are arranged in front of and behind a wash water spray head respectively to monitor a passing car body, a processor is adopted to receive the signals of the sensors and outputting instructions after processing to control the operation of wash water, a rail carrier dragged by a ground chain mechanism is adopted to transfer the washed scraped car in the automatic cleaning method, and the processor is adopted to monitor the traction direction of a ground chain and add up the number of backups of the carrier between the sensor T1 and the sensor T2; the rear end signals of the carrier are responded to, whether the number of backups of the ground chain exceeds a set number S1 or not is verified by the processor, the carrier is dragged to move backwards if the number of backups is smaller than or equal to S1, and if the number of backups is larger than S1, the ground chain is controlled to continue to drag the carrier to move forwards, and the wash water is closed. The cleaning work efficiency of the scraped car can be guaranteed on the premise of reducing or saving the occupied area of the automatic cleaning device and facilitating wash water recycling, and implementation is easy.

Owner:WUHAN GEM URBAN MINE EQUIP +3

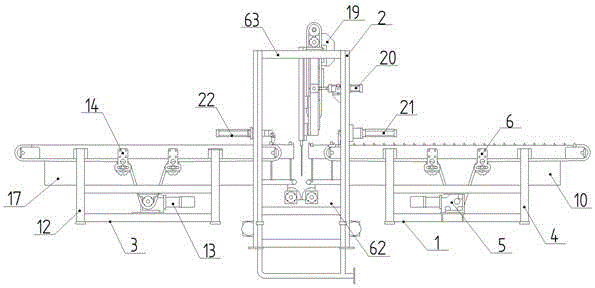

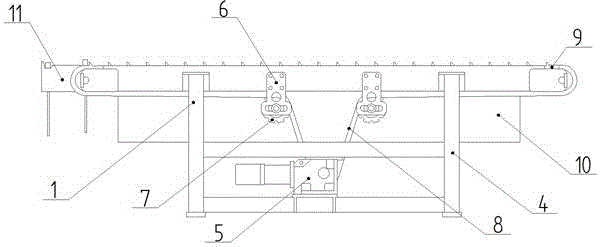

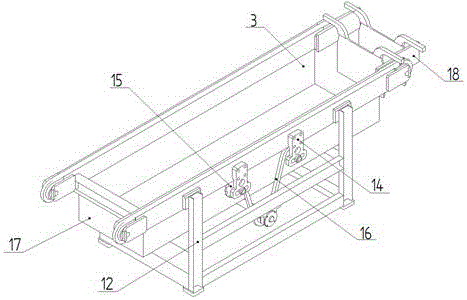

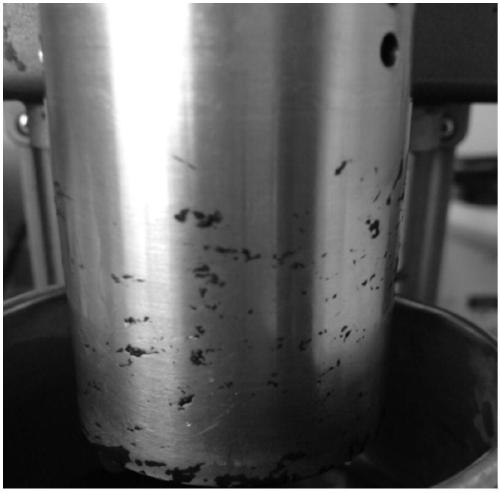

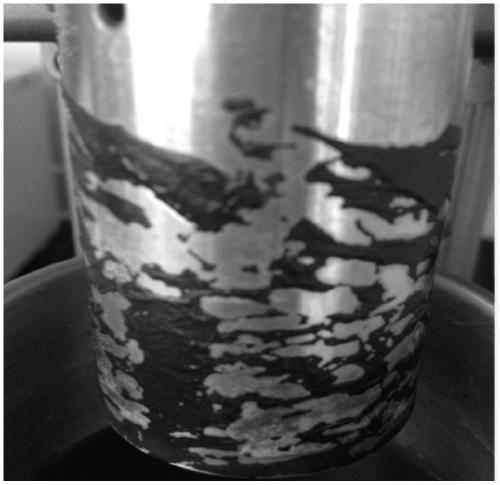

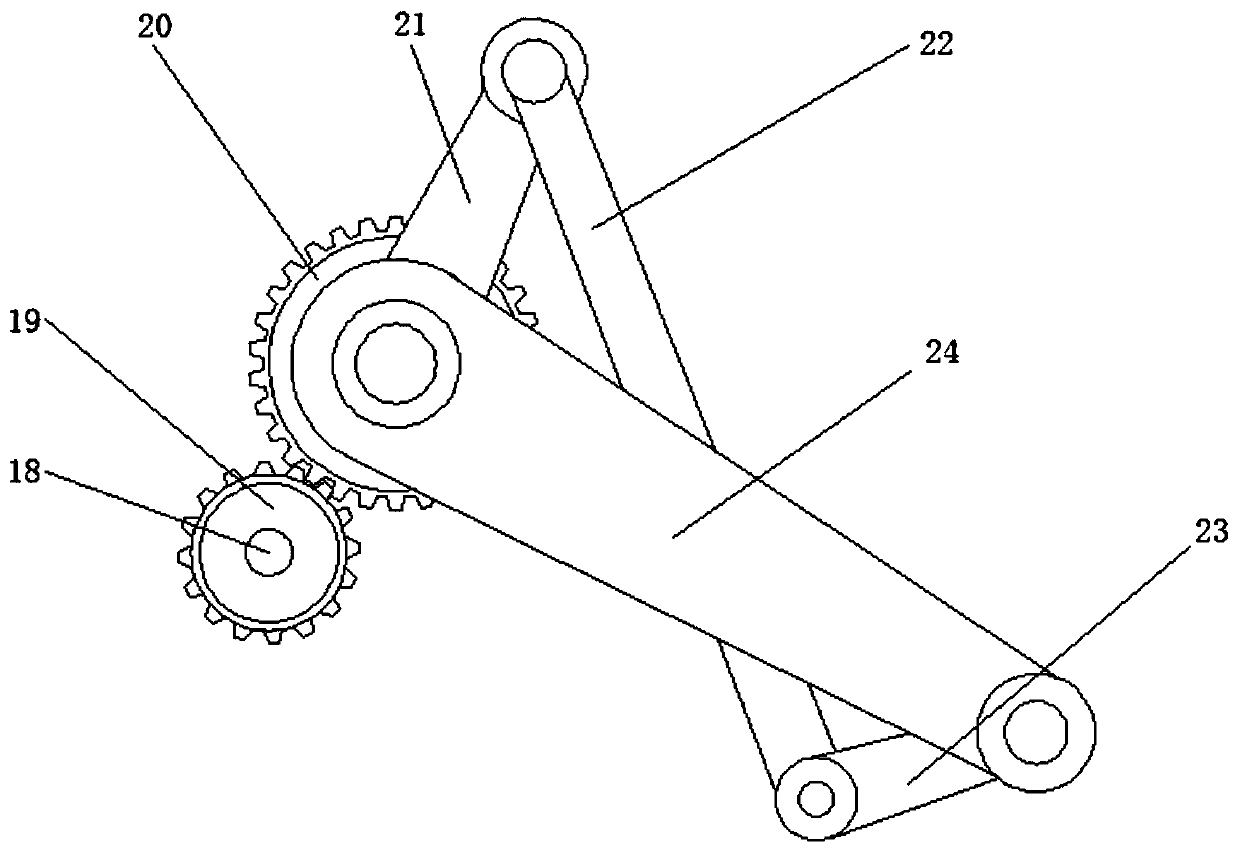

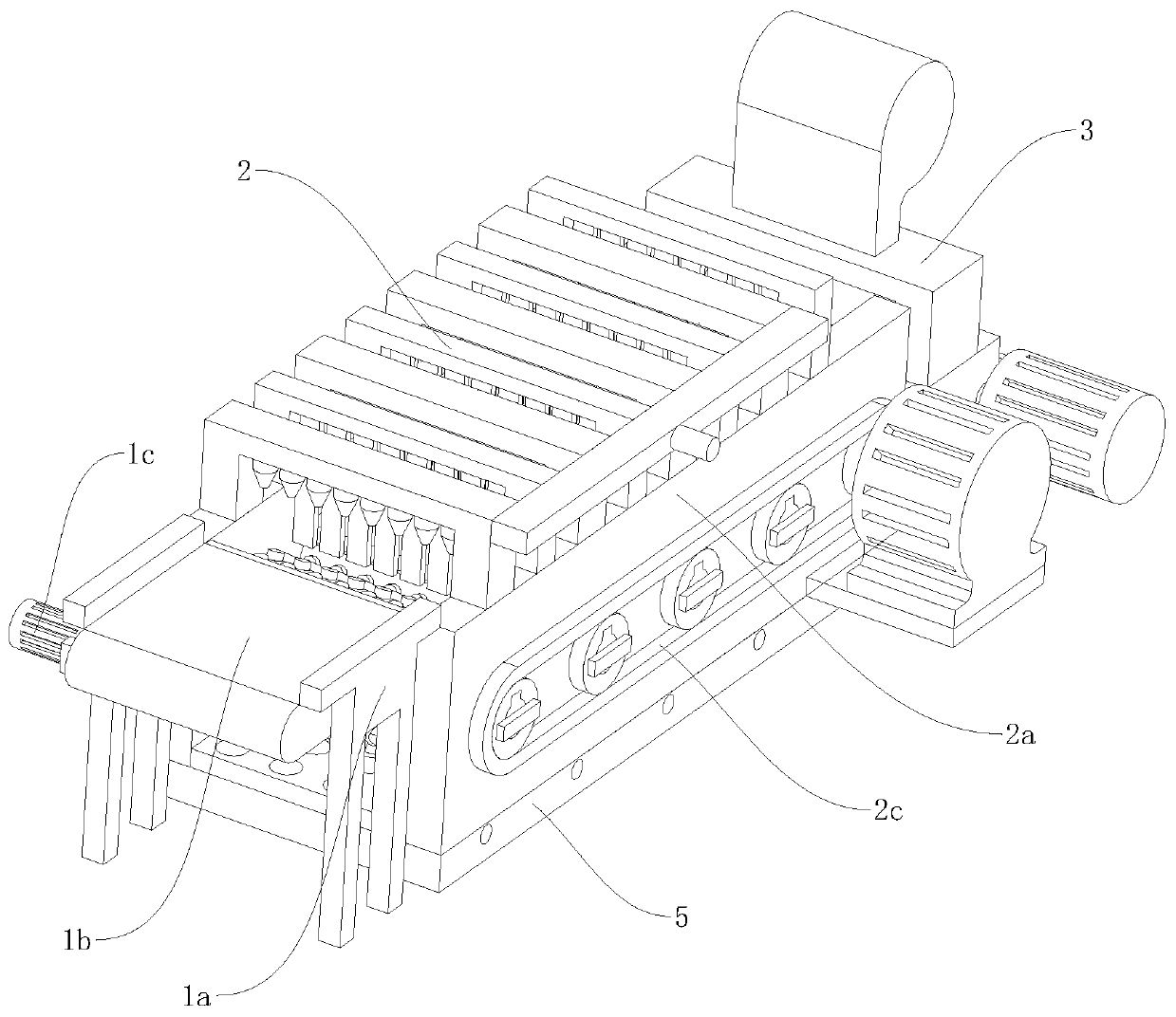

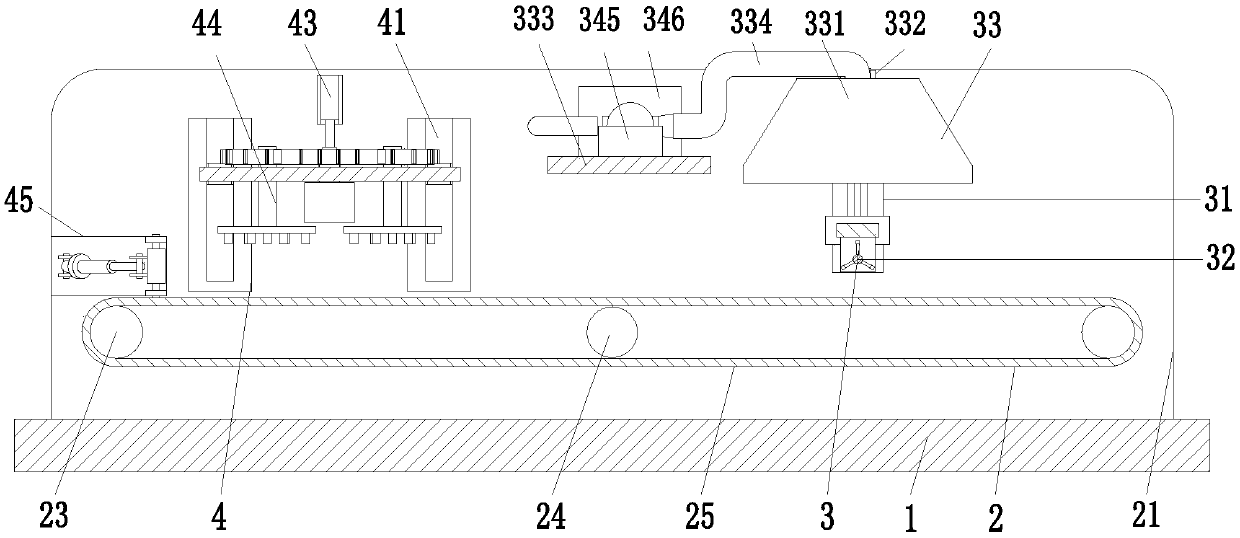

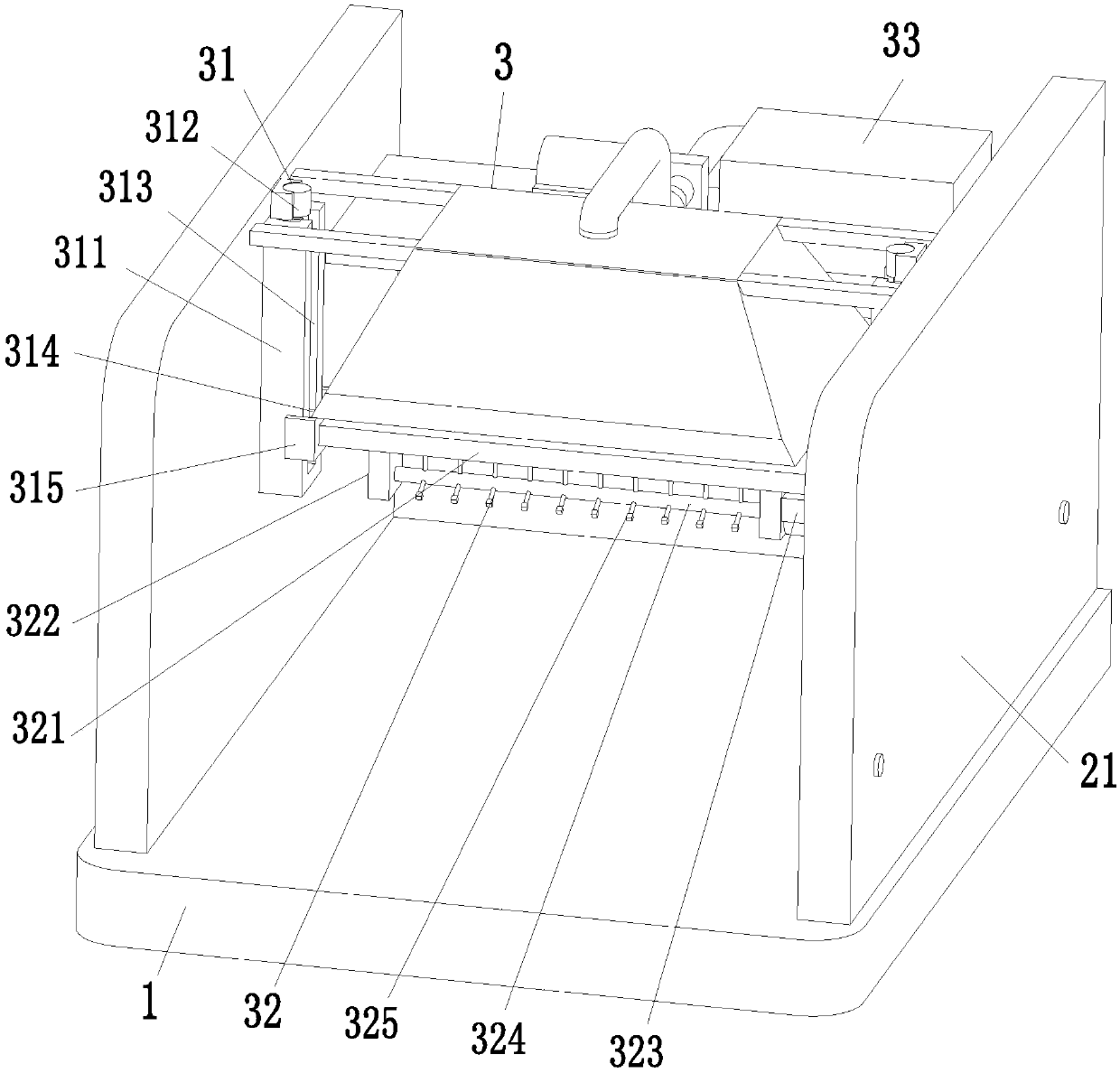

Silver residue washing machine

ActiveCN106563656AReduce labor intensityReduce cleaning efficiencyCleaning using toolsCleaning using liquidsWastewaterPulp and paper industry

The invention relates to a silver residue washing machine and belongs to the technical field of smelting equipment. The silver residue washing machine comprises a receiving plate device, a washing device and a discharging and conveying device, wherein the receiving plate device and the discharging and conveying device are installed on the two sides of the washing device correspondingly. The receiving plate device comprises a receiving plate machine underframe, a receiving plate motor, a tensioning installation plate I, a head chain wheel I, a receiving plate chain, a waste liquid collection tank and a transitional plate I. The discharging and conveying device comprises a discharging machine underframe, a discharging motor, a tensioning installation plate II, a head chain wheel II, a discharging chain, a waste water collection tank and a transitional plate II. The washing device comprises a feeding assembly, a middle swinging assembly, a push plate assembly, a hook plate assembly and a washing roll assembly. The silver residue washing machine can relieve the labor intensity of workers, reduce pollution to the environment and reduce harm of electrolyte to human bodies, workers do not need to participate in the washing process, automatic washing is achieved, the washing cost is reduced, the cleaning efficiency is improved, and earnings of factories are increased. The washing machine is simple in structure and convenient to install and maintain.

