Patents

Literature

101 results about "Clean needles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

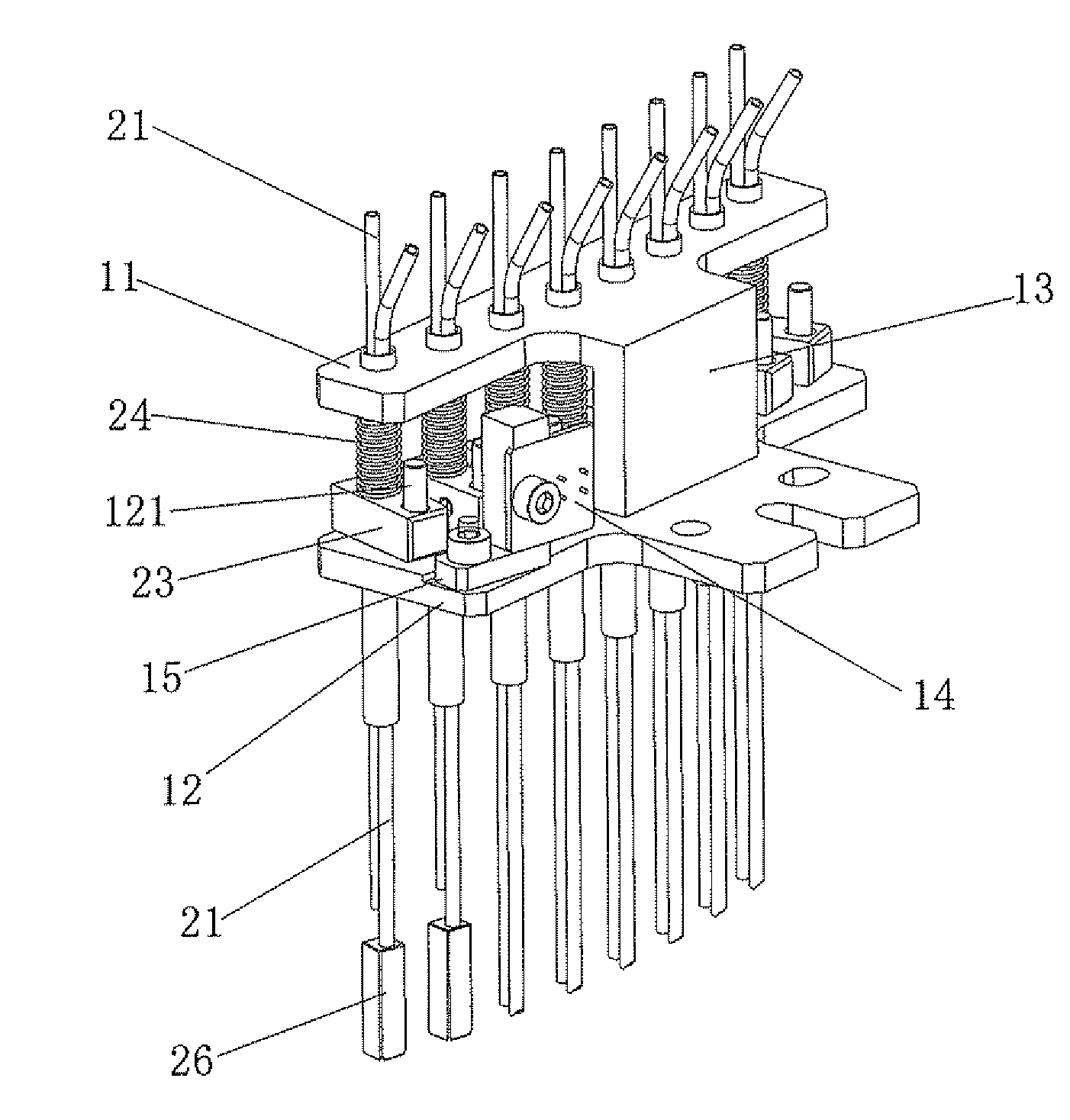

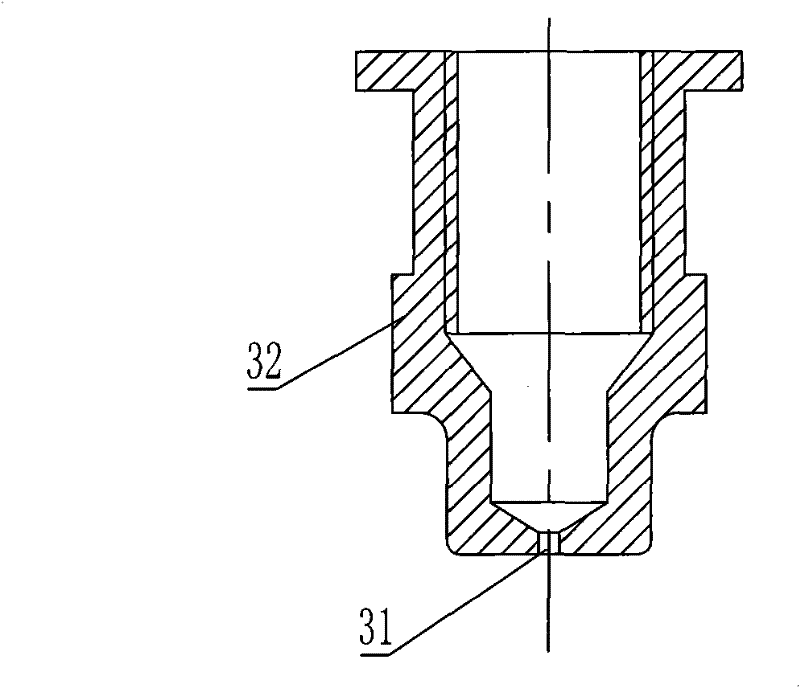

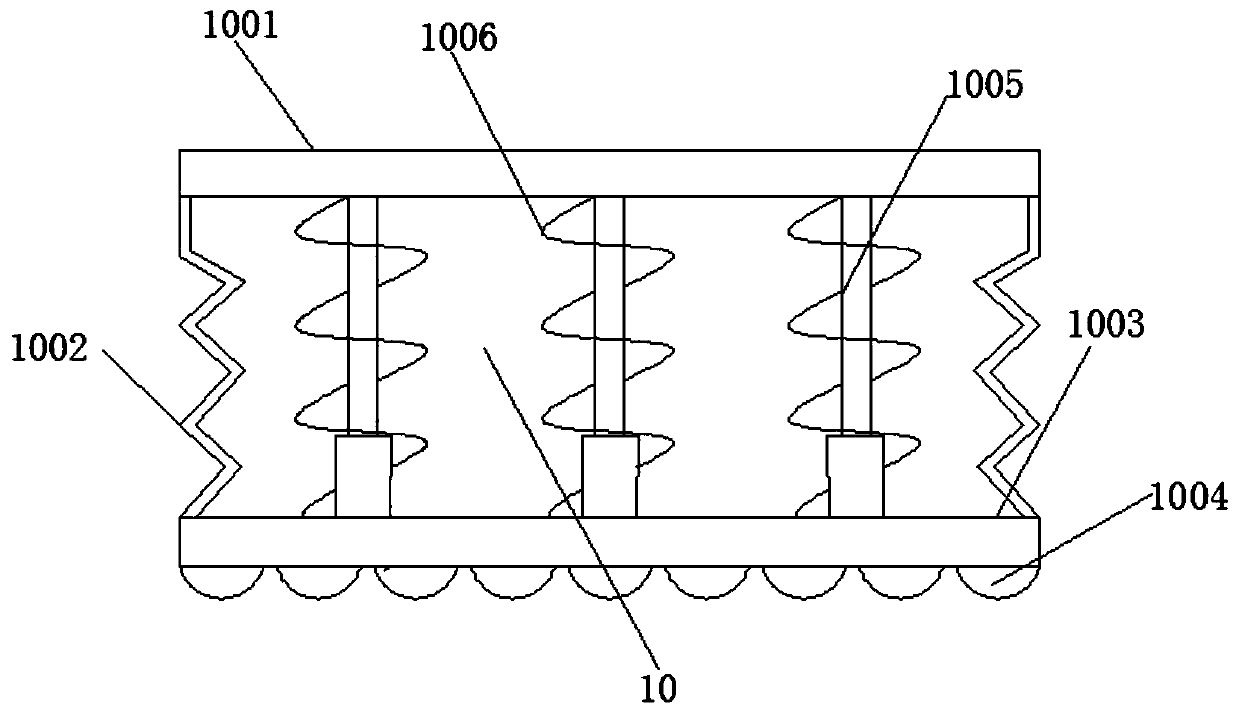

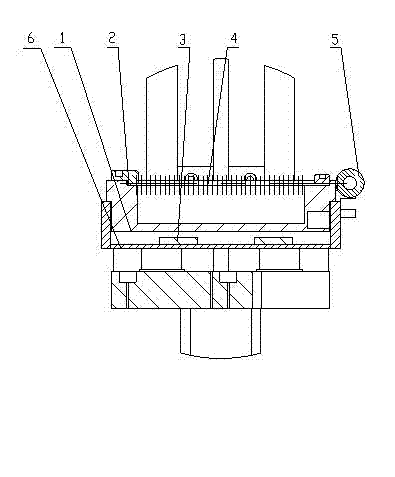

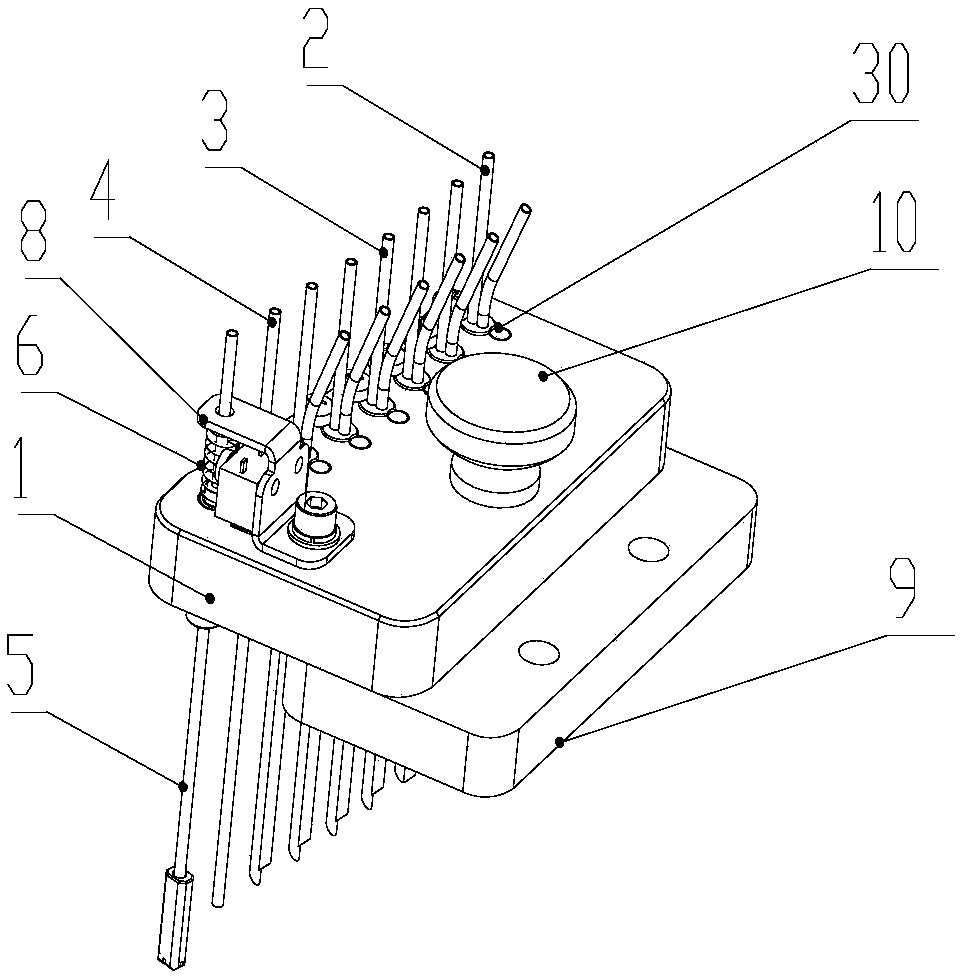

Reaction cuvette wash unit

InactiveUS20080101990A1Effective protectionSimple structureMaterial analysis by optical meansBurettes/pipettesCuvetteCleaning needle

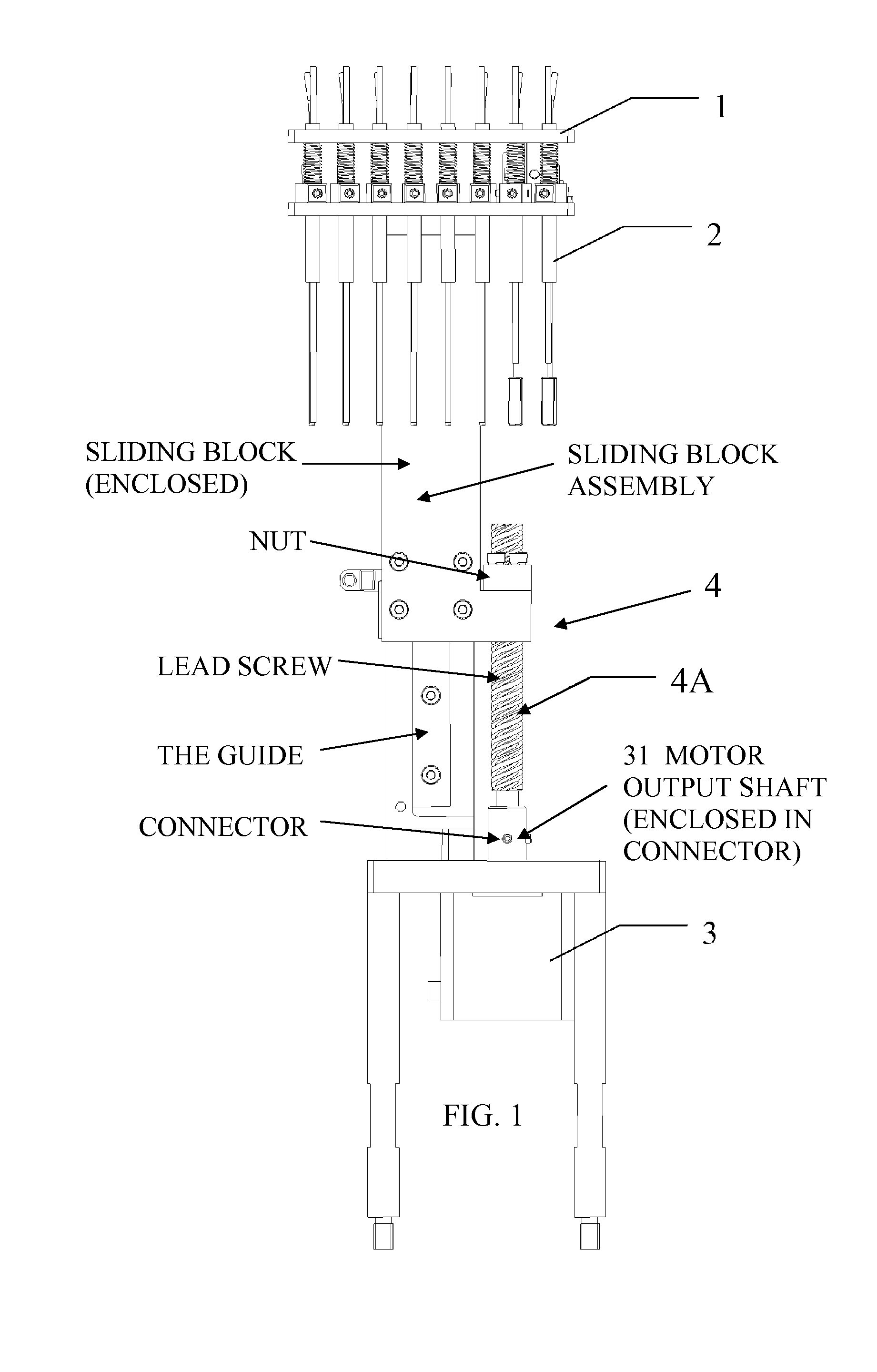

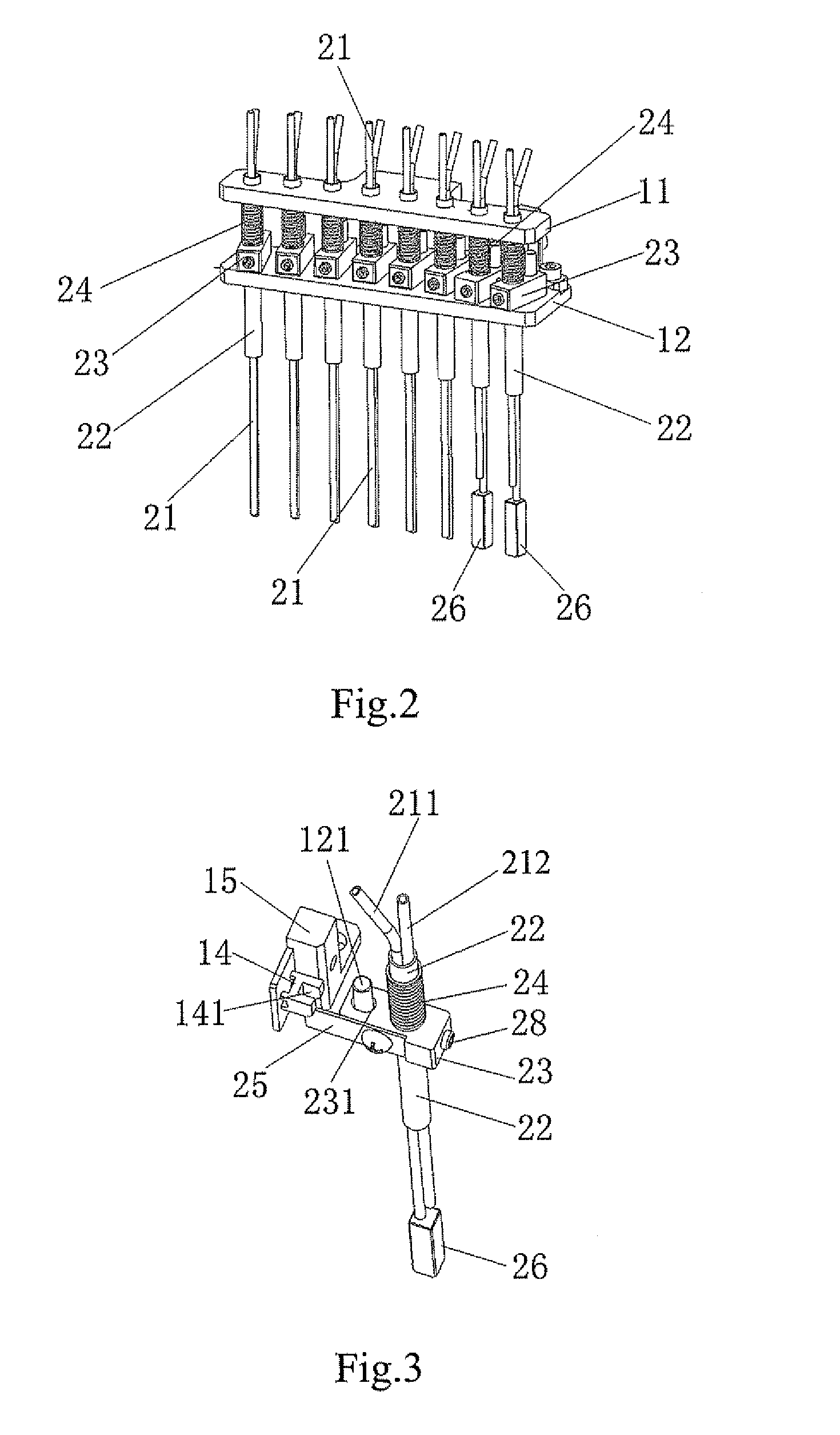

The invention discloses a reaction cuvette wash unit comprising a cleaning needle assembly, a straight guide pair, a slide screw pair, a motor, a trigger component associated with a cleaning needle of the cleaning needle assembly in a manner to move with that cleaning needles and a sensor used to sense the position of the trigger component. When the trigger component moves to a predetermined position, the sensor is triggered and sends a signal to a controller such that the controller controls in a manner to stop the motor. Each of cleaning needle components further comprises a sheath holder and an elastic member. The elastic member is designed to provide an elastic contact while the cleaning needles touch the bottom surface of the reaction cuvette, such that a relatively small force is exerted upon the bottom of the reaction cuvette, thereby effectively protecting the reaction cuvette from damage.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

