Method for separating enriched effective components from plant extract

A plant extract, separation and enrichment technology, applied in the field of separation and enrichment of active ingredients, can solve the problems of large waste disposal energy consumption, large use of organic solvents, affecting the safety of finished products, etc., achieving long downtime and reducing pollution. Wide range of emissions and impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

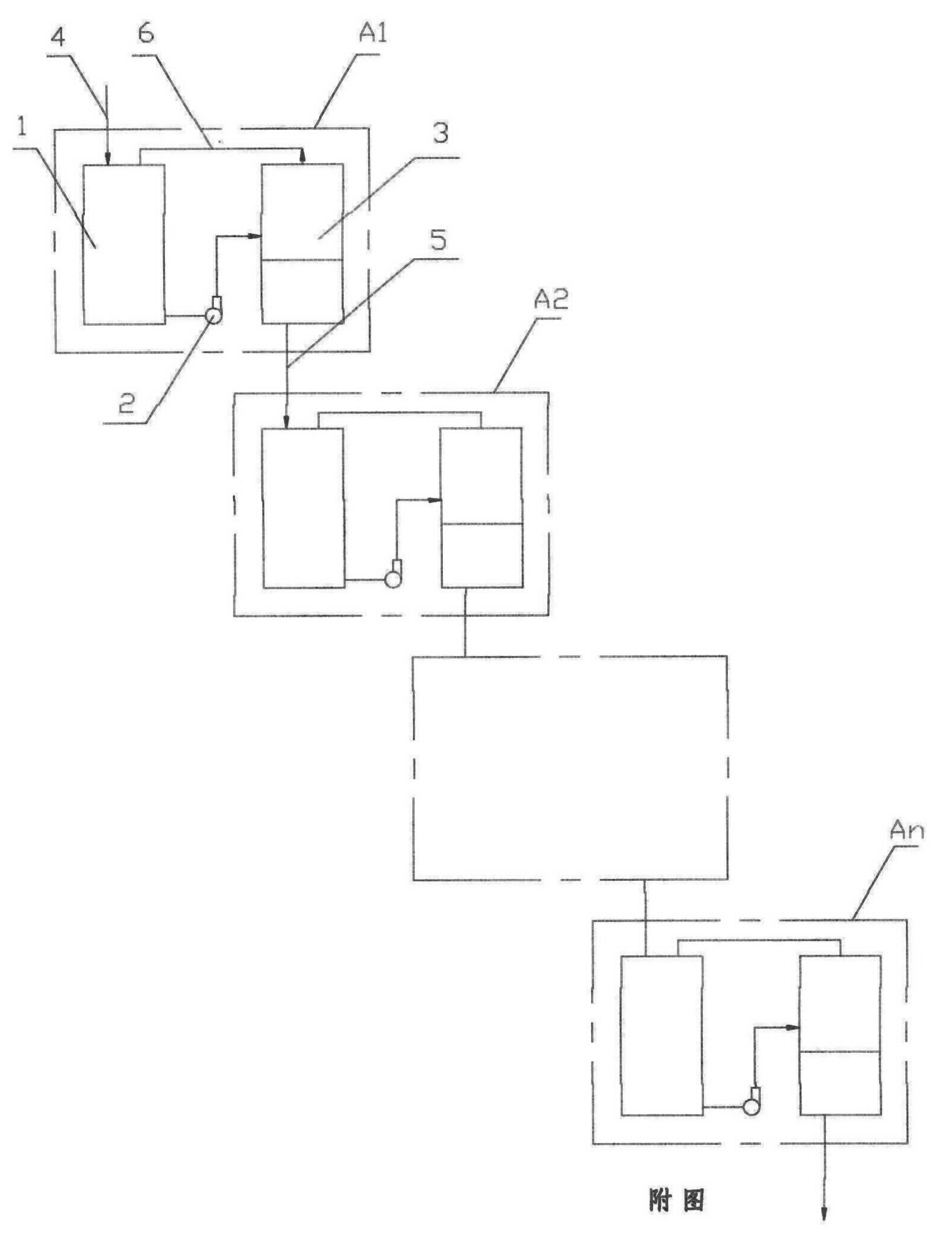

Image

Examples

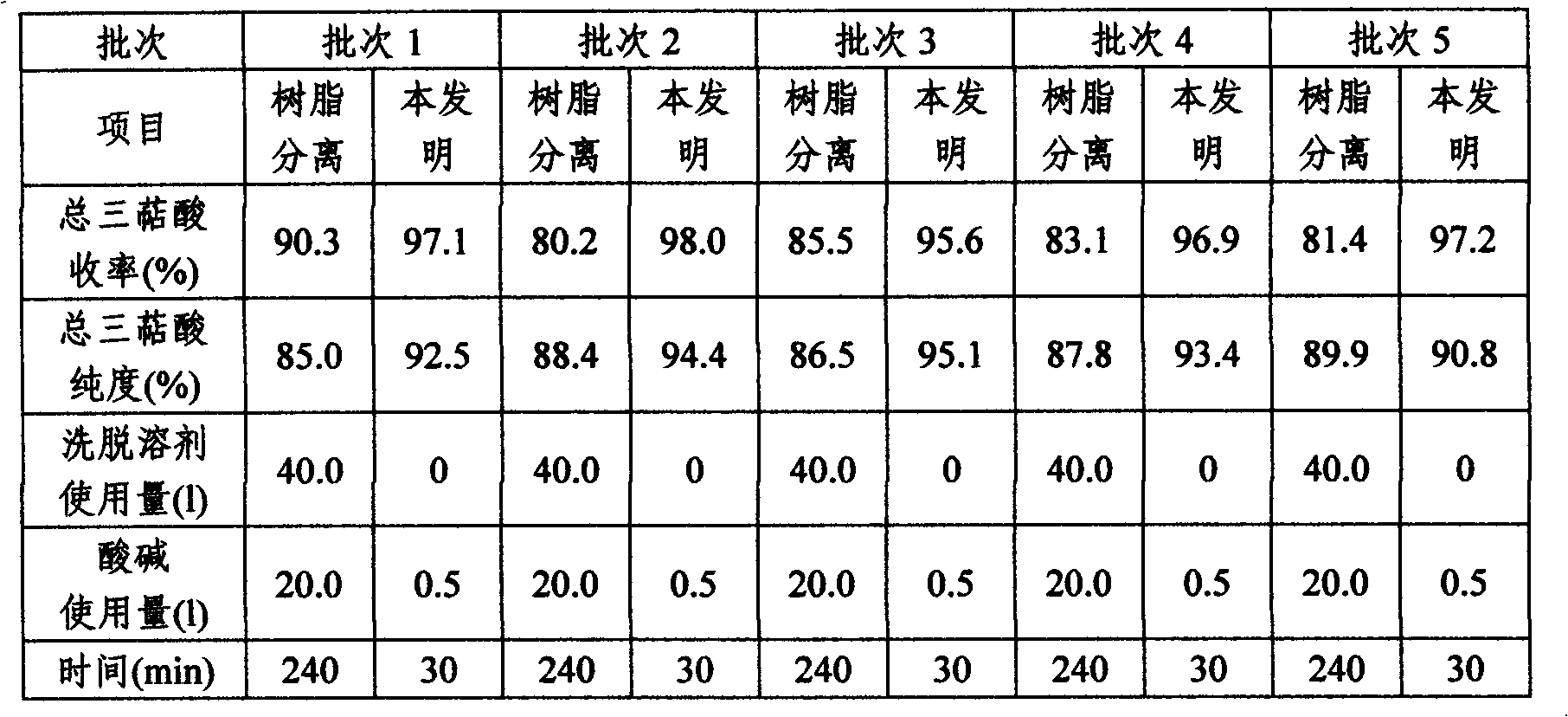

Embodiment 1

[0054] Embodiment 1: the method for extracting and separating total triterpene acid enrichment liquid from loquat leaf

[0055] The first step of water extraction: take 2kg of dry loquat leaf coarse powder, add 20L of water, mix well, heat to 100 degrees, boil for 60 minutes, cool to below 60 degrees, discard the water extract, and keep the medicinal residue for later use;

[0056] The second step of ethanol extraction: add the dregs and 95% ethanol into the reflux device, heat the extraction for 1 hour, take out the extract, leave the dregs in the reflux device for the next extraction, and repeat the operation 3 times, adding 95% each time Ethanol 20L, the 3 times of ethanol extracts were combined for later use, and the dregs were discarded;

[0057] The third step of coarse filtration: use industrial filter cloth as the medium to filter the ethanol extract, discard the filter residue, and reserve the filtrate;

[0058] The fourth step is a fine filtration: the filtrate is f...

