Inclined tube sedimentation tank capable of being cleaned on line

A technology of inclined tube sedimentation tank and inclined tube, applied in the direction of sedimentation separation, sedimentation tank, separation method, etc., can solve the problems of many mechanical equipment, long system downtime, low cleaning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The application and implementation method of the device of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

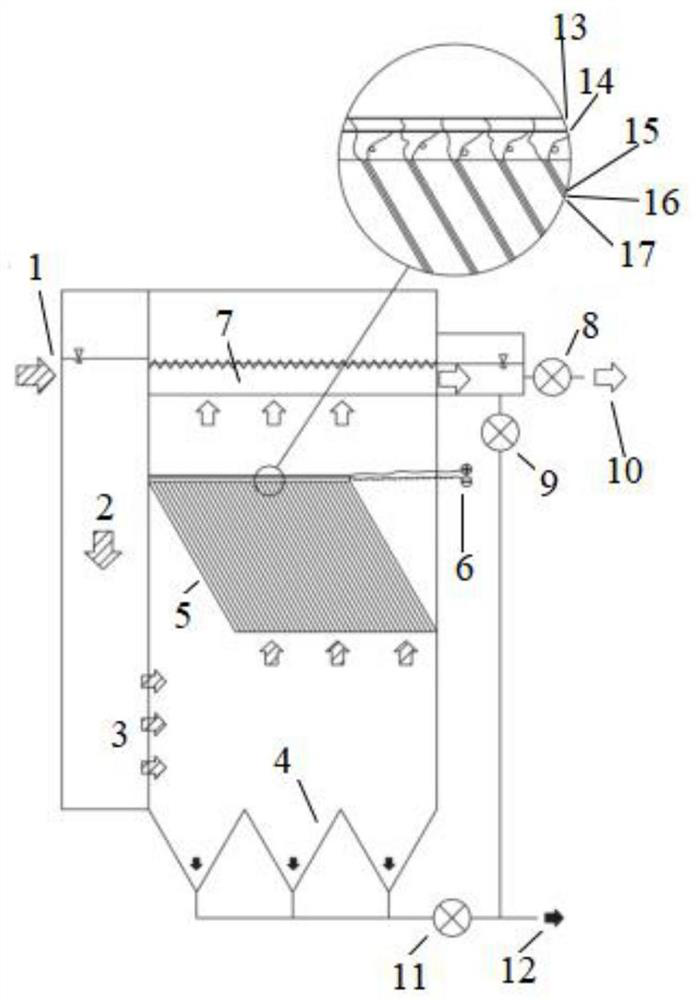

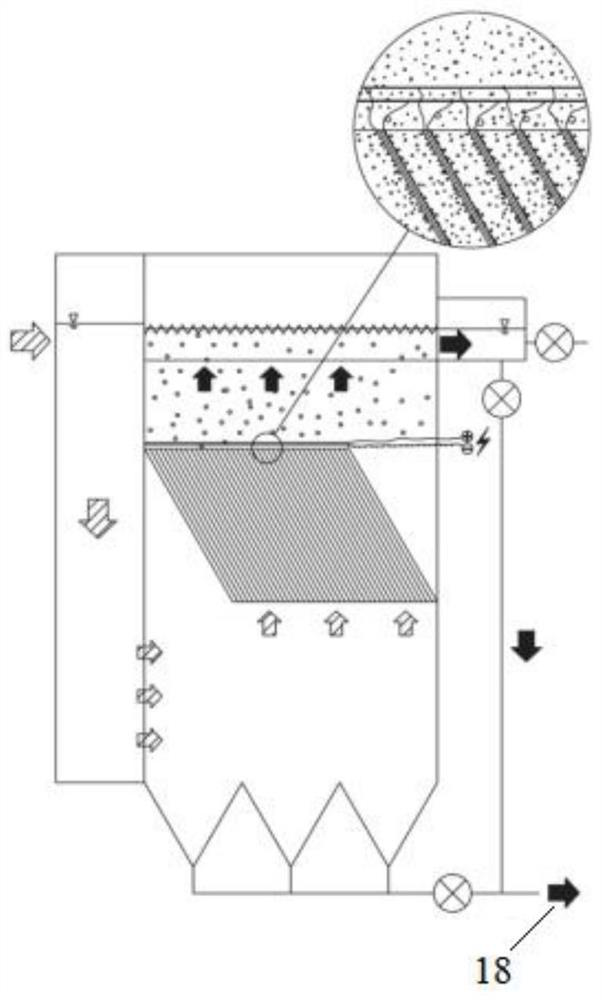

[0032] Such as figure 1As shown, in the normal operation mode, after the raw water is coagulated by adding flocculants and coagulants, it enters the water distribution tank 2 from the water inlet 1, and enters the sedimentation area through the water distribution flower wall 3, and the flocs formed by some colloids and particles in the water are deposited. The area directly sinks into the mud collecting bucket 4, or slides down to the mud collecting bucket 4 at the bottom of the sedimentation area after settling in the inclined pipe 5. The purified water flows upward through the inclined pipe 5, and after being collected by the sump 7, the water outlet 10 enters the next unit. At this time, the water outlet valve 8 is fully opened, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com