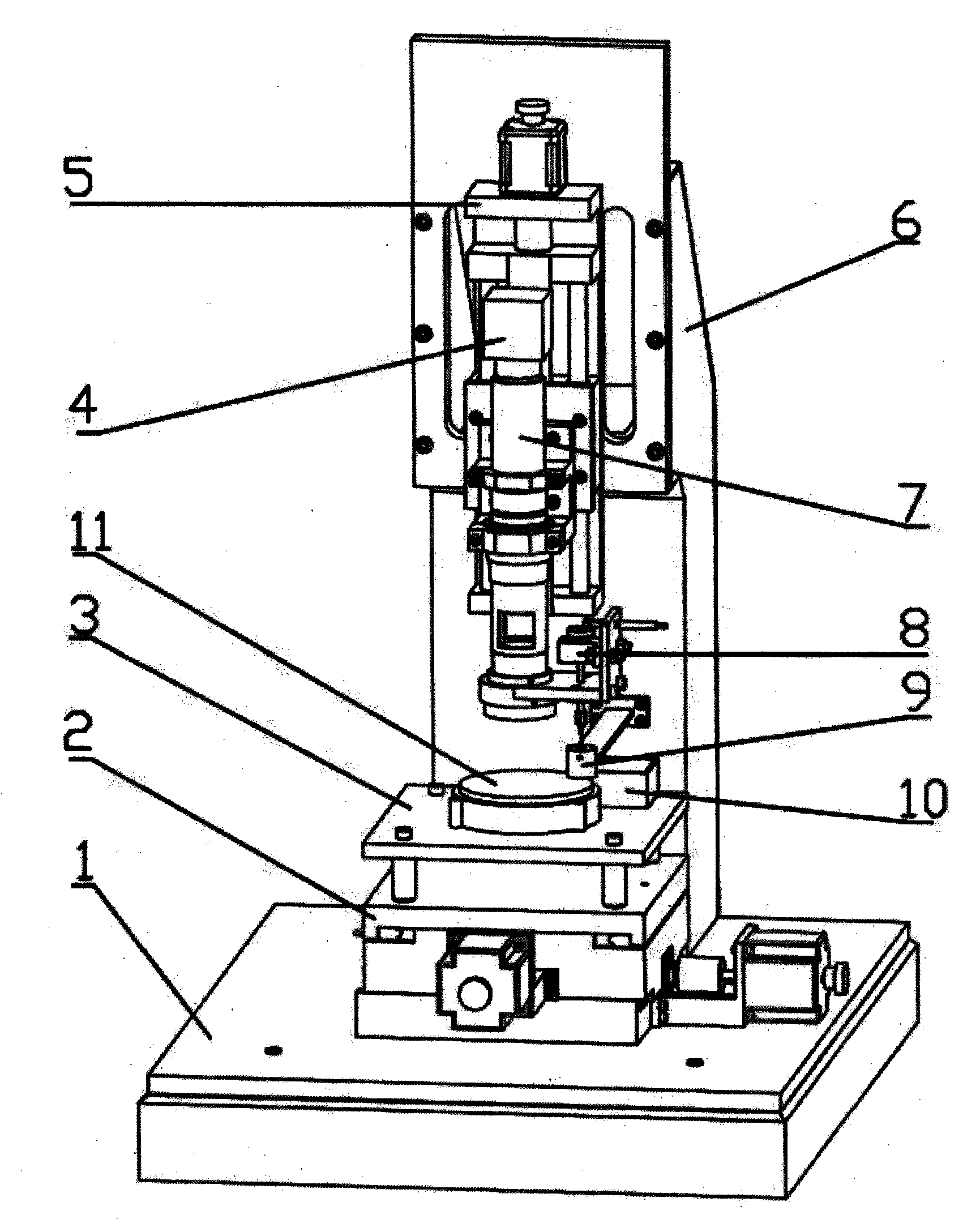

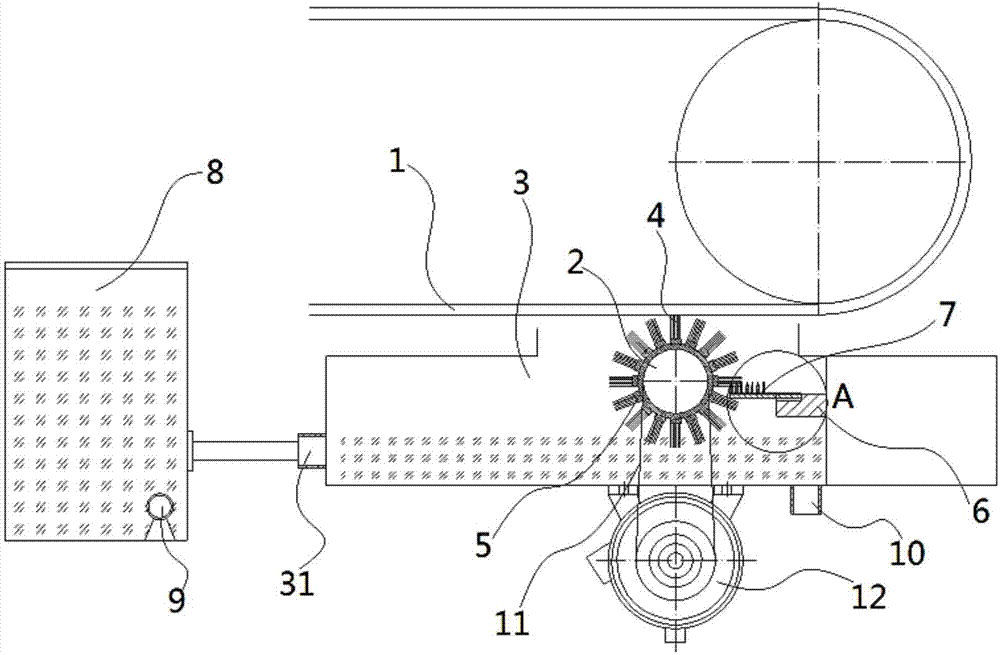

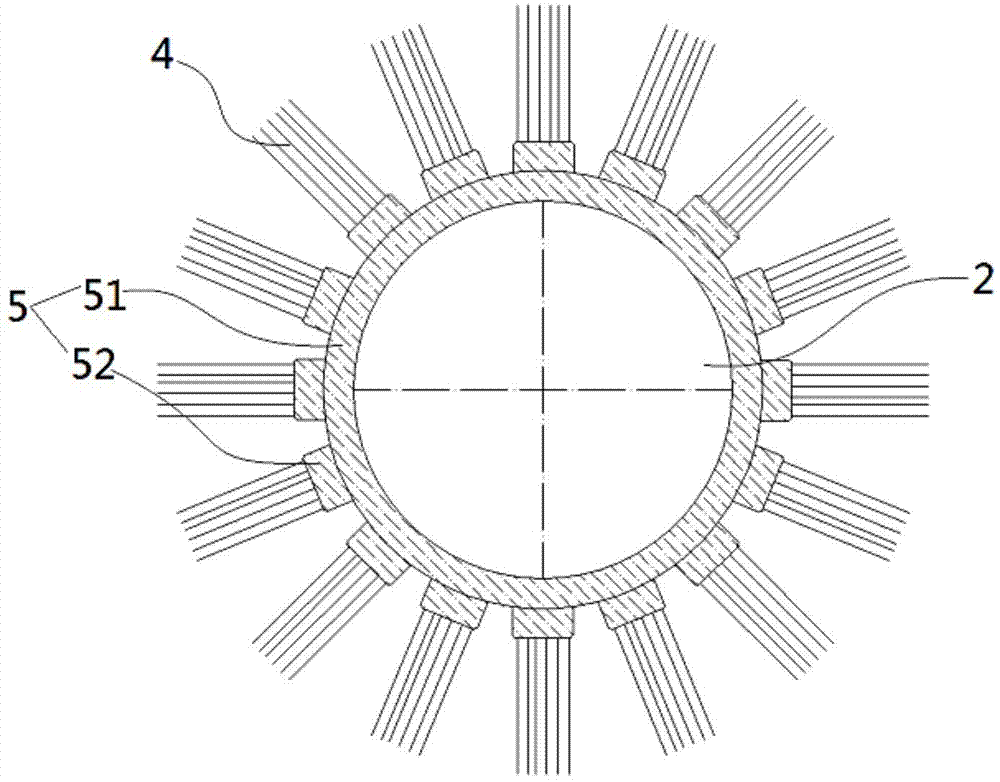

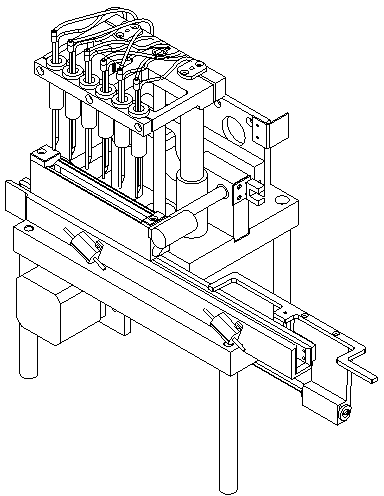

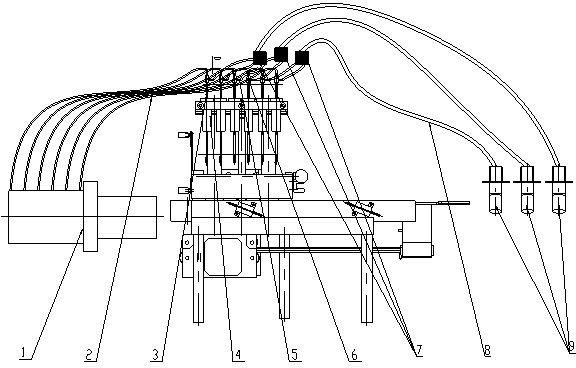

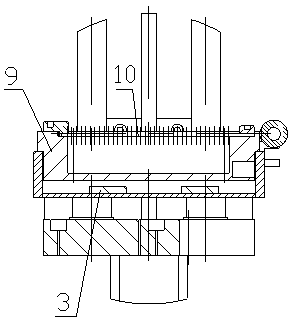

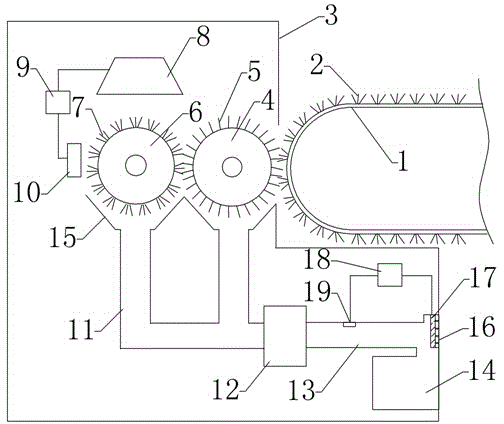

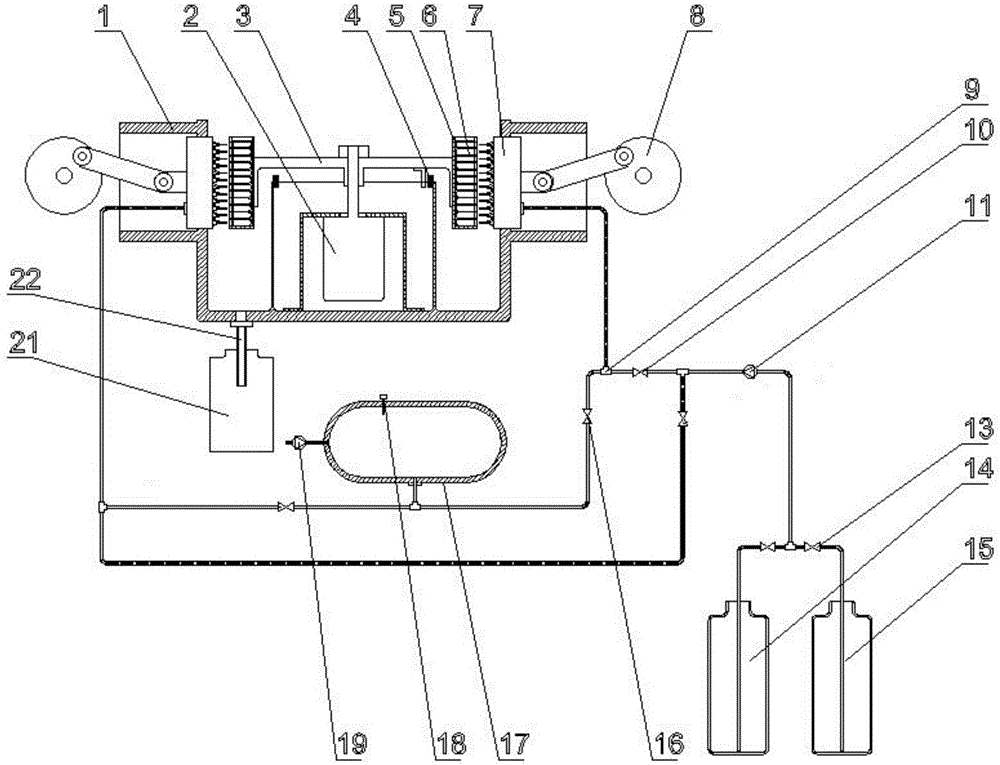

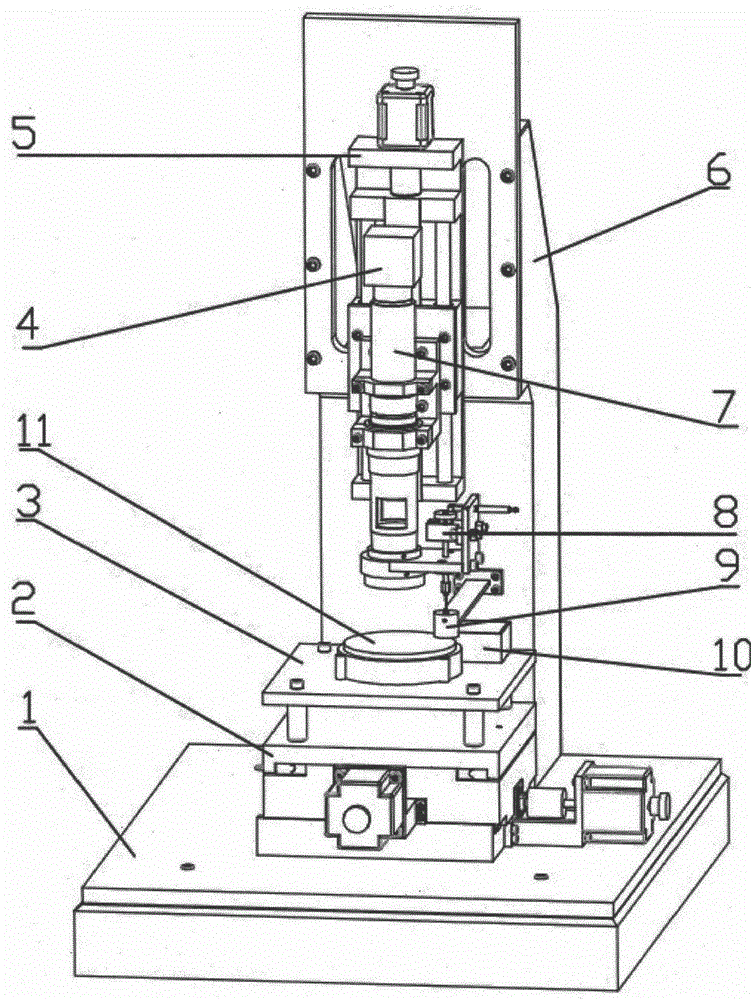

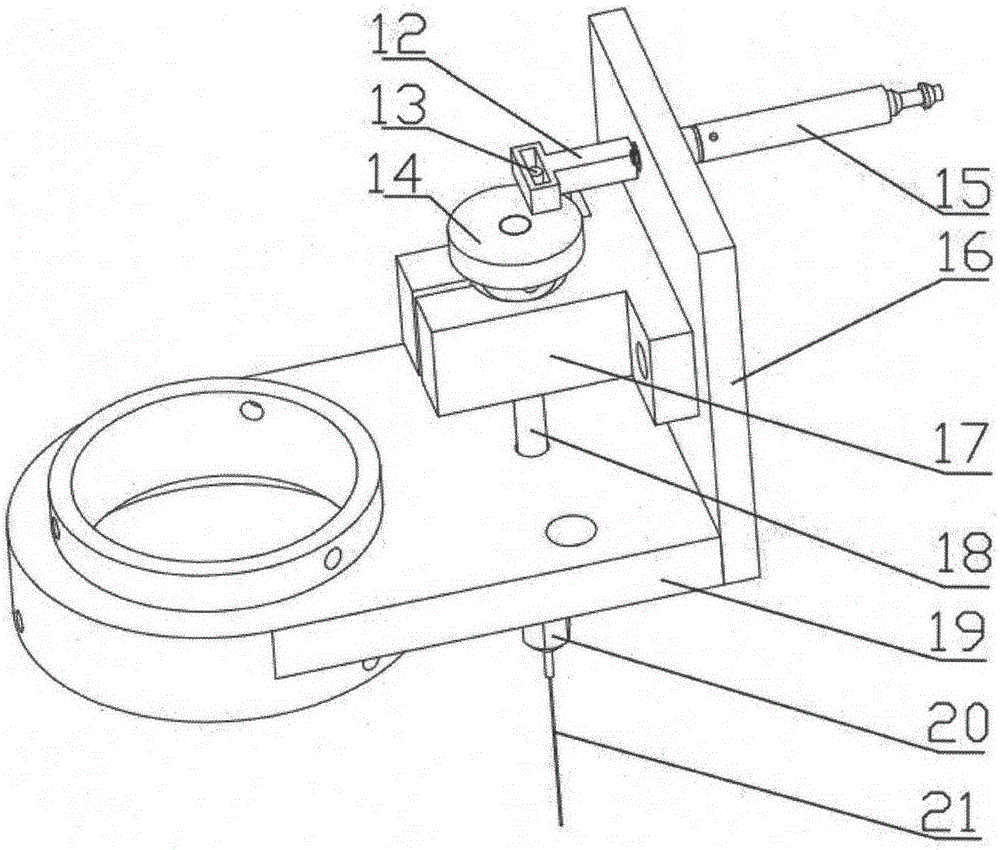

Fully-automatic cleaning device and method for spinneret plate micro-holes

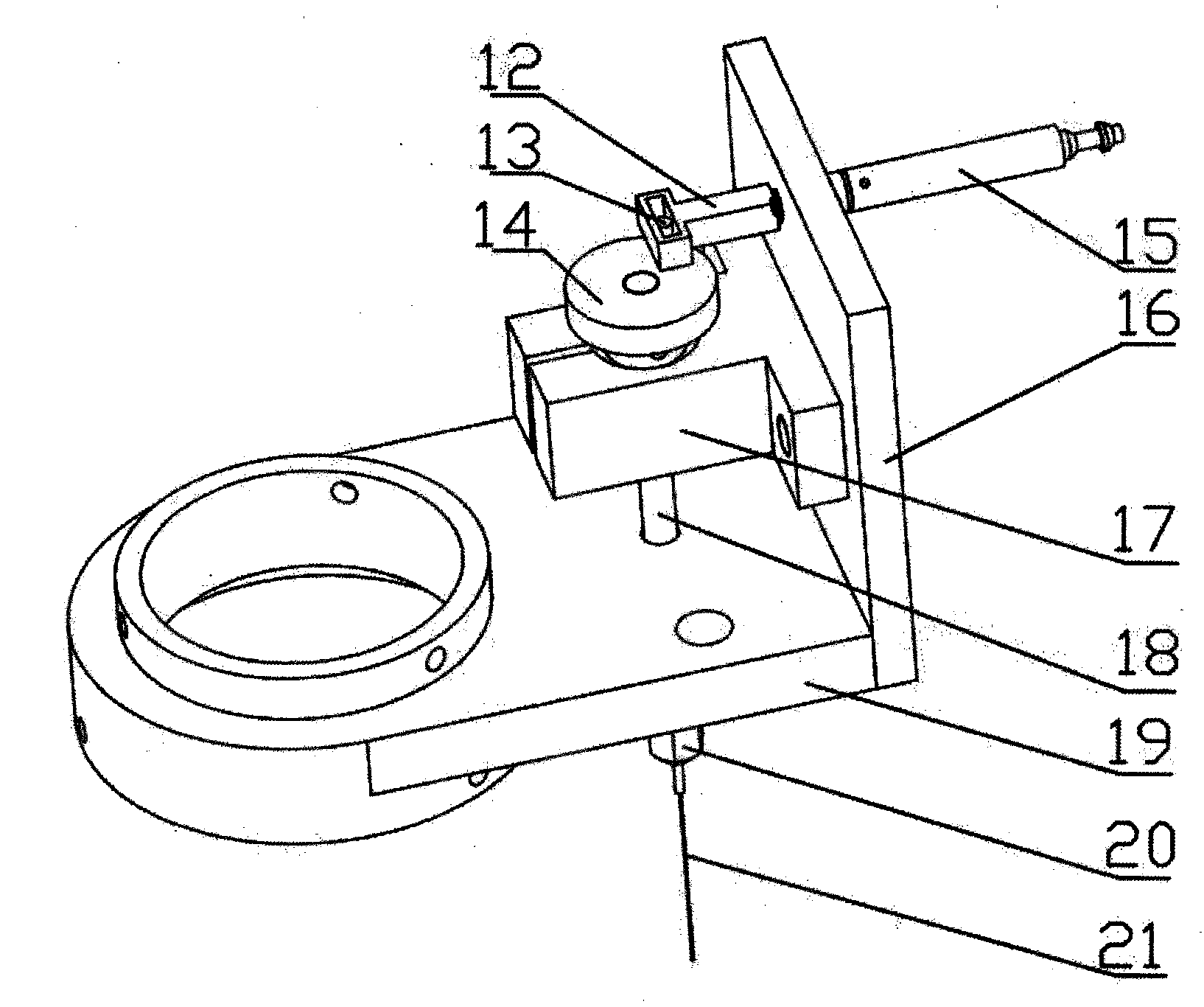

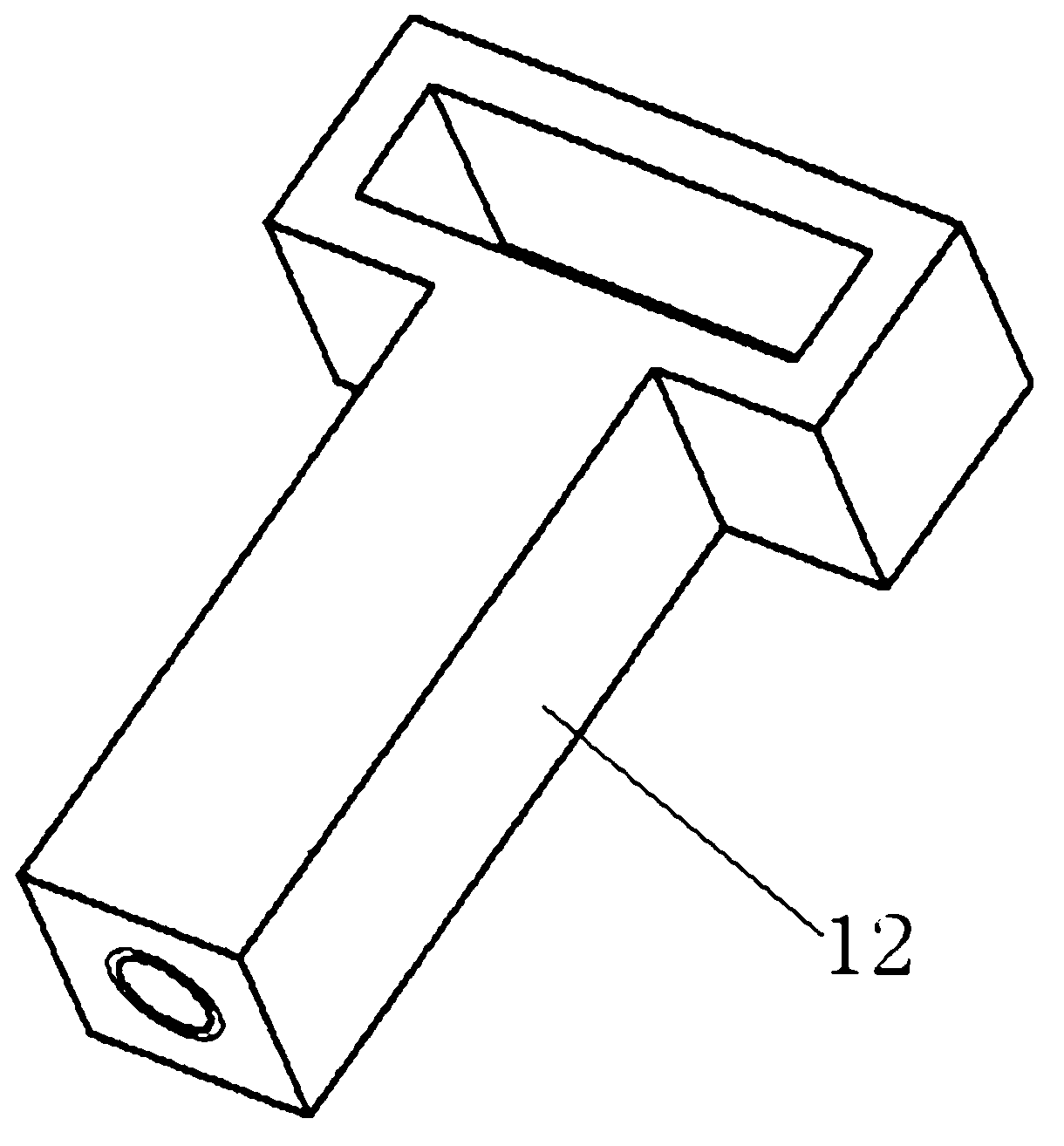

The invention relates to a fully-automatic cleaning device for spinneret plate micro-holes. The device is characterized in that an XY precision moving platform which can move forward, backward, left and right in a horizontal direction is arranged on a base; a spinneret plate clamp used for accommodating a to-be-checked spinneret plate is arranged on the XY precision moving platform; a supporting arm fixedly connected with the base is arranged on a side edge of the XY precision moving platform; a Z-axis precision electronic control stand is fixed on the supporting arm; the Z-axis precision electronic control stand drives a cleaning part to move up and down in a vertical direction; a cleaning needle is arranged at the bottom of the cleaning part; the cleaning part drives the cleaning needle to rotate around an axis of the cleaning part; and a standard guide hole is formed below the cleaning needle. Manual cleaning of original pinneret plate micro-holes can be replaced with the device, so that impurities of the spinneret plate micro-holes can be cleaned away automatically, the operation efficiency for spinneret plates in chemical fiber production can be substantially increased, and at the same time, the production efficiency of an enterprise can be substantially improved.