Owner:KUNMING UNIV OF SCI & TECH

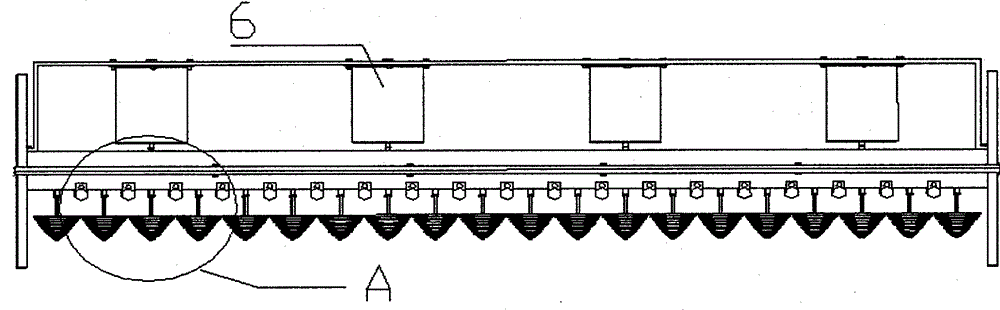

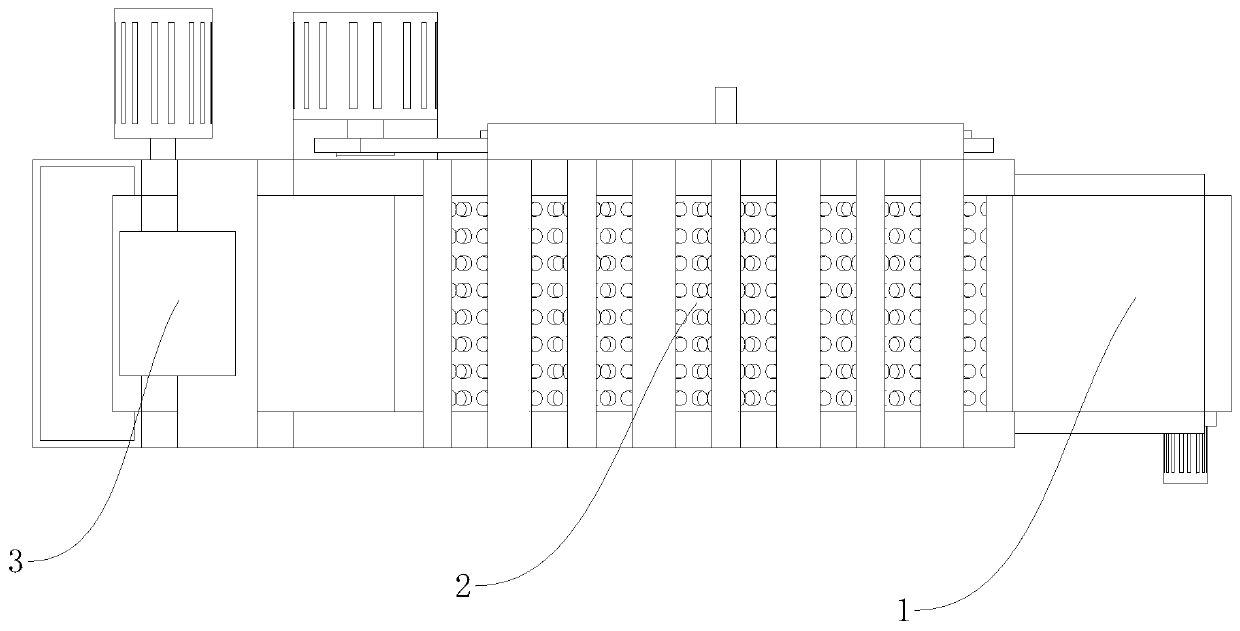

Rotary cleaning equipment for floating seedling trays

InactiveCN103817114ASolve cleaning problemsAchieve multiple usesCleaning using toolsCleaning using liquidsWater resourcesEngineering

The invention discloses rotary cleaning equipment for floating seedling trays. The rotary cleaning equipment comprises conical cleaning brushes and spraying pipes. A driving device comprises lifting rods and motors. A transmission device comprises gear shafts, cleaning brush shafts, bearings and the like. A box comprises an upper box cover, a lower box cover, bolts, a motor fixing plate and the like. The rotary cleaning equipment is characterized in that each seedling hole is equipped with one inverted conical soft nylon plastic brush, the size of each brush is slightly smaller than the size of the seedling holes, and the diameter of each cleaning brush is slightly larger than the length of a diagonal line of each square seedling hole, and the height of each cleaning brush is slightly larger than the height of the seedling holes. The cleaning brushes rotate on the inner walls of the seedling holes, so that stains can be removed, and can be cleaned by cleaning solution sprayed by the spraying pipes. The rotary cleaning equipment is novel and reasonable in design, simple to manufacture and easy to operate. Automatic rotary cleaning can be realized in the whole process. Besides, the rotary cleaning equipment is capable of thoroughly cleaning, safe, reliable and high in work efficiency, and water resources are saved.

Owner:SOUTHWEST UNIV

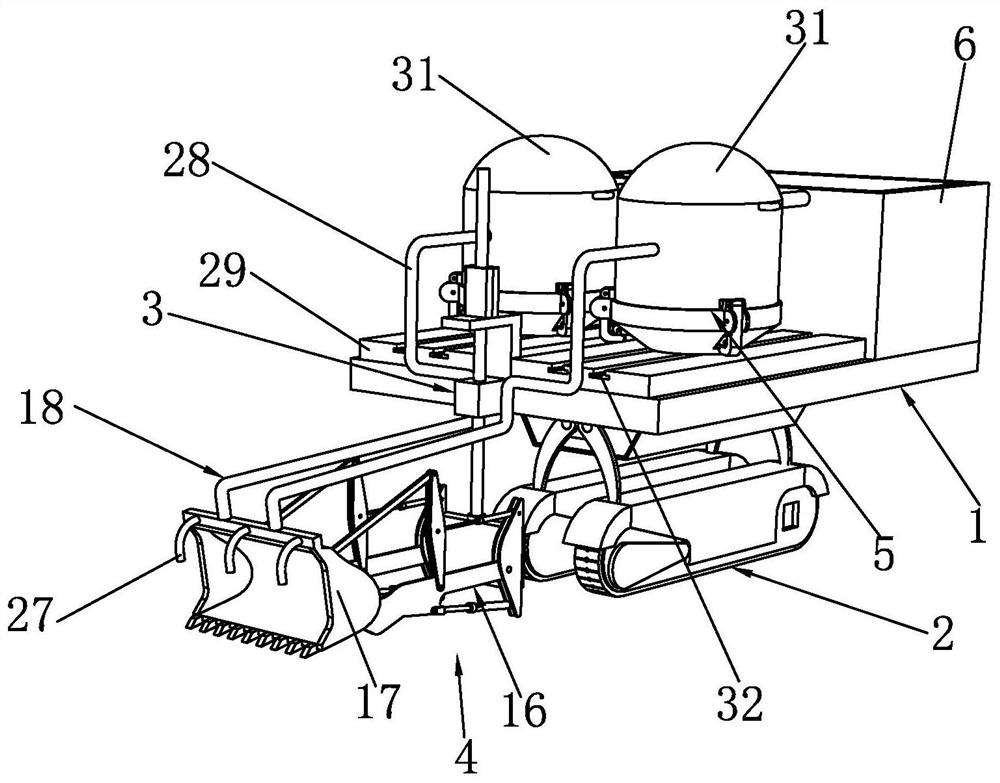

Plain river bottom silt clearing device and clearing method thereof

PendingCN112726716AEnsure balanceEasy to dredgeMechanical machines/dredgersRiver routingEnvironmental engineering

The invention discloses a plain river bottom silt clearing device and a clearing method thereof. The plain river bottom silt clearing device comprises a boat, wherein a driving device is arranged at the bottom of the boat, a lifting assembly is arranged at the front side of the boat, a clearing assembly is slidingly connected with the side, away from the boat, of the lifting assembly, a storage device is arranged at the front side of the top surface of the boat, a balance weight water tank is arranged at the rear side of the top surface of the boat, the storage device communicates with the balance weight water tank, and the clearing assembly communicates with the storage device. The method comprises the following steps: (1) conducting preparation before desilting; (2) stacking silt centralizedly; (3) conducting desilting; (4) storing the silt; and (5) conducting desilting on residual desilting points. According to the plain river bottom silt clearing device and the clearing method thereof, through the clearing assembly, river bottom silt at different depths can be cleared, the clearing assembly is used for clearing the silt at the river bottoms, meanwhile, the silt at the river bottoms is transported into the storage device, the silt placed in the storage device naturally sinks, and river water located above the storage device is transported into the balance weight water tank at the rear end of the boat, so that balance of the boat is guaranteed.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Insulator contamination special cleaner

ActiveCN102279122AReduce drop inEasy constructionPreparing sample for investigationCleaning using liquidsCleansers skinEngineering

The invention relates to a special cleanser for the dirt of an insulator. The special cleanser provided by the invention is characterized by comprising a bracket, an insulator adjusting bolt, a pulley, a collection disk and a crank, wherein the collection disk is arranged at the bottom of the bracket; the insulator adjusting bolt is fixed in an opening at the top of the bracket; the pulley is installed on the insulator adjusting bolt; and the crank is connected with the pulley. The device provided by the invention does not need to be fixed by being supported with hands, decreases the falling enhancement of metal dirt and reduces the enhancement of a half of existing additional pollutants. Personnel can be adjusted to optimization in the place needing to be cleaned, and the cleanser provided by the invention realizes labor saving and time saving, reduces low cleaning efficiency caused by overlong operating time, ensures that operating personnel are easy to grasp construction and realizes simple and clean operation sampling. Compared with a traditional cleaning tool, the cleanser provided by the invention greatly reduces the chance of existing dirt and pollution operating personnel,simultaneously reduces the labor intensity of the operating personnel and ensures the quality of sampling.

Owner:STATE GRID CORP OF CHINA

Mining filter element cleaning process

InactiveCN109675372AReduce labor intensityReduce cleaning efficiencyCleaning using liquidsFilter regenerationThermal shrinkageMegasonic cleaning

The invention discloses a mining filter element cleaning process and provides a clean and efficient filter element cleaning process. The invention adopts the following technical scheme: the mining filter element cleaning process comprises the following steps: 1, removing oil: adopting warm water at the temperature of 35 to 55 DEG C in an oil-removing cleaning tank, adding an oil-removing agent andperforming soaking oil removal; 2, cleaning for the first time: cleaning a mining filter element soaked in the step 1 with clean water in the cleaning tank; 3, performing ultrasonic cleaning: puttingthe mining filter element which is completely washed in the step 2 into an ultrasonic cleaning machine and cleaning; 4, cleaning for the second time: putting the mining filter element which is cleaned in the step 3 into the cleaning tank and soaking and cleaning; 5, descaling: putting the filter element which is soaked and cleaned into a rust-removing scale cleaning tank and soaking; 6, cleaningfor the third time: putting the mining filter element which is soaked in the step 5 into the cleaning tank and completely washing with clean water; 7, performing high-pressure backwashing; 8, performing filter element experiment, if qualified, entering a step 9 to perform packaging, and if unqualified, returning to the step 1 to clean again; 9, drying; and 10, performing thermal shrinkage packaging.

Owner:ZAOZHUANG WENXING MINING IND EQUIP FACTORY

Domestic sewage discharging and filtering system

ActiveCN111467864AReduce cleaning efficiencyReduce the efficiency of exclusionStationary filtering element filtersFilter systemMechanical engineering

The invention relates to a domestic sewage discharging and filtering system which comprises a connecting pipe, a cleaning pipe, a removing device, a cleaning device and a driving device, wherein the cleaning pipe is installed at the right end of the connecting pipe, the removing device is installed in the cleaning pipe, the cleaning device is arranged on the right side of the removing device, andthe cleaning device is installed on the inner wall of the cleaning pipe. According to the system, the problems that when existing equipment is used for filtering garbage in domestic sewage, garbage inthe sewage cannot be cleaned in a multi-stage filtering manner, garbage with different volumes cannot be cleaned respectively, the phenomenon that the garbage is incompletely cleaned easily occurs, so that the garbage cleaning effect is reduced, meanwhile, the garbage cannot be blocked in the garbage cleaning process, the phenomenon that the garbage falls easily occurs in the cleaning process, the garbage cleaning efficiency is reduced, the phenomenon that a pipeline is blocked easily occurs, and the sewage discharging efficiency is reduced are solved.