Embodiment 2

[0060] Embodiment 2: The method for extracting and separating total triterpene acid enrichment liquid from Hedyotis diffusa

[0061] The first step of water extraction: take 2kg of dried Hedyotis diffusa powder, add 20L of water, mix well, heat to 100 degrees, boil for 60 minutes, cool to below 60 degrees, discard the water extract, and keep the drug residue for later use;

[0062] The second step of ethanol extraction: add the dregs and 95% ethanol into the reflux device, heat the extraction for 1 hour, take out the extract, leave the dregs in the reflux device for the next extraction, and repeat the operation 3 times, adding 95% each time Ethanol 20L, the 3 times of ethanol extracts were combined for later use, and the dregs were discarded;

[0063] The third step of coarse filtration: use industrial filter cloth as the medium to filter the ethanol extract, discard the filter residue, and reserve the filtrate;

[0064] The fourth step is a fine filtration: the filtrate is f...

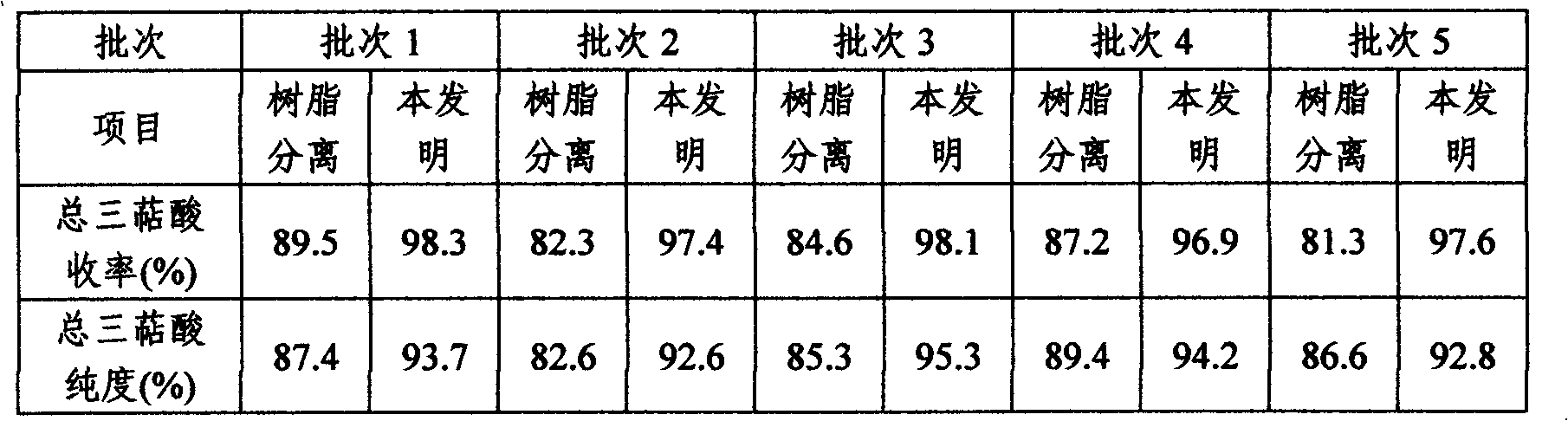

Embodiment 3

[0066] Embodiment 3: the method for extracting capsanthin and capsaicin from red pepper

[0067] The first step of water extraction: Add 2kg of dry red pepper coarse powder and 20L of water into the extraction tank, heat to 100 degrees, keep boiling for 1 hour, cool to 60 degrees Celsius, release the extraction liquid, and keep the residue in the tank for subsequent extraction Extract once, repeat heating and extracting in this way 3 times, combine the 3 times of water extracts for later use, and discard the slag;

[0068] The second step of coarse filtration: use industrial filter cloth as the medium to filter the water extract, discard the filter residue, and reserve the filtrate;

[0069] The third step of fine filtration: the filtrate is filtered with a ceramic membrane with a pore size of 0.003 μm by tangential flow filtration, capsanthin greater than 3kD (kilodaltons) is retained in the mother liquor for other uses, and the filtrate is 1.3mg / ml concentration of capsaici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com