Owner:DONGHUA UNIV

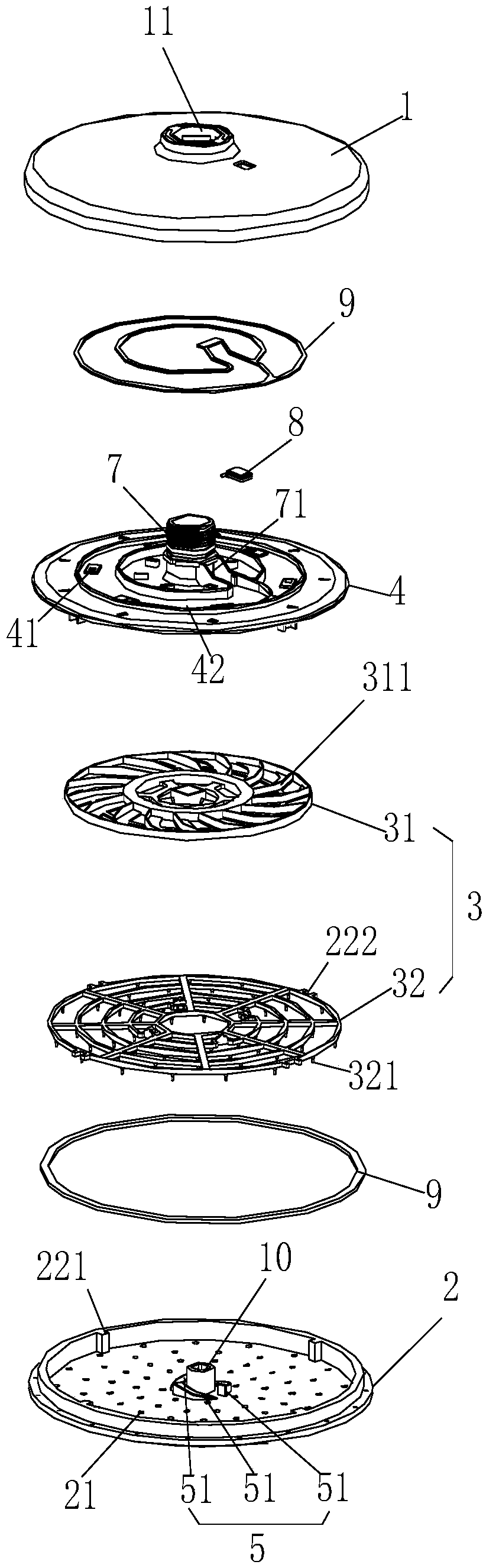

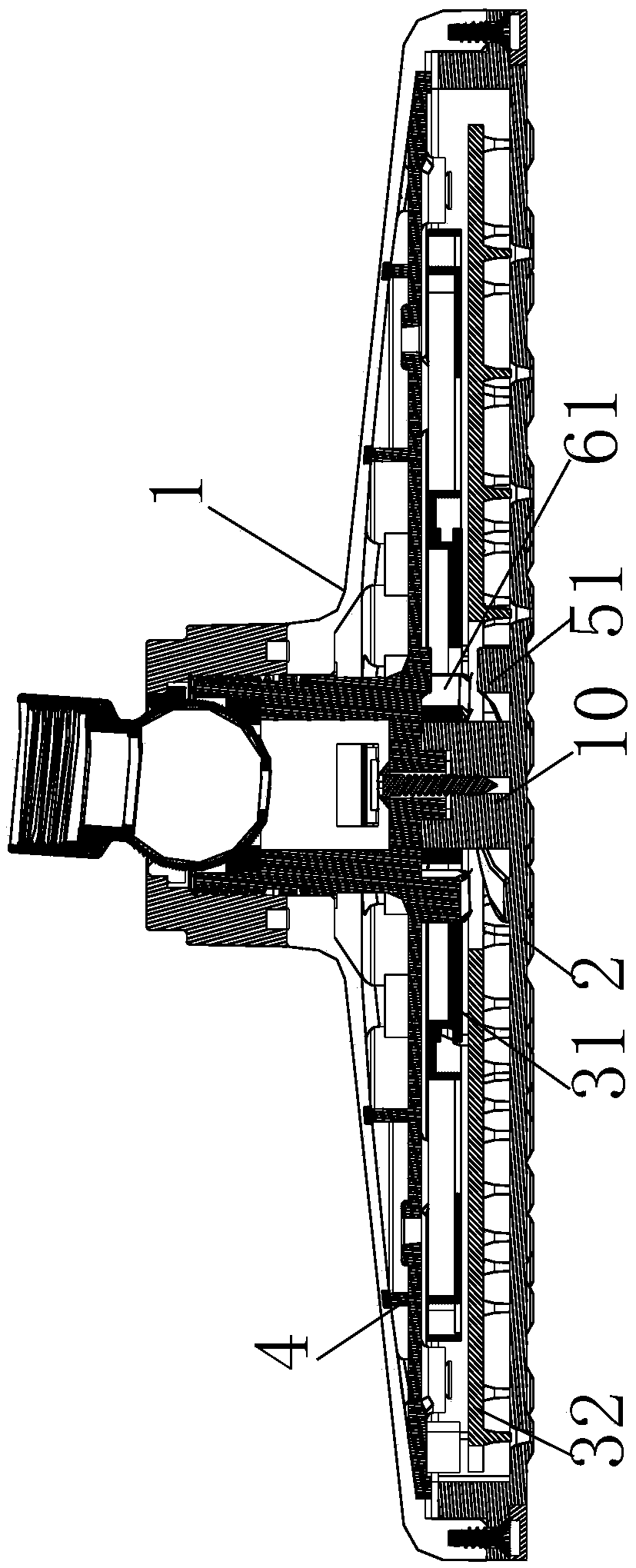

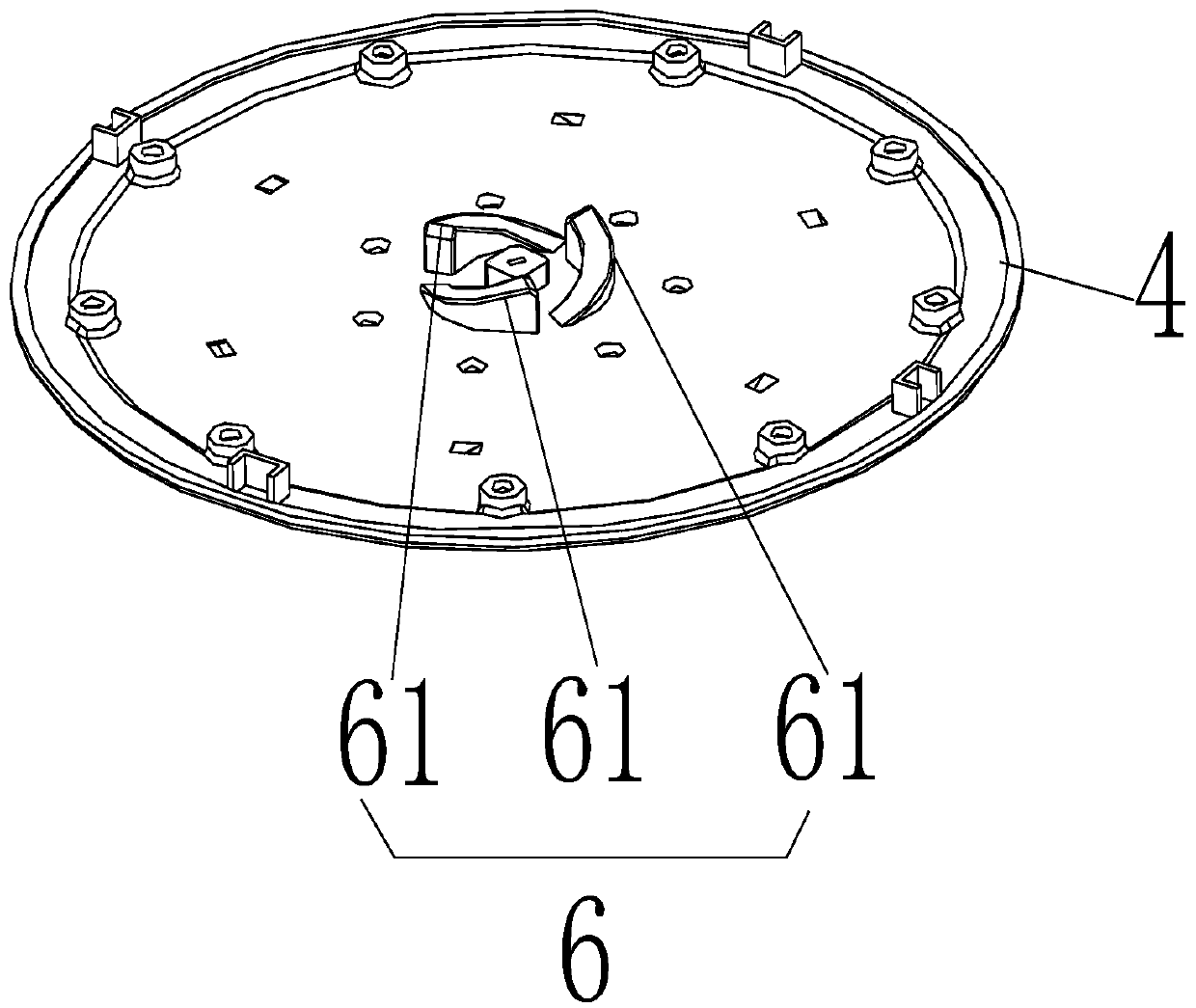

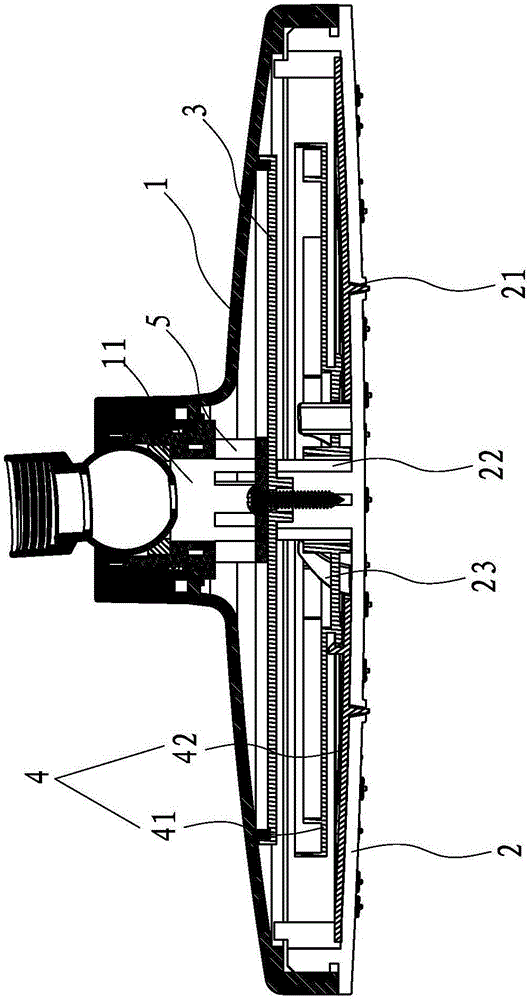

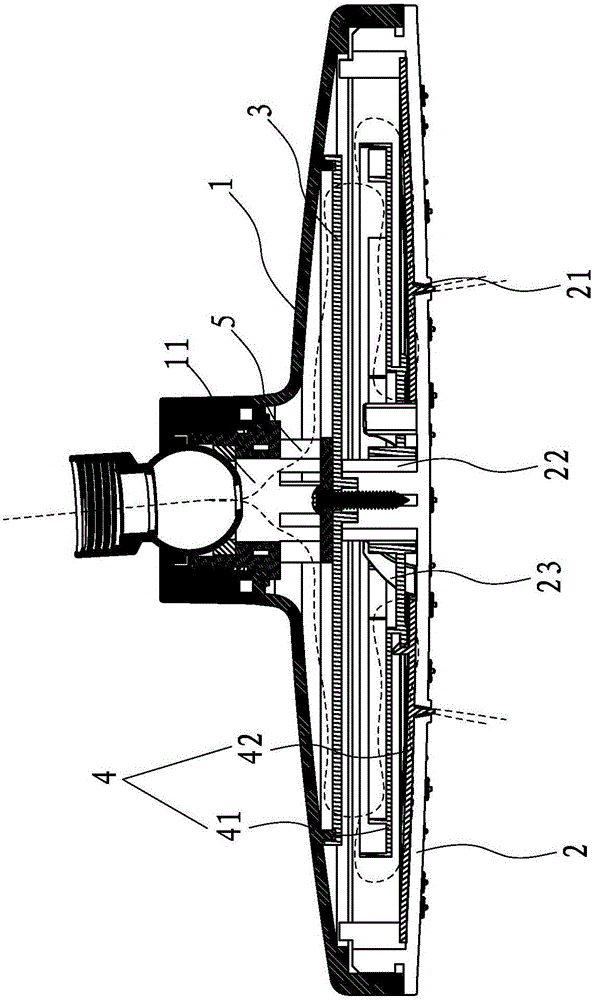

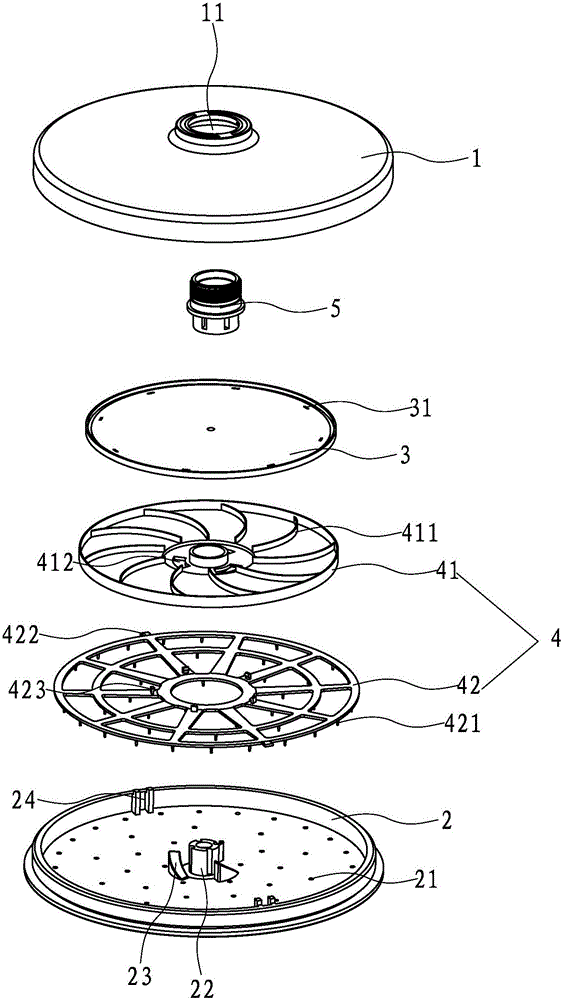

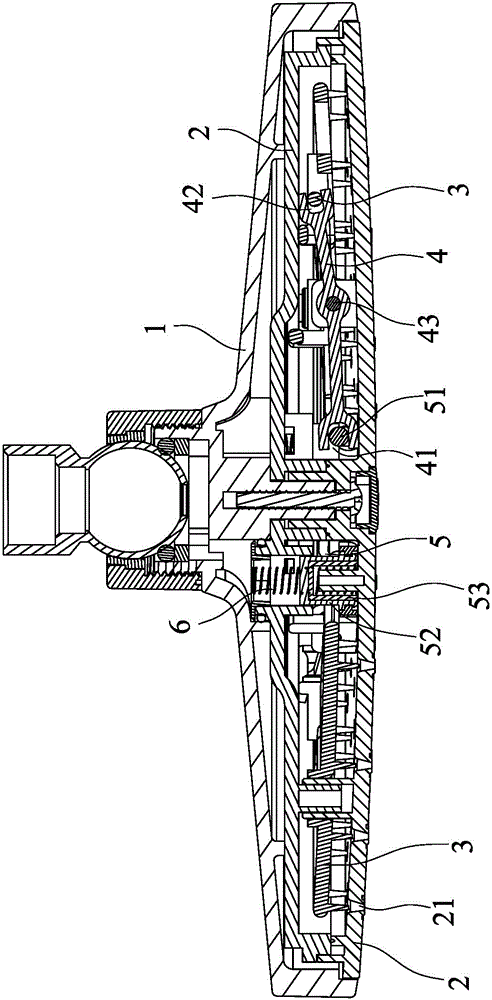

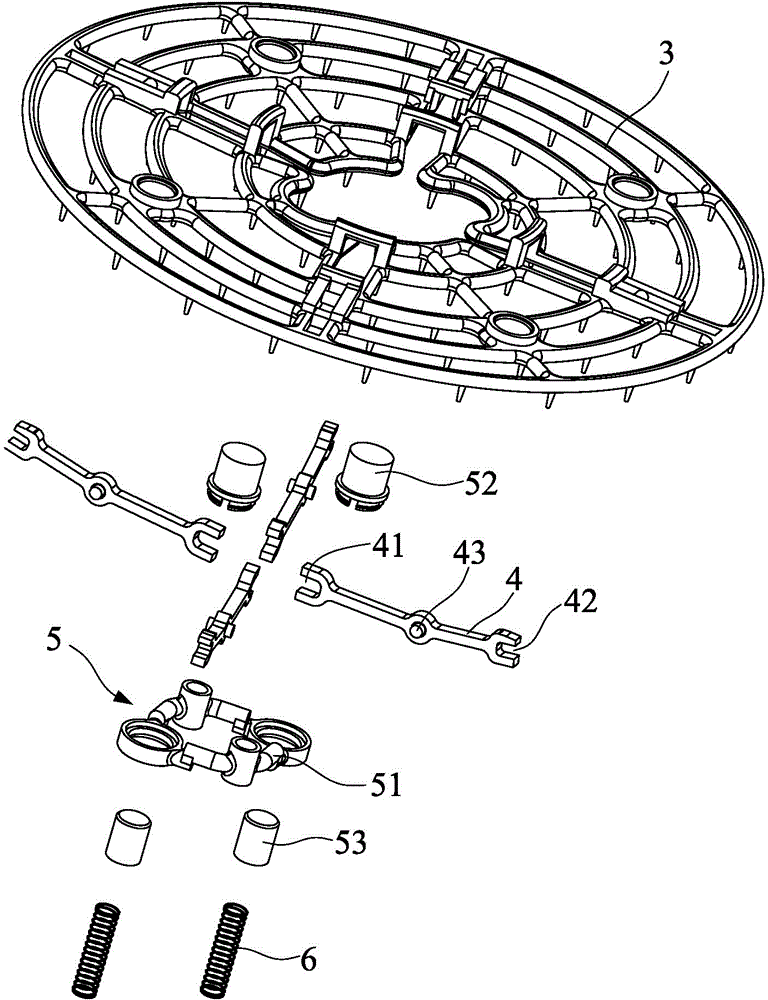

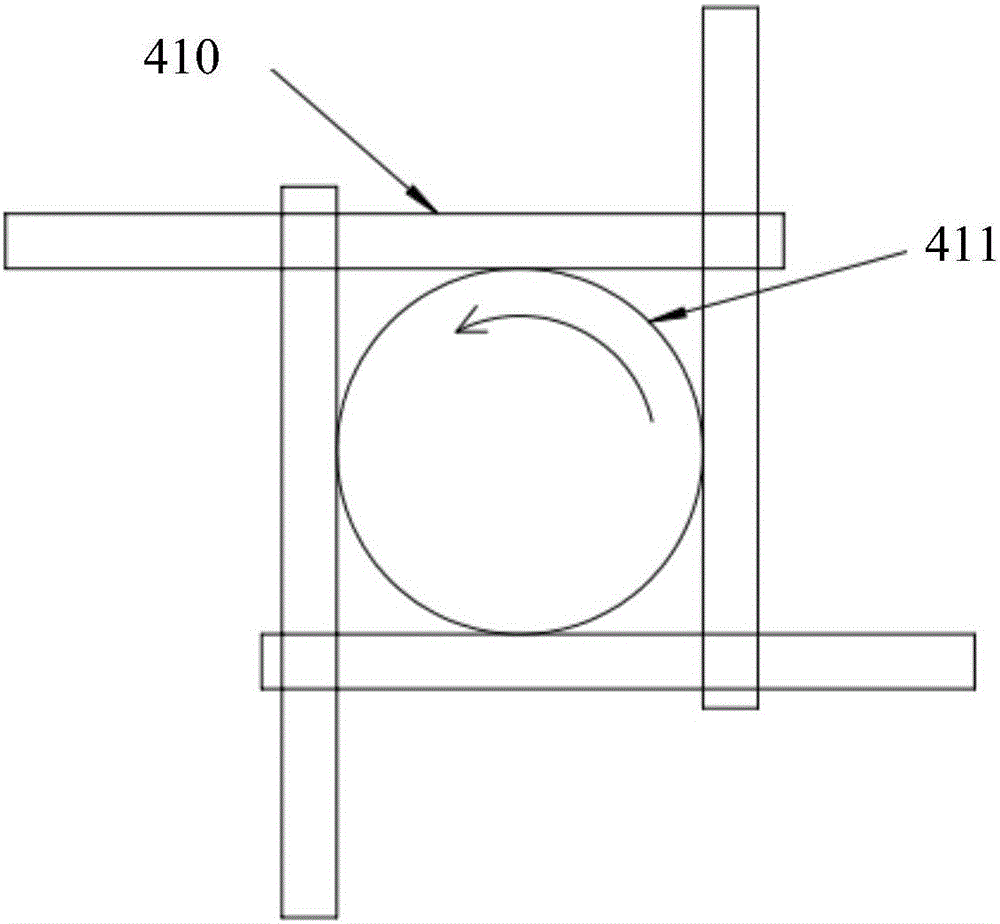

Dynamic cleaning water outlet device

ActiveCN105498994AMeet the design requirementsSmall water pressure lossSpray nozzlesCleaning needleEngineering

The invention discloses a dynamic cleaning water outlet device which comprises a body and a water outlet panel arranged on the body. A containing cavity is formed between the body and the water outlet panel, a water inclining body and a cleaning needle plate are installed in the containing cavity in sequence from top to bottom; a rotating shaft is arranged on the water inclining body and / or the water outlet panel; the cleaning needle plate comprises a rotary disc and a needle plate body, and the rotary disc has a fan blade structure; guiding holes are formed in the water inclining body; a limiting device is further arranged in the containing cavity; a first guiding mechanism which is used for making the horizontal height of the water outlet panel increased when the rotary disc rotates is arranged on the water outlet panel, a second guiding mechanism which is used for making the horizontal height of the water inclining body decreased when the rotary rotates is arranged on the end face, corresponding to the first guiding mechanism, of the water inclining body, and the cleaning needle plate can move up and down along the rotating shaft under the acting force of water pressure. When the dynamic cleaning water outlet device is adopted for a shower and the water way is opened, cleaning needles can move up and down continuously, dynamic cleaning during the shower is achieved, and the dynamic cleaning water outlet device has the advantage of being good in cleaning effect.

Owner:XIAMEN SHUIDA SANITARY WARE

Self-cleaning top-spraying device

ActiveCN105149122AGuaranteed cleanlinessAvoid enteringSpray nozzlesCleaning needleBiochemical engineering

The invention relates to the technical field of top-spraying sprinklers, particularly to a self-cleaning top-spraying device. The device comprises a body, a water outlet panel and a cleaning needle disk, wherein the water outlet panel is arranged on the body; a water inlet is formed in the body; water outlet holes are formed in the water outlet panel; a rotating shaft is arranged on the water outlet panel; the cleaning needle disk comprises a rotating disk and a needle disk; the rotating shaft is sleeved with the rotating disk rotatably; the needle disk is clamped below the rotating shaft and can move relative to the rotating disk; cleaning needles corresponding to the water outlet holes are arranged on the needle disk; a fan blade structure which drives the rotating disk to rotate under current scour is arranged on the rotating disk; a spiral lifting platform which is used for increasing the horizontal height of the rotating disk when the rotating disk rotates is arranged on the water outlet panel; and a limiting device which limits the rotating of the needle disk and doesn't limit up-and-down motion of the needle disk is arranged on the water outlet panel. The self-cleaning top-spraying device solves the problem of the service life of an existing return spring and makes the whole structure simple; and lifting and dropping of the cleaning needles is realized through opening and closing of water currents, so that self-cleaning after a shower each time is realized.

Owner:XIAMEN SHUIDA SANITARY WARE

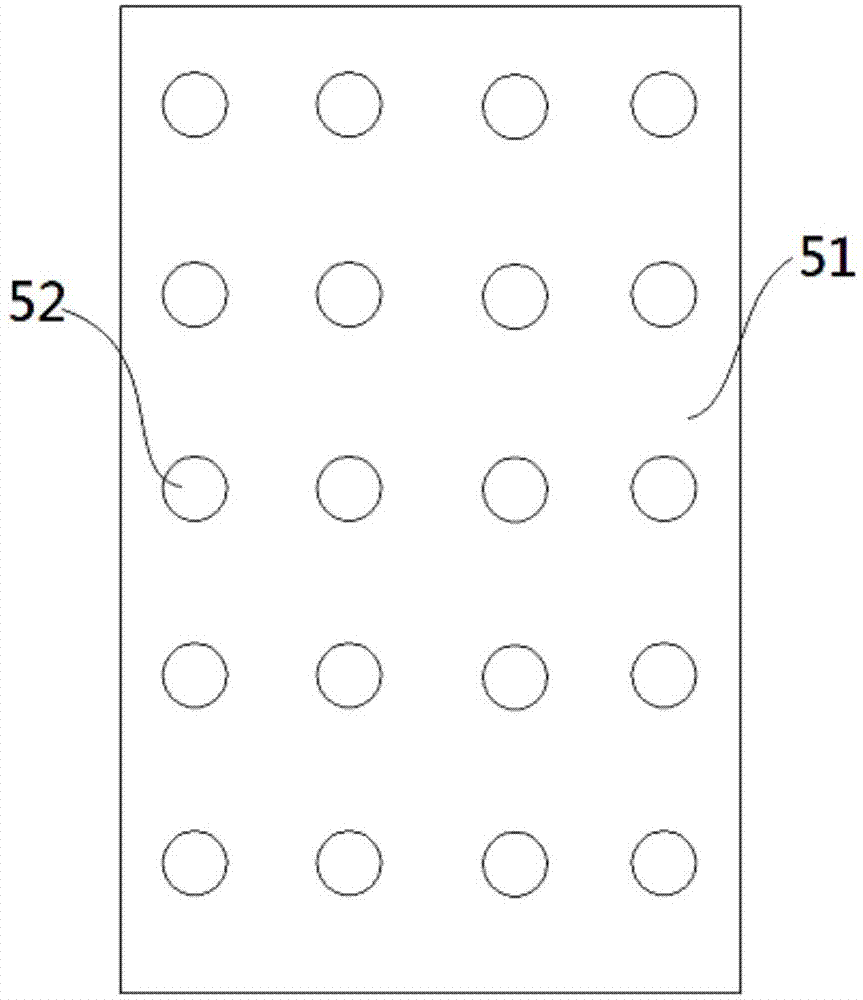

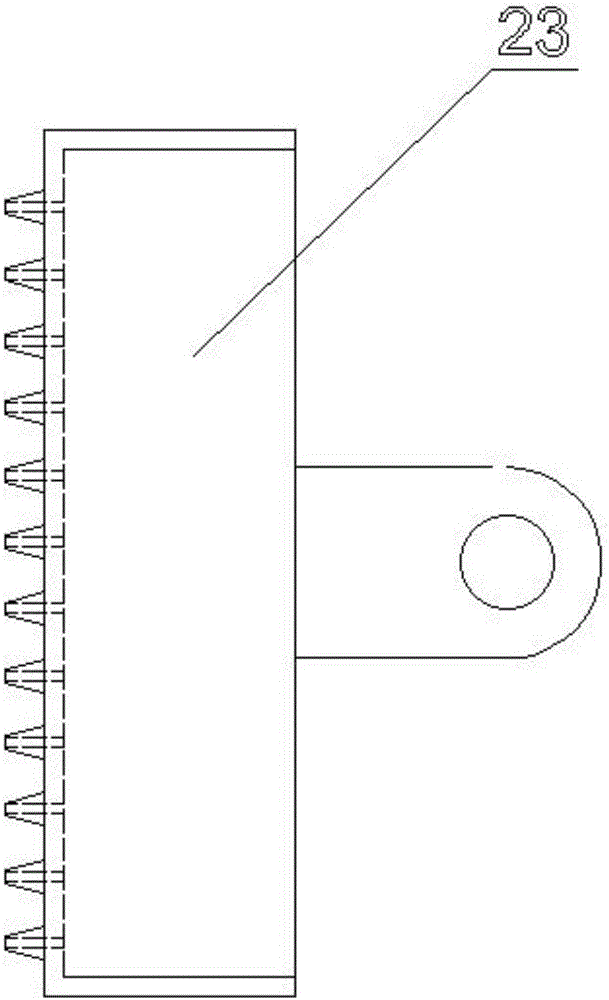

Vibration screen provided with lifting type hole cleaning needle plate

InactiveCN107744941AAvoid affecting the work processTimely processingSievingScreeningCleaning needleEngineering

The invention discloses a vibration screen provided with a lifting type hole cleaning needle plate. The vibration screen comprises a screen frame, a screen box, a screen plate, a vibration motor and the hole cleaning needle plate. The screen box is arranged at the upper end of the screen frame. Damping springs are connected between the screen frame and the screen box. The screen plate is arrangedin the screen box. The vibration motor is arranged at the lower end of the screen box. A cover plate is laid at the upper end of the screen box. Two telescopic rods are vertically and symmetrically arranged on the two sides of the lower end of the cover plate, and the hole cleaning needle plate is connected between the lower ends of the two telescopic rods. The hole cleaning needle plate is arranged above the screen plate. The hole cleaning needle plate comprises a base plate which is horizontally arranged and a plurality of hole cleaning needles vertically arranged on the lower end face of the base plate. The multiple hole cleaning needles correspond to a plurality of circular screen holes in the screen plate in an up-down manner. By means of the above manner, the hole cleaning needle plate can be used for dredging the screen holes when the screen holes of the screen plate are blocked, and the screening work progress can be prevented from being influenced.

Owner:WUXI YUNENG COAL DRESSING MACHINERY PLANT

Top-jetting cleaning device

InactiveCN104307673AAuto clearRealize self-cleaning functionSpraying apparatusCleaning needleEngineering

The invention discloses a top-jetting cleaning device. The top-jetting cleaning device comprises a body, a water discharge panel, a cleaning needle, a lever and a lever driving mechanism, wherein the water discharge panel and the body are buckled into an accommodating cavity; the cleaning needle, the lever and the lever driving mechanism are arranged in the accommodating cavity; the water discharge panel is provided with a water discharge hole; the cleaning needle is arranged movably relative to the water discharge panel, and corresponds to the water discharge hole; the force applying end of the lever is connected with the lever driving mechanism; the stressed end of the lever is connected with the cleaning needle; the lever driving mechanism is provided with a reset spring; the lever driving mechanism is used for driving the lever to swing; the stressed end of the lever is used for driving the cleaning needle to be separated from or be inserted into the water discharge hole. By adopting the top-jetting cleaning device, dirt in a water discharge nozzle can be cleaned automatically, and a good cleaning effect is achieved.

Owner:XIAMEN KEEKOE SANITARY WARE

Multifunctional automatic sample injector

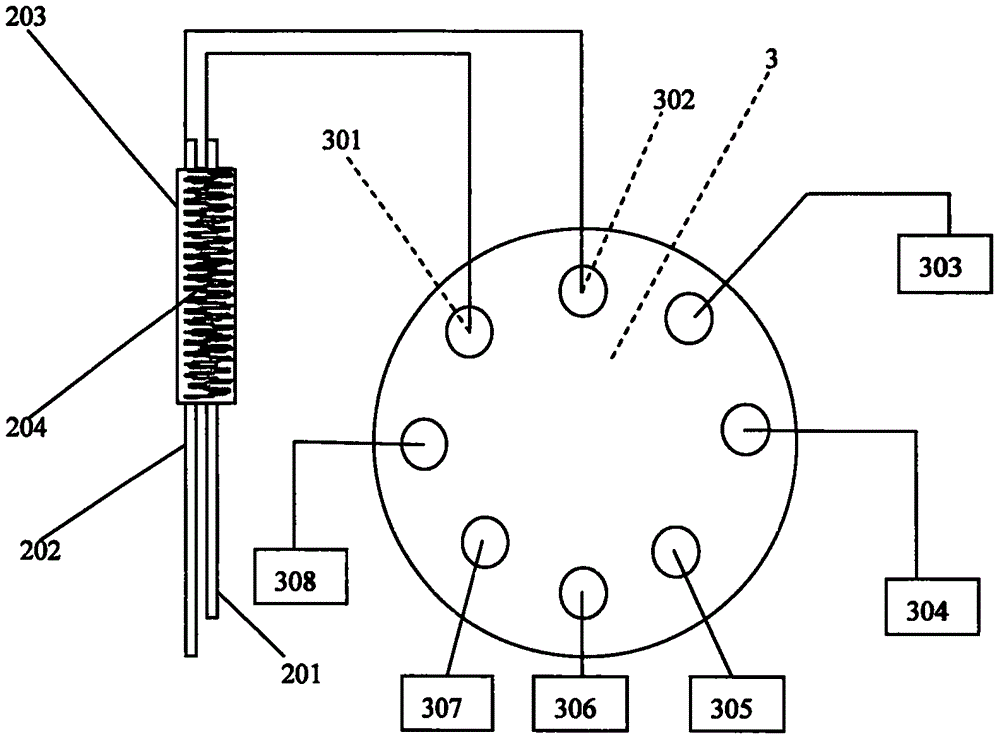

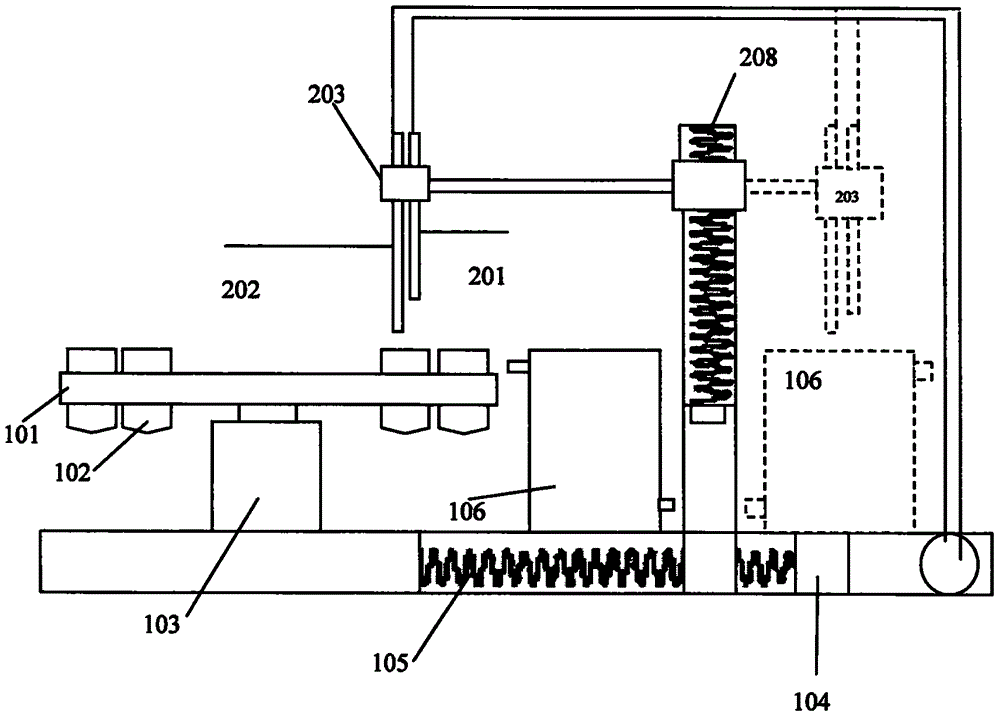

A kind of multifunctional autosampler, it is characterized in that, mainly comprises 101-sample tray (horizontal rotor); 102-sample vial; 103-sample tray driving motor; 104-driving motor; 105-leading screw; 106-cleaning liquid 107‑base; 201‑sampling needle; 202‑washing needle; 203‑slider; 204‑spring; valve; 301-port of multiport valve and 201 injection needle; 302‑port of multiport valve and 202 cleaning needle; 303‑test water in line with laboratory use; 304‑cleaning solution bucket (bottle) (such as acid solution or Alkaline solution); 305-Reagent barrel (bottle); 306-Waste liquid barrel (bottle); 307-Mixed reactor; 308-Standard solution barrel (bottle). It can be used for automatic sampling in the determination of seawater, high-chloride and high-salt wastewater, surface water, groundwater, drinking water, domestic sewage, and industrial wastewater; it can be used for automatic sampling in laboratory determination, online determination, and emergency portable on-site determination.

Owner:张开航

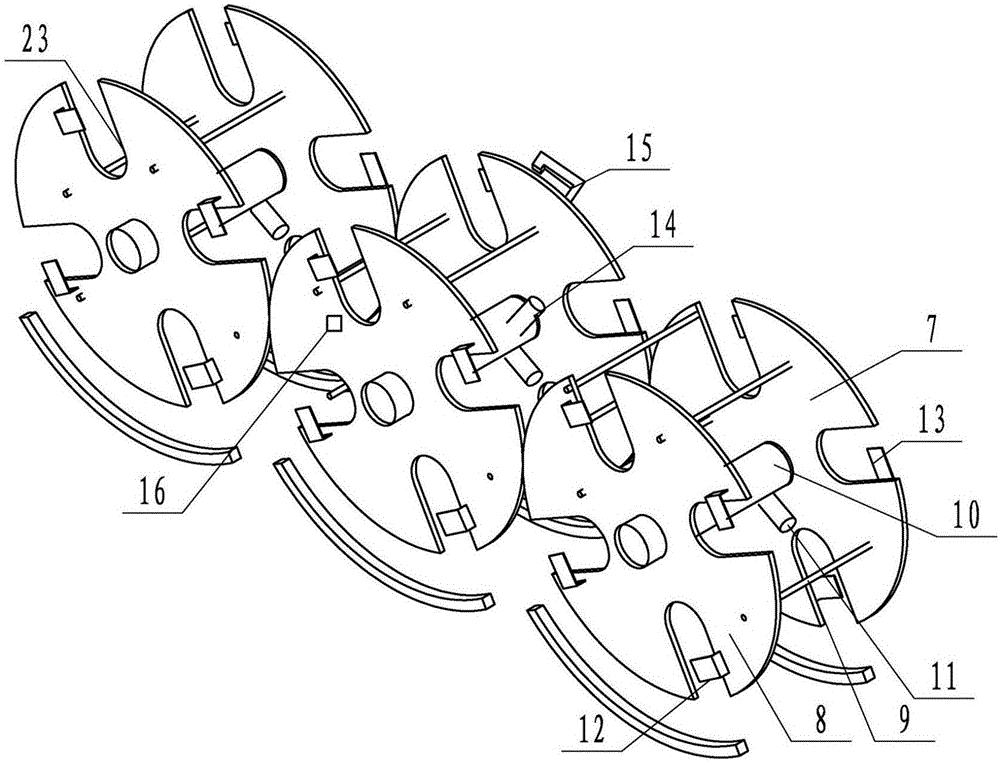

Magnetism separating device

ActiveCN104722526AGuaranteed adsorption areaGuaranteed adsorption timeBiological testingCleaning using liquidsCleaning needleEngineering