Owner:浙江湾北建设有限公司

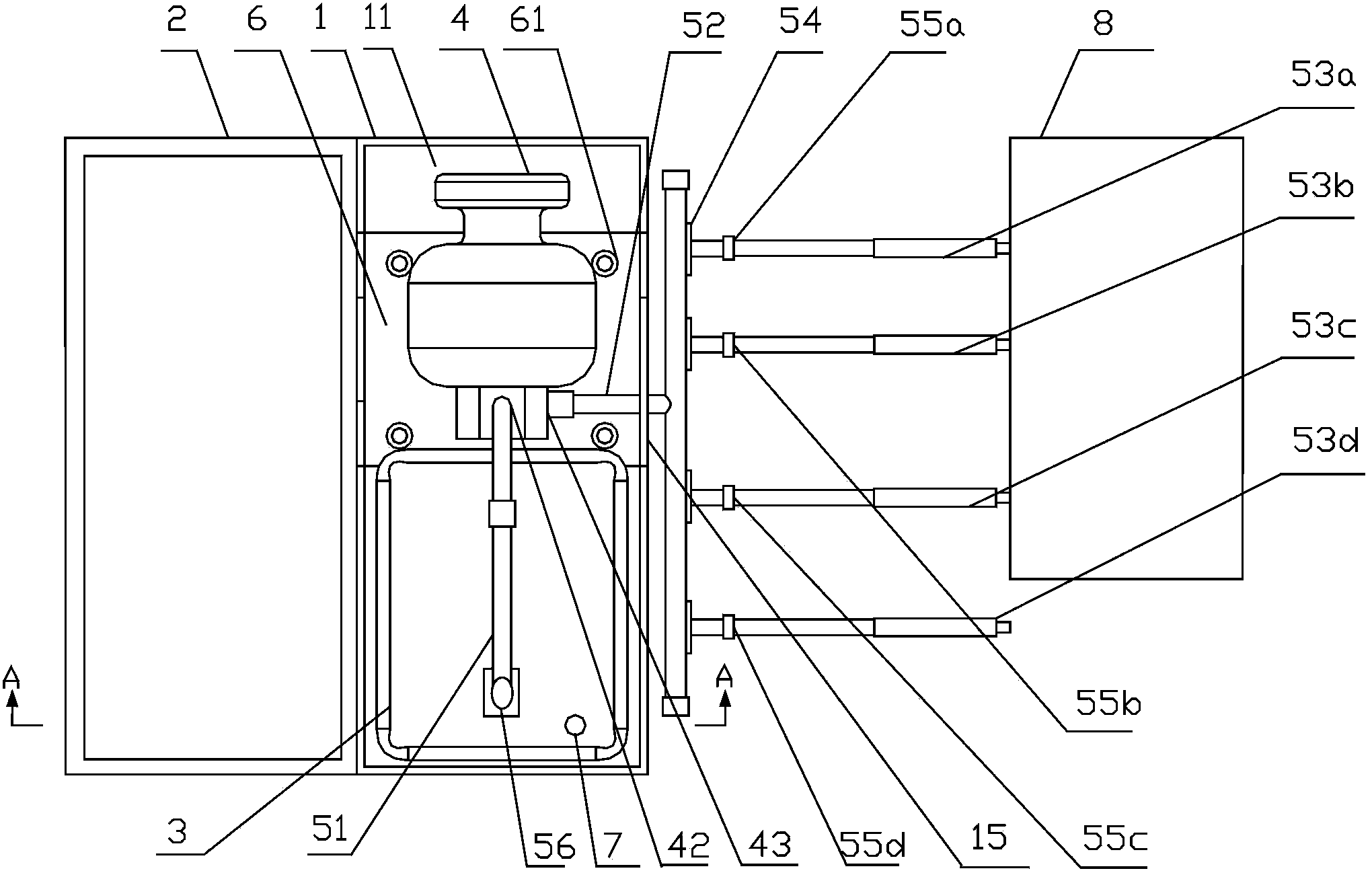

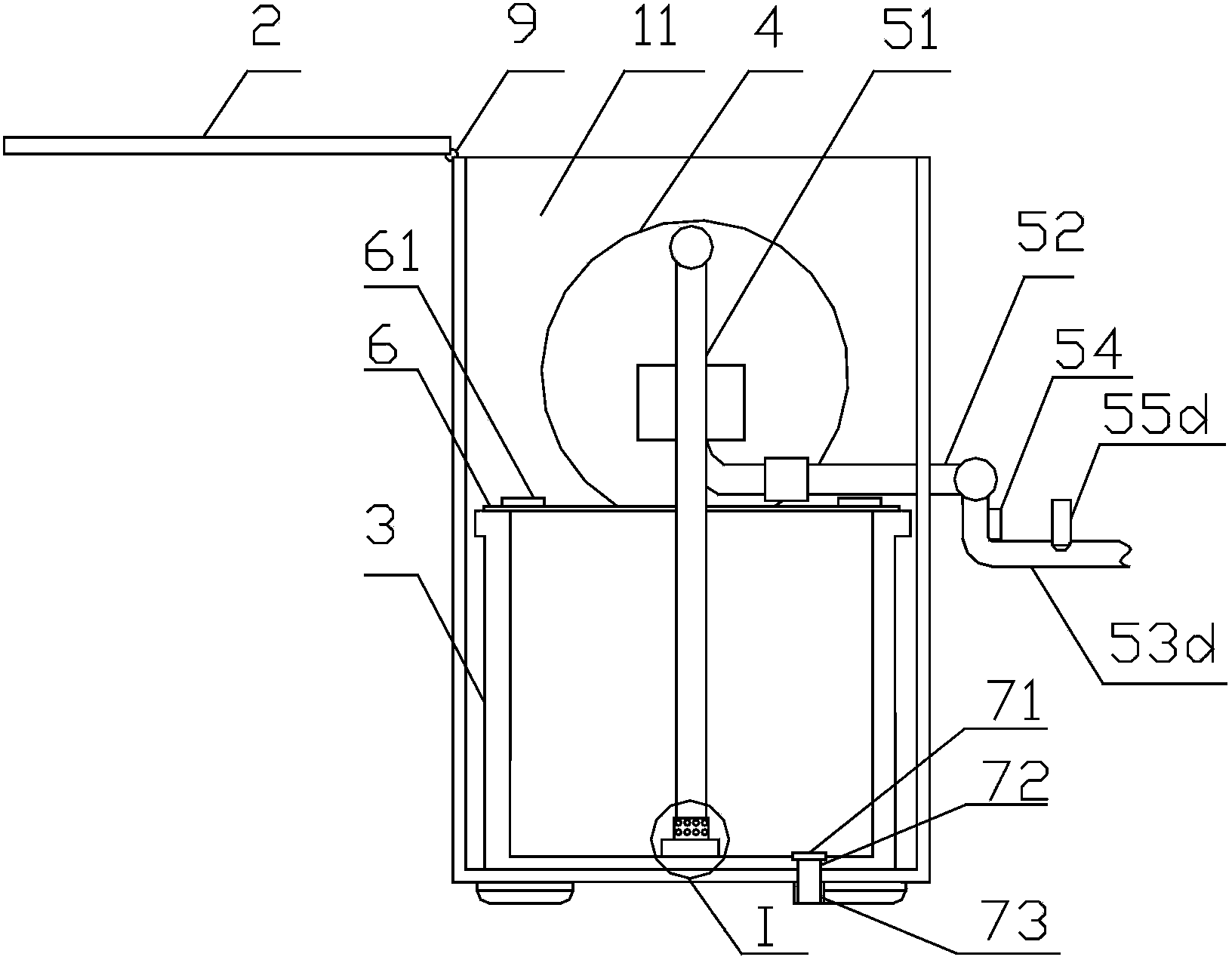

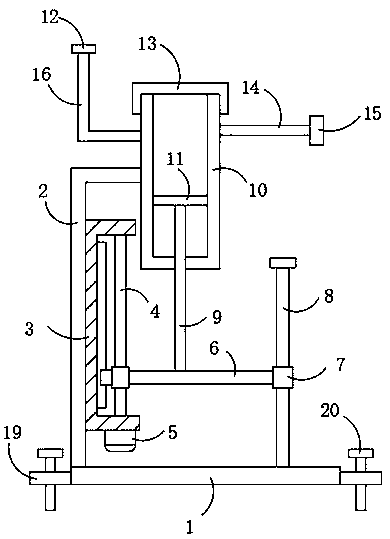

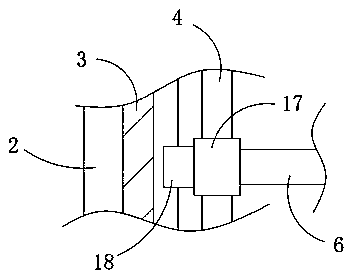

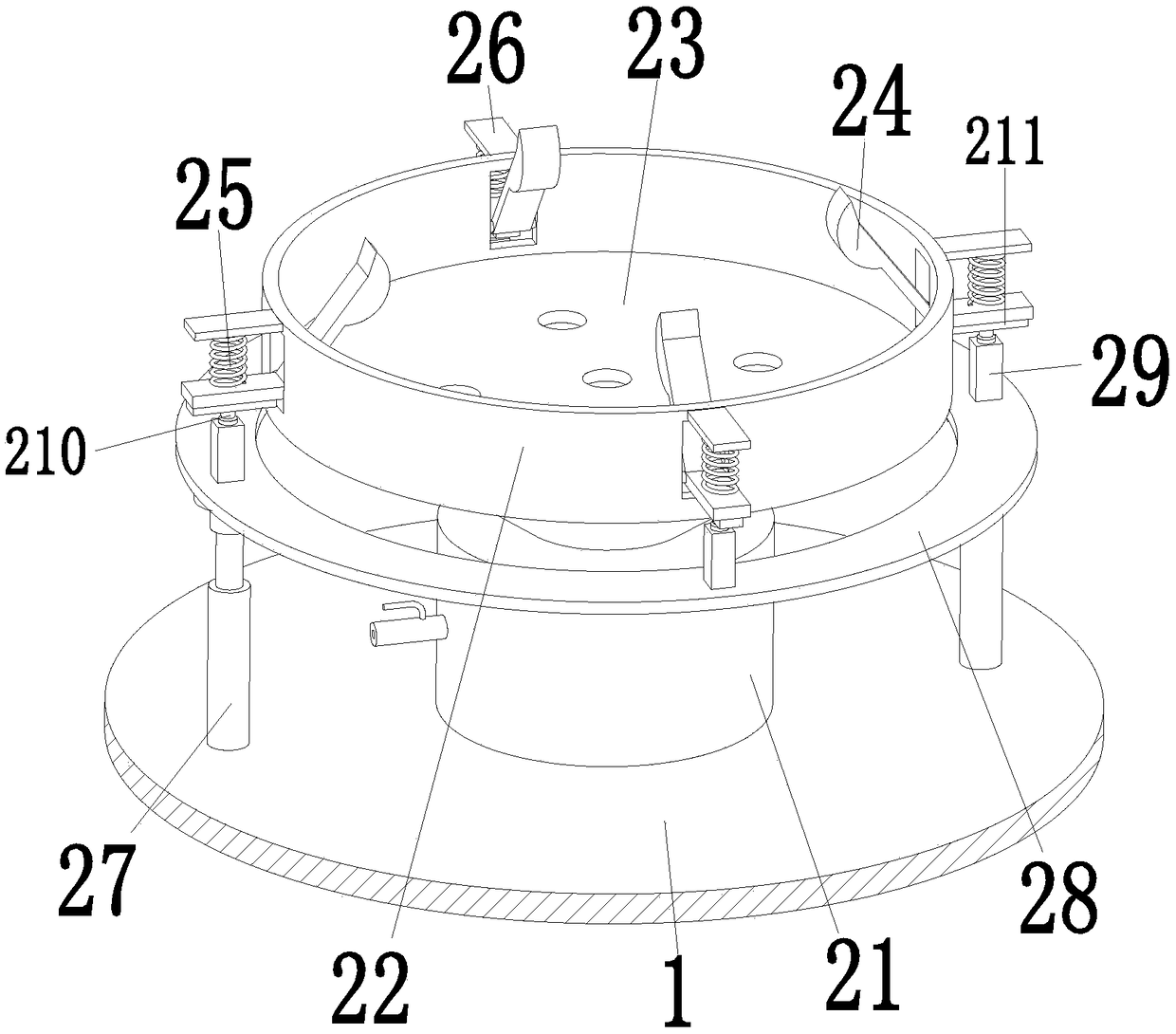

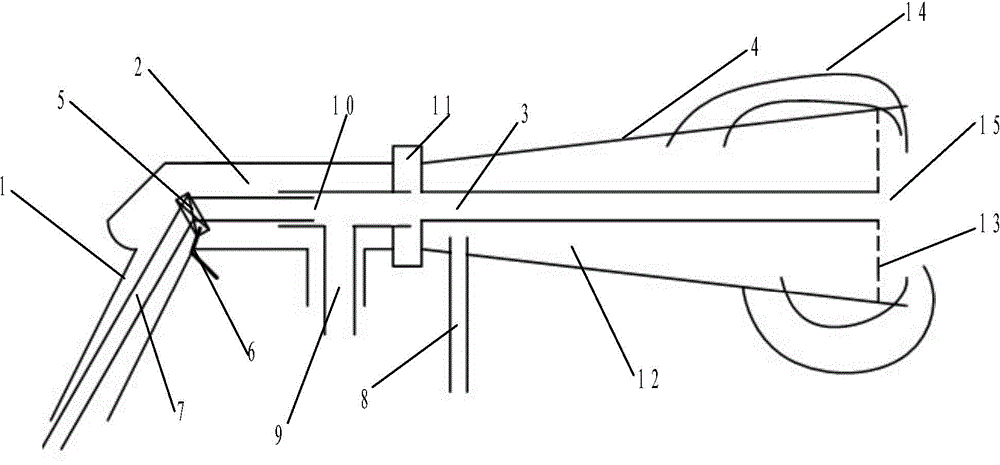

Intelligent treating robot for electrolyte on surface of lithium battery

ActiveCN109092769AReduce labor intensityImprove efficiencyDrying solid materials without heatCleaning using liquidsRecovery positionElectrolyte

The invention relates to an intelligent treating robot for an electrolyte on the surface of a lithium battery. The intelligent treating robot comprises a bottom plate; a recovery positioning device ismounted in the middle of the bottom plate; a fixing working frame is mounted on the bottom plate; a fixing adjusting device is mounted on the inner wall of the upper end of the fixing working frame and located over the recovery positioning device; an annular electric sliding block is mounted on the bottom plate, and a clearing device is mounted on the annular electric sliding block; the recoverypositioning device comprises a recovery box mounted on the bottom plate; a recovery working frame is mounted at the upper end of the recovery box; a positioning supporting plate is mounted on the inner wall of the recovery working frame; and recovery positioning grooves are evenly formed in the recovery working frame in the circumferential direction of the recovery working frame, and recovery positioning claws are mounted in the recovery positioning grooves through pin shafts. The function of automatic intelligent clearing of the electrolyte on the surface of the lithium battery can be achieved, manual operation is not needed, the moisture in the clearing process can be effectively controlled, the labor intensity of a worker is lowered, and the working efficiency is improved.

Owner:领航国创新能源电池技术研究院(北京)有限公司

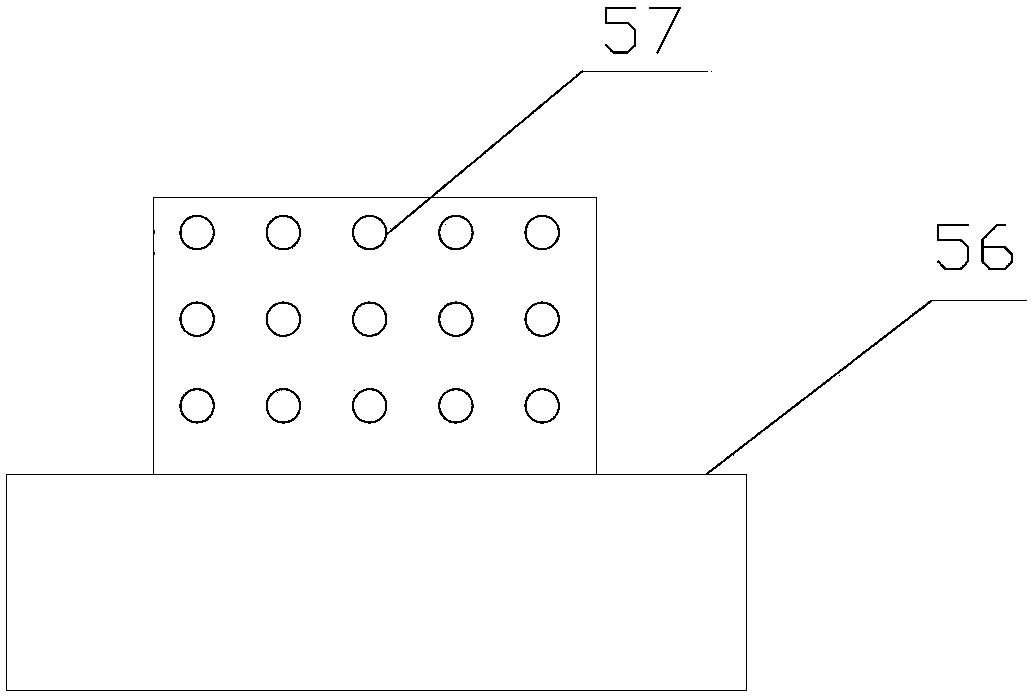

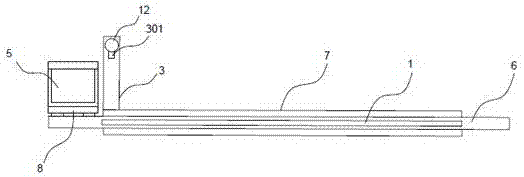

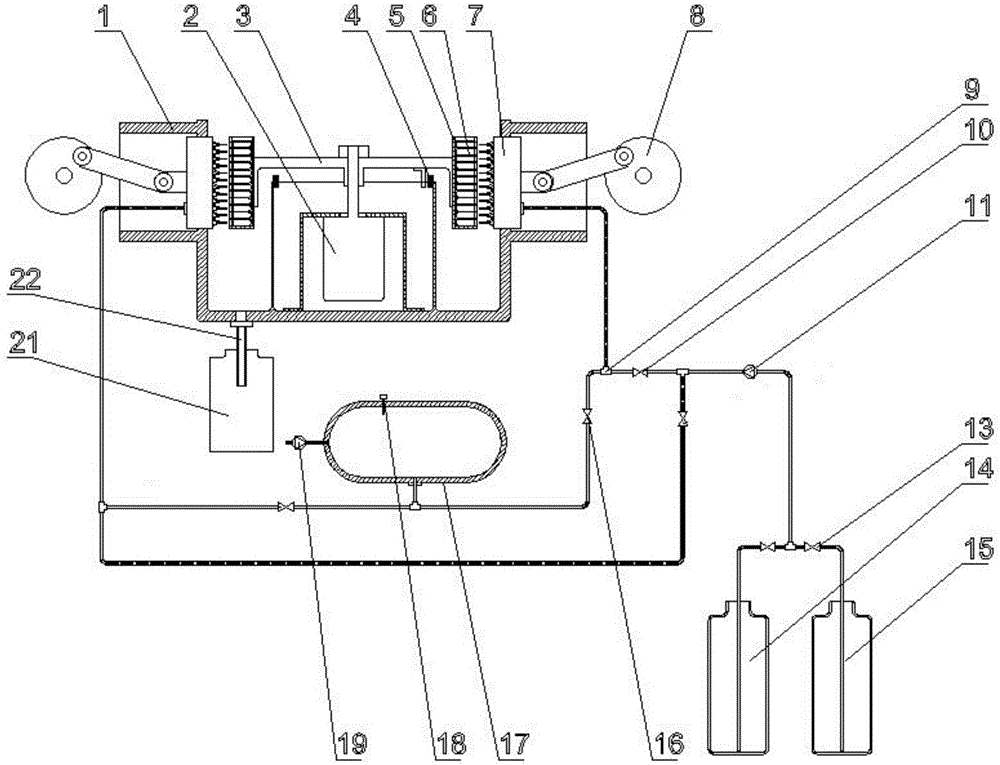

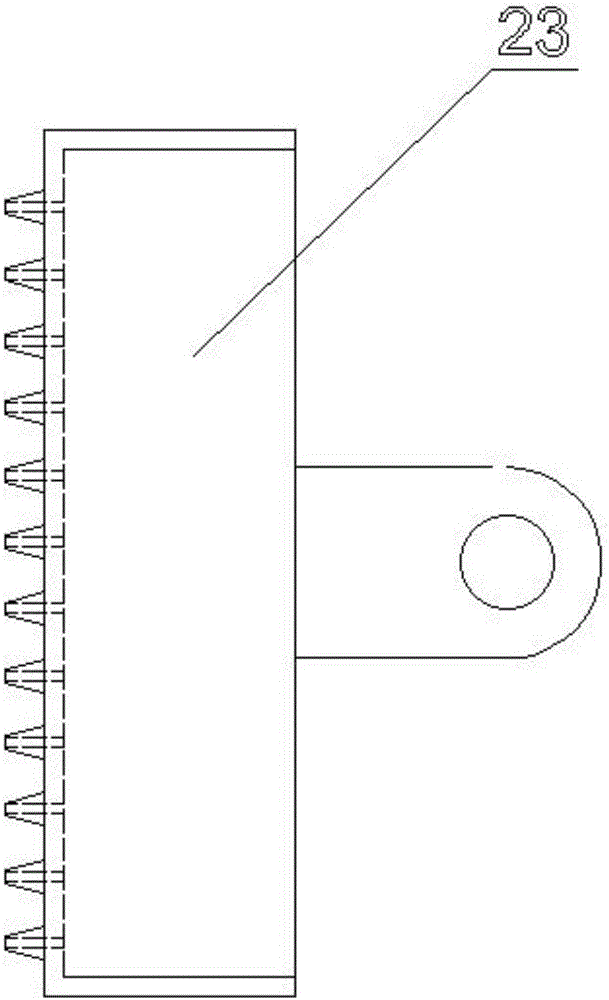

Rapid vertical type plate cleaning machine for microporous reaction plates

InactiveCN106733933AImprove cleaning efficiencyShorten the timeDrying solid materials without heatCleaning using gasesCleaning needleMicrowell Plate

The invention discloses a rapid vertical type plate cleaning machine for microporous reaction plates. The rapid vertical type plate cleaning machine comprises a cleaning barrel. A centrifugal motor is arranged in the cleaning barrel. A centrifugal disc is mounted on an output shaft of the centrifugal motor. Multiple microporous plate trays are uniformly arranged on the outer side wall of the centrifugal disc, wherein the microporous plate trays are used for storing the microporous reaction plates. Holes are machined in the microporous plate trays. The sizes, the number and the distances of the holes are the same as those of holes in the microporous reaction plates to be cleaned. Cleaning needle assemblies are arranged on the upper portion of the side wall of the cleaning barrel. Each cleaning needle assembly comprises a cleaning needle mounting plate and cleaning needles fixed to the corresponding cleaning mounting plate. The number and the distancea of the cleaning needles are the same as those of the holes in the microporous plate trays. The rear portions of the cleaning needle mounting plates are connected with a pipeline and connected with a liquid pump and a gas storage tank correspondingly through a T joint. The liquid pump is connected with a cleaning solution bottle and a pure water bottle through pipelines. The gas storage tank is connected with a pneumatic pump through a pipeline. By means of the rapid vertical type plate cleaning machine, cleaning time is remarkably shortened; work efficiency is improved; and work intensity is lowered.

Owner:TAIZHOU ZECEN BIOTECH CO LTD

Double-effect washing type spacer fluid for well cementation and preparation method of spacer fluid

InactiveCN109370550AImprove permeabilityExcellent emulsification and solubilizationDrilling compositionSuspending AgentsFatty alcohol

The invention belongs to the field of petroleum and gas well drilling and cementation technologies and oilfield chemical technologies and provides a double-effect washing type spacer fluid for well cementation and a preparation method of the spacer fluid. The spacer fluid is prepared from raw materials as follows: clear water, a washing agent, a suspending agent, a retarder, a weighting agent anda defoaming agent; the washing agent is prepared from raw materials as follows: water, sodium alcohol ether sulfate, octylphenol polyethylene-10, fatty alcohol polyethylene ether, alkyl glycoside anda cleaning aid. The double-effect washing type spacer fluid for well cementation has dual functions of washing and spacing, has efficient oil film cleaning capacity, can improve the interface cementing quality, realize high-quality cementing and sealing of annulus interfaces and guarantee stability of mud and has a function of avoiding contact pollution and thickening of oil-based mud and the spacer fluid. The preparation method of the double-effect washing type spacer fluid is scientific in design, simple to operate and suitable for industrial mass production.

