Rapid vertical type plate cleaning machine for microporous reaction plates

A technology of microporous reaction plate and plate washer, which is applied in the direction of drying solid materials, chemical instruments and methods, and drying solid materials without heating. Cleaning efficiency and other issues, to achieve the effect of shortening the drying time, shortening the cleaning time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

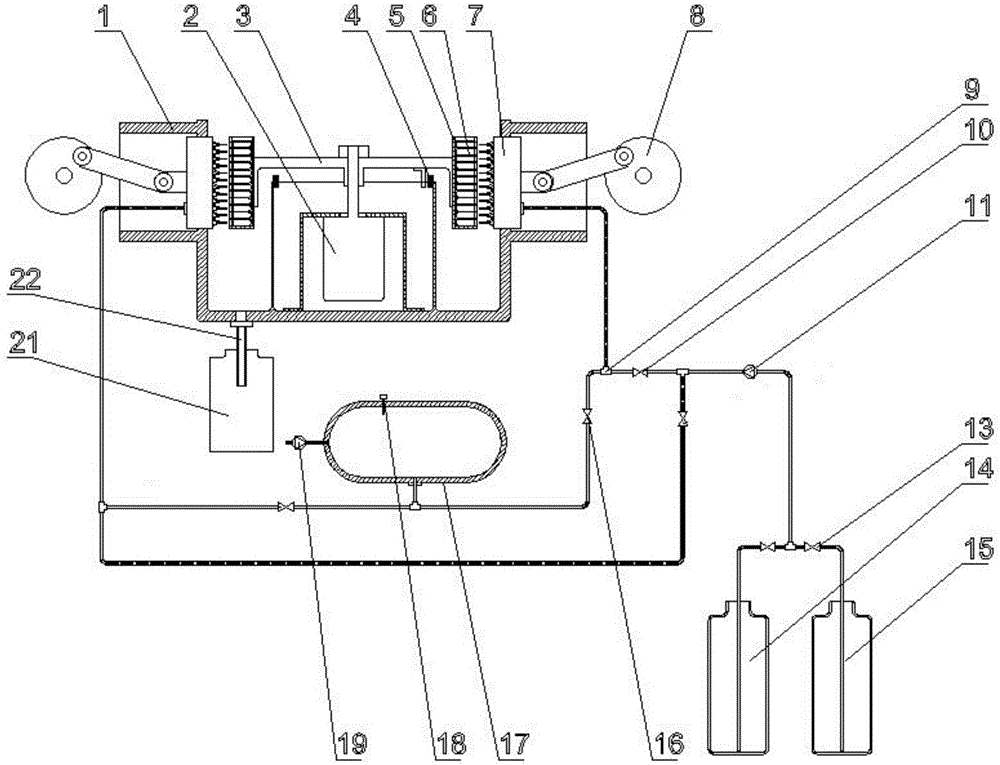

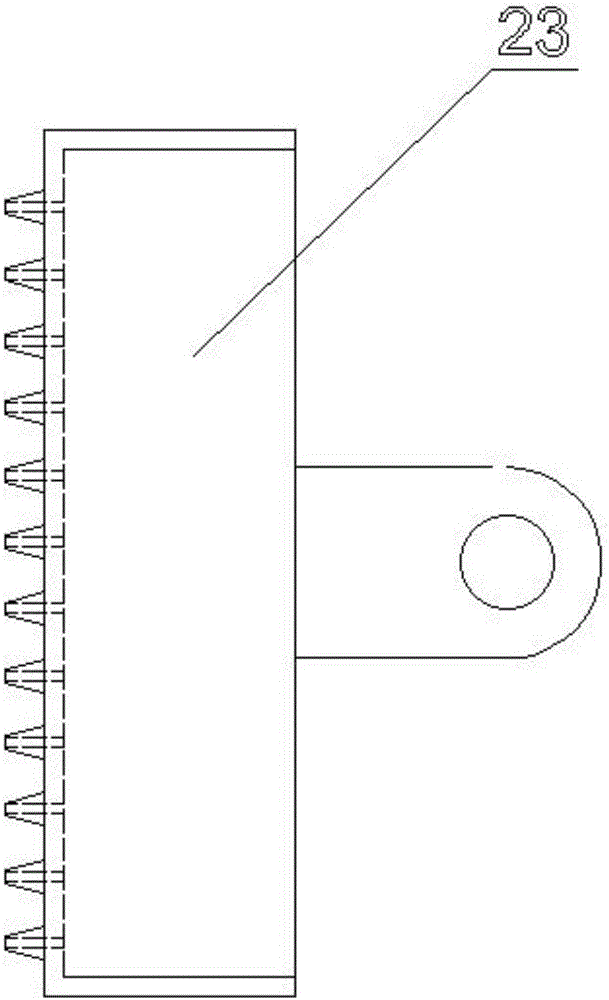

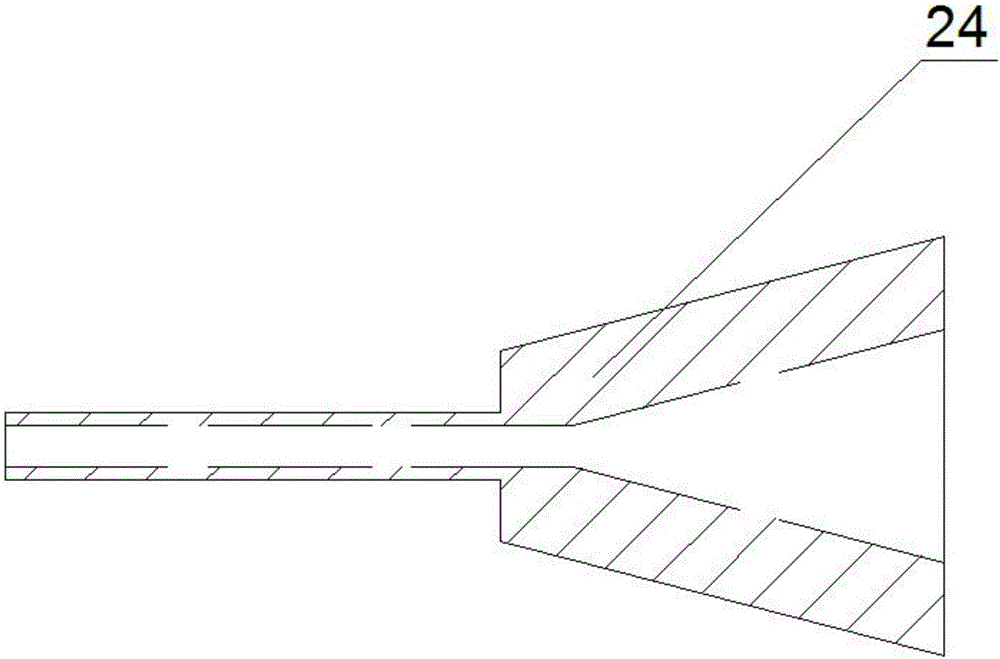

[0030] Such as Figure 1 to Figure 4 As shown, a rapid vertical plate washer for microporous reaction plates of the present invention includes a cleaning bucket 1 in which a centrifugal motor 2 is provided, and a centrifugal disk 3 is installed on the output shaft of the centrifugal motor 2 , The outer side wall of the centrifuge disk 3 is evenly provided with four microplate trays 5 for placing microwell reaction plates, and the four microplate trays 5 are distributed on the side wall of the centrifuge disk 3 in cross symmetry . The microplate tray 5 is provided with openings 51, and the size, number and spacing of the openings 51 correspond to the holes on the microporous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com