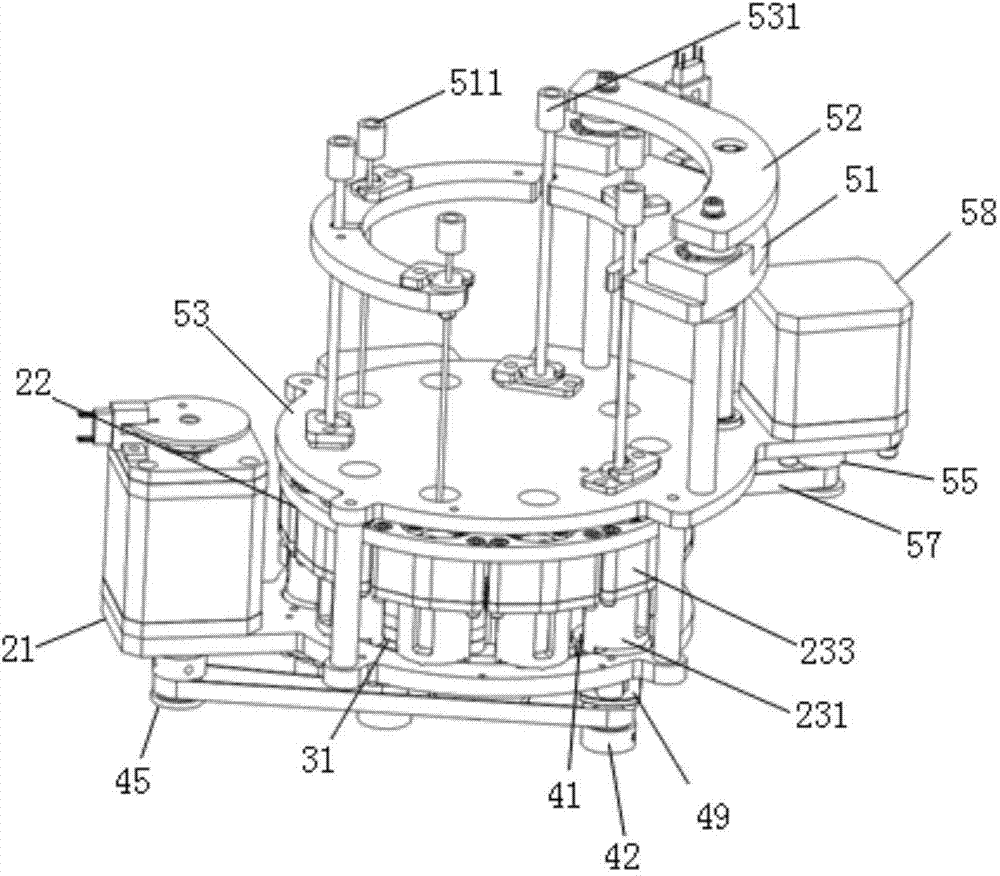

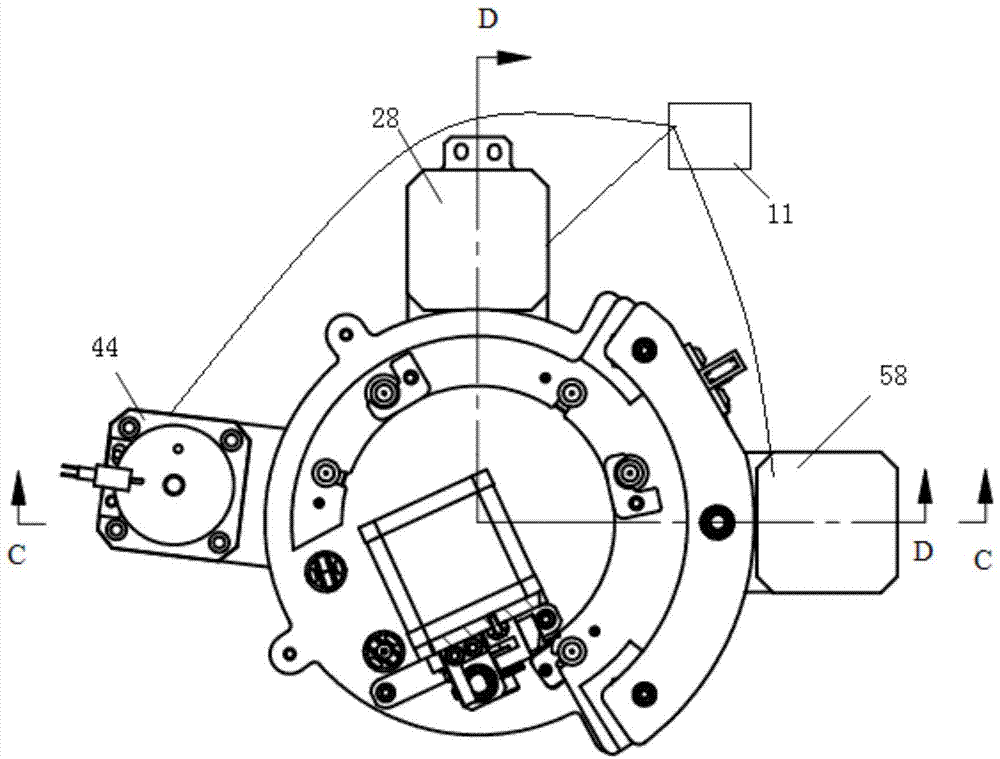

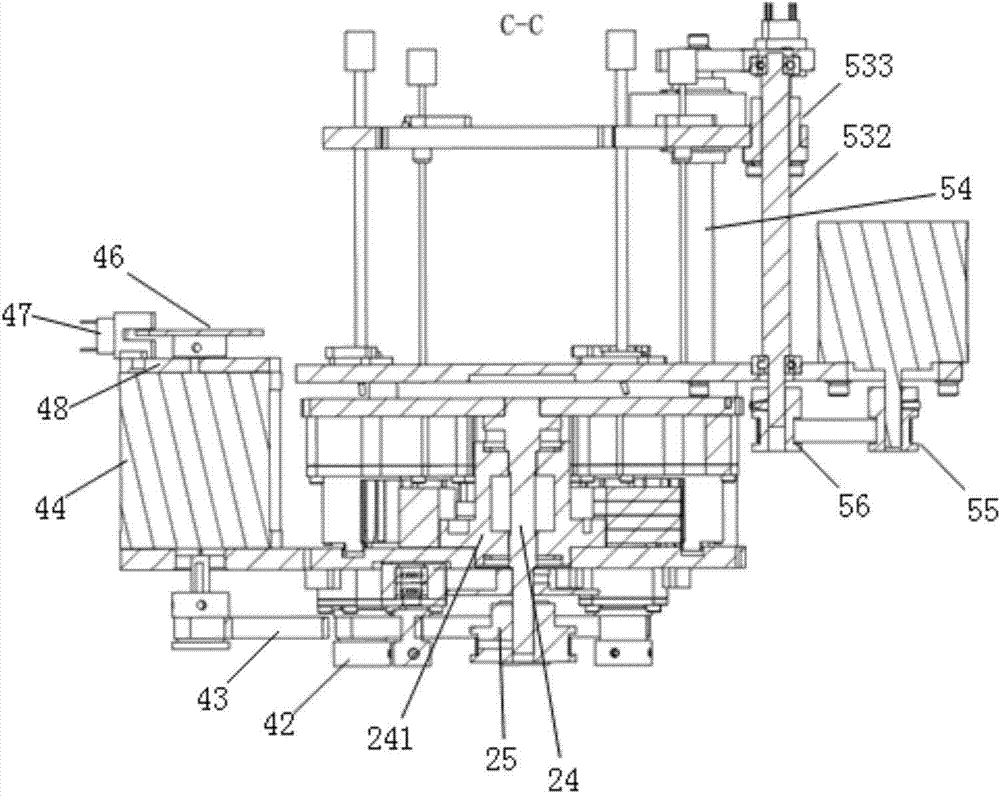

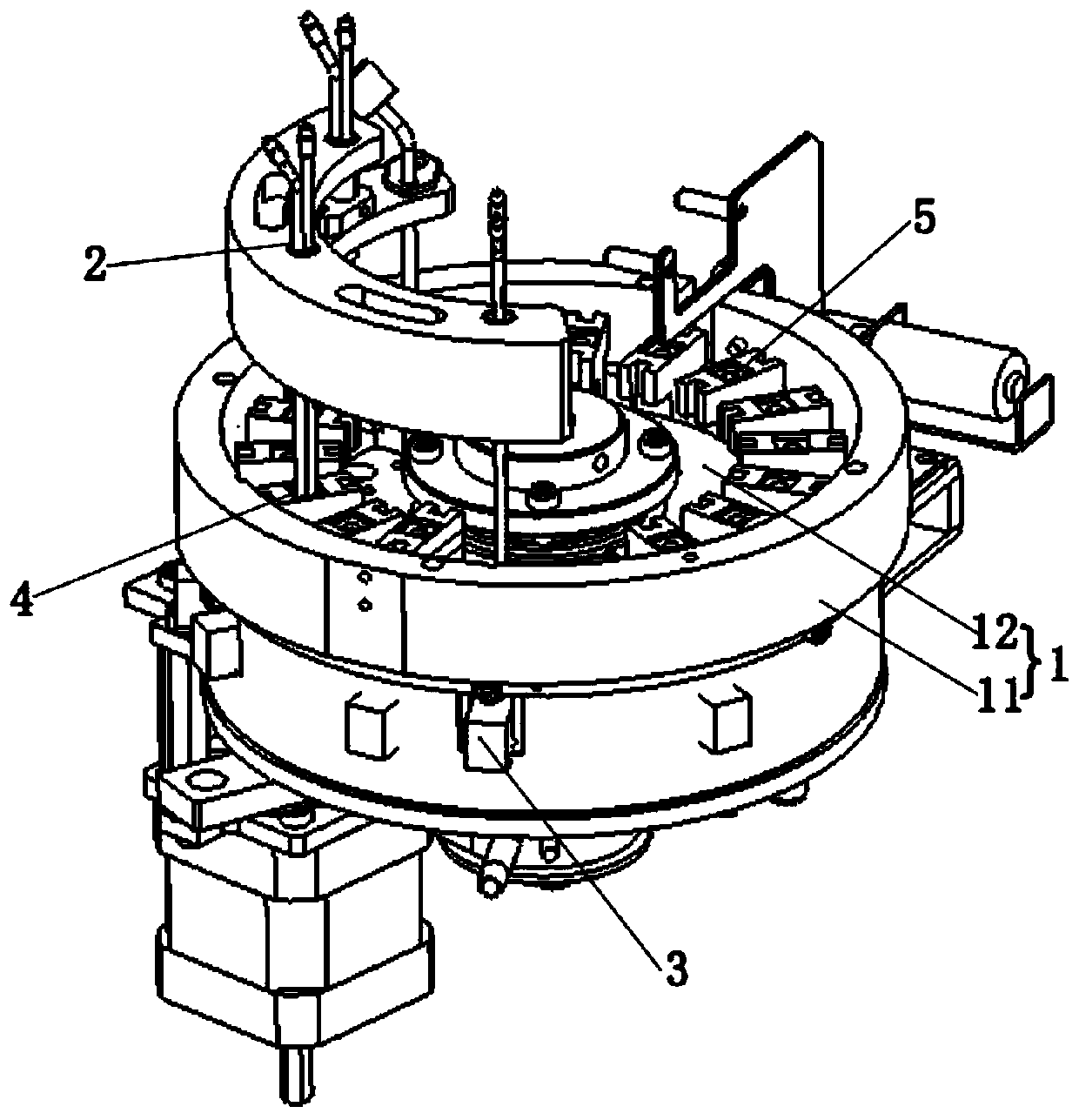

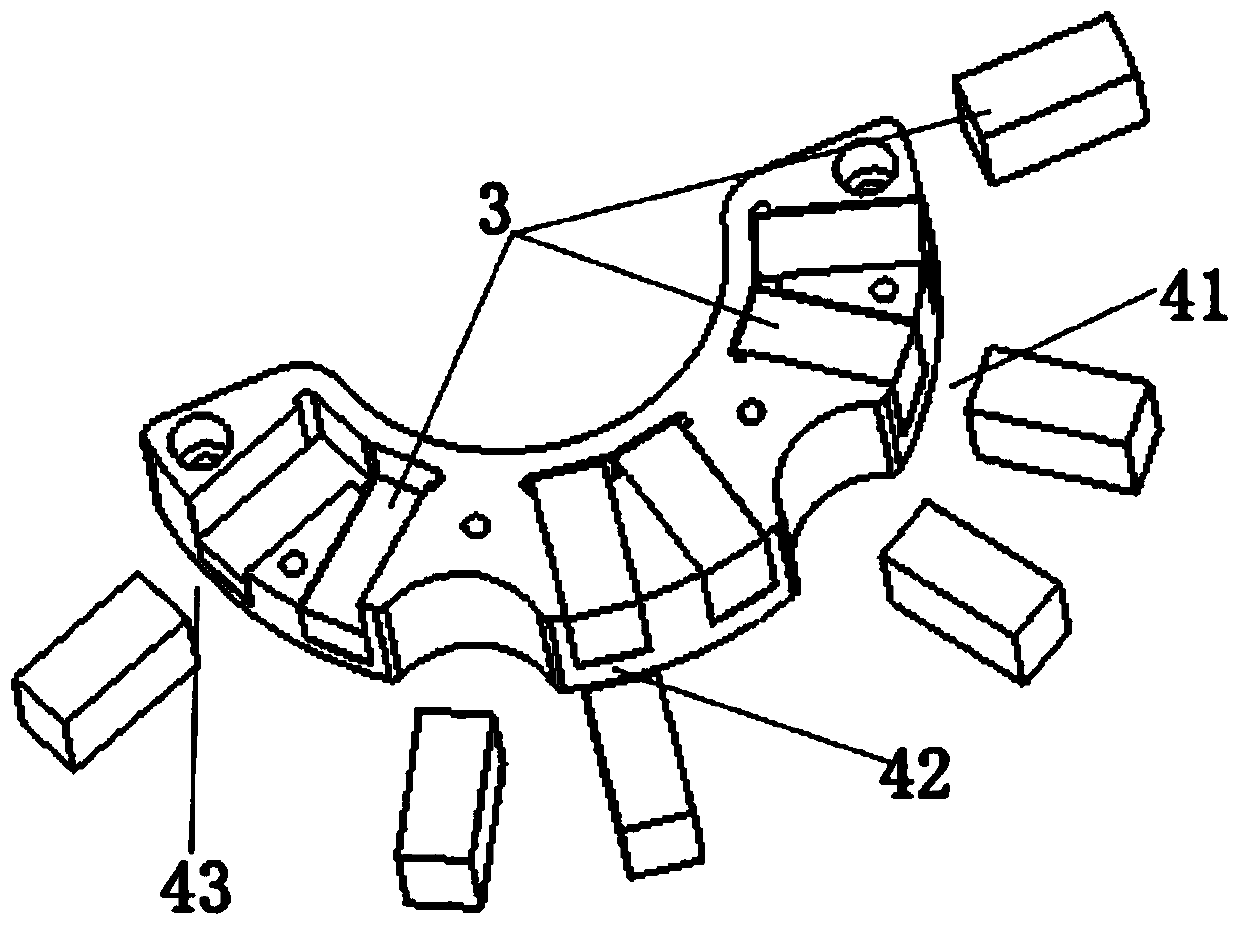

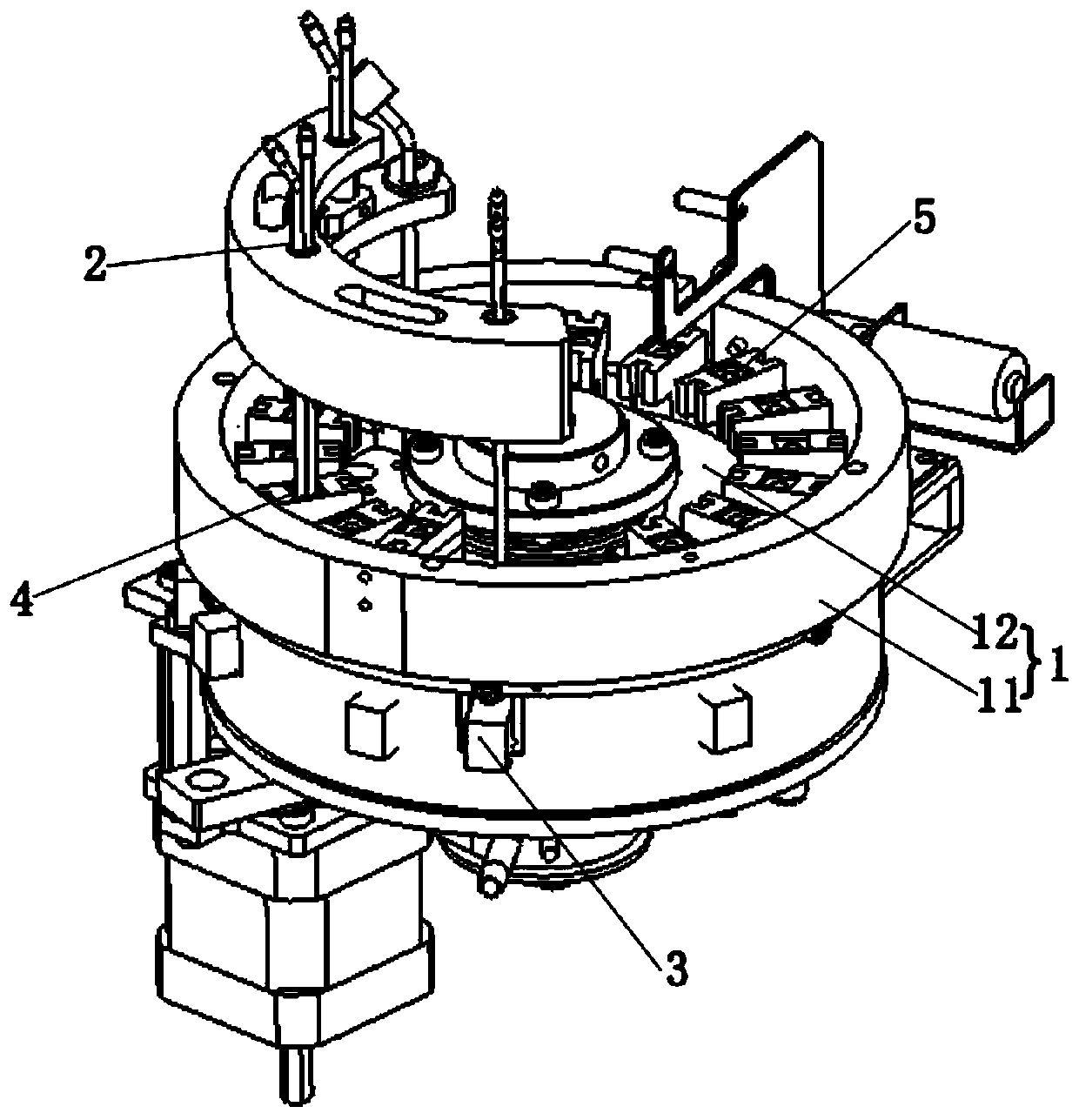

The invention relates to a magnetism separating device. The magnetism separating device comprises a cleaning turnplate mechanism, a magnet structure, a mixing mechanism and a cleaning needle mechanism, and the cleaning turnplate mechanism, the mixing mechanism and the cleaning needle mechanism are all connected with a controller. The magnetism separating device has the advantages that the magnet structure is fixedly located on the inner side face of a reaction cup, and the adsorption area and the adsorption time of a magnet block can be guaranteed through the adsorption position of the magnet structure; the mixing mechanism is synchronously driven by a rotation stepping motor and a rotation synchronous belt, synchronous rotation mixing of cleaning fluid in the multiple reaction cups can be achieved, and the washing efficiency is improved greatly; under the condition that the cleaning effect is guaranteed, the magnetism separating device accelerates the detecting speed, simplifies the instrument structure and has broad prospects.

Owner:北京贝尔医疗设备有限公司

Bird nest eliminating device used on high-voltage tower

ActiveCN105790159AImprove gripAvoid scatterApparatus for overhead lines/cablesCleaning needlePower grid

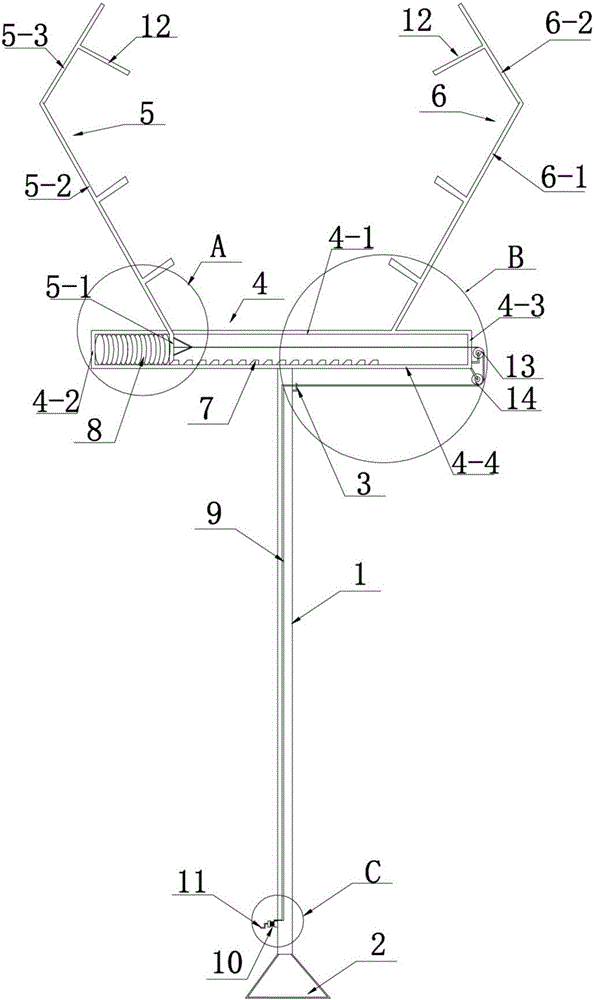

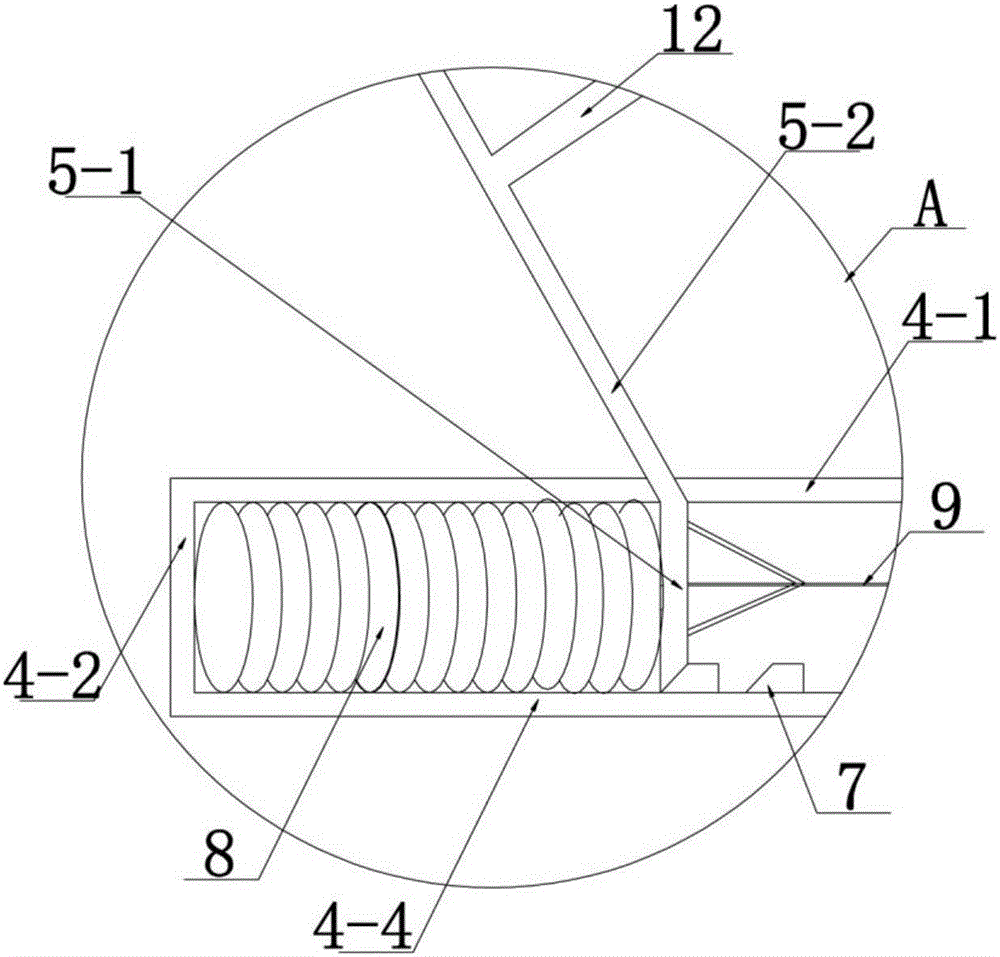

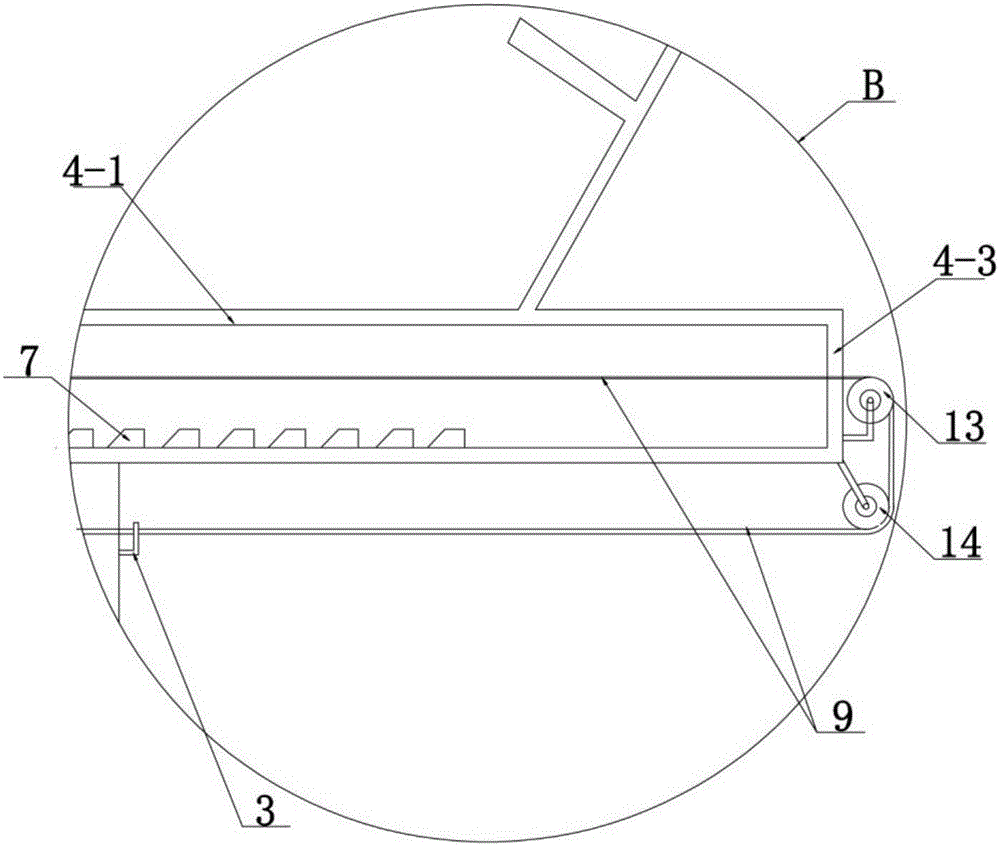

The invention discloses a bird nest eliminating device used on a high-voltage tower. The bird nest eliminating device comprises a vertical rod and a grabbing mechanism. The grabbing mechanism comprises a box body, a fixed clamping handle, a movable clamping handle, a telescopic spring and a control mechanism. The movable clamping handle and the fixed clamping handle are respectively arranged at the left end and the right end of the box body. The inside of the fixed clamping handle and the inside of the movable clamping handle are respectively provided with a plurality of cleaning needles. The box body comprises a top board, a left side board, a right side board and a bottom board. The bottom of the bottom board is connected with the upper end of the vertical rod. The fixed clamping handle is connected with the top board. The lower end of the movable clamping handle penetrates through a box body chute and extends into the box body. The telescopic spring is mounted in the box body. The control mechanism comprises a traction rope, a reel, a rocking handle, a hook, a guiding wheel and a pulley. The bird nest eliminating device has advantages of simple structure and convenient operation. Not only can integral stable grabbing and movement of the bird nest for preventing scattering or inclination of the bird nest in the grabbing process be realized, but also the bird nest eliminating device is suitable for integral movement of the bird nests with different sizes. The bird nest eliminating device performs functions of effectively eliminating the bird nests on the high-voltage tower and ensuring normal operation of a power grid.