Owner:成都欧美克石油科技股份有限公司

Washing device

ActiveCN104014502AEasy to operateDoes not change the molecular structureCleaning using liquidsUniversal jointHigh pressure

The invention discloses a washing device. The washing device comprises a gun body, a first high-temperature steam pipe, a valve device and an extraction liquid pipe, wherein the gun body comprises a stock and gun barrel segments communicated with the stock, the gun barrel segments include the first gun barrel segment, the second gun barrel segment and the third gun barrel segment, one end of the first gun barrel segment is communicated with one end of the stock, the other end of the first gun barrel segment is communicated with one end of the second gun barrel segment through a universal joint with a hollow cavity, the second gun barrel segment is sleeved with the third gun barrel segment, one end of the third gun barrel segment is connected with the universal joint, an annular space is formed by the end of the third gun barrel segment and the universal joint, and the other end of the third gun barrel segment extends to the front side of the other end of the second gun barrel segment to form a diffusion space; the first high-temperature steam pipe is arranged in the gun body, one end of the first high-temperature steam pipe is communicated with one end of the universal joint, and the other end of the first high-temperature steam pipe extends out of the other end of the stock to be communicated with a high-temperature high-pressure steam generation device; the valve device is arranged between the stock and the first gun barrel segment and used for connecting and disconnecting the first high-temperature steam pipe; the extraction liquid pipe enters the first gun barrel segment and is communicated with the first high-temperature steam pipe and the universal joint.

Owner:ZHEJIANG HELI HYDROGEN ENERGY TECH CO LTD

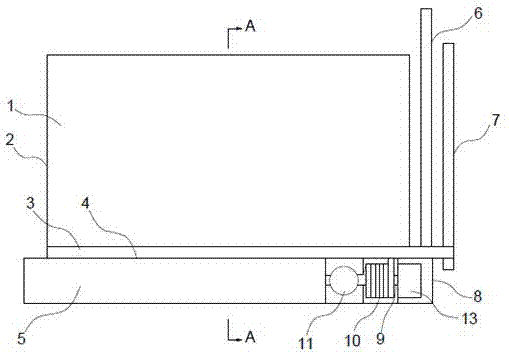

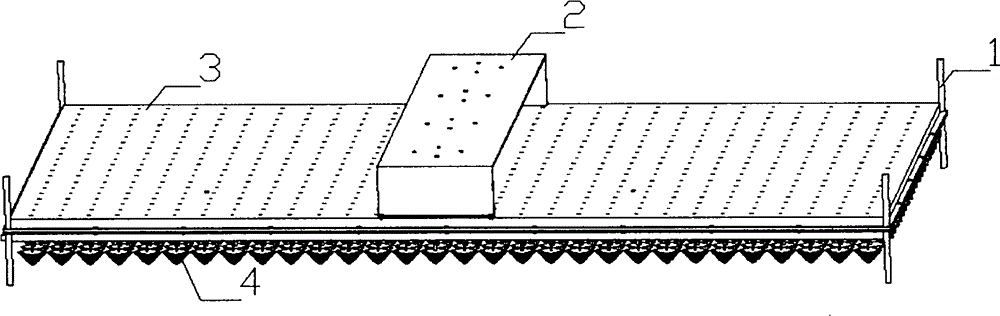

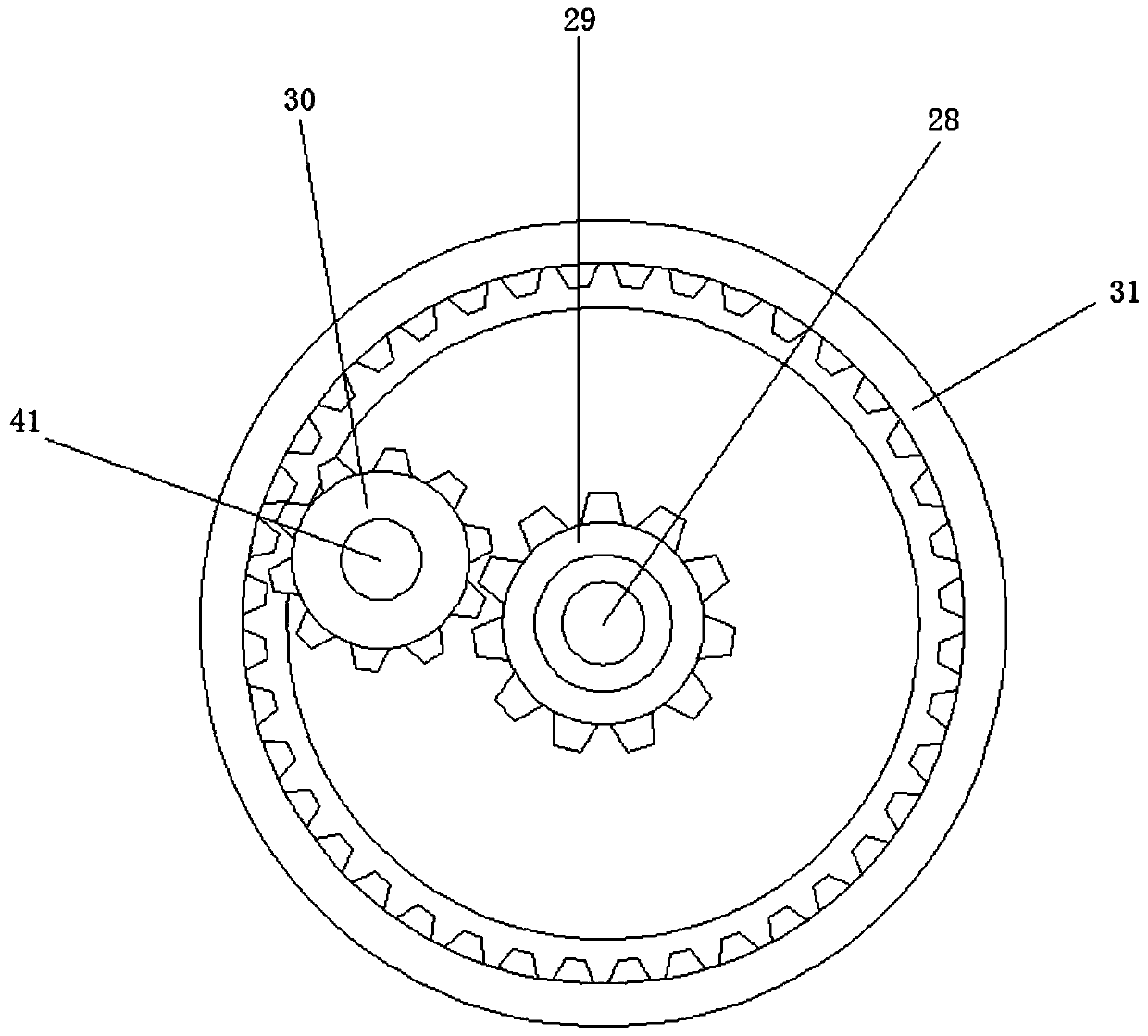

Solar plate ash removal device with adjustable angle

The invention relates to the technical field of new-energy equipment, and discloses a solar plate ash removal device with an adjustable angle. The solar plate ash removal device comprises a base, wherein a first handle is movably connected to the interior of the base, a first connection shaft is movably connected to the bottom end of the first handle, a second connection shaft is movably connectedto the bottom end of the first connection shaft, a first connecting piece is movably connected to the top end of the second connection shaft, second dagger gears are movably connected to the right end of a first sleeving shaft, a sleeving plate is movably connected to the right end of a second sleeving shaft, a ninth connecting rod is movably connected to the outer side of the sleeving plate, a tenth connecting rod is movably connected to the interior of a planetary gear, a fourth connection shaft is movably connected to the interior of the second dagger gears, and an ash removal device bodyis movably connected to one end of the fourth connection shaft. According to the solar plate ash removal device with the adjustable angle, through the connection of the first handle and an input shaft, the problems that cleaning of solar cell panels mainly relies on manual labor, resulting in low cleaning efficiency, large labor intensity and greatly-improved cost are solved.

Owner:王君华

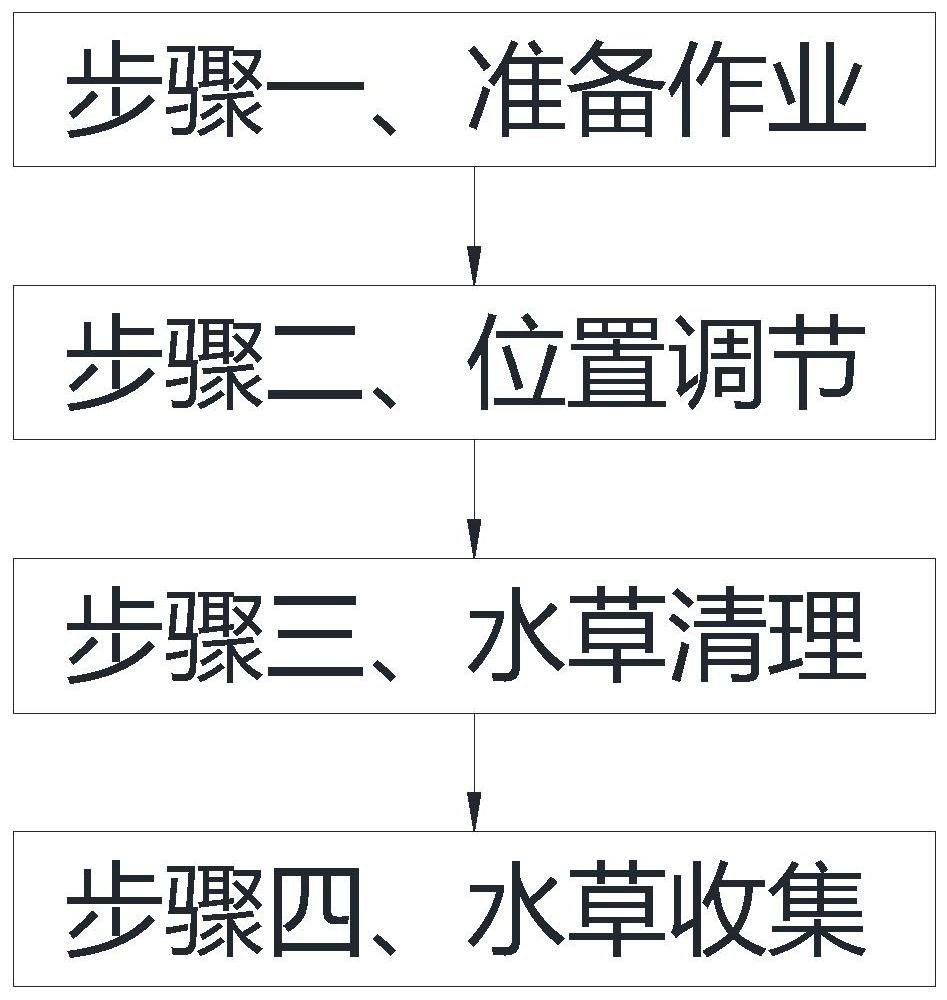

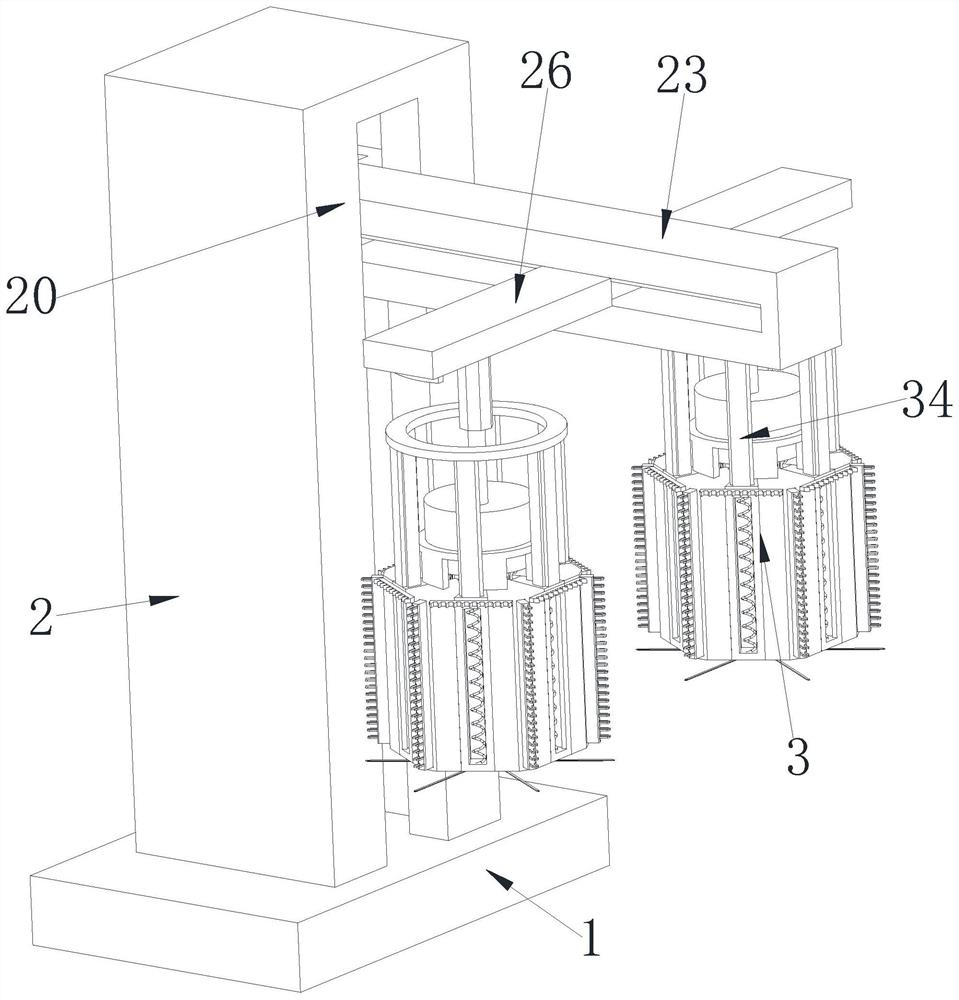

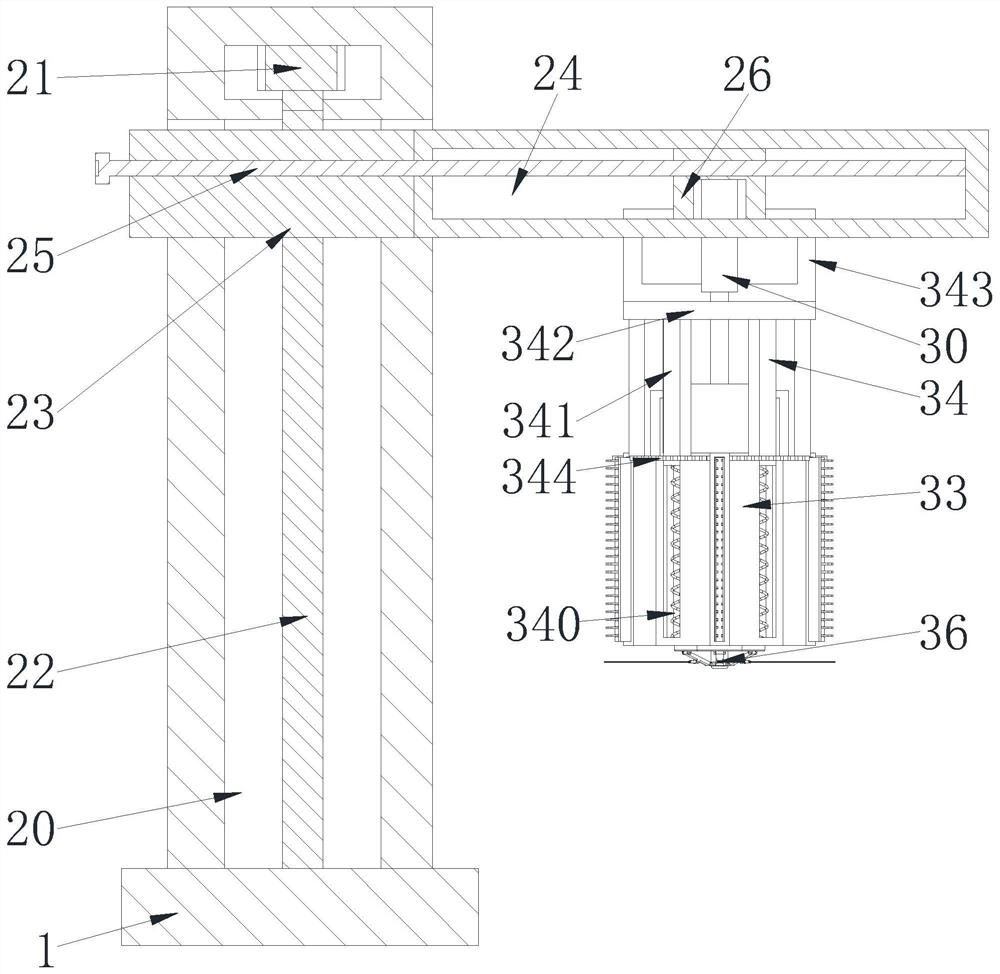

River ecological environment restoration treatment method

ActiveCN111893971AEasy to pull outEasy to cleanWater resource protectionWater cleaningEcological environmentEngineering

The invention relates to a river ecological environment restoration treatment method. The method uses river ecological environment restoration treatment equipment. The river ecological environment restoration treatment equipment comprises a base, an adjusting unit and cleaning devices, the adjusting unit is arranged on the base, and the cleaning devices are symmetrically arranged at the upper endof the adjusting unit in a bilateral symmetry mode. The method can solve the problems existing in the cleaning of waterweeds in a river channel at present that when an existing cleaning device is usedfor cleaning the waterweeds, the waterweeds are simply cleaned and removed from the water surface of the river channel, but waterweeds root on the water bottom still exist to cause that the waterweeds are full of the water surface again, a water body is damaged, and a waterweeds cleaning mode is not used for treating symptoms and signs; and the waterweeds which are adhered to the waterweeds cleaning device and cleaned from the river channel can be tightly wound on the cleaning device to be difficult to remove, subsequent continuous cleaning of the waterweeds is troublesome, the cleaning effect of the cleaning device on the waterweeds is obviously reduced, the cleaning efficiency is reduced, and the trouble is doubled.

Owner:江苏信环生态环境治理有限公司

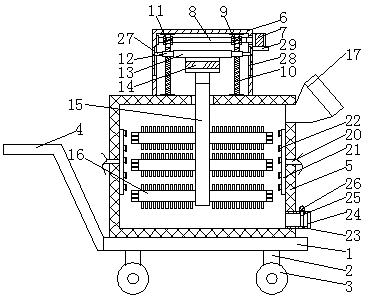

Cleaning device for peanut processing

The invention discloses a cleaning device for peanut processing. The cleaning device comprises a base plate. Four corners of the bottom of the base plate are each fixedly connected with a supporting rod, rollers are movably connected to the bottoms of the supporting rods through rotating shafts, a pull rod is fixedly connected to the left side of the base plate, a box is fixedly connected to the top of the base plate, a sealing box is fixedly connected to the top of the box, a first motor is fixedly connected to the top of the right side of the sealing box, and the output shaft of the first motor penetrates through an inner cavity of the sealing box and is fixedly connected with a rotating rod. Peanuts can be efficiently cleaned, and the problems that in the prior art, water is used for flushing peanuts mostly, then, a brush is used for stirring and removing mud on the outer surfaces of the peanuts, time and labor are wasted according to existing methods, the peanut cleaning efficiencyis low, peanuts cannot be cleaned and processed better and more comprehensively, and follow-up peanut processing is facilitated are solved.