Owner:国网山东省电力公司招远市供电公司

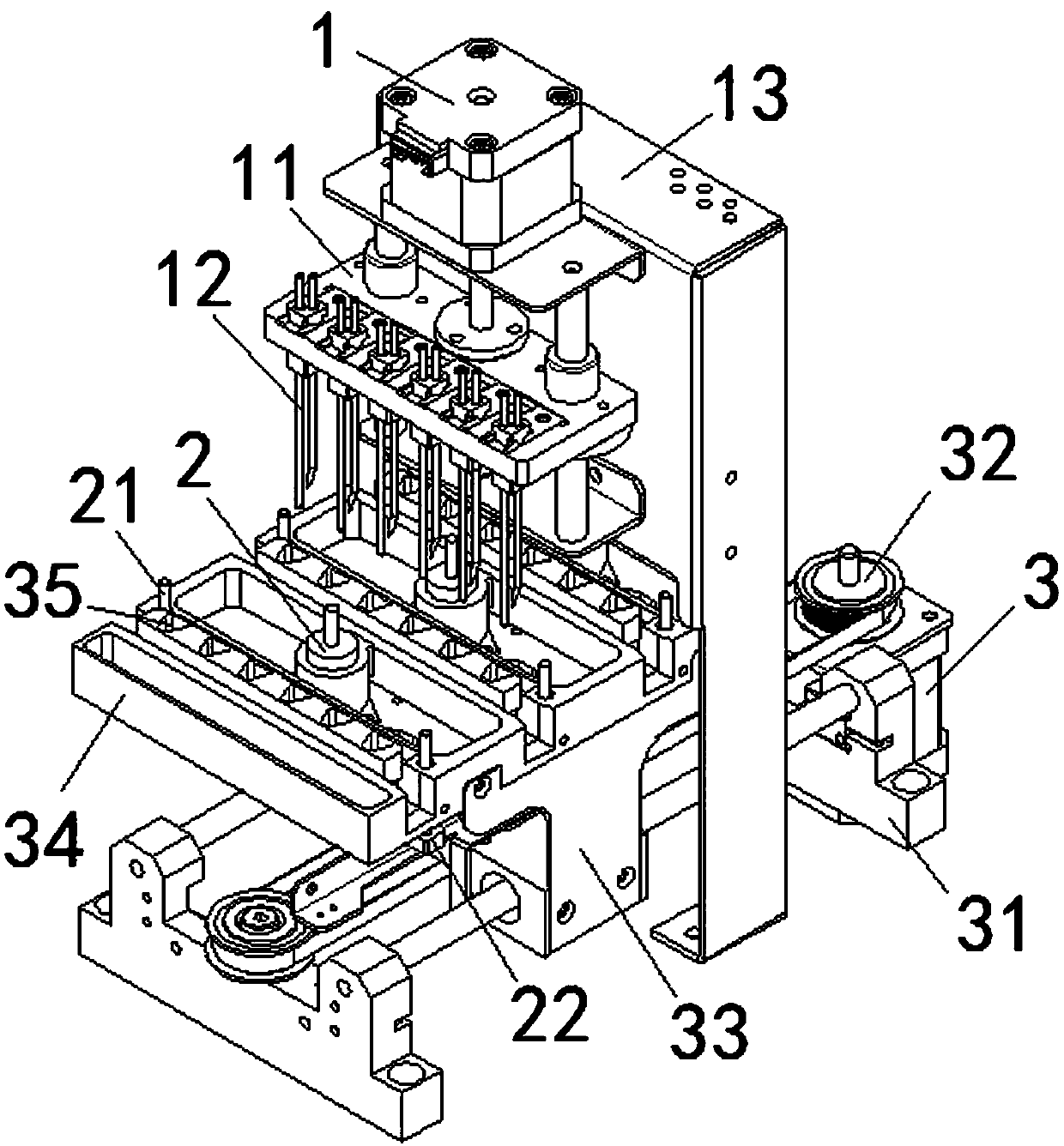

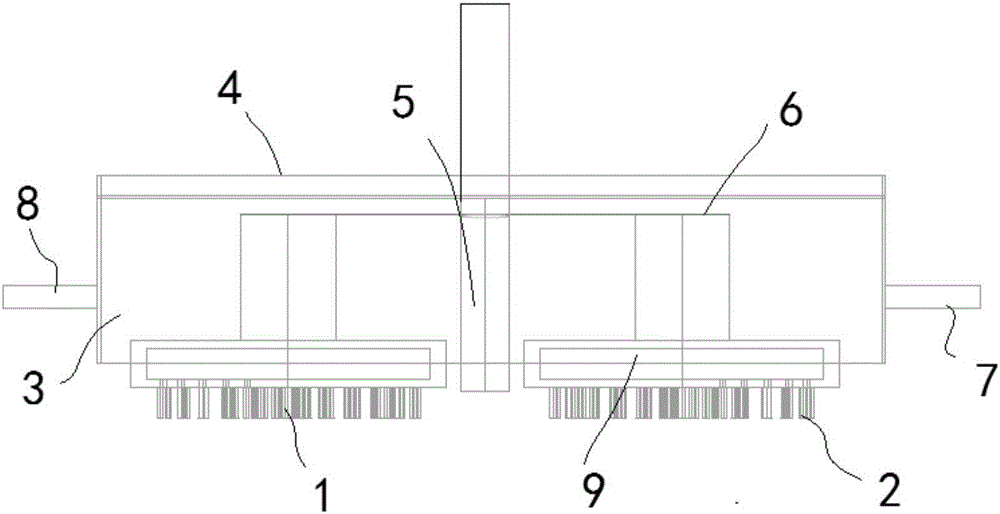

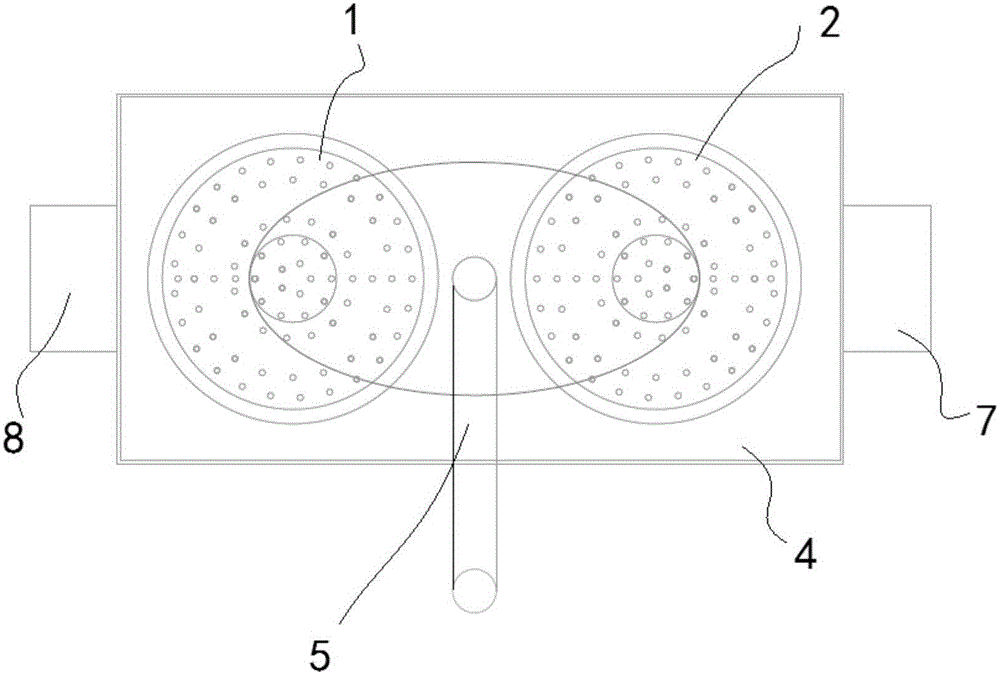

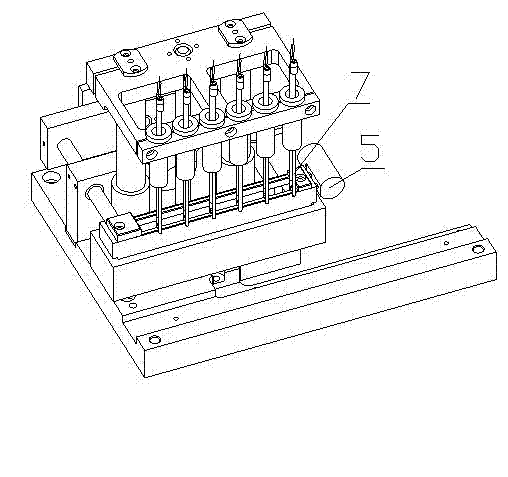

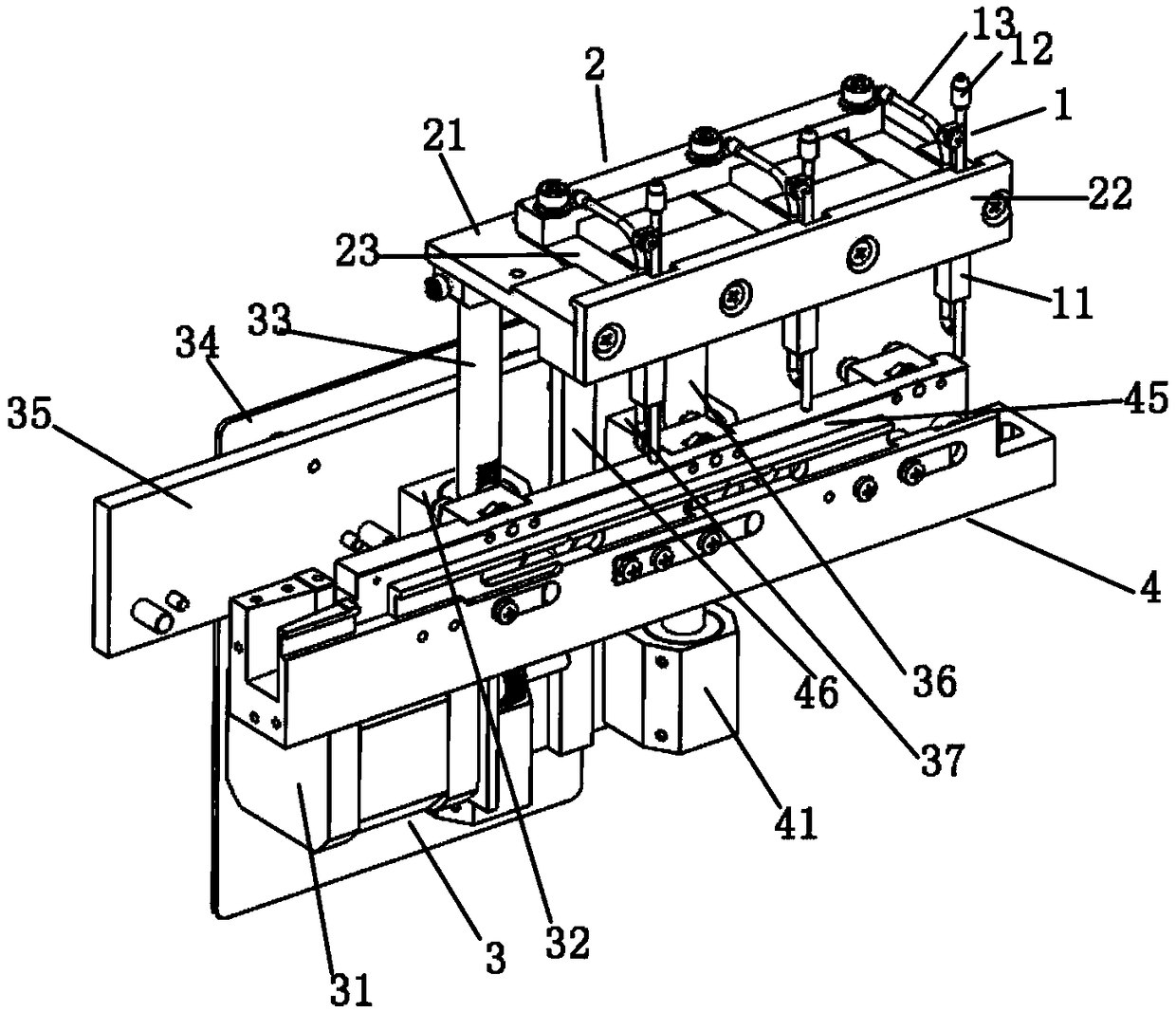

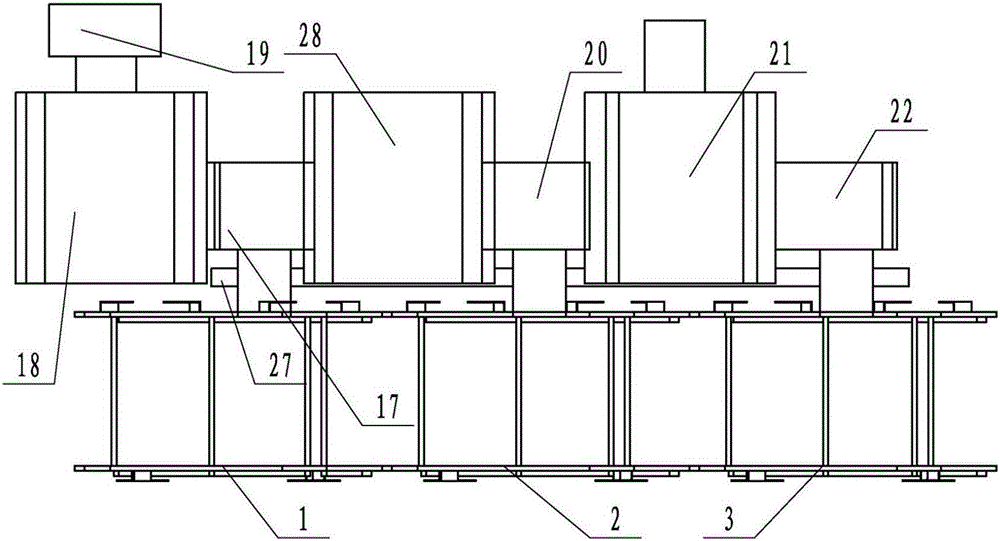

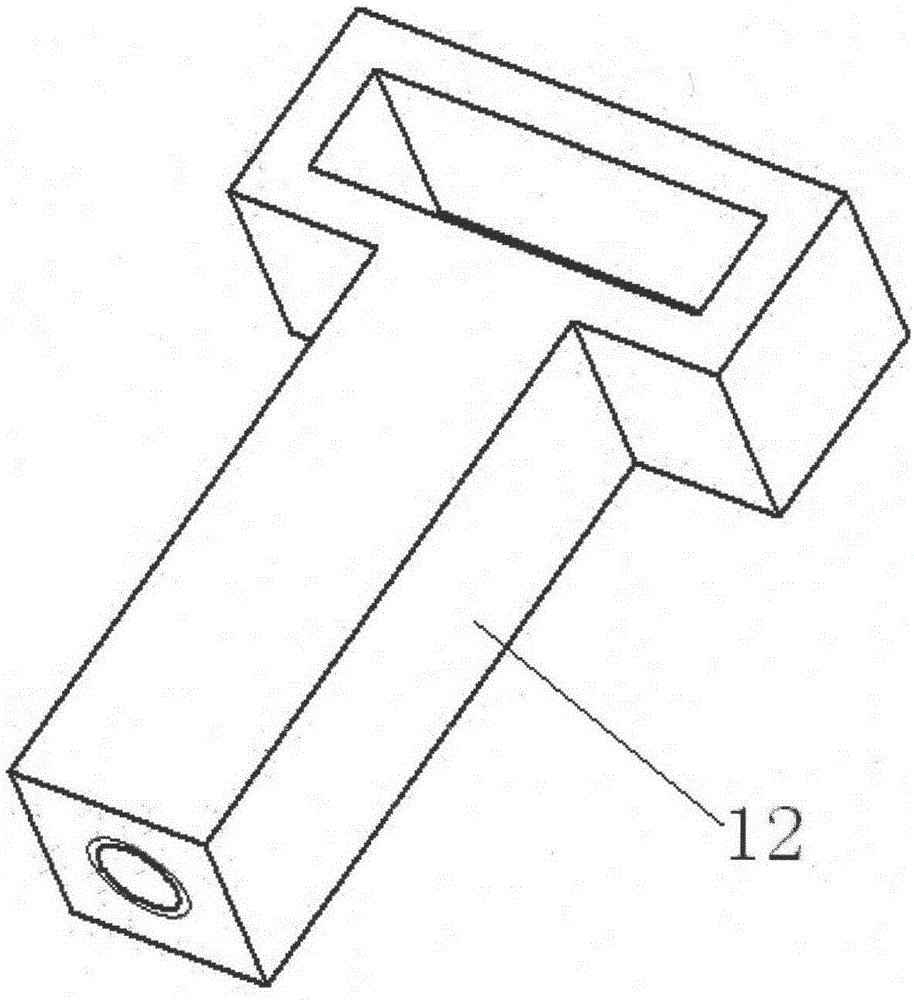

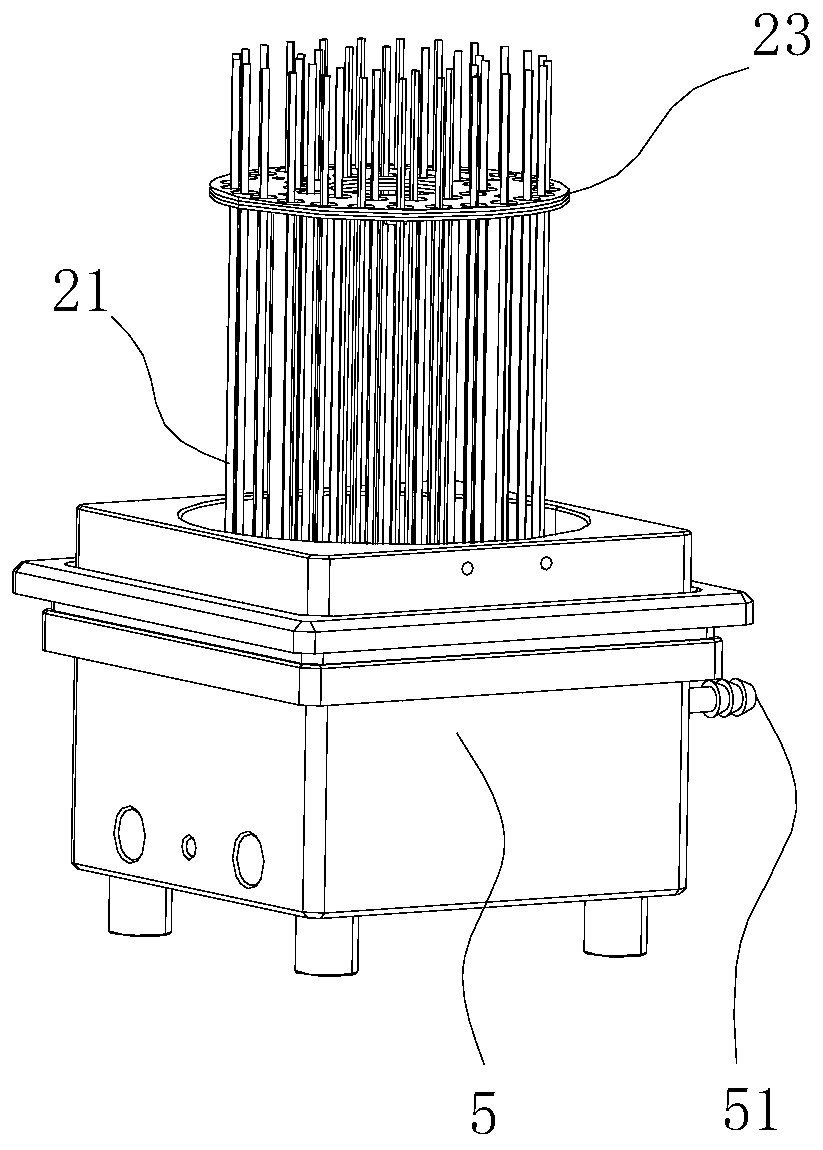

Magnetic particle chemiluminescent analyzer cleaning device and method

PendingCN108015071AClean thoroughlyAchieve adsorptionHollow article cleaningMaterial analysisCleaning needleBiochemical engineering

The invention relates to a magnetic particle chemiluminescent analyzer cleaning device and method, and belongs to the technical field of magnetic particle cleaning. The magnetic particle chemiluminescent analyzer cleaning device comprises a first power device, a cleaning needle fixing plate driven by the first power device to move up and down, and cleaning needles arranged on the cleaning needle fixing plate. A reaction cup support plate is arranged below the cleaning needles and provided with a containing groove for containing a reaction cup. A second power device is arranged on the reactioncup support plate, and a power shaft of the second power device is connected with a magnet fixing plate. The magnet fixing plate is located on one side of the containing groove and is driven by the second power device to move up and down. The position, corresponding to the reaction cup, on the magnet fixing plate is provided with a magnet. The magnetic particle chemiluminescent analyzer cleaning device and method have the beneficial effects that the problem that magnetic particles are hard to scatter after being gathered is solved, clean and thorough cleaning of the magnetic particles is guaranteed, and accordingly accuracy and stability of the analysis result are guaranteed.

Owner:上海裕隆生物科技有限公司

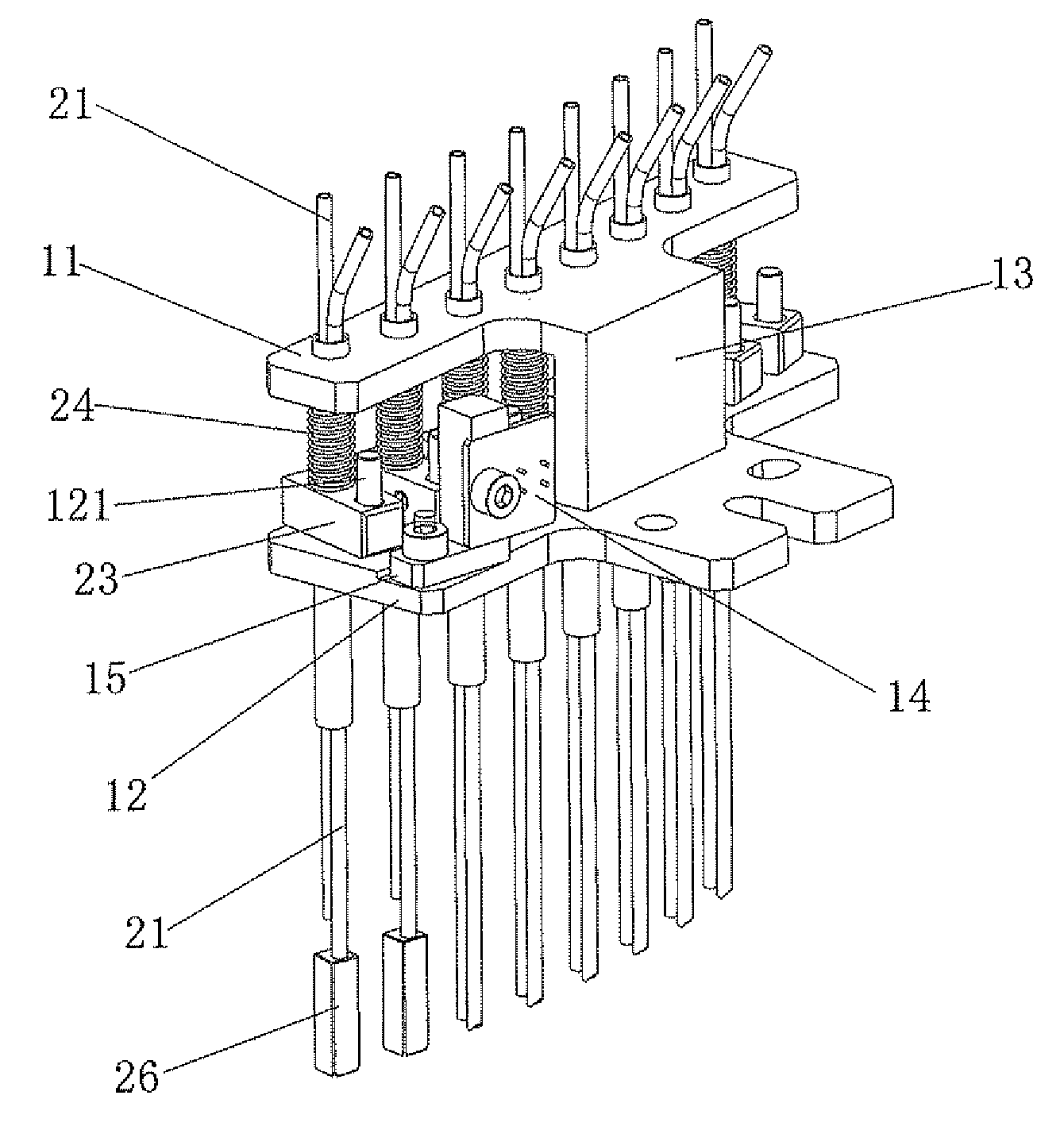

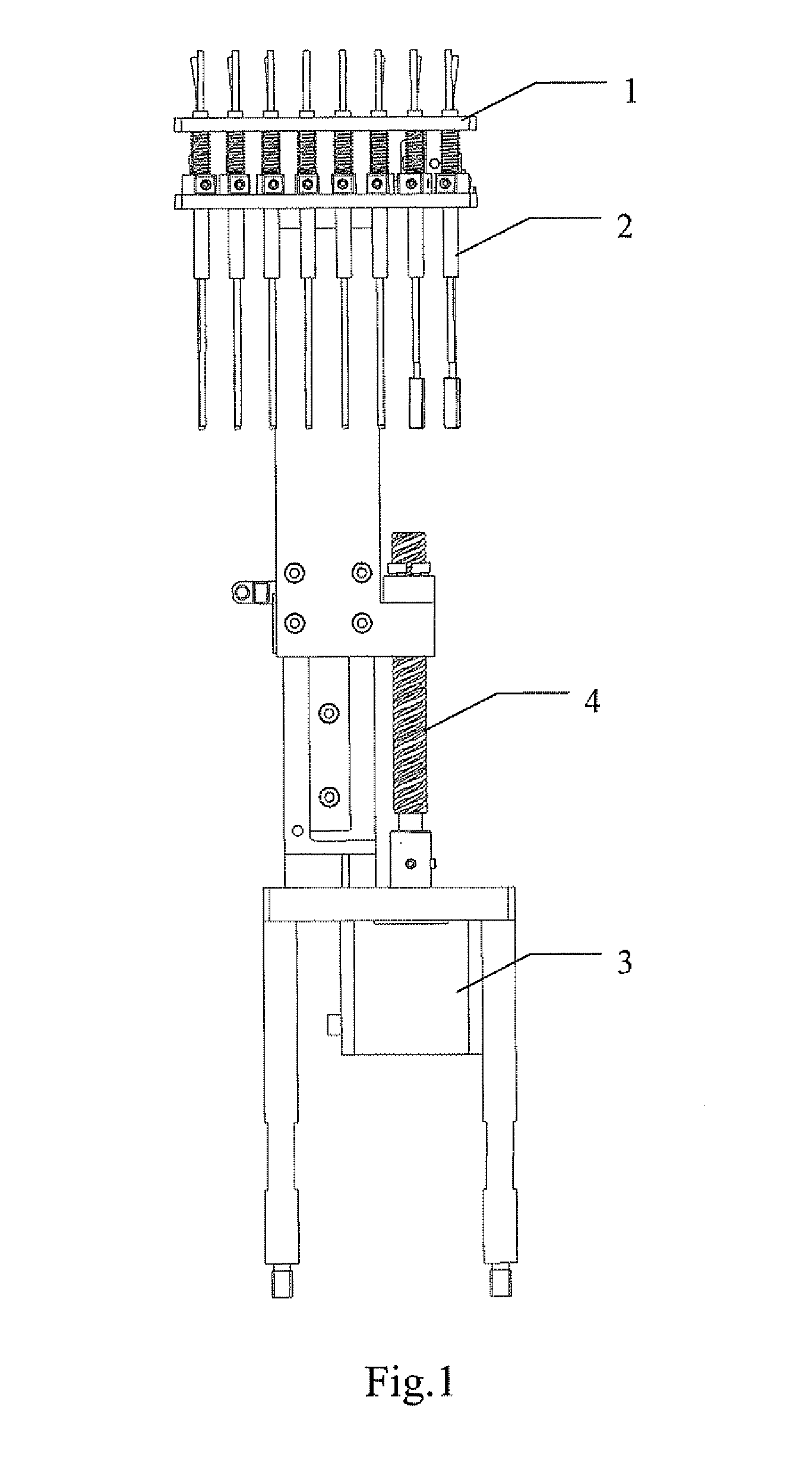

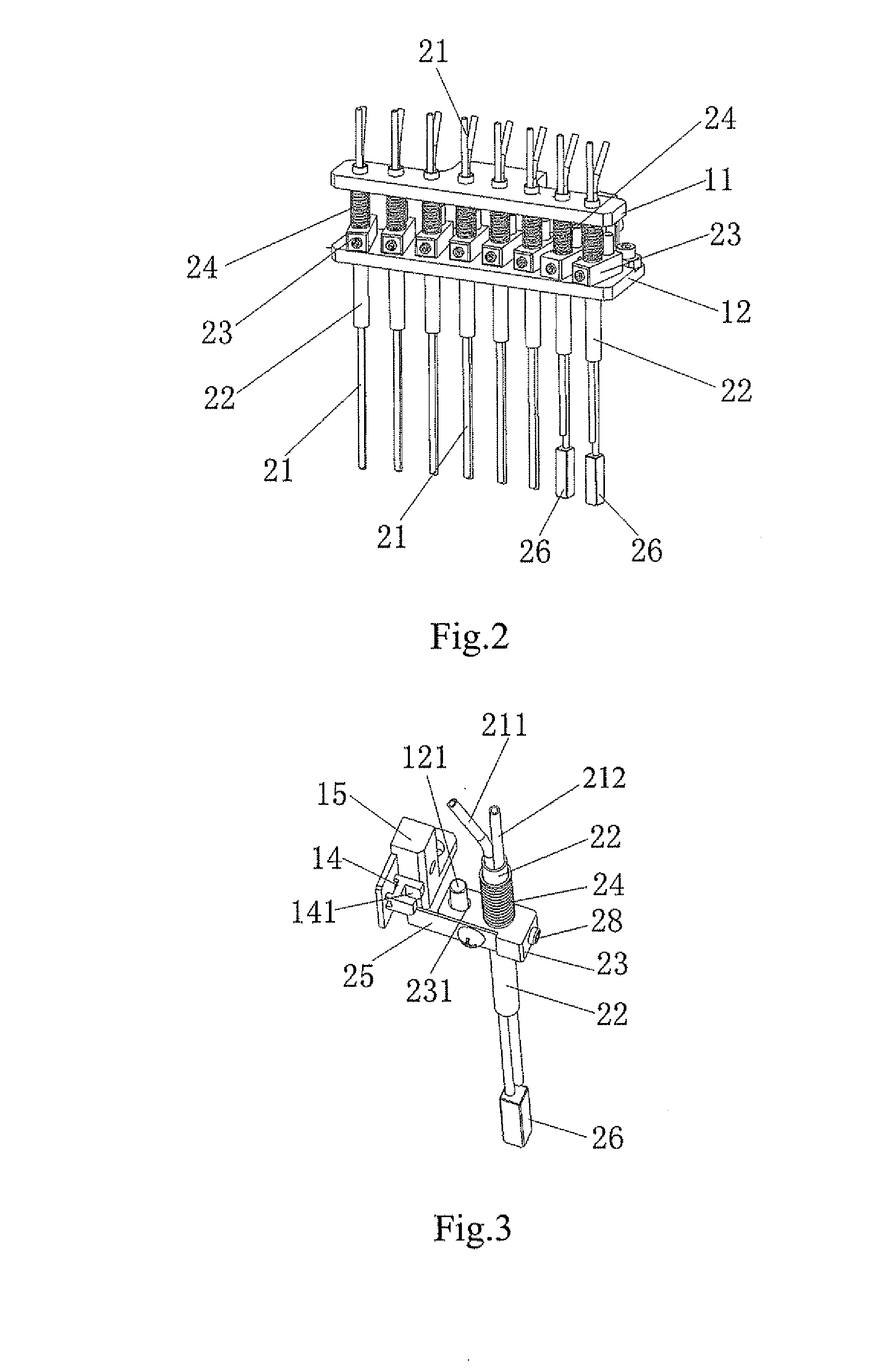

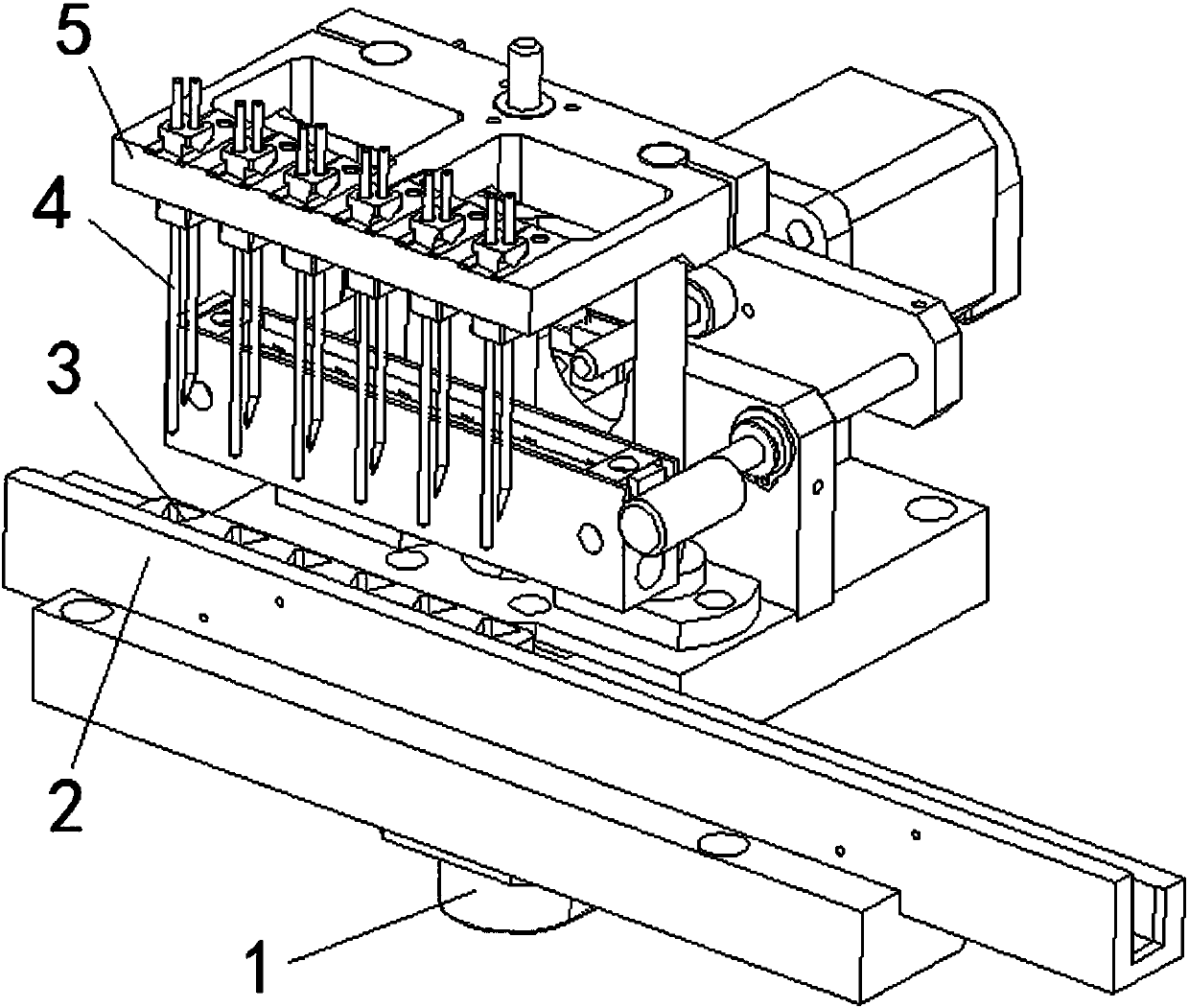

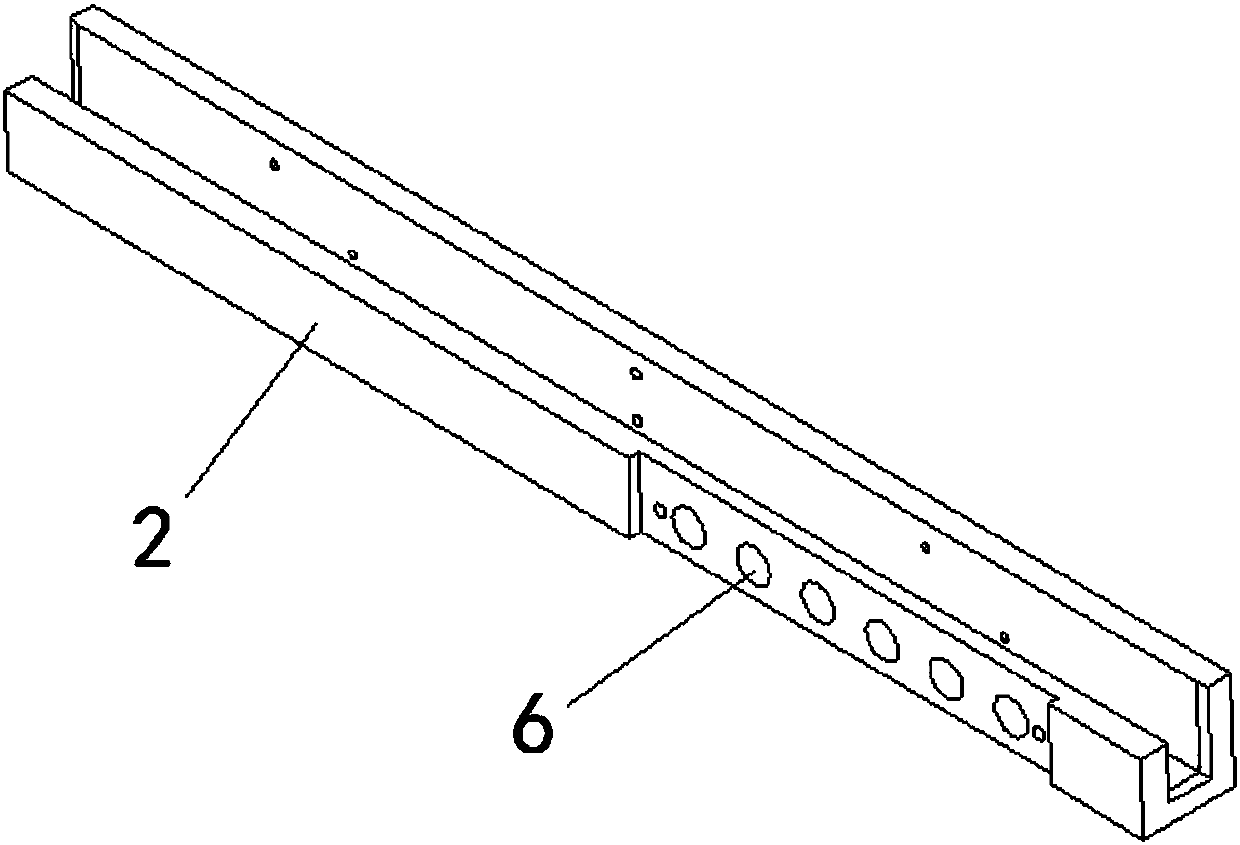

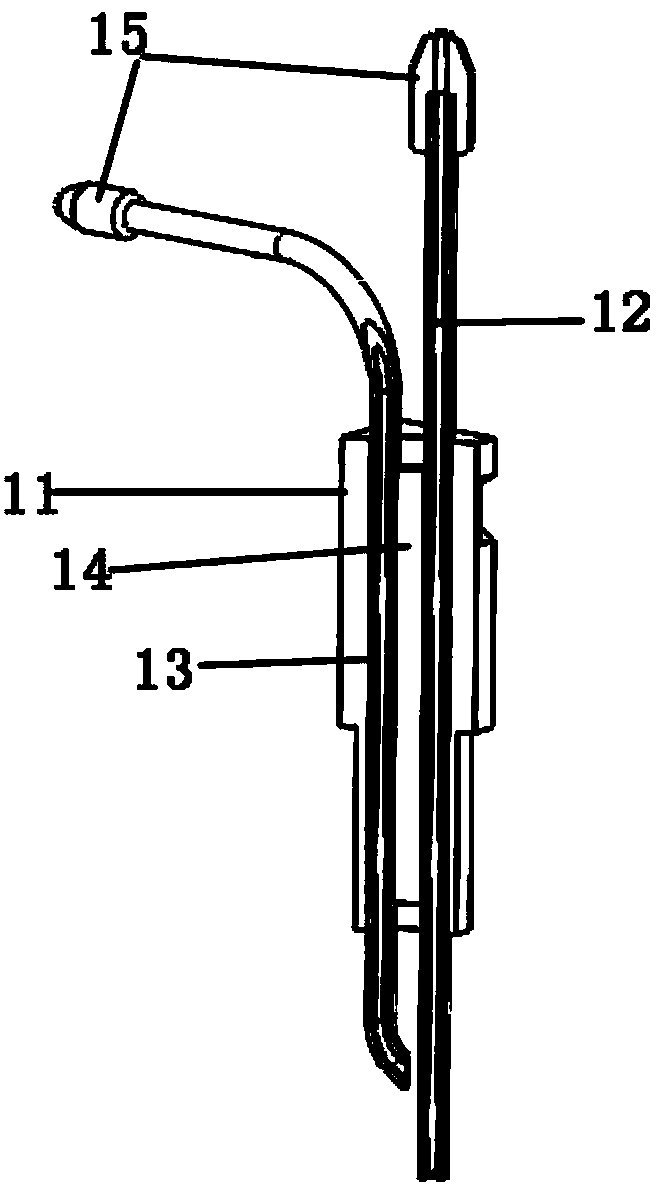

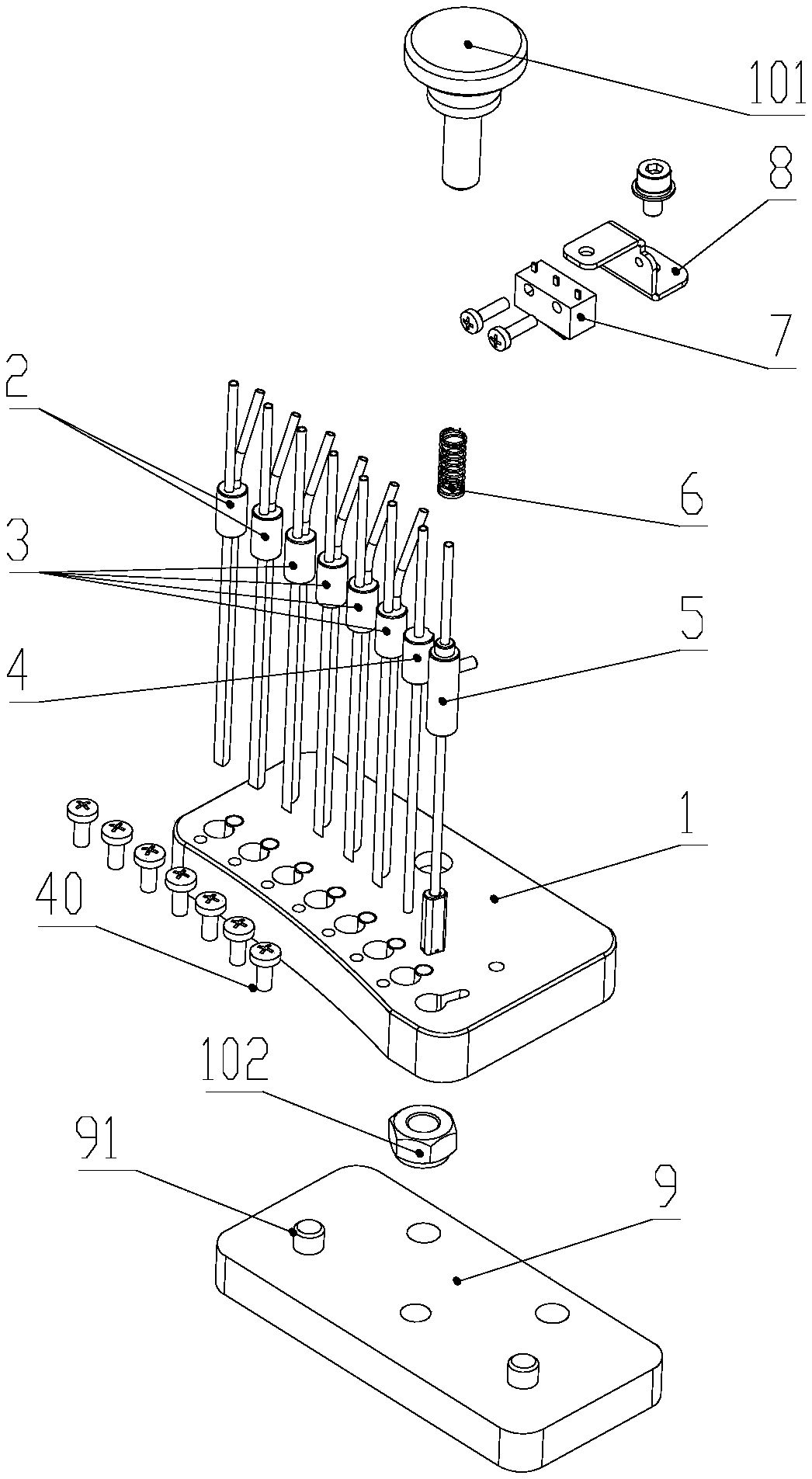

Reaction cuvette wash unit

InactiveUS8007740B2Effective protectionSimple structureMaterial analysis by optical meansBurettes/pipettesCuvetteCleaning needle

The invention discloses a reaction cuvette wash unit comprising a cleaning needle assembly, a straight guide pair, a slide screw pair, a motor, a trigger component associated with a cleaning needle of the cleaning needle assembly in a manner to move with that cleaning needle, and a sensor used to sense the position of the trigger component. When the trigger component moves to a predetermined position, the sensor is triggered and sends a signal to a controller such that the controller controls in a manner to stop the motor. Each of cleaning needle components further comprises a sheath holder and an elastic member. The elastic member is designed to provide an elastic contact while the cleaning needles touch the bottom surface of the reaction cuvette, such that a relatively small force is exerted upon the bottom of the reaction cuvette, thereby effectively protecting the reaction cuvette from damage.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

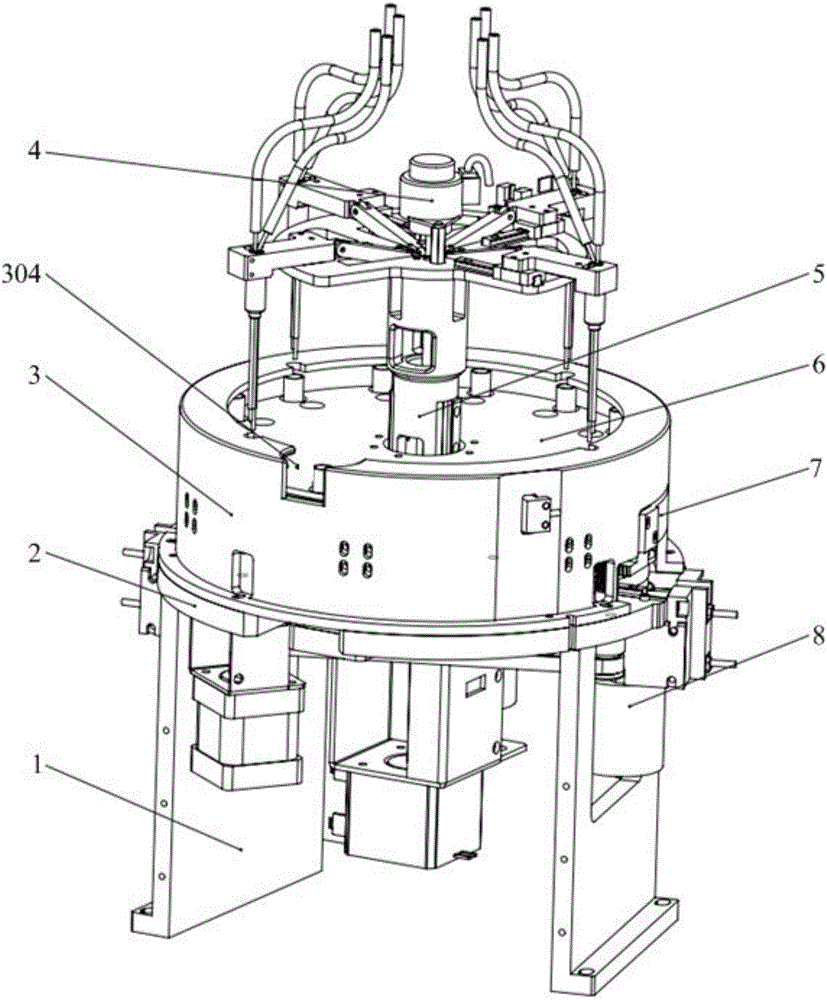

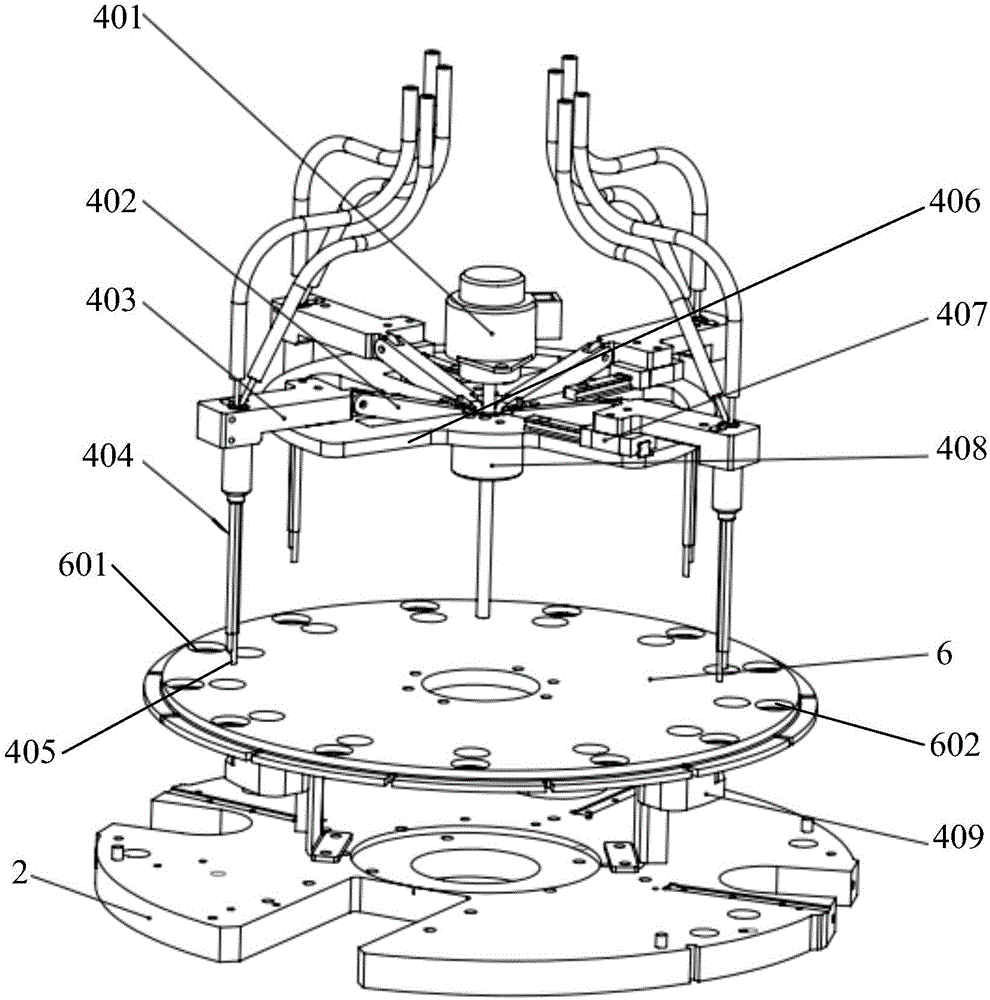

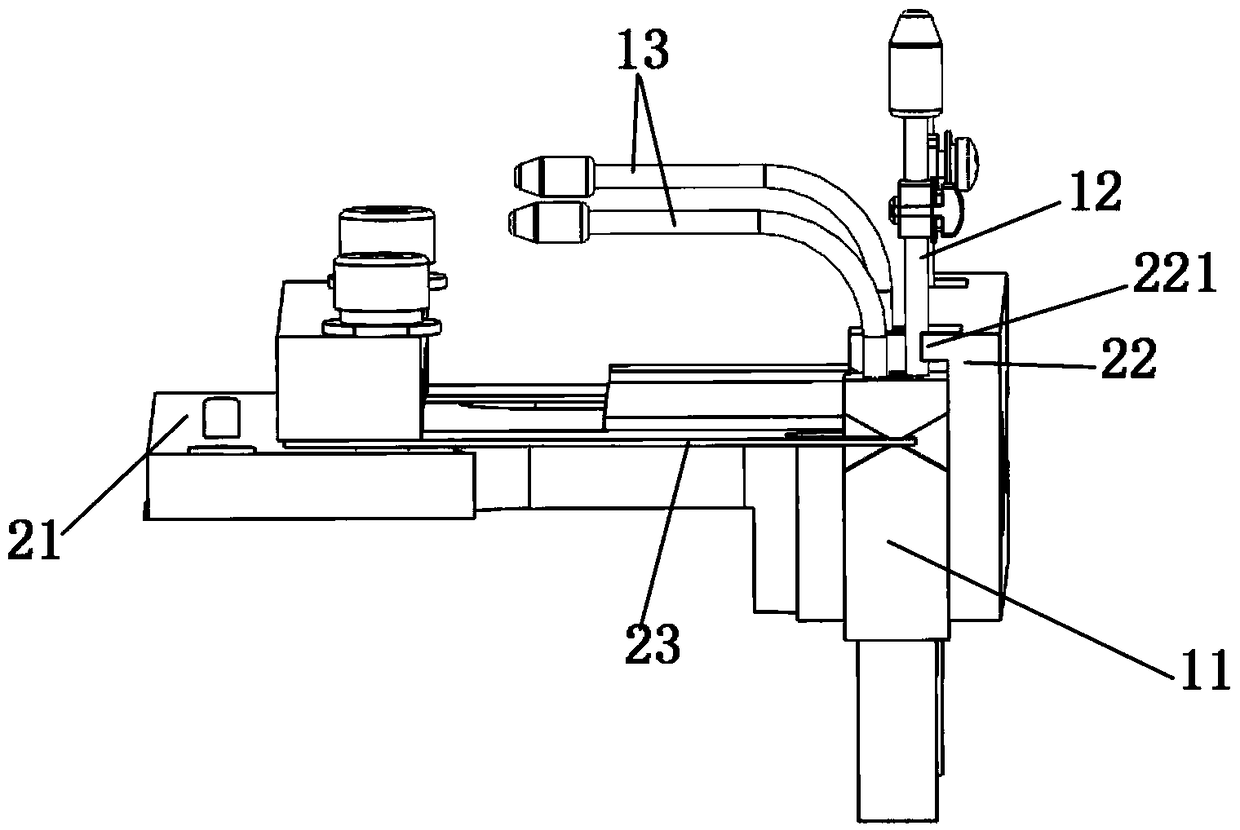

Magnetic cleaning and separating device of immunity analyzer

ActiveCN109909217AFully cleanedPrevent suckingBiological testingCleaning using liquidsCleaning needleMagnetic bead

The invention relates to a magnetic cleaning and separating device of an immunity analyzer. The magnetic cleaning and separating device of the immunity analyzer comprises a reaction cup conveying assembly, a cleaning needle assembly, a magnet body assembly and a plurality of cleaning positions, wherein the magnet body assembly comprises two oppositely-arranged magnet body pairs arranged on the twosides of an operation path of a reaction cup correspondingly and single magnet bodies arranged on one side of the operation path of the reaction cup; and the magnet body pairs correspond to the cleaning positions, the single magnet bodies are located between the cleaning positions or located in front of the first cleaning position in the operation path direction of the reaction cup, at least onemagnet body is arranged between the every two adjacent cleaning positions or located at the position, in front of the first cleaning position in the operation path direction of the reaction cup, of each side of the operation path of the reaction cup, the magnet bodies, located between the cleaning positions or located in front of the first cleaning position in the operation path direction of the reaction cup, are alternately arranged on the two sides of the operation path of the reaction cup correspondingly, and the directions of magnetic poles of every two adjacent magnet bodies are opposite.According to the magnetic cleaning and separating device, the magnetic separation time is extremely short, the purpose of fully cleaning magnetic beads is achieved, and the magnetic beads can be effectively prevented from being sucked by cleaning needles.

Owner:SUZHOU HYBIOME BIOMEDICAL ENG CO LTD

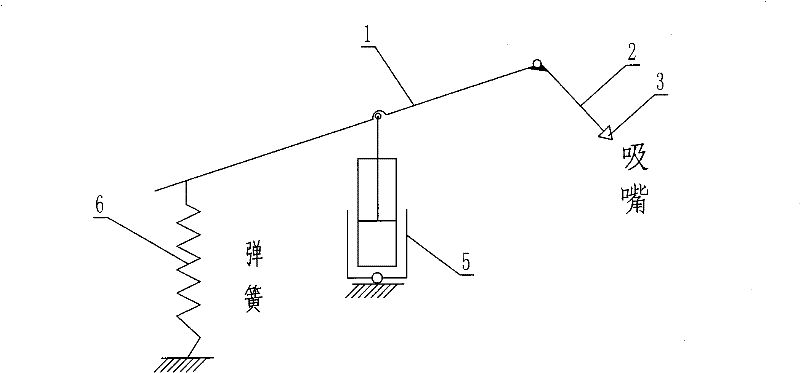

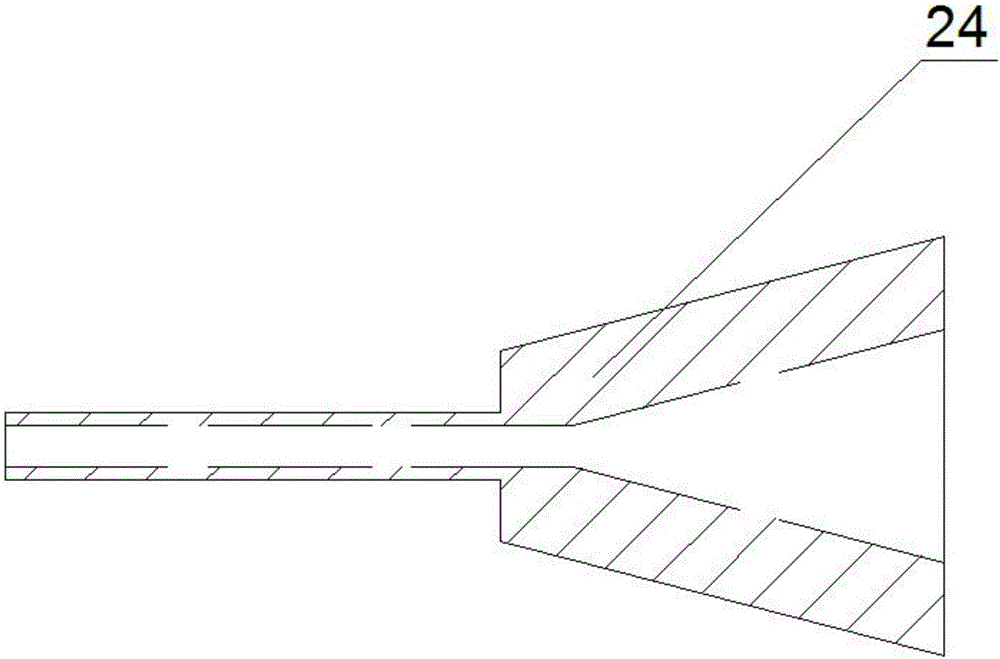

Automatically cleaning suction nozzle

InactiveCN102450125AStructured listReliable actionSeed depositing seeder partsSingle grain seedersCleaning needlePositive pressure

The invention discloses an automatically cleaning suction nozzle. The suction nozzle comprises a suction nozzle housing, a cleaning needle driven by a piston is arranged in the suction nozzle housing, the lower part of the piston is provided with a return spring, and the side of the piston is provided with a gap for the gas circulation. The cleaning needle is driven by the piston, the piston is in an upward floating state under the action of elastic force of the return spring when the suction nozzle is in a negative pressure environment, seed suction channels are guaranteed to be unblocked through the side gaps, and suction nozzles are exposed to complete the seed adsorption; and in the seed sowing process, the instant the negative pressure of a vacuum generator is transmitted to positive pressure, the piston acted by outside force overcomes the elastic force of the return spring and downward moves, and the cleaning needle penetrates into the suction nozzle apertures to poke out foreign materials, so the cleaning of the suction nozzle apertures is completed. The suction nozzle of the invention, which has the advantages of simple structure and reliable motion, can satisfy low cleanliness seed suction and sowing operations of a seeder.

Owner:崔敏娟

Automatic cleaning needle bed auxiliary equipment

The invention relates to an automatic cleaning needle bed auxiliary equipment. The auxiliary equipment comprises two cleaning bushes arranged side by side, the cleaning hairbrushes are connected with a hairbrush motor and are arranged in a shell, the shell is internally provided with a vacuum dust suction pipe used for connecting with a vacuum dust suction device, and the rear ends of the cleaning hairbrushes are connected with a detergent injection barrel used for injecting detergent. According to the invention, automatic cleaning equipment is redesigned, and an online vacuum dedusting device is additionally arranged, so that process steps of online cleaning and dedusting can be realized at the same time, and operation procedure completed by an operator in two steps can be combined to be simultaneously completed in one time.

Owner:TIANJIN LISHEN BATTERY

Reaction cup cleaning device and sample analyzer

ActiveCN106269753AReduce the chance of dirty cleaningReduce the chance of cross-contaminationHollow article cleaningCleaning needleReciprocating motion

The invention discloses a reaction cup cleaning device and a sample analyzer. The reaction cup cleaning device comprises a mounting rack, a reaction cup disc, a cleaning mechanism, a lifting mechanism and a driving component, wherein the lifting mechanism is used for driving the cleaning mechanism to ascend and descend; the driving component is mounted on the mounting rack and is used for driving the reaction cup disc to rotate; holding holes for holding reaction cups are formed in the reaction cup disc; the cleaning mechanism comprises a needle component, needle cleaning tanks for cleaning liquid sucking needles, and a cleaning driving mechanism; the needle component comprises the liquid sucking needles and cleaning needles; the cleaning driving mechanism is used for driving the needle component to move in a reciprocating manner; when being driven to move to a first final point, the needle component is positioned above a holding hole of a cleaning position; when the needle component is driven to move to a second final point, the liquid sucking needles are positioned above the needle washing tanks. By adopting the reaction cup cleaning device, the rates that the liquid sucking needles are not completely cleaned and are subjected to cross pollution are reduced.

Owner:MACCURA MEDICAL INSTR CO LTD

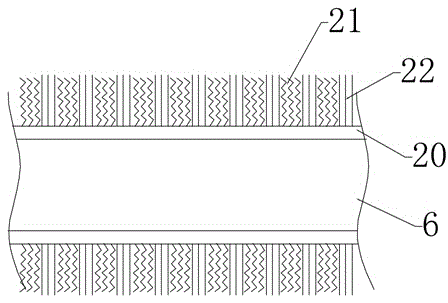

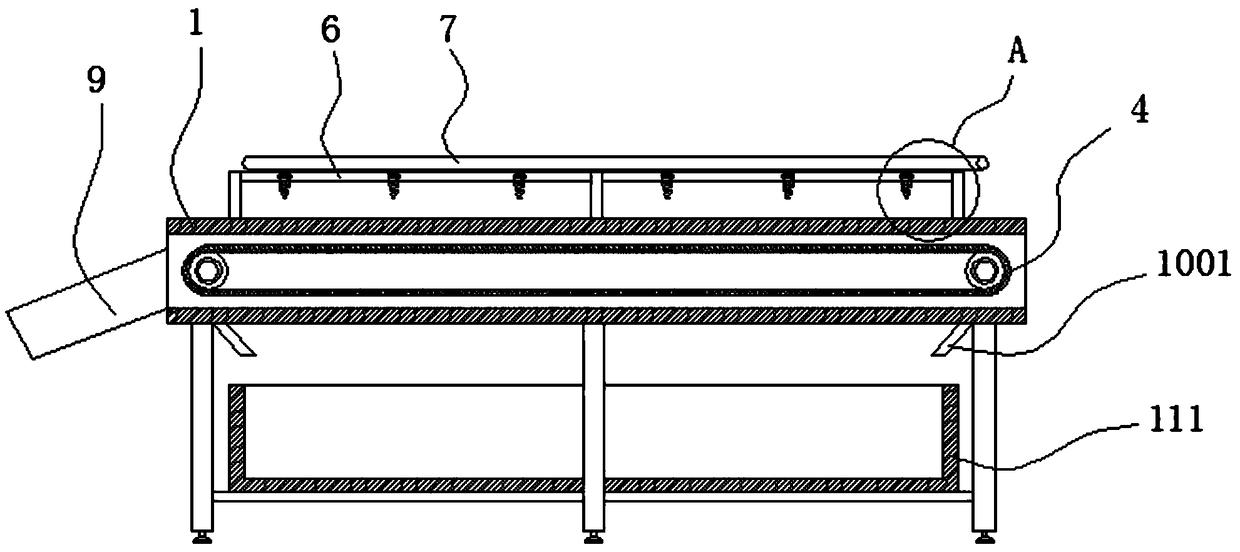

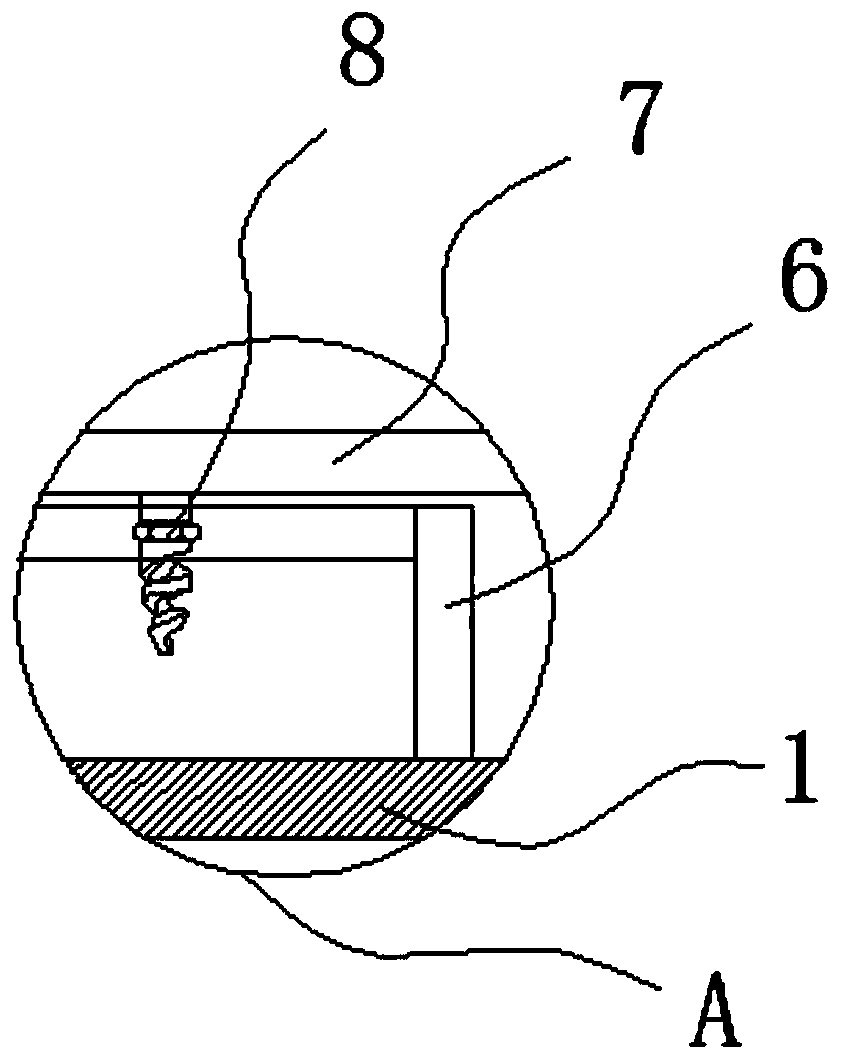

Guiding-belt water-cleaning device for circular screen printers

ActiveCN104842646AImprove cleaning efficiencyGuaranteed cleanlinessScreen printersPrinting press partsCleaning needleEngineering

The invention discloses a guiding-belt water-cleaning device for circular screen printers. The guiding-belt water-cleaning device comprises a guiding belt, a brush roller and a water trough, a plurality of brushes are fixed on the outer circumference of the brush roller, a brush clamping layer sleeves the brush roller and comprises a body and a plurality of cylindrical sleeves protruding outwards from the body, the cylindrical sleeves wrap the corresponding brushes tightly, and the height of the cylindrical sleeves is smaller than that of the corresponding brushes; an elastic soft brush cleaning needle is arranged on the inner wall of the water trough nearby one side of the brush roller and comprises a base and a plurality of evenly distributed cleaning needle bodies fixed on the base, and the brush cleaning needle partially extends out of the side edge of a support seat with the extending part contacting with one ends of the brushes; a water inlet is formed in one side wall of the water trough and is communicated with a water tank, a water pump is arranged in the water tank, and a sewage outlet is formed in the wall of the water trough under the support seat. Water in the water trough can flow to have sewage clamped in the brush roller cleaned, and cleaning efficiency of the guiding belt is improved.

Owner:南通中宸印染有限公司

Cleaning device and cleaning method

ActiveCN103230897ARealize individual control operationEnsure thoroughnessCleaning using liquidsPeristaltic pumpCleaning needle

A cleaning device comprises a reaction cup cleaning system for cleaning a reaction cup and a cleaning tank system for cleaning a needle group. The reaction cup cleaning system comprises cleaning needles and waste liquid needles. The waste liquid needles are connected with a multi-head peristaltic pump through a connecting pipe, at least one cleaning needle is connected with a plunger pump through a connecting pipe, and an electromagnetic control valve is installed between the cleaning needles and the plunger pump. The cleaning device has the advantages that the electromagnetic control valve is added in the reaction cup cleaning system, two cleaning needles share one control valve, so that independent control operation of each cleaning needle can be achieved; cleaning thoroughness of the cleaning needles is guaranteed by use of an ultrasonic cleaning tank; the cleaning needles are used for cleaning magnetic bead surface combination objects, the waste liquid needles are used for timely disposing waste liquid, and the magnetic bead surface combination objects and discards are cleaned thoroughly due to joint use of the cleaning needles and the waste liquid needles; and the cleaning device is simple in structure, convenient to use, free of cross infection and low in cost.