Owner:郑州谓凡智能科技有限公司

Automatic sugarcane cleaning and de-mud equipment

InactiveCN110122901AFacilitate large-scale harvestingPlay a barrier roleFood treatmentBiochemical engineeringFixed frame

The invention relates to the field of agricultural product cleaning equipment, in particular to automatic sugarcane cleaning and de-mud equipment, which comprises a feeding device, a cleaning device and a drying device, the feeding device is disposed at one end of the cleaning device, and the drying device is disposed at the other end of the cleaning device, the cleaning device comprises a cleaning box body and cleaning barrels, a cleaning roller is inserted in the middle axle of the cleaning barrel, the cleaning roller is connected to the main body of a cleaning box, a driving component is arranged on the main body of the cleaning box, a nozzle fixing frame is arranged above the cleaning box, and a high-pressure spray head and an inlet water pipe are arranged on the nozzle fixing frame. The equipment is used for cleaning and removing mud from sugarcane, and the sugarcane to-be-cleaned is put into the feeding device, and then transferred to the cleaning device, and the driving component drives the cleaning roller to rotate, each cleaning barrels is rotated in the same direction, and the sugarcane is sent to the drying device, the high-pressure spray head on the nozzle holder sprayswater against the sugarcane to perform the flushing function, and the automatic and batch cleaning can be realized to significantly improve the efficiency.

Owner:徐士钦

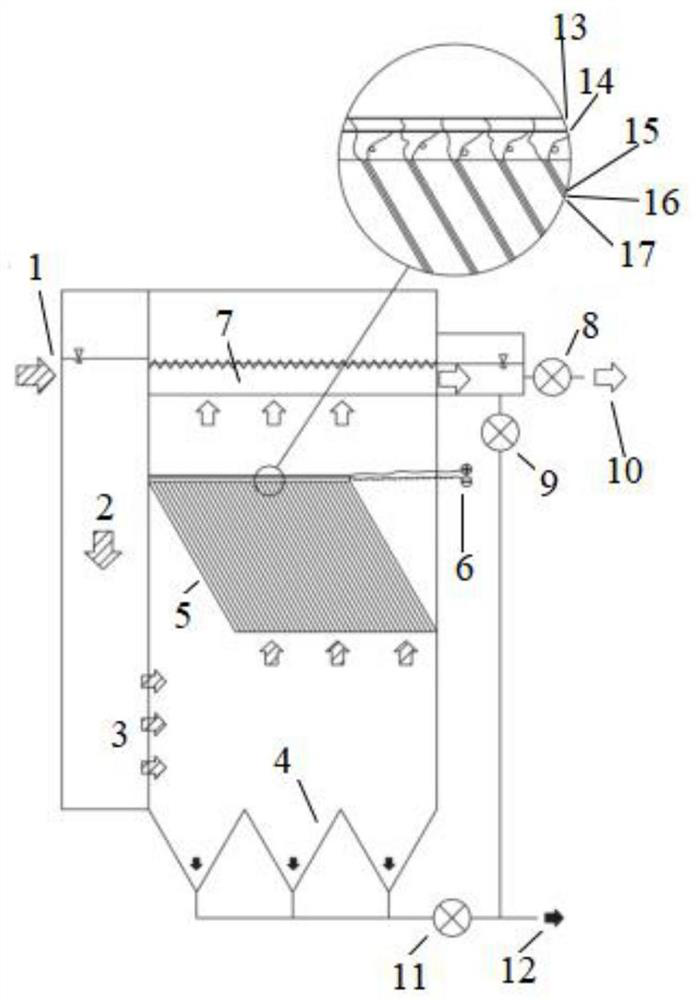

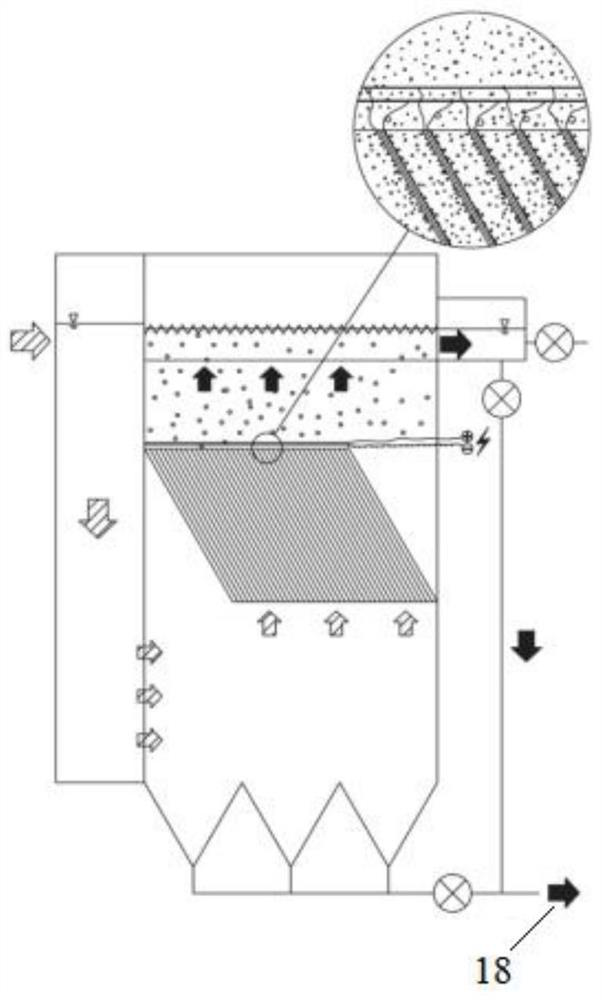

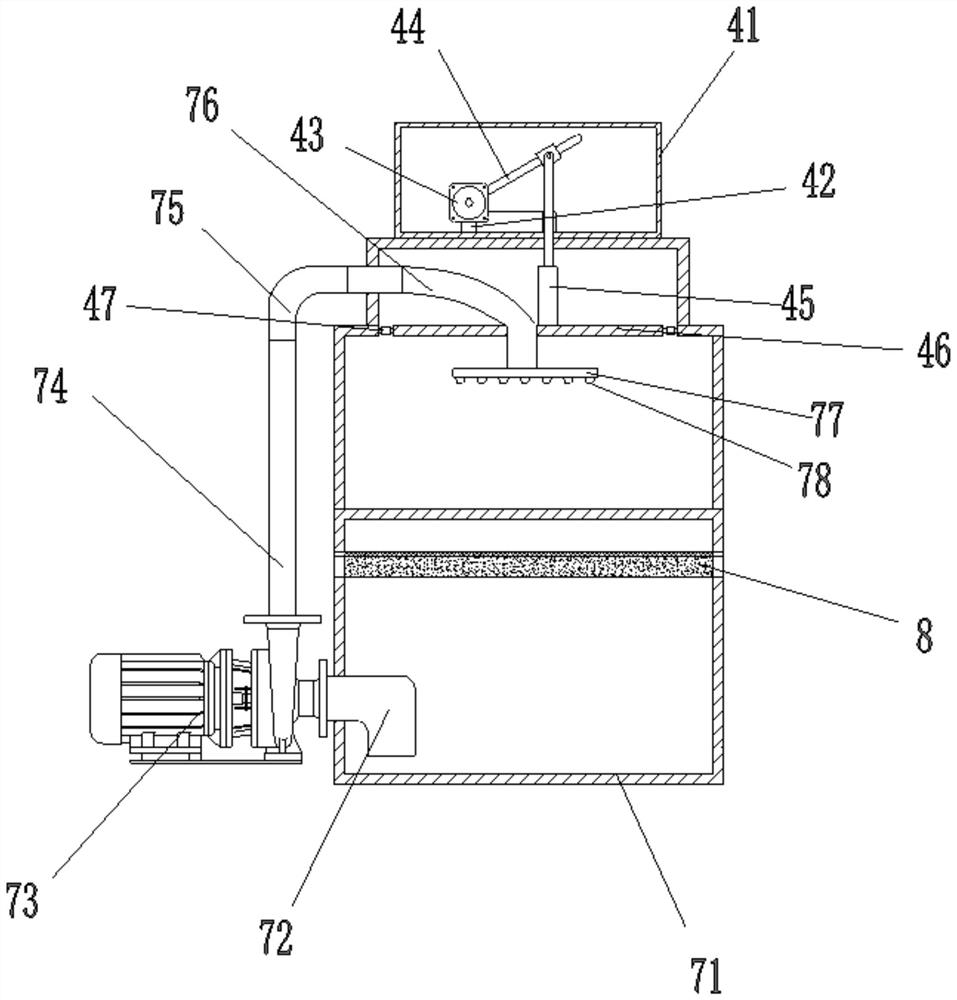

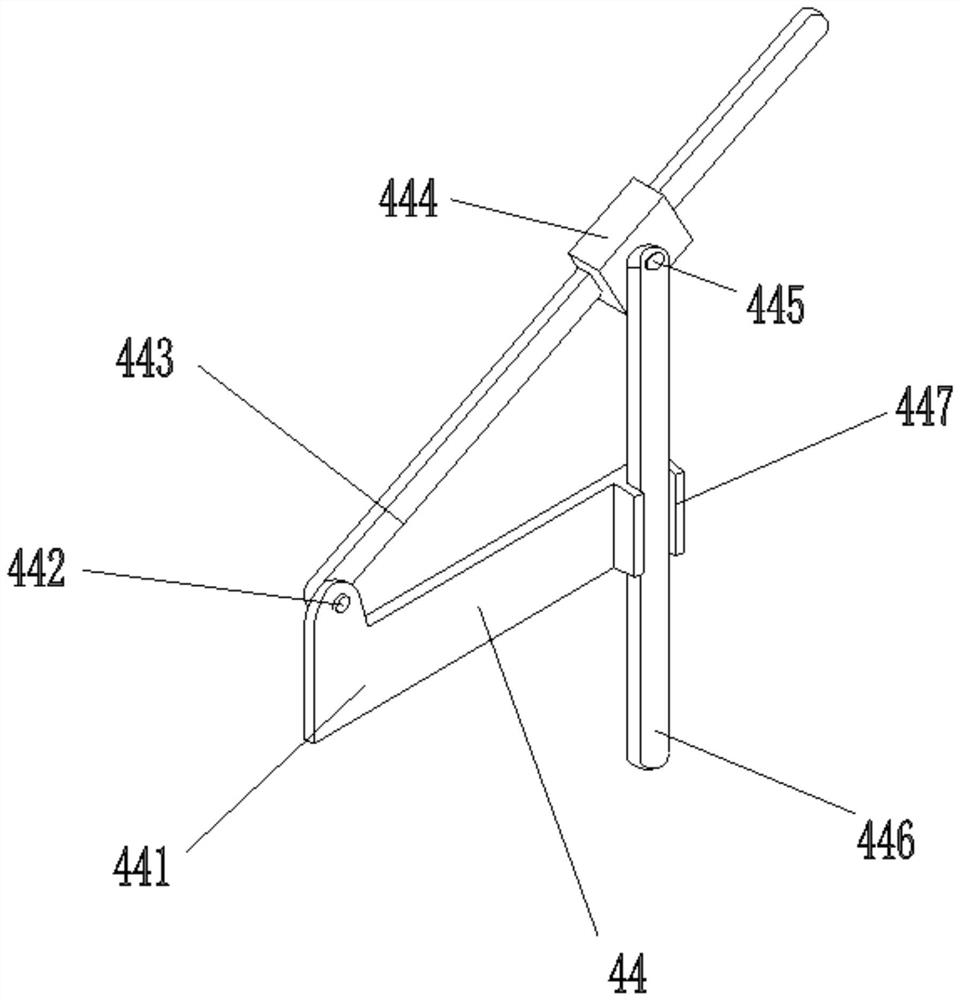

Inclined tube sedimentation tank capable of being cleaned on line

PendingCN113856254AExtended downtimeReduce cleaning efficiencySedimentation settling tanksElectrolysed waterSludge

The invention discloses an inclined tube sedimentation tank capable of being cleaned on line. A cathode electrode plate and an anode electrode plate are respectively arranged on two sides of the inclined tube surface of the inclined tube sedimentation tank. When floc is deposited on the surface or the top of the inclined tube, the cathode electrode plate and the anode electrode plate are electrified, oxygen and hydrogen are generated by electrolyzing water, and microbubbles are formed on the surface of the inclined tube; then the microbubbles adhere to floc deposited in the inclined tube, so that the deposited floc floats on the water surface and enters the top water collecting tank to be discharged out of the system. According to the invention, the microbubbles are formed on the surface of the inclined tube through electrolyzed water or electrolyte in the electrolyzed water, and the microbubbles adhere to floc deposited in the inclined tube, so that the deposited floc floats on the water surface and enters the top water collecting tank to be discharged out of the system. The device is suitable for other solid-liquid flow directions such as a same-direction flow inclined pipe and a lateral flow inclined pipe; and the device is suitable for other sludge discharge forms such as mechanical sludge discharge and perforated pipe sludge discharge. The inclined tube sedimentation tank is suitable for pretreatment and advanced treatment of purified water, sewage, reclaimed water and seawater in the fields of municipal administration, industry, agriculture and the like.

Owner:北控水务(中国)投资有限公司

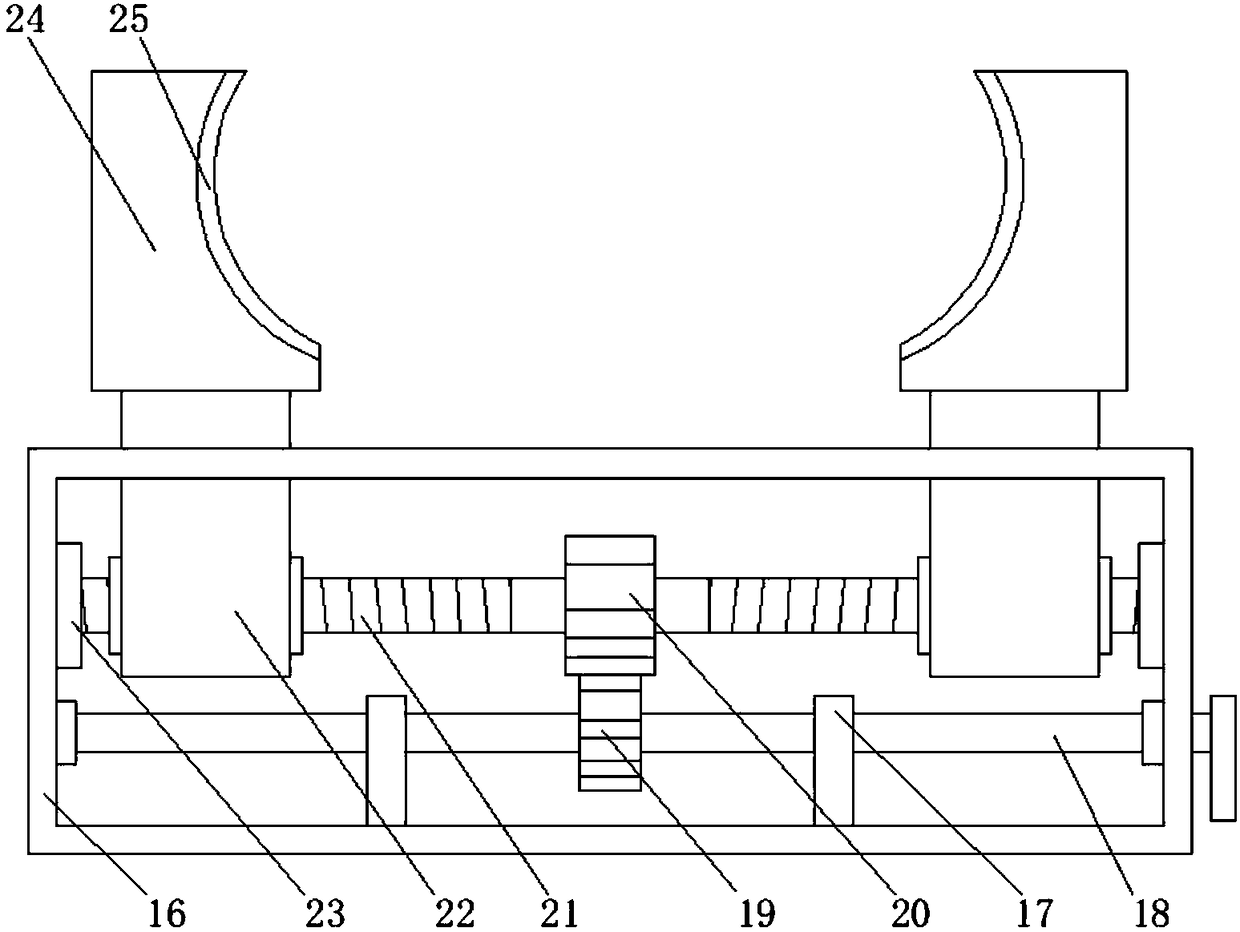

Clamping device based on metal corrugated pipe machining and grinding

ActiveCN108481099AReduce shakingImprove sanding effectRevolution surface grinding machinesGrinding drivesEngineeringMachining

The invention relates to the technical field of metal corrugated pipe machining, and discloses a clamping device based on metal corrugated pipe machining and grinding. The device comprises a protection dust suction cover, the bottom of the protection dust suction cover is fixedly connected with a case body, the surface of the case body is fixedly connected with a drive adjusting grinding main machine body, the inner wall of the bottom of the case body is fixedly connected with an asynchronous motor, the output end of the asynchronous motor is fixedly connected with a first belt wheel, the first belt wheel is in transmission connection with a second belt wheel through a belt, the inner wall of the second belt wheel is fixedly connected with a driving rod, and one end of the driving rod is sequentially connected with a stabilizing plate and a first bevel gear, and is fixedly connected with the inner wall of a first bearing. According to the clamping device based on metal corrugated pipemachining and grinding, due to a pushing body, a worker can conveniently clamp different lengths of corrugated pipes, the use range of the clamping device can be effectively widened, the corrugated pipes required to be ground are clamped, shaking during corrugated pipe grinding can be effectively reduced, and the corrugated pipe grinding effect can be effectively improved.