Owner:上海裕隆生物科技有限公司

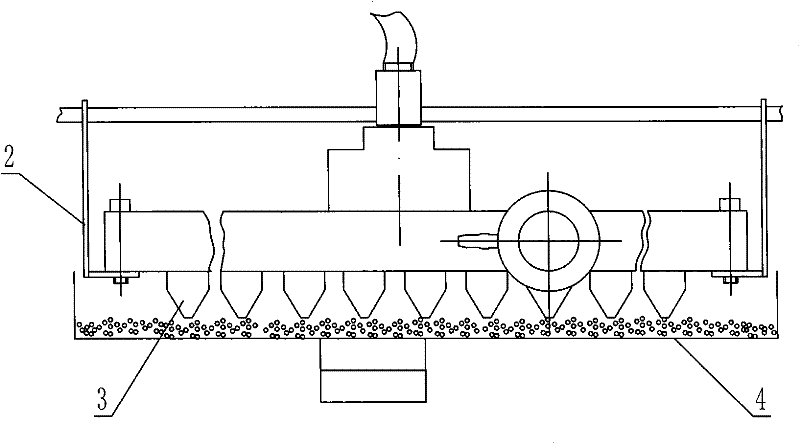

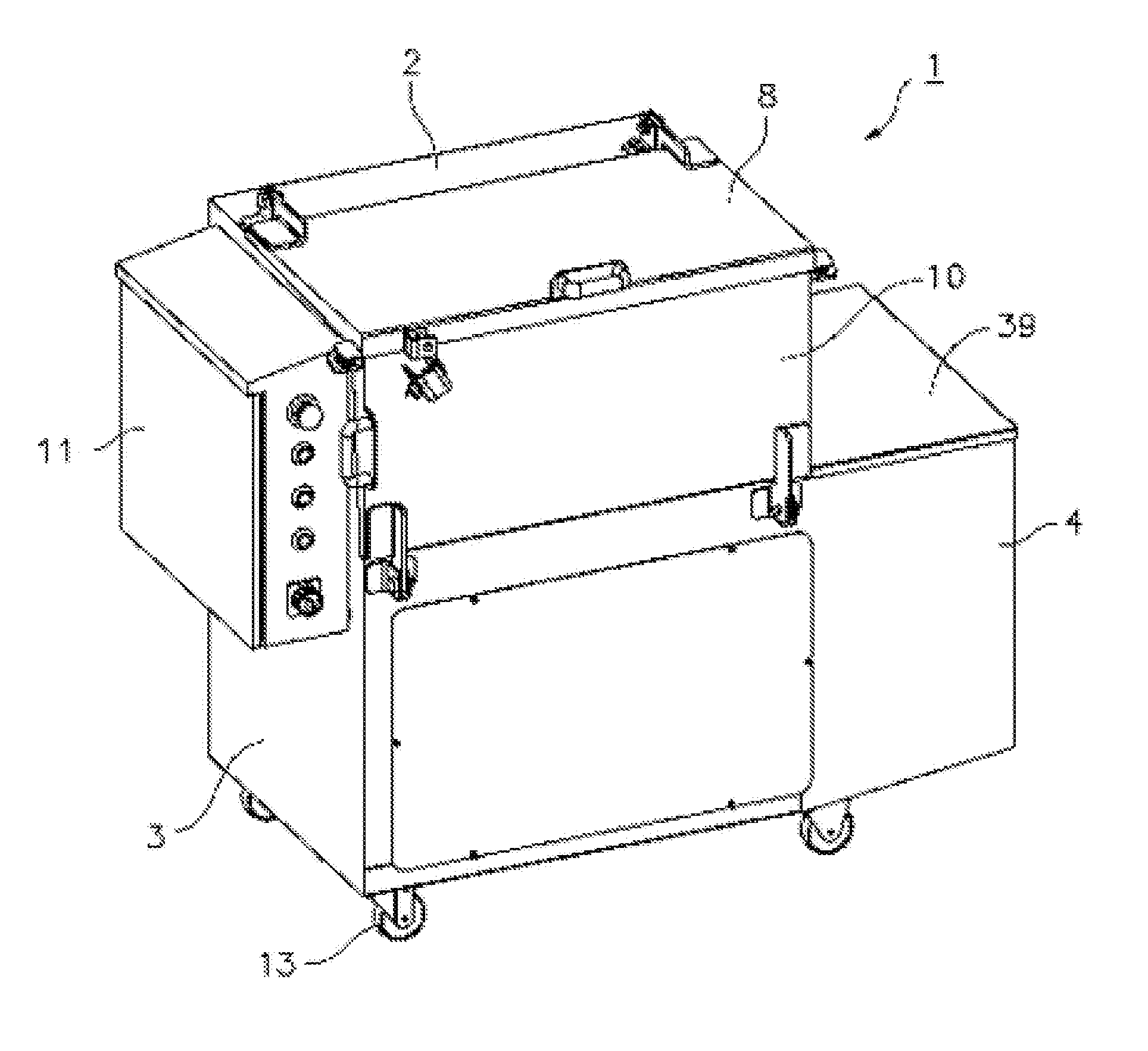

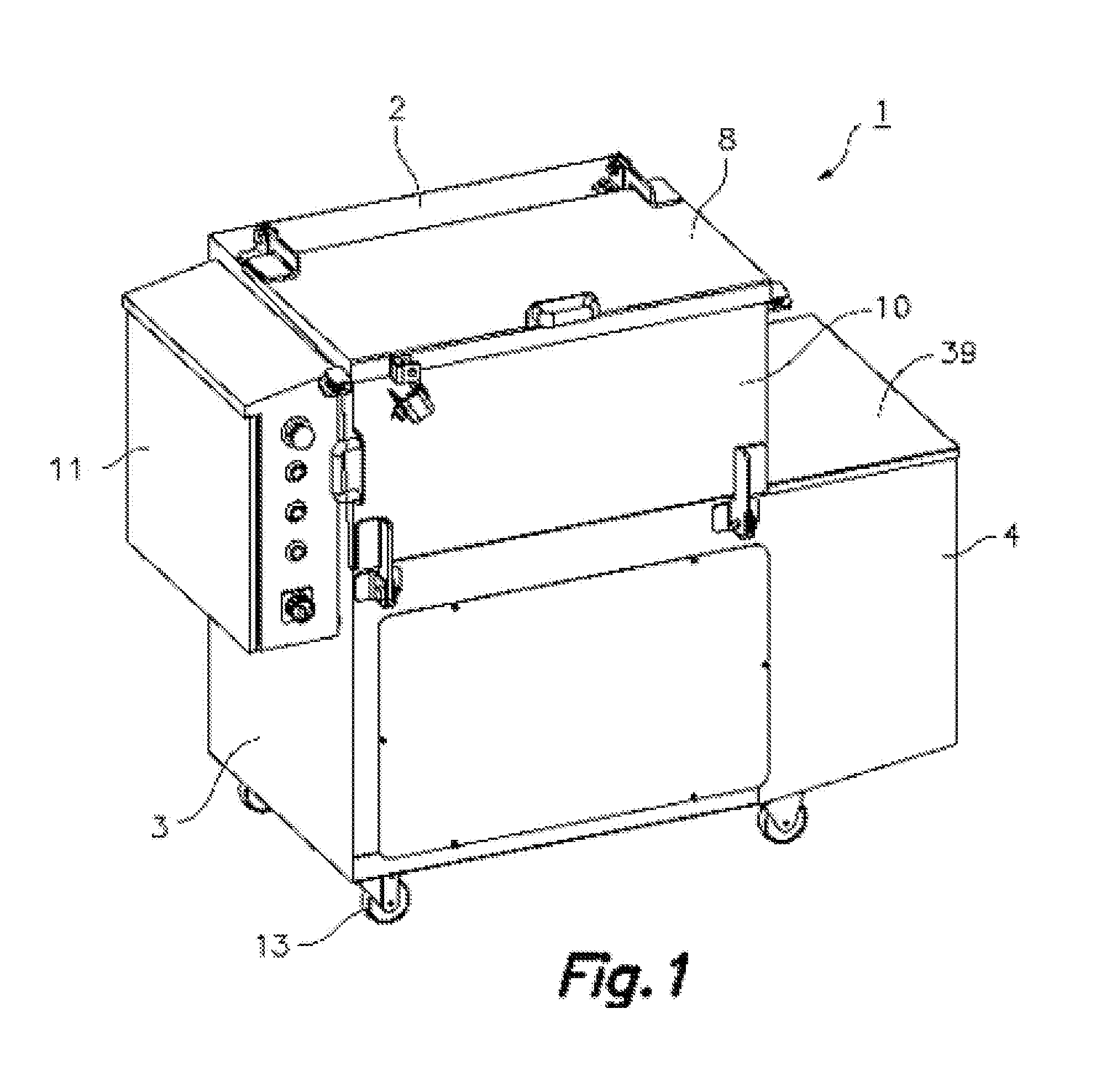

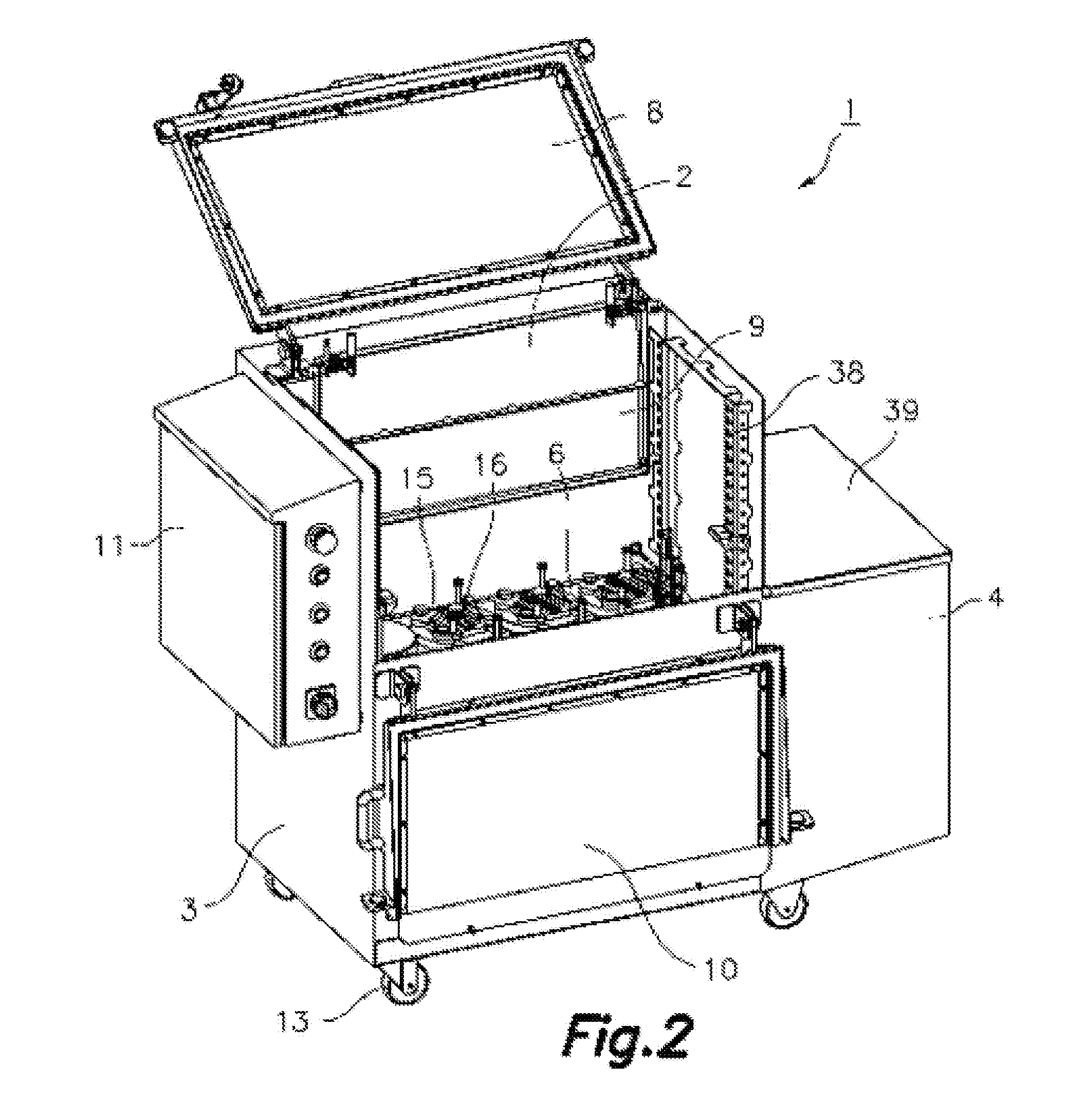

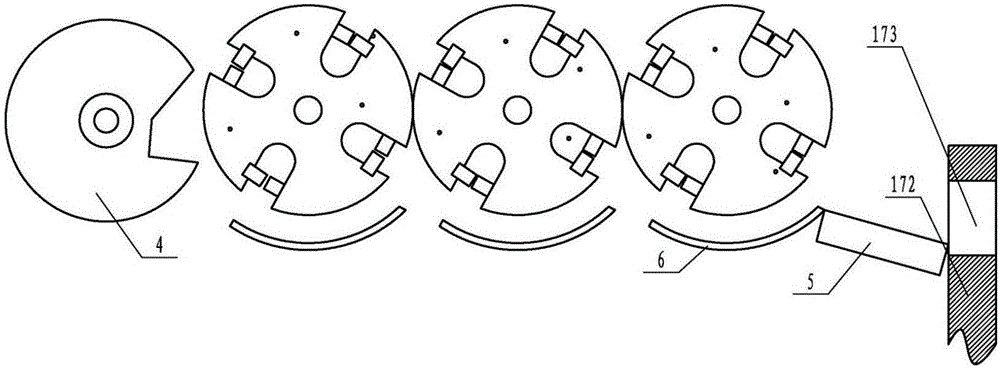

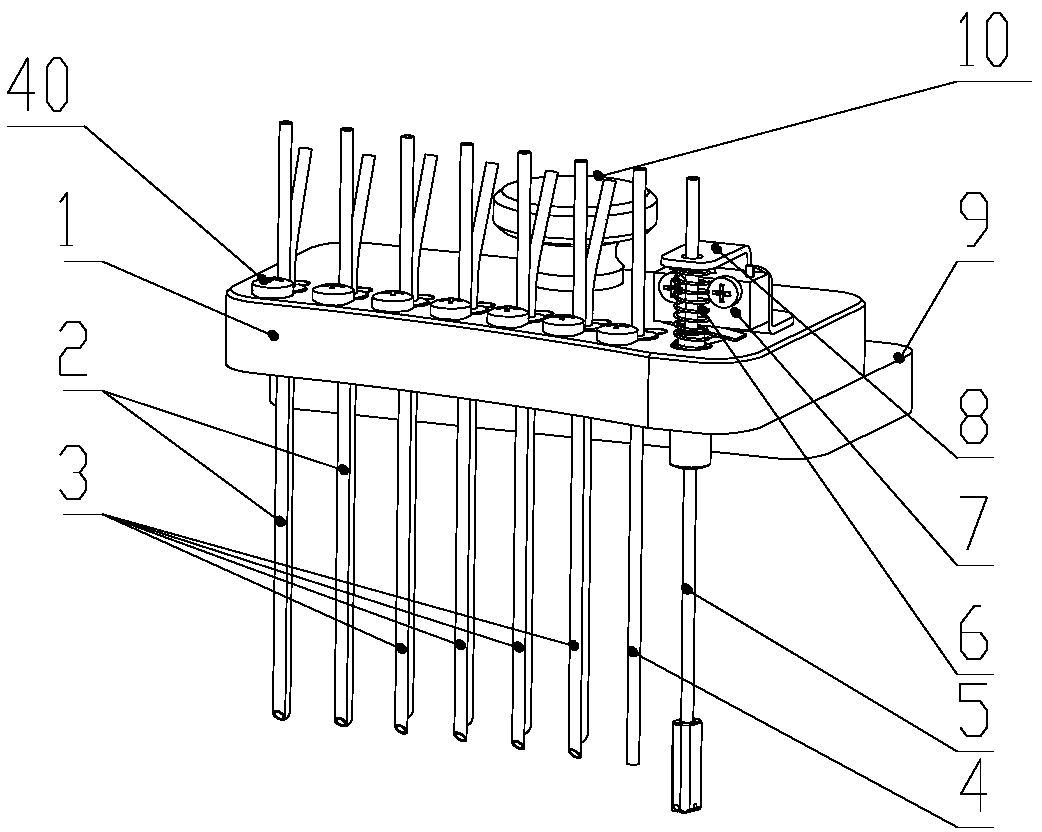

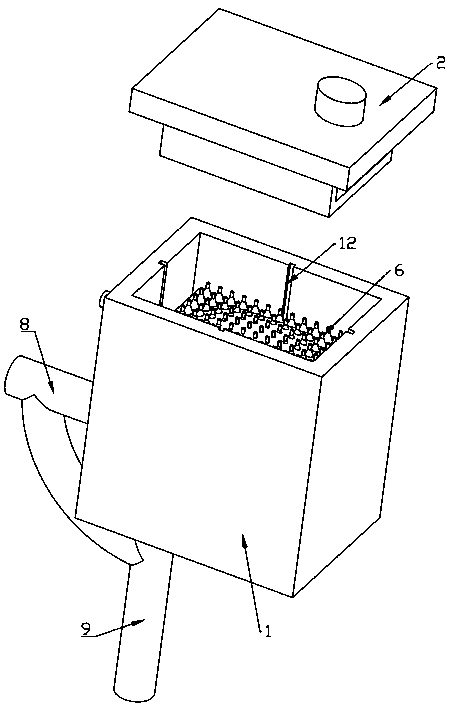

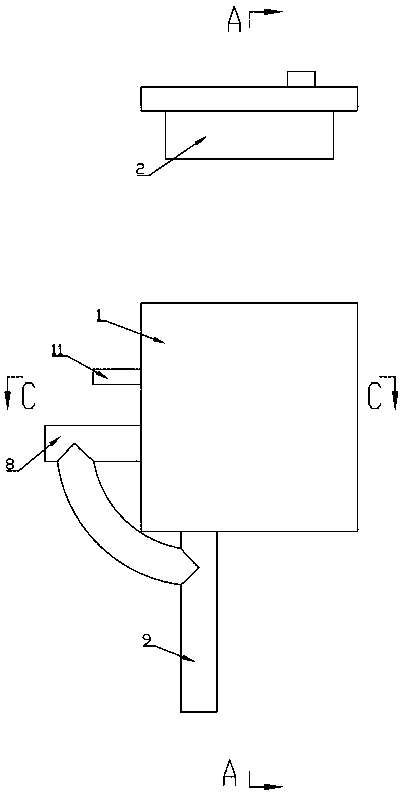

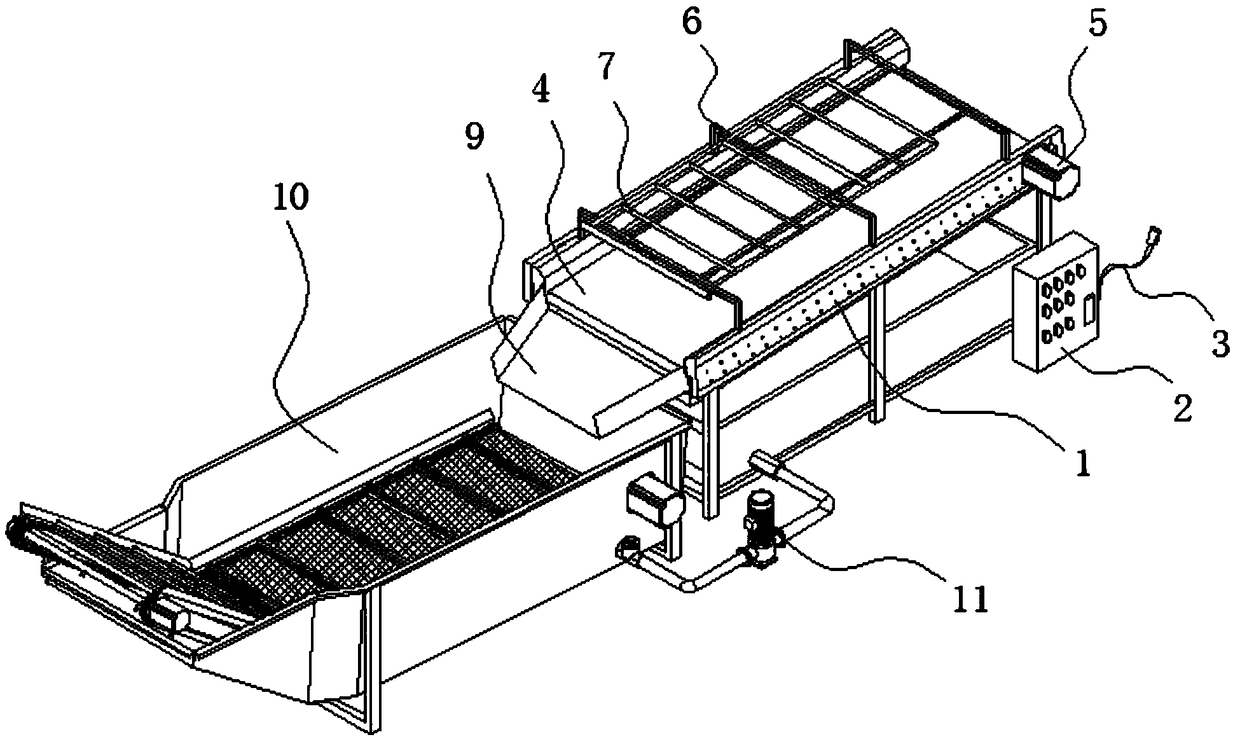

Method and machine for cleaning needles for injecting fluids into meat products

The method consists of forcing a cleaning solution, such as caustic soda, through an inner passage of the needles (40), then injecting pressurized air into said needles, and afterwards flushing pressurized water through the inside of the needles. The machine comprises upper and lower compartments (2, 3) separated by a tray (6), and a tank (4) for the cleaning solution. The tray (6) supports the needles to be cleaned, such that a lower portion thereof is inside a number of containers (17) from which said needles (40) receive said cleaning solution driven by a pump (29), the pressurized air (23) and the washing water (25), through ducts (19, 21, 23, 25, 27) provided with valves (20, 24, 26, 28) in communication with the containers (17). The tray (6) collects the fluids coming out of the upper holes of the needles (40).

Owner:METALQUIMIA SA

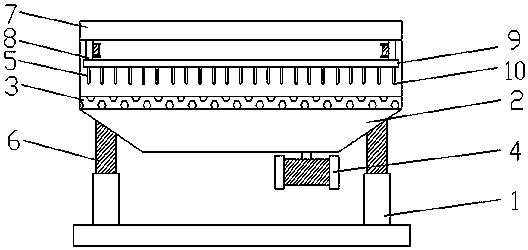

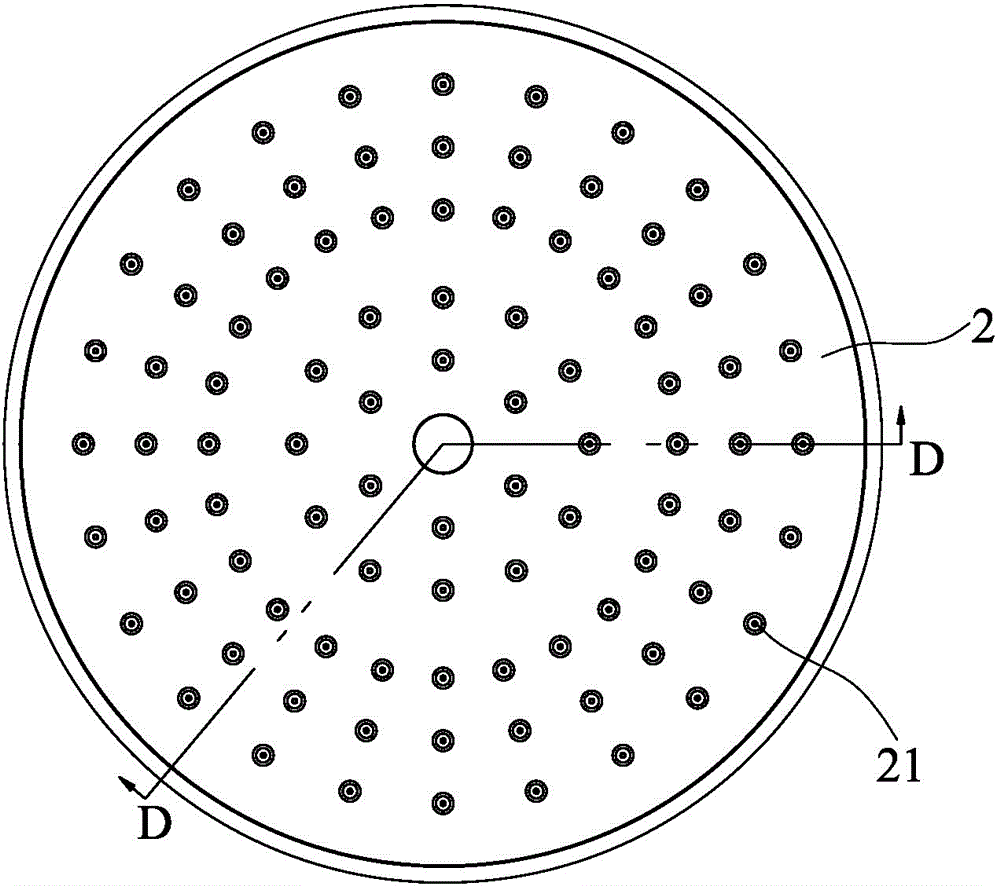

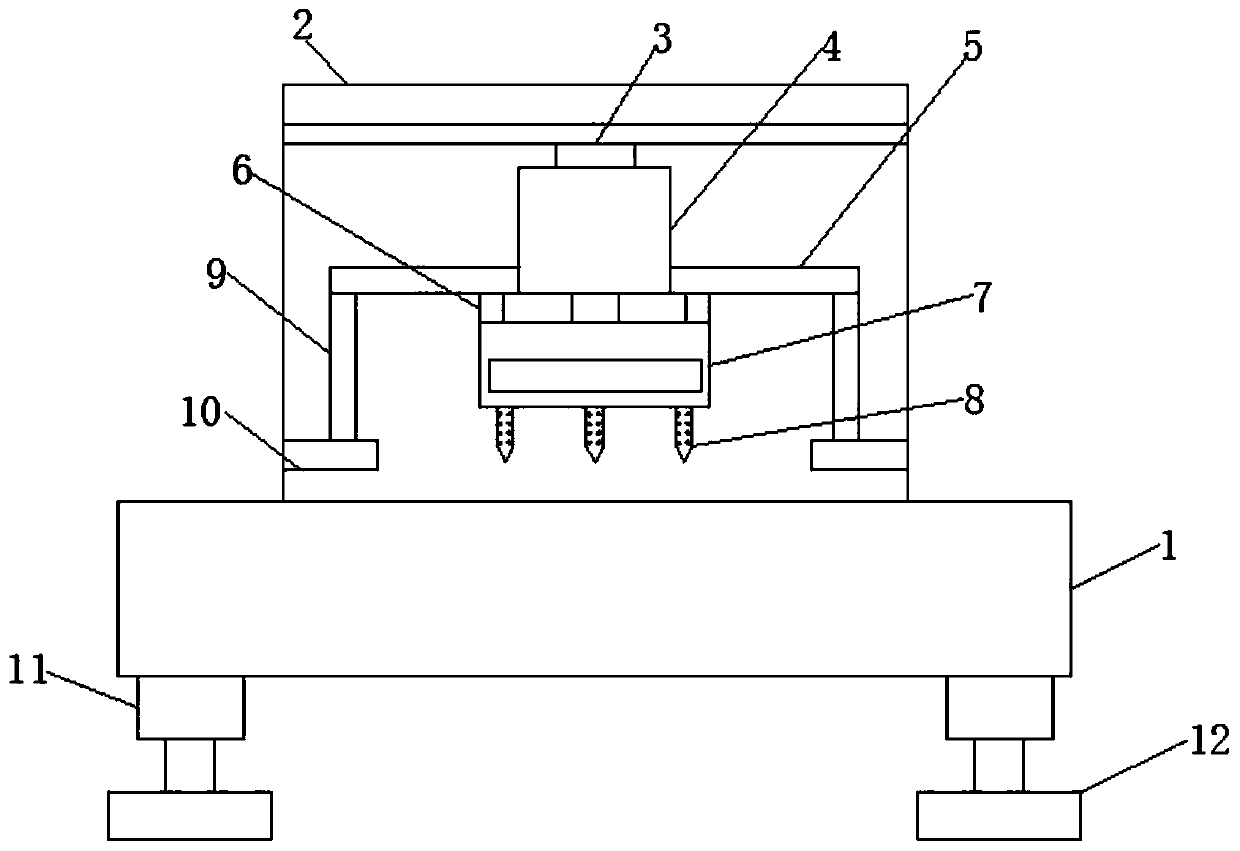

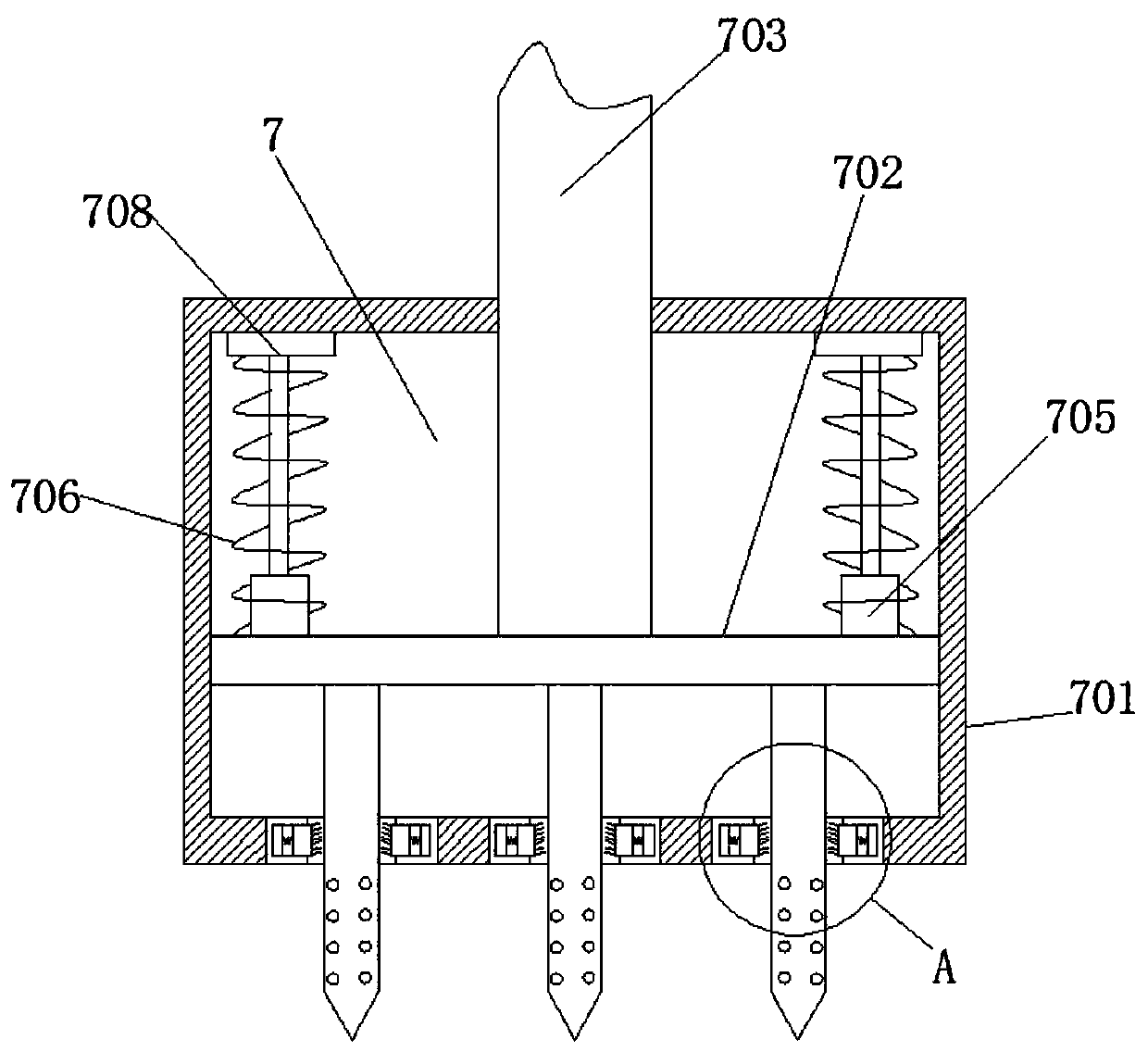

Self-cleaning needle machine for spinning

InactiveCN110219097AMove preciselyAvoid destructionNon-rotating vibration suppressionNeedling machinesFiberCleaning needle

The invention discloses a self-cleaning needle machine for spinning. The self-cleaning needle machine comprises a base and a mounting plate. Damping devices are fixedly connected to the lower end of the base. Support legs are connected to the damping devices. The mounting plate is fixedly connected to the upper end of the base. Compression devices are lengthened through electric telescopic rods. Asecond compression plate compresses a to-be-processed product. A plurality of protrusion blocks can well press the to-be-processed product. A buffering effect is achieved during compression through first telescopic rods and first springs; when puncture needles lift the to-be-processed product during rising due to movement mistakes, the first telescopic rods and the first springs play a bufferingrole to prevent the to-be-processed product from being pulled to cause damage; electromagnets are started up at a certain frequency and are electrified to produce attraction forces, sliders are pushedout, steel wires are attached to the side walls of the puncture needles, and accordingly, fibers brought out by the puncture needles are cleared away to ensure good operation of the puncture needles.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

Nap brush automatic cleaning device of napping machine

ActiveCN104646356AReasonable designEasy maintenanceCleaning using toolsCleaning using gasesCleaning needleBristle

The invention particularly relates to a nap brush automatic cleaning device of a napping machine. The nap brush automatic cleaning device comprises a casing, a needle roll, a brush roll, anti-static equipment, and vacuum material collecting equipment, wherein the needle roll is positioned in the casing, cleaning needles are fully distributed at the surface of the needle roll, cleaning brush bristles are fully distributed at the surface of the brush roll, the anti-static equipment comprises an ion fan and a surface potentiometric sensor which are electrically connected, the ion fan is arranged at the upper part of the brush roll, the surface potentiometric sensor is positioned besides the brush roll, the vacuum material collecting equipment comprises an air suction pipe, an air suction fan, an air outlet pipe and a material collecting box which are sequentially communicated, and a funnel-shaped opening is formed in the tail end of the air suction pipe, and is arranged at the lower parts of the needle roll and the brush roll. The nap brush automatic cleaning device has the advantages that the cleaning area is large, the dead angle is avoided, the static electricity is thoroughly neutralized, the automatic control is realized, the labor is saved, and the energy consumption is decreased.

Owner:FUJIAN CHANGGENG NEW MATERIALS CO LTD

Ultrasonic vibration cleaning tank and cleaning method utilizing same

The invention discloses an ultrasonic vibration cleaning tank and a cleaning method utilizing the same. The cleaning tank comprises a cleaning tank body and an ultrasonic vibrator. The cleaning tank body is used for accommodating to-be-cleaned needle sets. The ultrasonic vibrator is fixed in an ultrasonic vibrating room, and the side wall of the ultrasonic vibrating room is mounted on a bottom groove of the cleaning tank. The cleaning tank has the advantage of simple structure and good cleaning effect.

Owner:上海裕隆生物科技有限公司

Rapid vertical type plate cleaning machine for microporous reaction plates

InactiveCN106733933AImprove cleaning efficiencyShorten the timeDrying solid materials without heatCleaning using gasesCleaning needleMicrowell Plate

The invention discloses a rapid vertical type plate cleaning machine for microporous reaction plates. The rapid vertical type plate cleaning machine comprises a cleaning barrel. A centrifugal motor is arranged in the cleaning barrel. A centrifugal disc is mounted on an output shaft of the centrifugal motor. Multiple microporous plate trays are uniformly arranged on the outer side wall of the centrifugal disc, wherein the microporous plate trays are used for storing the microporous reaction plates. Holes are machined in the microporous plate trays. The sizes, the number and the distances of the holes are the same as those of holes in the microporous reaction plates to be cleaned. Cleaning needle assemblies are arranged on the upper portion of the side wall of the cleaning barrel. Each cleaning needle assembly comprises a cleaning needle mounting plate and cleaning needles fixed to the corresponding cleaning mounting plate. The number and the distancea of the cleaning needles are the same as those of the holes in the microporous plate trays. The rear portions of the cleaning needle mounting plates are connected with a pipeline and connected with a liquid pump and a gas storage tank correspondingly through a T joint. The liquid pump is connected with a cleaning solution bottle and a pure water bottle through pipelines. The gas storage tank is connected with a pneumatic pump through a pipeline. By means of the rapid vertical type plate cleaning machine, cleaning time is remarkably shortened; work efficiency is improved; and work intensity is lowered.

Owner:TAIZHOU ZECEN BIOTECH CO LTD

Cleaning and separating device for chemiluminescent analyser

PendingCN109433767ACompact structureSmall footprintHollow article cleaningCleaning needleBiomedical engineering

The invention relates to a cleaning and separating device for a chemiluminescent analyser. The cleaning and separating device comprises a cleaning needle assembly, a cleaning needle assembly mountingframe for fixedly mounting the cleaning needle assembly, a cleaning needle assembly drive structure for enabling the cleaning needle assembly to move upwards or downwards, and a reaction cup conveyingassembly for moving a reaction cup to a position below the cleaning needle assembly, wherein the cleaning needle assembly comprises a needle tube fixed base, a waste liquor needle and a flushing needle, the waste liquor needle and the flushing needle are fixedly arranged on the needle tube fixed base; the bottom of the flushing needle is bent, and the bottom opening faces towards the outer wall of the waste liquor needle; spacing between the bottom opening of the flushing needle and the outer wall of the waste liquor needle is 1.2-1.8 mm; a perpendicular distance from the bottom opening of the flushing needle to the bottom opening of the waste liquor needle is 4-8 mm; and an included angle between the middle axis of the bottom opening of the flushing needle and the vertical direction is 125-145 degrees. When the flushing needle of the cleaning and separating device injects liquor, a liquor splashing phenomenon is avoided; and meanwhile, the purpose of flushing the outer wall of the waste liquor needle is achieved.

Owner:SUZHOU HYBIOME BIOMEDICAL ENG CO LTD

All-glass injector ultraclean brushing machine

ActiveCN106238389AReasonable structureEasy to useCleaning using toolsCleaning using liquidsCleaning needleClean needles

The invention relates to an all-glass injector ultraclean brushing machine. The machine comprises a feeding device, a detecting and identifying frame for distinguishing and identifying a needle core and a needle sleeve, an indexing transmission device for clamping and conveying the needle core and the needle sleeve, a cleaning pool for cleaning the needle core and the needle sleeve, a washing tool arranged in the cleaning pool, an indexing transmission control device for controlling rotation of the indexing transmission device, and a discharge device for storing the cleaned needle core and needle sleeve. The all-glass injector ultraclean brushing machine is reasonable in structure, convenient for use, skillful in design and advanced in process.

Owner:STATE GRID CORP OF CHINA +2

Anti-collision cleaning device of reaction cup

The invention provides an anti-collision cleaning device of a reaction cup. The device has the advantages that the structure is simple, the sensitivity is high, and the anti-collision reliability is improved. The anti-collision cleaning device comprises a mounting plate connected with a driving mechanism, two or more than two cleaning needles and at least one drying needle are arranged on the mounting plate, the cleaning needles and the drying needle are distributed alternatively in the arrangement direction of the reaction cup, the anti-collision cleaning device further comprises an inductionpiece used for indicating collision risk of the cleaning needles, the cleaning needles are fixed on the mounting plate, the drying needle is provided with a degree of freedom moving up and down relative to the mounting plate, and the tail end of the drying needle is lower than the tail ends of the cleaning needles by a first preset distance. According to the device, in the process of the mountingplate driving the cleaning needles and the drying needle to move downwards, the tail end of the drying needle is blocked to move upwards relative to the mounting plate, the when the moving amount exceeds a first preset safety distance, the induction piece is triggered, and the first preset safety distance is smaller than or equal to the first preset distance.

Owner:东软威特曼生物科技(沈阳)有限公司

Quick plate washing machine for microporous reaction plate and plate washing method

PendingCN106623205AReduce volumeEasy to carryDrying solid materials without heatDrying machines with local agitationCleaning needleEngineering

The invention relates to a quick plate washing machine for a microporous reaction plate and a plate washing method. The invention aims to solve the problem that in the prior art, the cleaning equipment is great in volume, long in cleaning time and low in biological safety grade. The quick plate washing machine provided by the invention comprises a box body and a cover body which are hermetically connected, an elisa plate placing chamber is arranged in the cover body, through holes corresponding to plate pores of the elisa plate in quantity and size are formed, and an elisa plate cleaning system and an elisa plate swabbing-off system are arranged in the cover body; the elisa plate cleaning system comprises a cleaning plate, cleaning needles corresponding to the plate pores of the elisa plate in quantity and size are arranged on the upper surface of the cleaning plate, and the cleaning needles are hollow inside and are externally connected to a liquid source of a cleaning liquid after communicating a cavity in the bottom of the cleaning plate; the elisa plate swabbing-off system comprises an air outlet pipe arranged on the plate washing machine and a negative pressure source connected to the air outlet pipe. The quick plate washing machine provided by the invention has the beneficial effects that the quick plate washing machine is small in size which is 1 / 3 of that of the elisa quick plate washing machine in the prior art, short in cleaning time, low in noise and high in cleaning degree.

Owner:吴建国

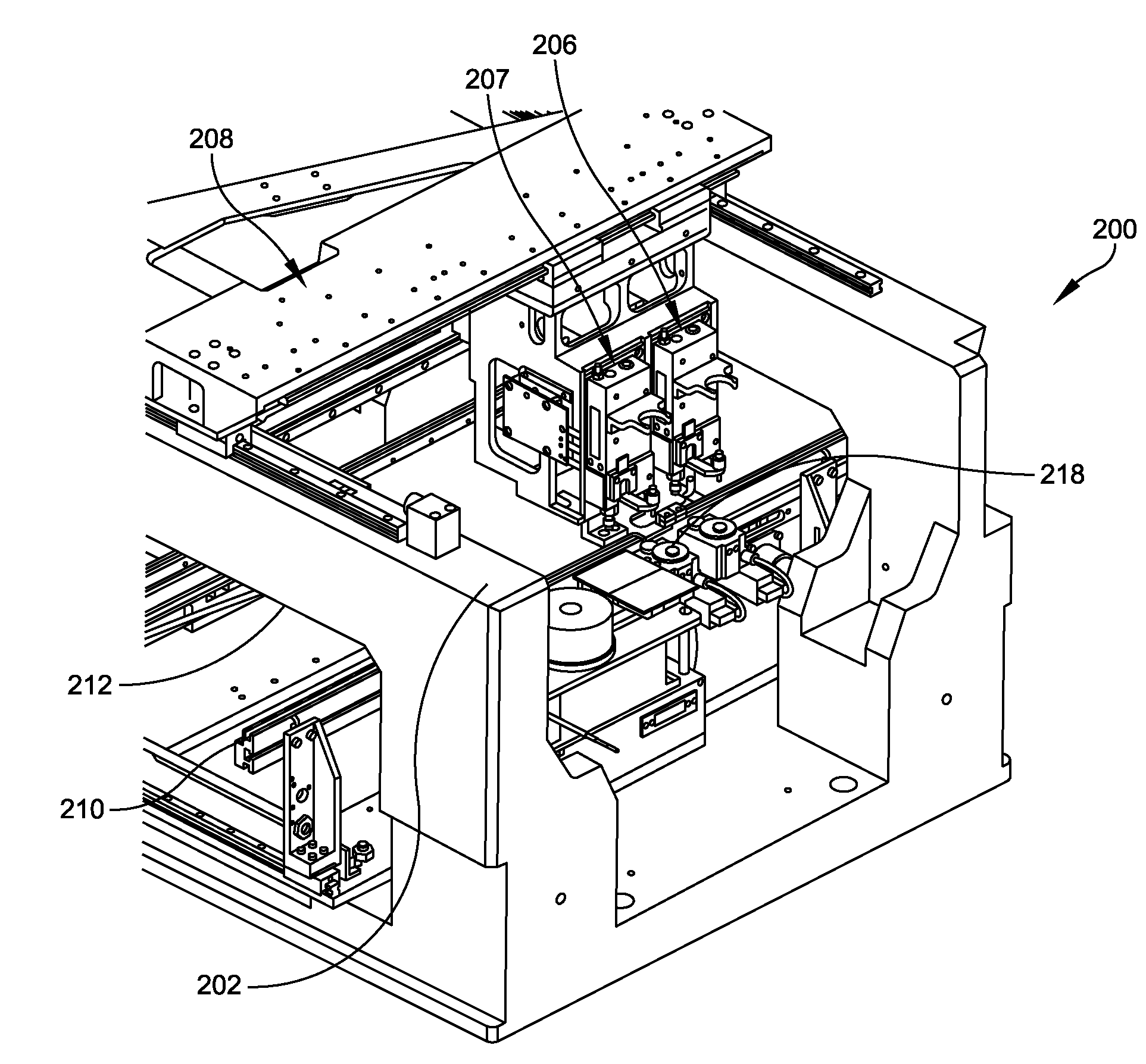

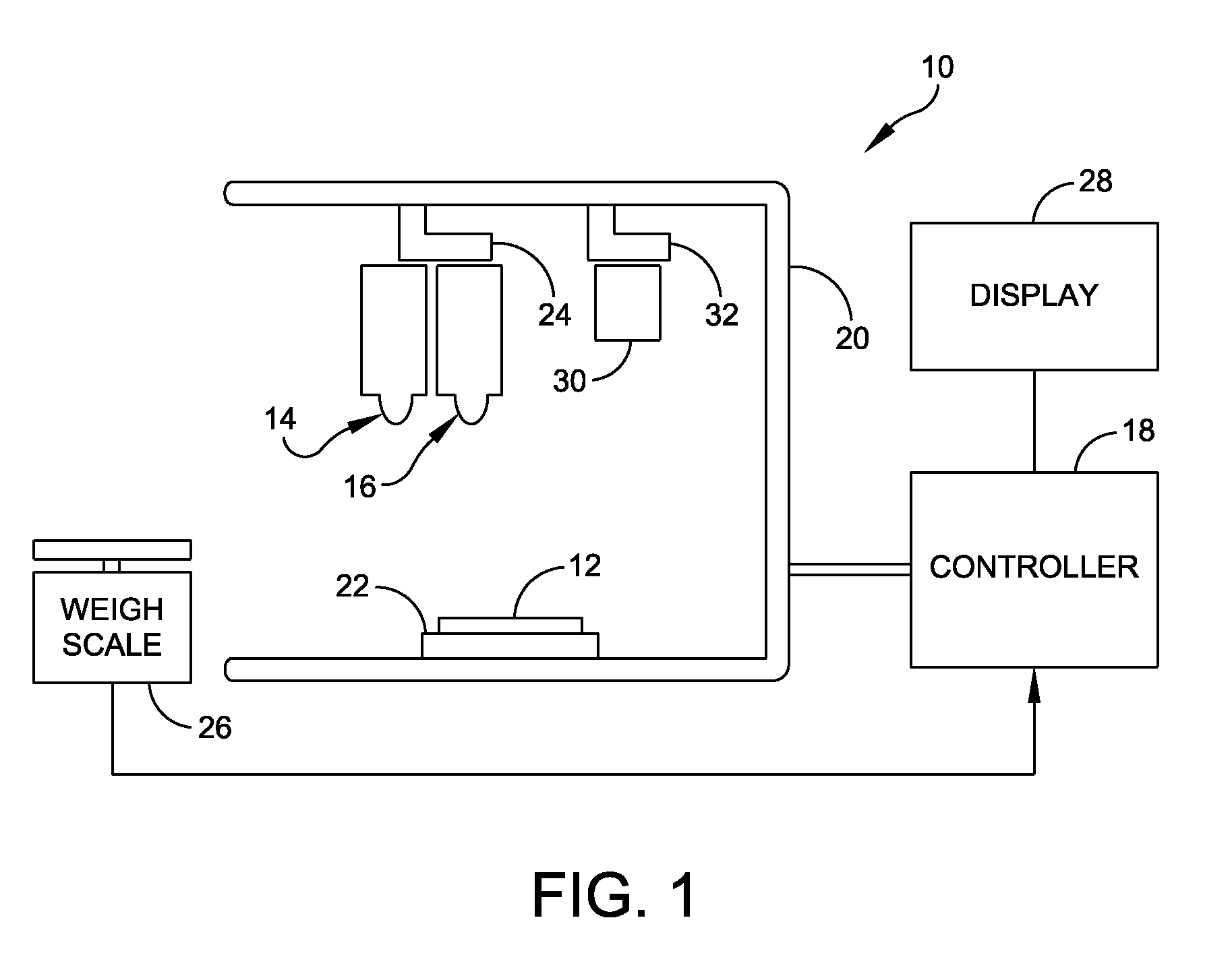

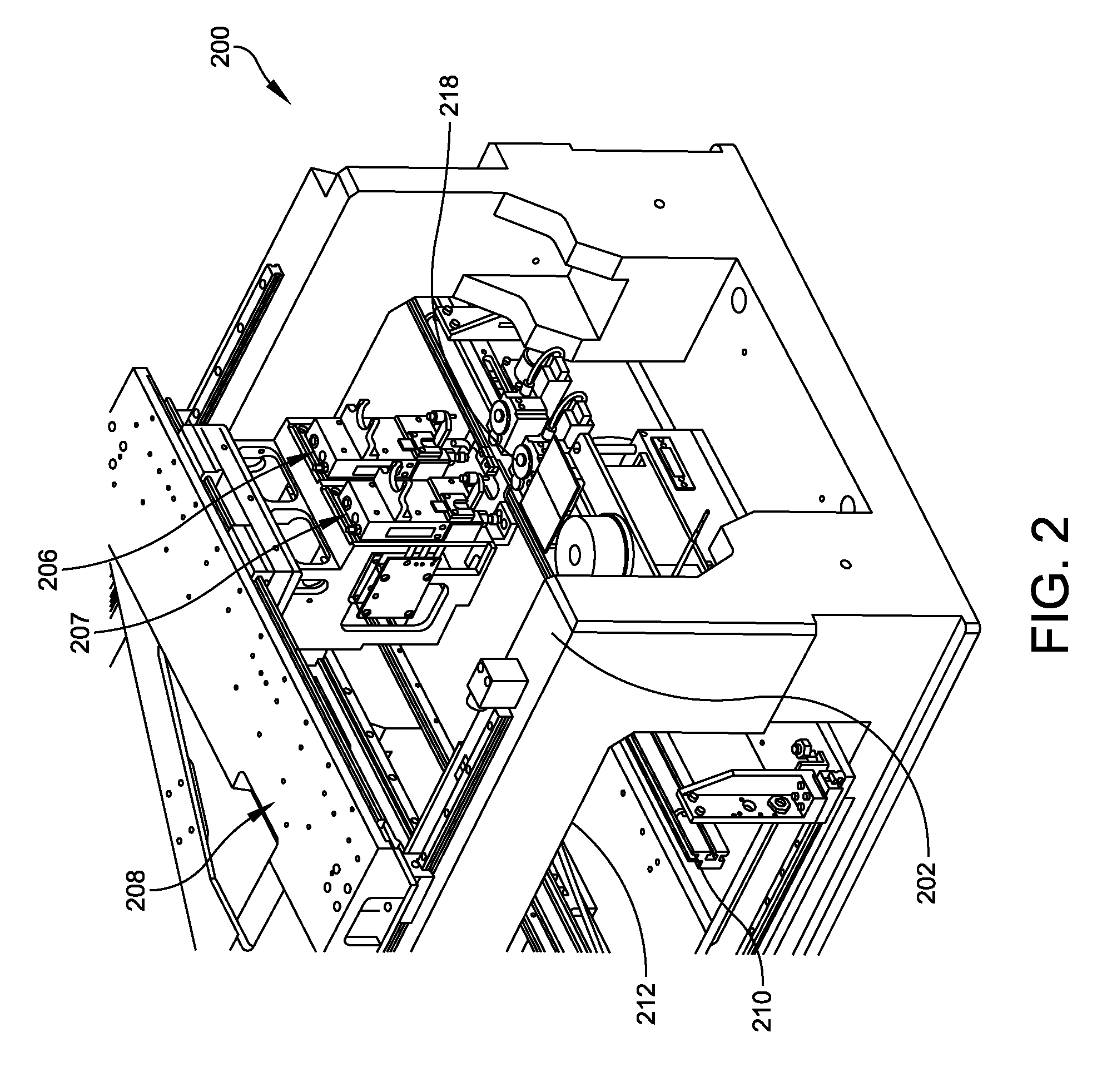

Automated multiple head cleaner for a dispensing system and related method

ActiveUS20140120241A1Eliminates operator interventionExtend process cycle timeHollow article cleaningLiquid spraying apparatusCleaning needlePrinted circuit board

A material deposition system is configured to deposit material on an electronic substrate, such as a printed circuit board. The material deposition system includes a frame, a support coupled to the frame and configured to support an electronic substrate during a deposit operation, a gantry coupled to the frame, and two deposition heads coupled to the gantry. Each deposition head includes a needle, with the deposition heads being movable over the support by movement of the gantry. The material deposition system further includes a needle cleaner assembly movable on a needle cleaner gantry, with the needle cleaner assembly being configured to clean needles of the deposition heads. The material deposition system further includes a controller configured to control the operation of the needle cleaner assembly to perform a needle cleaning operation.

Owner:ILLINOIS TOOL WORKS INC

Flavored needle mushroom cleaning device

PendingCN109259271AFully cleanedQuality improvementClimate change adaptationFood treatmentMicroorganismCleaning needle

Owner:泉州市佳创工业产品设计有限公司

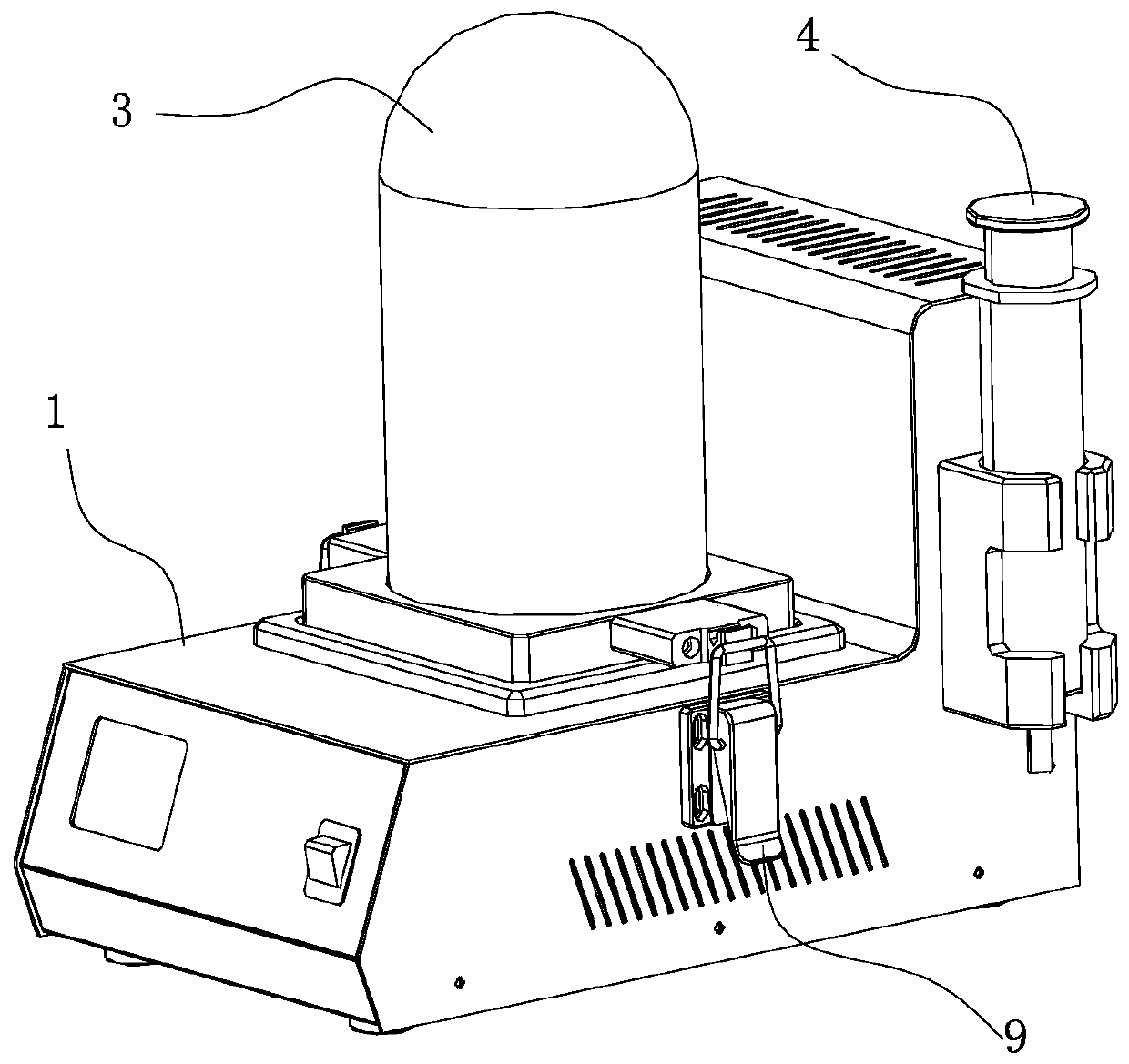

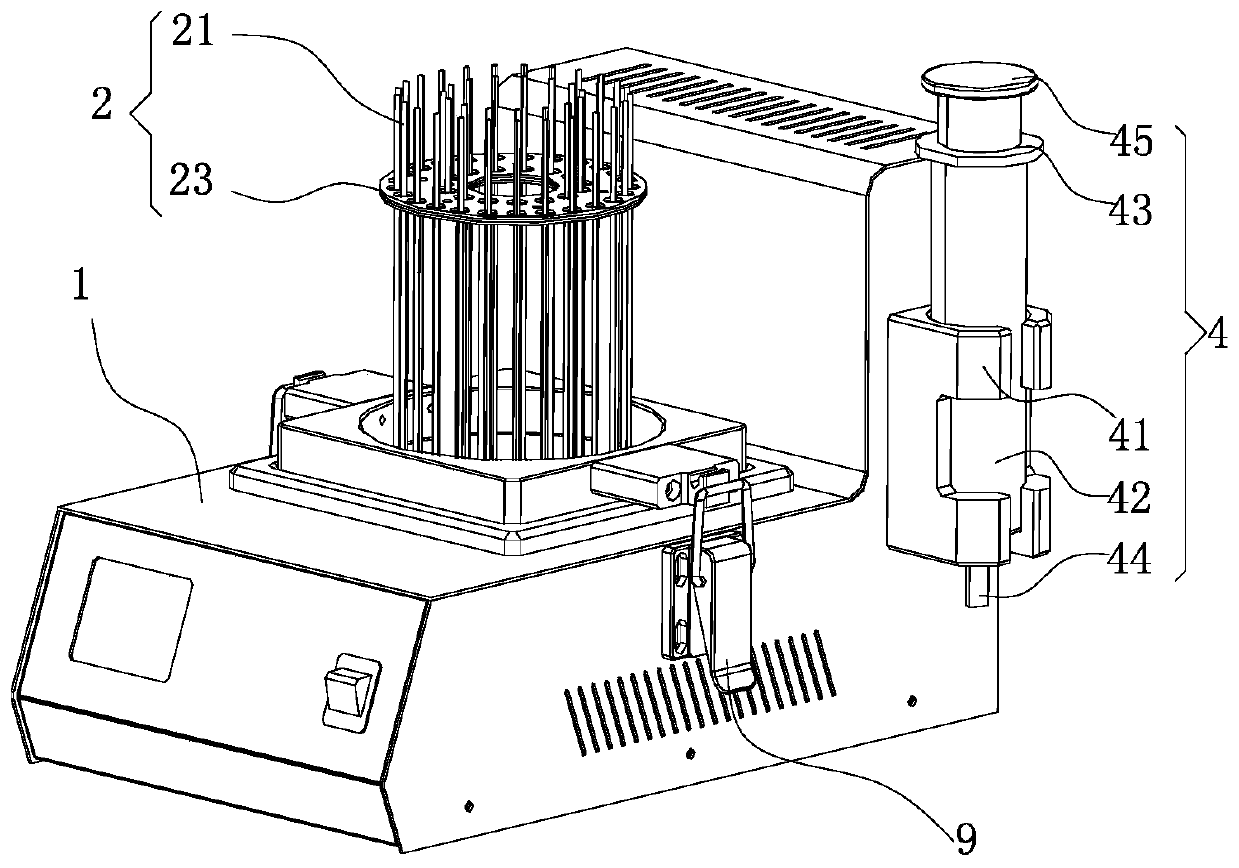

A device and method for fully automatic cleaning of spinneret micropores

The invention relates to a fully-automatic cleaning device for spinneret plate micro-holes. The device is characterized in that an XY precision moving platform which can move forward, backward, left and right in a horizontal direction is arranged on a base; a spinneret plate clamp used for accommodating a to-be-checked spinneret plate is arranged on the XY precision moving platform; a supporting arm fixedly connected with the base is arranged on a side edge of the XY precision moving platform; a Z-axis precision electronic control stand is fixed on the supporting arm; the Z-axis precision electronic control stand drives a cleaning part to move up and down in a vertical direction; a cleaning needle is arranged at the bottom of the cleaning part; the cleaning part drives the cleaning needle to rotate around an axis of the cleaning part; and a standard guide hole is formed below the cleaning needle. Manual cleaning of original pinneret plate micro-holes can be replaced with the device, so that impurities of the spinneret plate micro-holes can be cleaned away automatically, the operation efficiency for spinneret plates in chemical fiber production can be substantially increased, and at the same time, the production efficiency of an enterprise can be substantially improved.

Owner:DONGHUA UNIV

Automatic cleaning device

The invention belongs to the technical field of biochemical experiment instrument and equipment, and particularly relates to an automatic cleaning device. The automatic cleaning device comprises a high-pressure steam generating chamber and a heating assembly, wherein the high-pressure steam generating chamber and the heating assembly are used for heating and pressurizing cleaning liquid, the cleaning liquid can be quickly vaporized into solvent steam so as to form high-pressure gas, the high-pressure hot steam then enters a plurality of vertically-arranged cleaning needles and is sprayed to the inner walls of nuclear magnetic sample delivery pipes which are arranged outside the cleaning needles in a sleeving mode through nozzles of the cleaning needles, the steam is used for taking out residues on the inner walls of the nuclear magnetic sample delivery pipes, and the residues are discharged out of a cleaning bin through a waste discharging pipeline below the nuclear magnetic sample delivery pipes and are subjected to centralized treatment, so that the nuclear magnetic sample delivery pipes are cleaned. According to the automatic cleaning device, efficient and automatic operation can be realized, the operation process is safe and environment-friendly, and the automatic cleaning device has great popularization value and application prospect.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com