Owner:MAANSHAN FEIDA BELLOWS MFG CO LTD

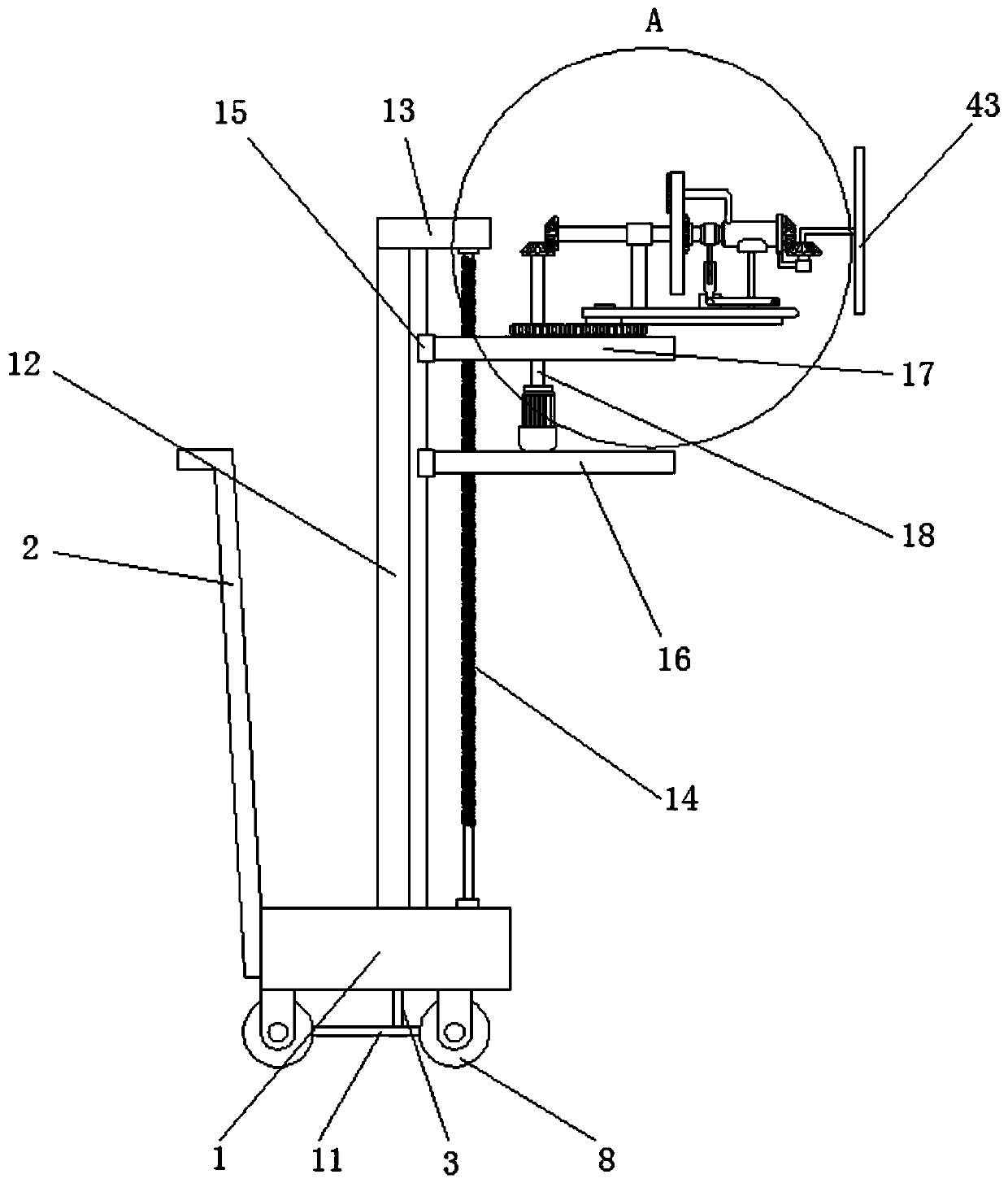

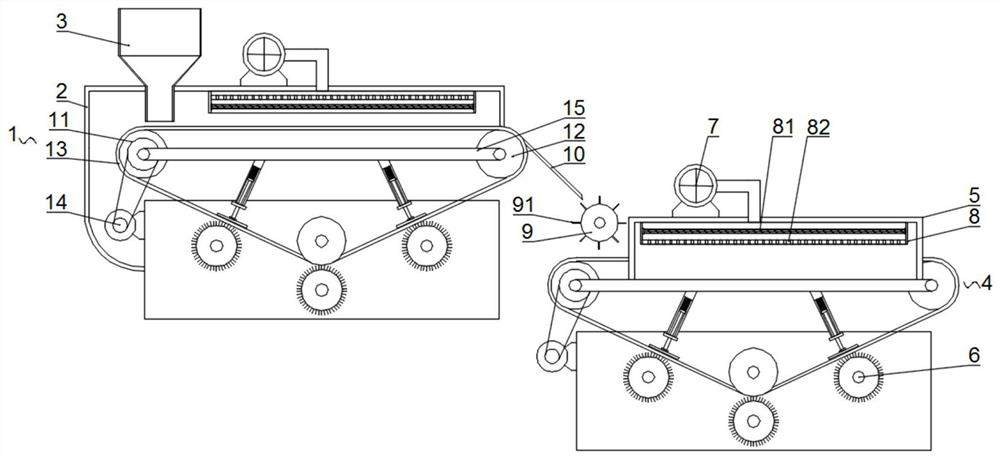

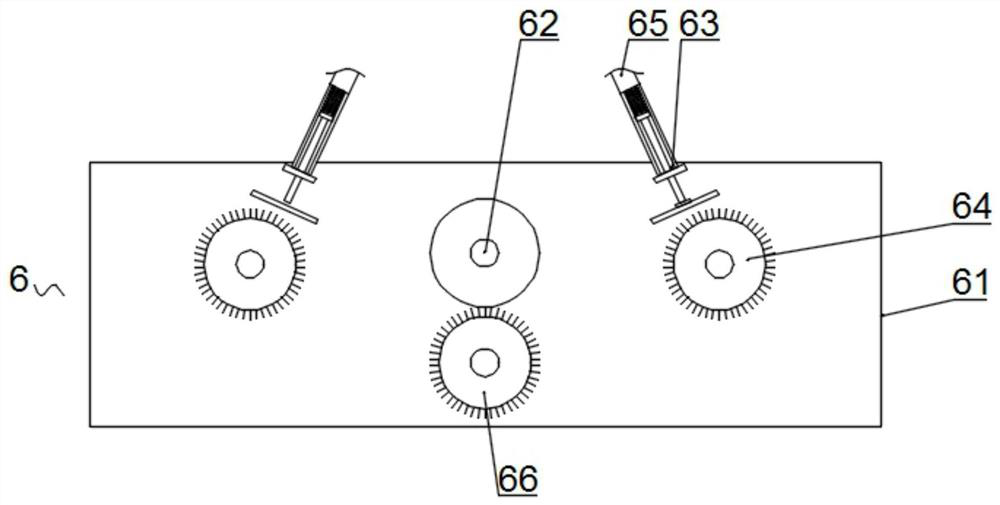

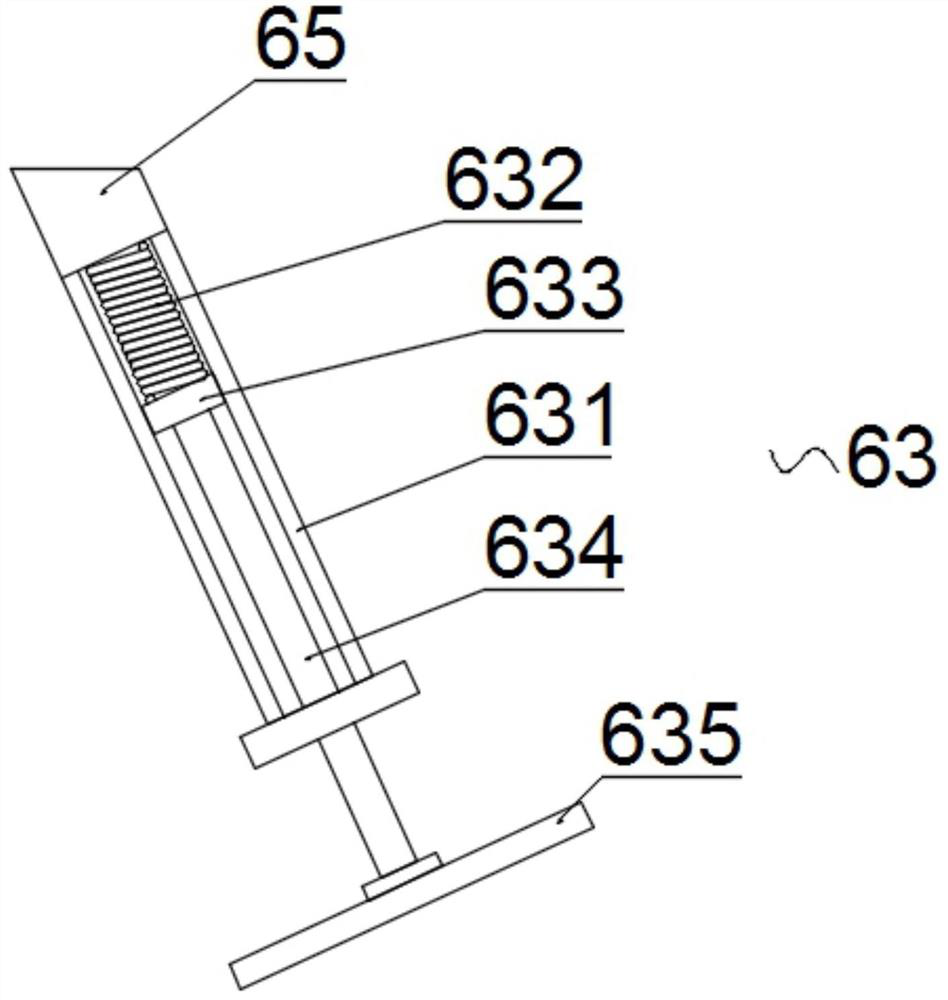

Eel fillet baking device with belt cleaning function

PendingCN111642528ALabor intensiveReduce cleaning efficiencyCleaningBaking ovenDrive wheelElectric machinery

The invention relates to an eel fillet baking device with a belt cleaning function, in particular to the technical field of eel processing equipment. The eel fillet baking device comprises a first conveying device, a first baking cover, a discharging hopper, a second conveying device, a second baking cover, cleaning mechanisms, a fan, a heating chamber and a turnover wheel, wherein the turnover wheel is arranged above the feeding end of the second conveying device; a material guide plate is obliquely arranged between the discharging end of the first conveying device and the turnover wheel; each of the first conveying device and the second conveying device comprises a driving wheel, a driven wheel, a conveying belt and a driving motor; the driving wheels are driven by the driving motors; and the cleaning mechanisms used for cleaning the conveying belts are arranged below the first conveying device and the second conveying device. The cleaning efficiency of the conveying belts is improved, the labor intensity of workers is reduced, and the baking uniformity of eel fillets is guaranteed.

Owner:福清海峰食品有限公司

Universal wheel hub cleaning equipment

PendingCN113145533AComprehensive cleaningReduce cleaning efficiencyDrying gas arrangementsCleaning using liquidsElectric machineryRinse water

The invention discloses universal wheel hub cleaning equipment. The universal wheel hub cleaning equipment structurally comprises a conveying belt, a machine shell, a protection box, an auxiliary device, a hot air drying device, a first fixing block, a circulating device, a filtering device, a machine body, a switch, a water inlet, a water outlet, a power line, an observation window, a first shell, a supporting rod, a first motor, an auxiliary mechanism, a fixing rod, a movable plate, a first connecting piece and a drying device. The universal wheel hub cleaning equipment has the beneficial effects that by arranging the auxiliary device at the top end of the protection box, a hub can be comprehensively cleaned, the cleaning efficiency and quality are improved, by arranging the hot air drying device on the right side of the back of the machine shell, time and labor are saved, the working efficiency is improved, and by arranging the circulating device at the bottom of the machine body, the water circulating function is achieved, flushing water can be used repeatedly, and waste of water resources is avoided.

Owner:张康成

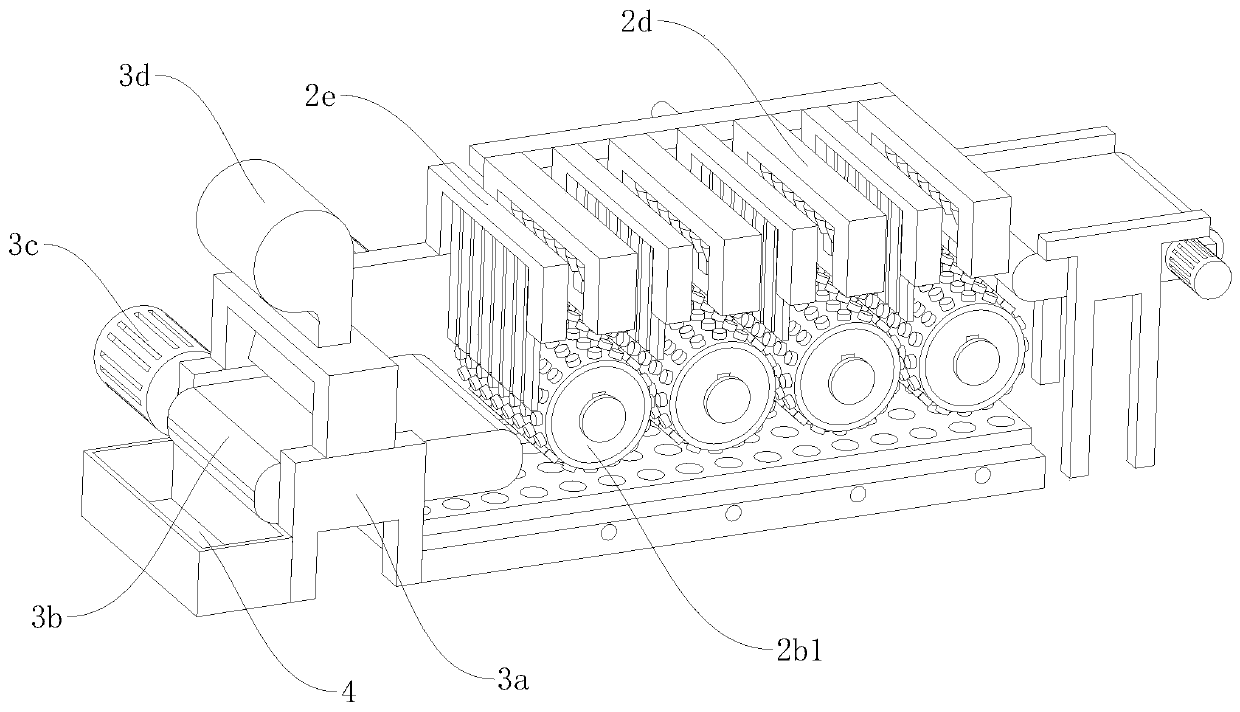

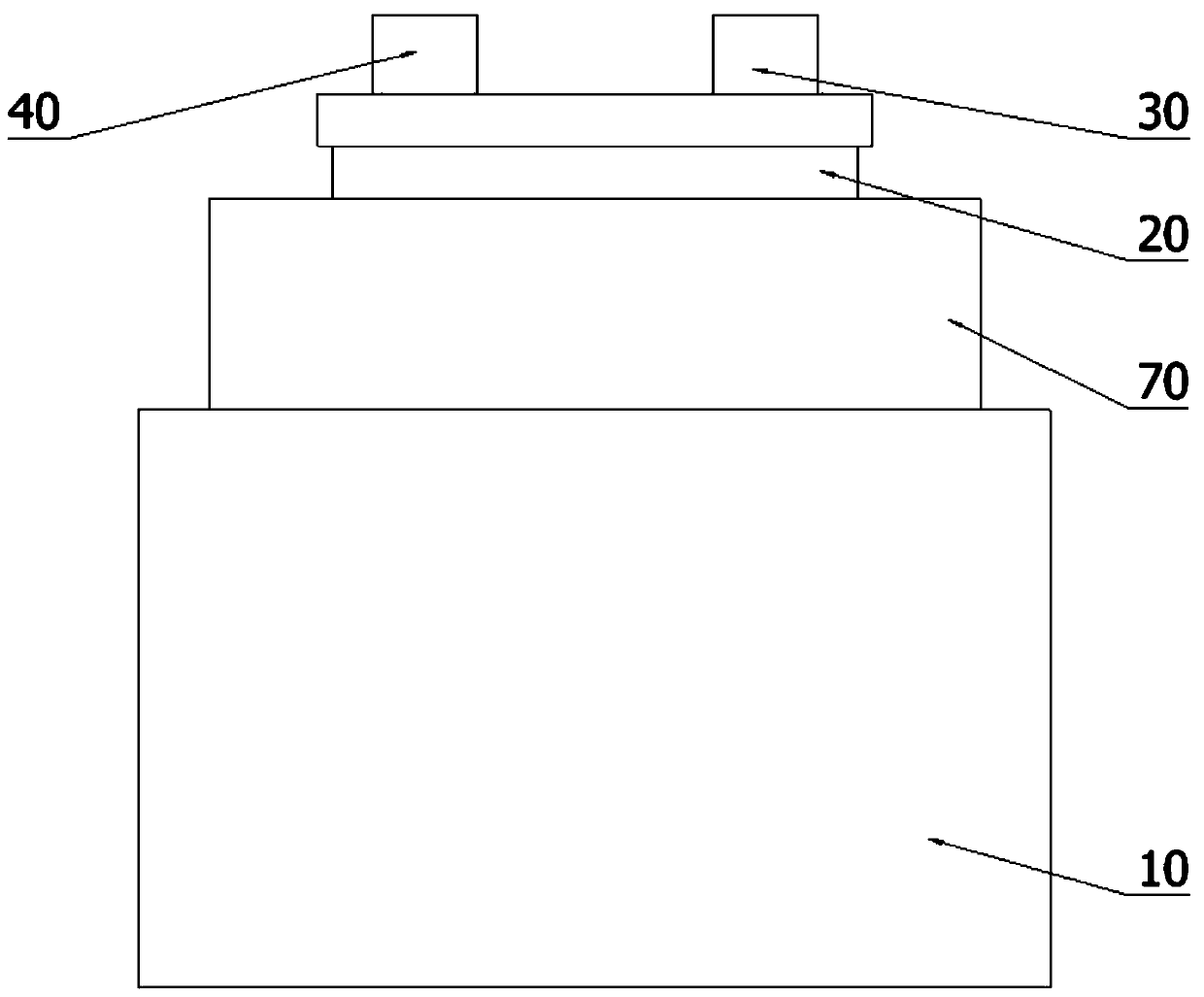

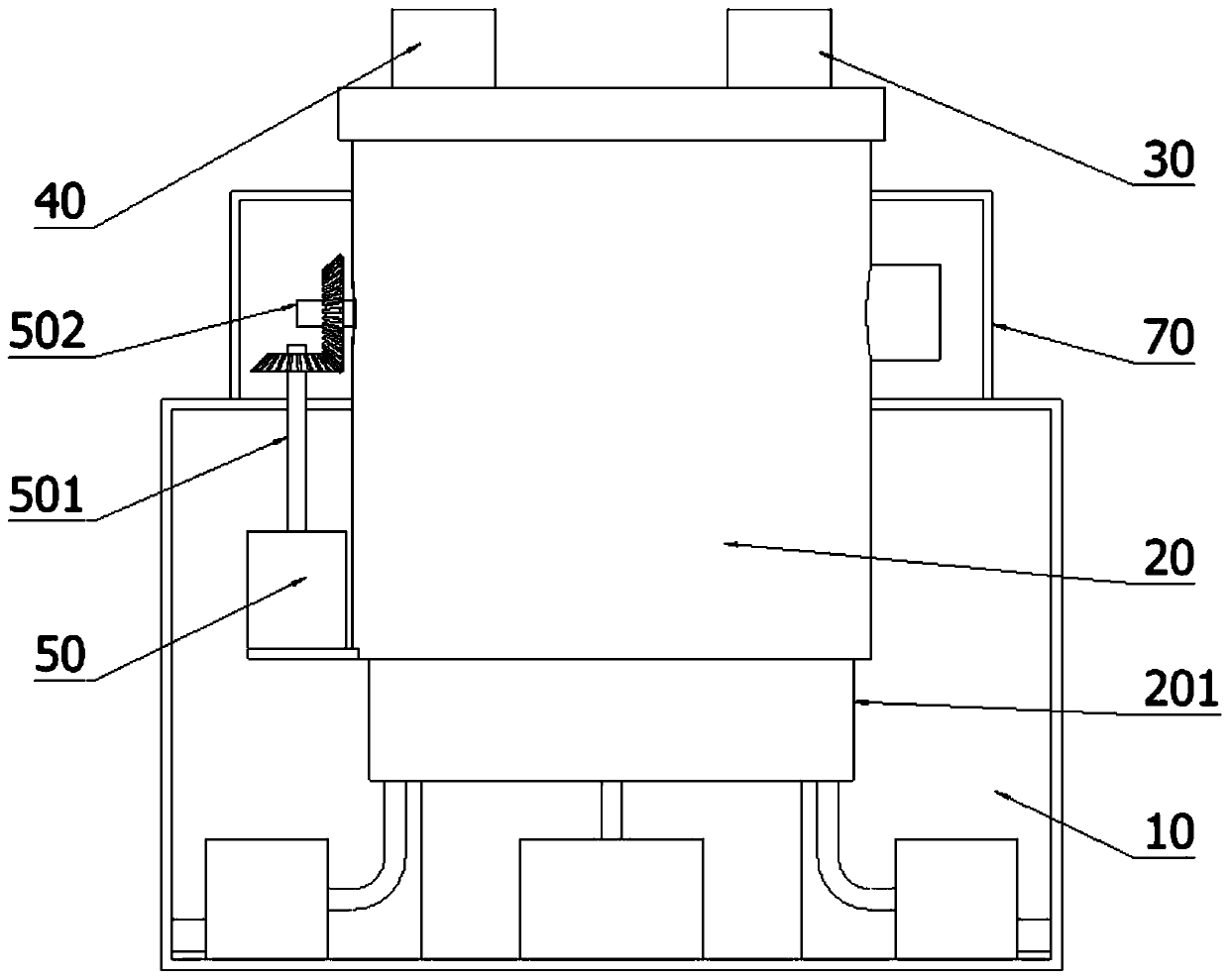

Filter element cleaning equipment for industrial dehumidifier

The invention relates to filter element cleaning equipment for an industrial dehumidifier. The filter element cleaning equipment for the industrial dehumidifier comprises a bottom plate, a conveying rack, a cotton absorbing device and a cleaning device, wherein the conveying rack is arranged at the upper end of the bottom plate; the cotton absorbing device is mounted on the left side of the upperend of the conveying rack; the cleaning device is mounted on the right side of the upper end of the conveying rack; and the cleaning device is positioned on the right side of the cotton absorbing device. The problems that when a filter element of an existing dehumidifier is cleaned, the filter element is always cleaned manually, the manual cleaning efficiency is low, the labor intensity is large,fluffs, cotton fibers and broken ends which are attached to the surface of the filter element cannot be swept or collected, moreover, during manual cleaning, waste materials easily harm health of workers, the filter element cannot be swept automatically, operation is complicated, the labor intensity is high, cleaning efficiency is low and the like can be solved, functions of absorbing cotton of the surface of the filter element and cleaning the surface of the filter element can be fulfilled automatically, and the filter element cleaning equipment for the industrial dehumidifier has the advantages of simplicity and convenience in operation, low labor intensity, high cleaning efficiency and the like.

Owner:ZHEJIANG OULUN ELECTRIC

Neodymium iron boron waste material screening device and using method

The invention discloses a neodymium iron boron waste material screening device, and relates to the technical field of neodymium iron boron processing. The screening device comprises a base body, a placing part, a protective cover, a rotating part and a control part, wherein a containing space is formed in the base body; the placing part is connected with the base body, and the placing part comprises a connecting body arranged inside the base body; the protective cover is arranged above the base body, and the protective cover and the placing part have same axis; the rotating part is arranged inside the placing part, and the rotating part comprises a rotating shell arranged inside the placing part; and the control part is arranged on one side of the placing part, and the control part comprises a driven shaft, wherein the driven shaft is fixedly connected with the connecting body, the driven shaft penetrates through the rotating part, and the driven shaft and the rotating part have same axis. According to the neodymium iron boron waste material screening device, when being subjected to recovery treatment, a neodymium iron boron waste material is cleaned and screened first, so that theeffect of the treatment process is ensured; and meanwhile, impurities in the cleaned neodymium iron boron waste material are reduced, so that the workload during recovery treatment is reduced.

Owner:XINFENG BAOGANG XINLI RARE EARTH

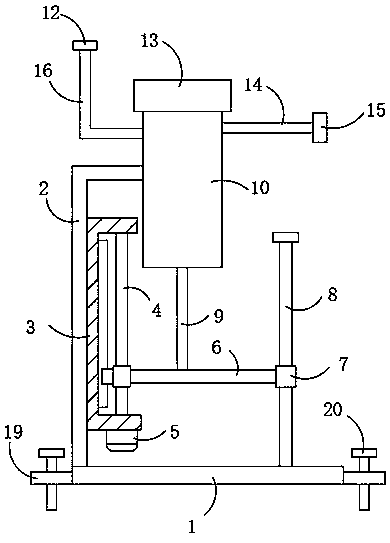

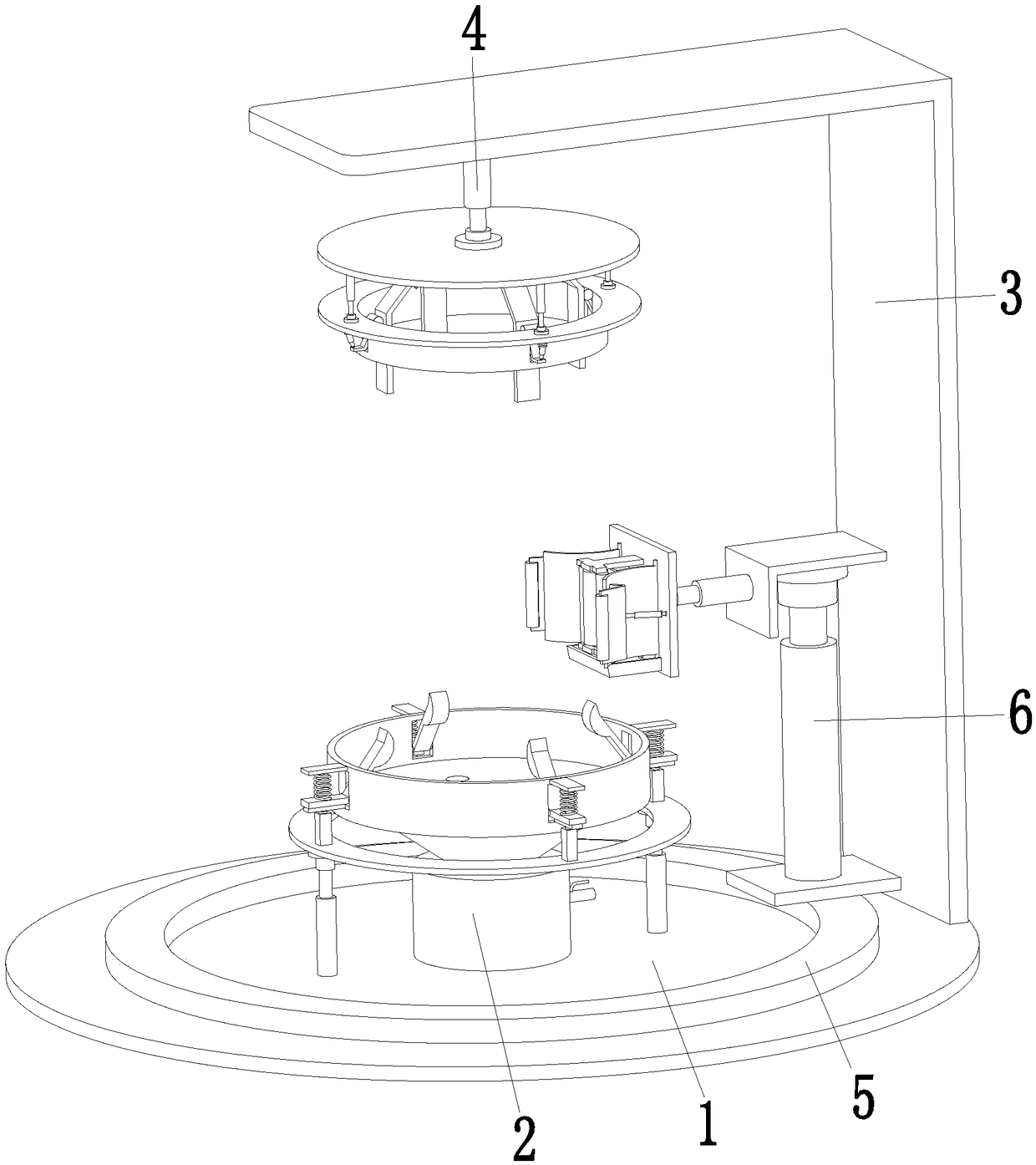

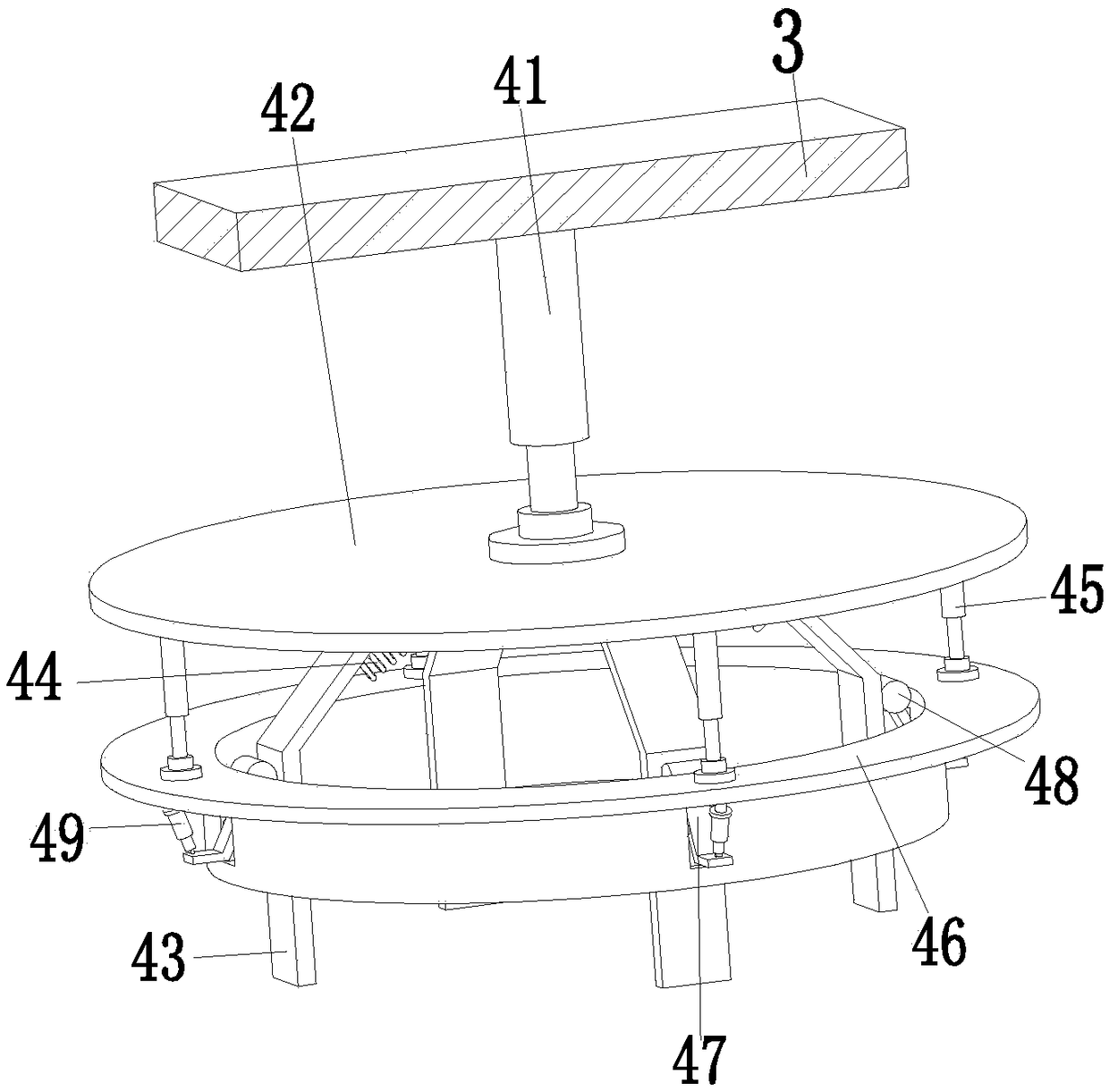

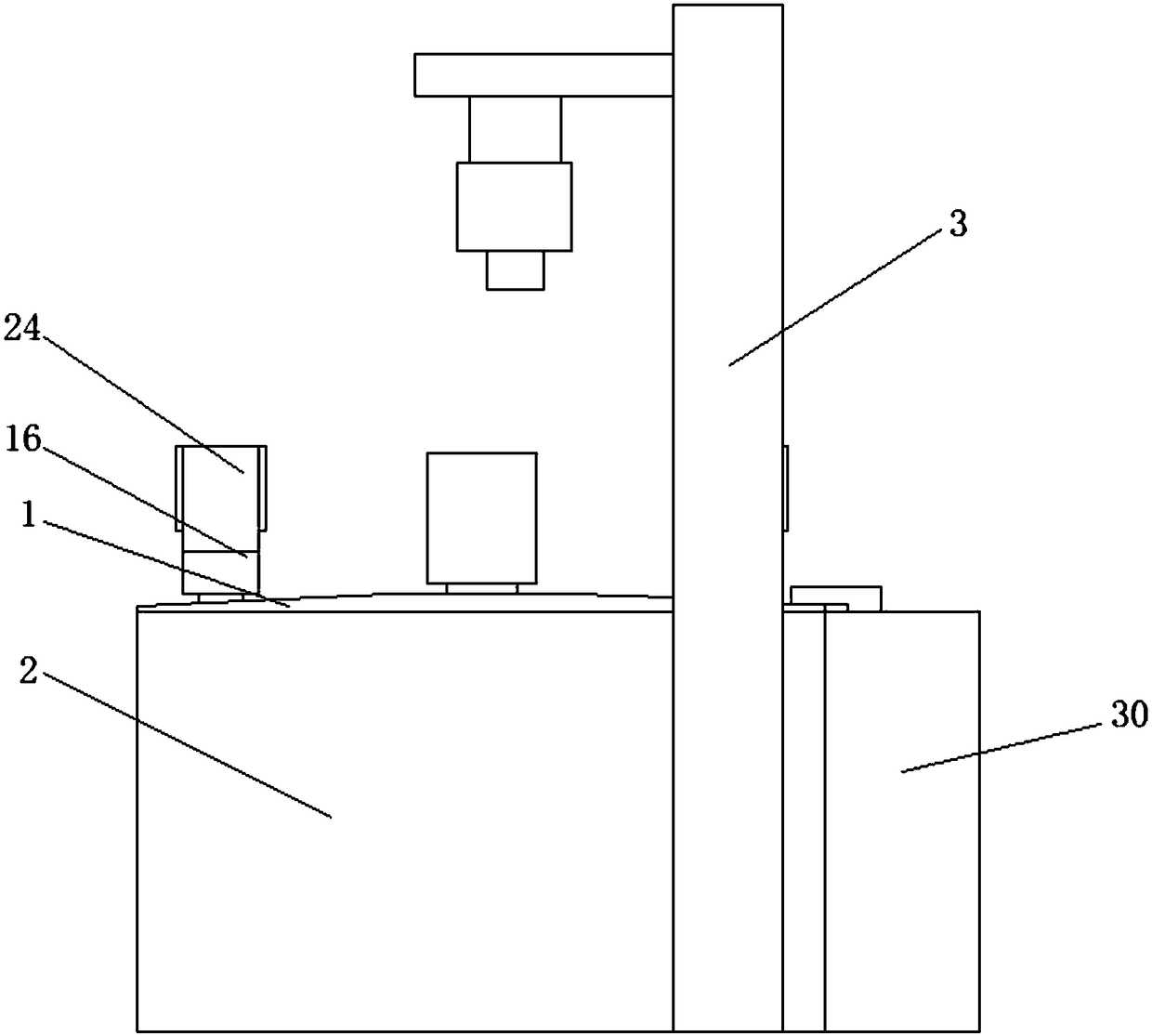

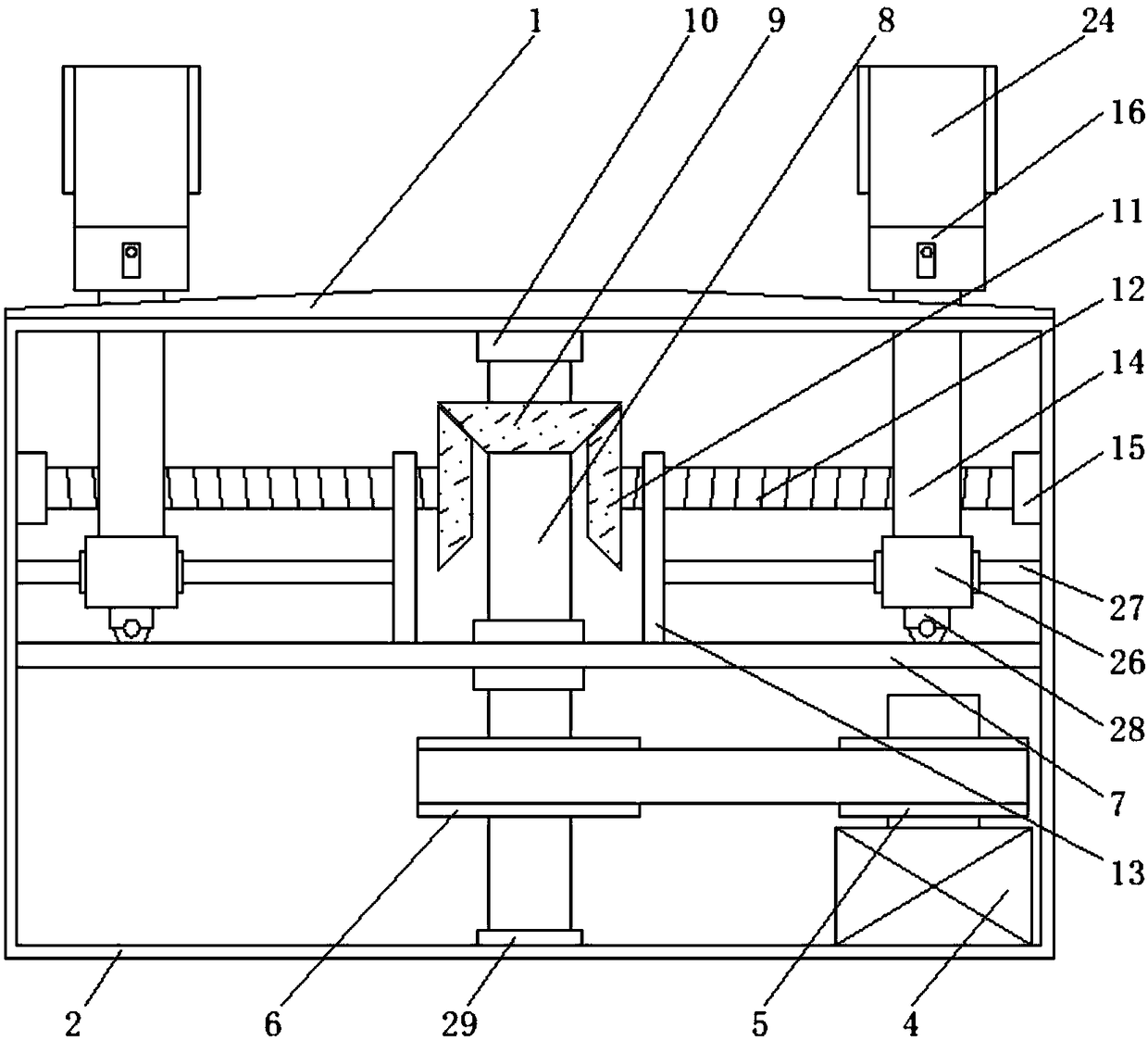

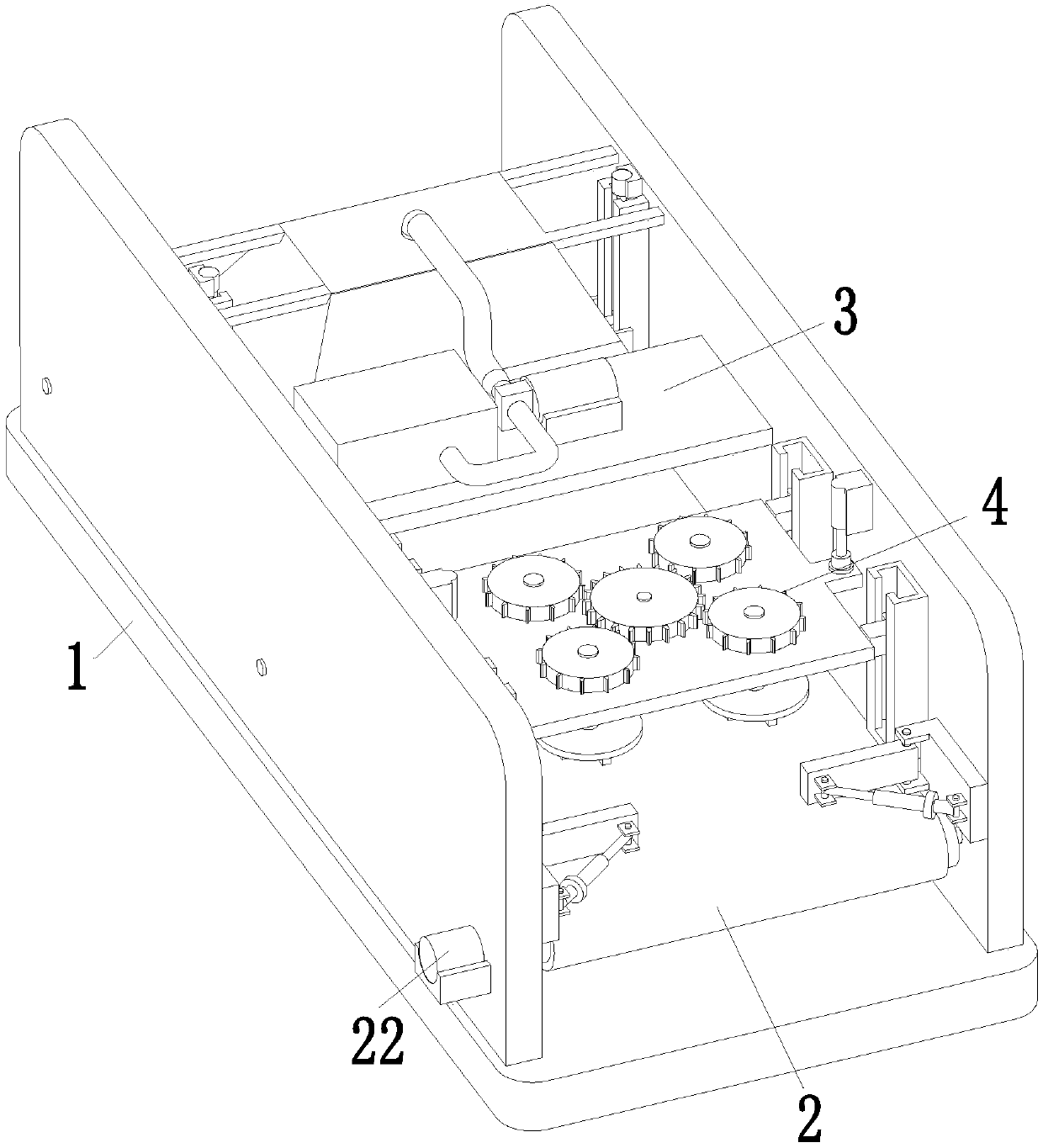

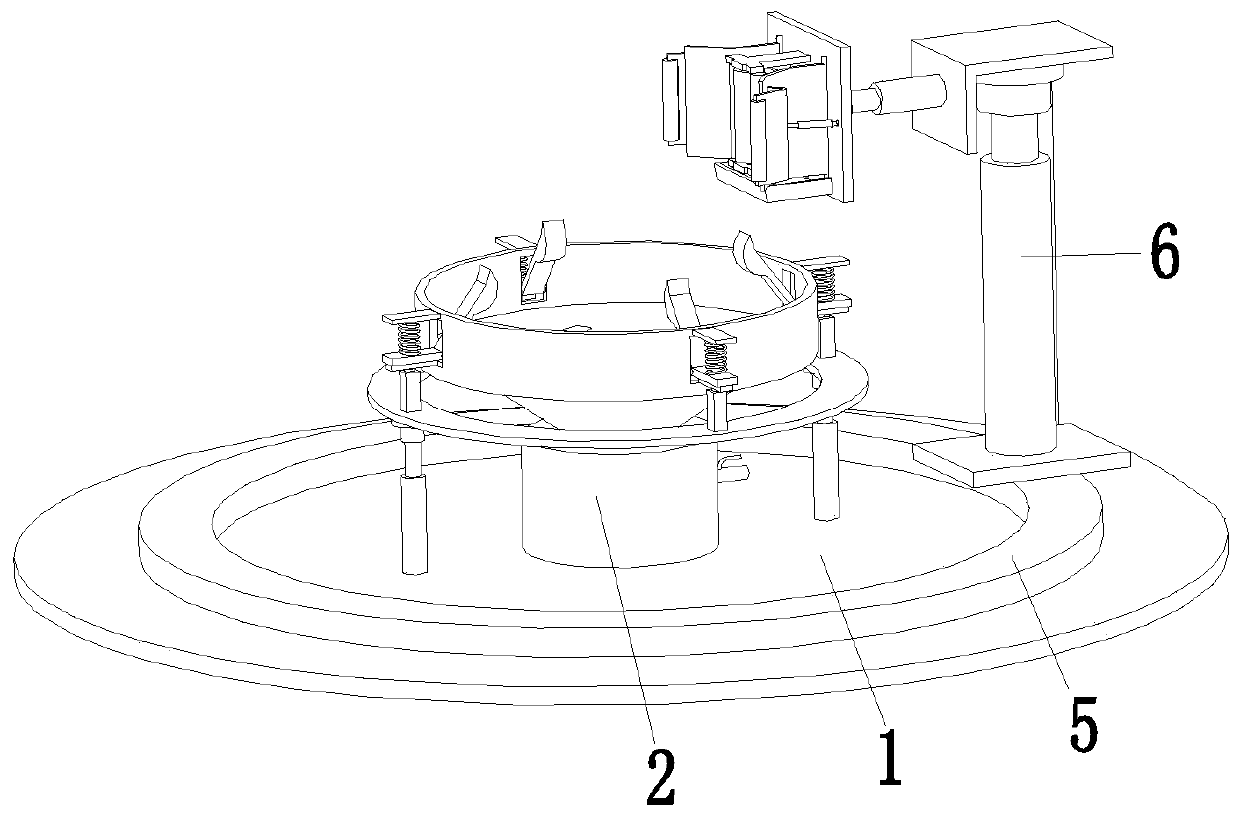

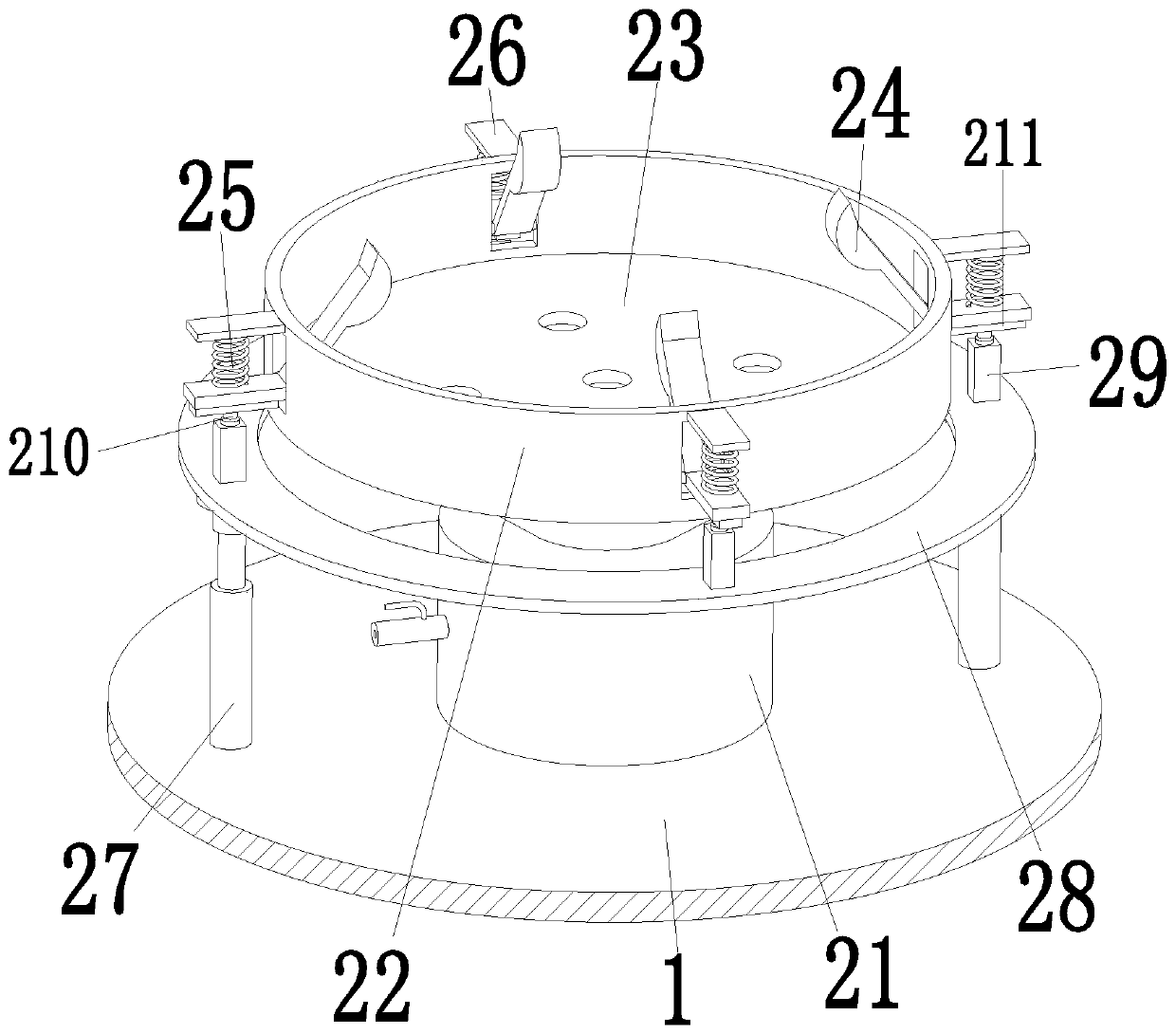

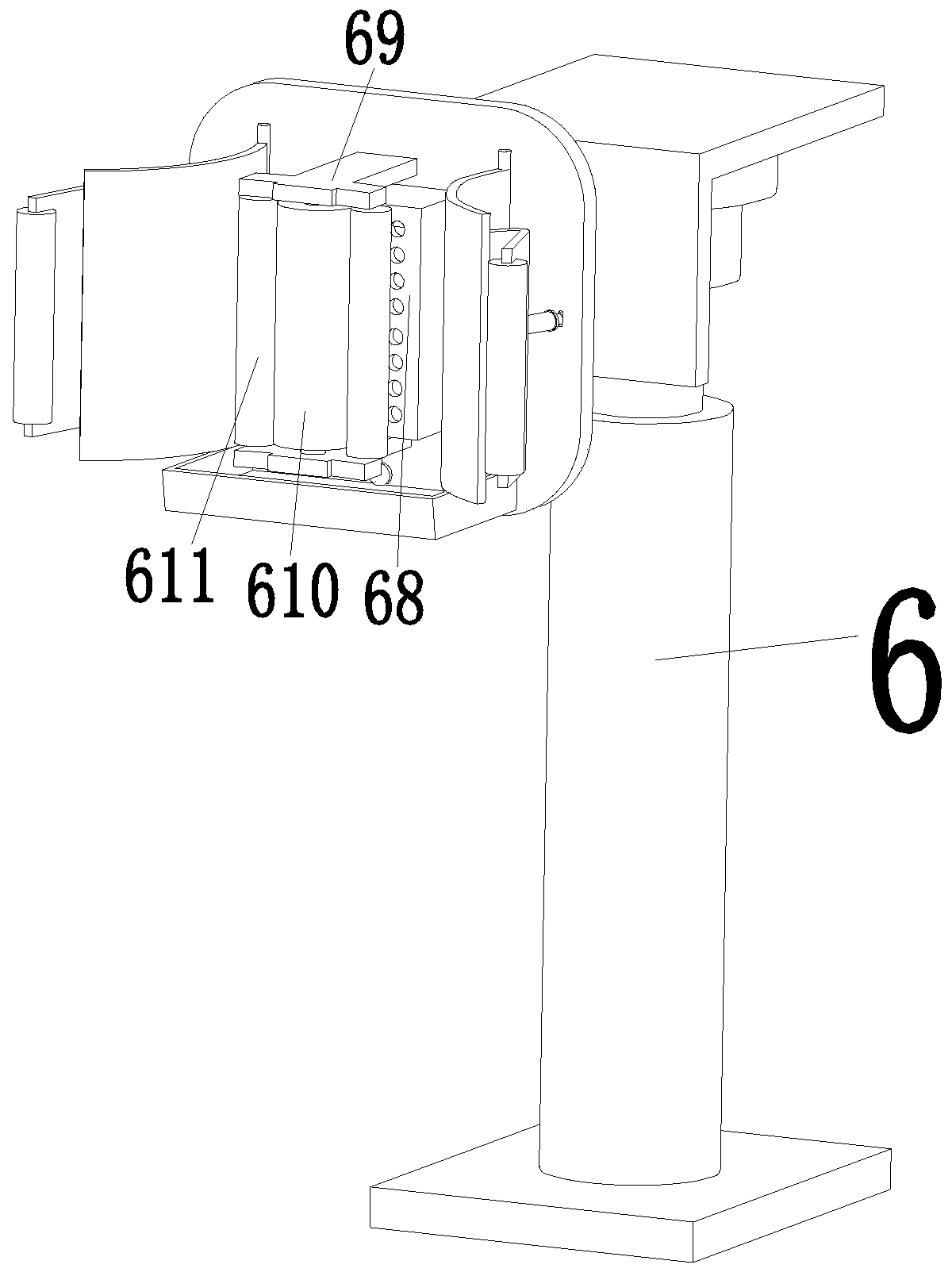

A lithium battery electrolyte automatic treatment system and its electrolyte treatment process

ActiveCN109107955BEffective controlReduce labor intensityDrying solid materials without heatCleaning using toolsElectrolytic agentPhysical chemistry

The invention relates to an automatic lithium battery electrolyte treatment system and its electrolyte treatment process, which includes a bottom plate, a recovery positioning device is installed in the middle of the bottom plate, an annular electric slider is installed on the bottom plate, and a cleaning device is installed on the annular electric slider. The recycling positioning device includes a recycling box installed on the bottom plate, a recycling work frame is installed on the upper end of the recycling box, and a positioning support plate is installed on the inner wall of the recycling work frame. The invention can solve the existing problem in the cleaning process of the electrolyte on the surface of the lithium battery that the electrolyte spilled on the surface of the lithium battery is manually cleaned with the help of anti-corrosion materials such as sponges. The water on the surface of the lithium battery cannot be controlled manually when cleaning the electrolyte with the help of sponges. The excess water on the surface of the lithium battery cannot be recovered in time, which can easily cause the excess water to enter the interior of the lithium battery. The electrolyte is corrosive, and manual cleaning with the help of a sponge poses safety risks and is harmful to human health.

Owner:领航国创新能源电池技术研究院(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com