Nap brush automatic cleaning device of napping machine

An automatic cleaning and raising machine technology, which is applied to the cleaning methods, cleaning methods and utensils using gas flow, and cleaning methods using tools, etc. Achieve the effect of prolonging the service life, realizing automatic energy-saving control and thorough treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

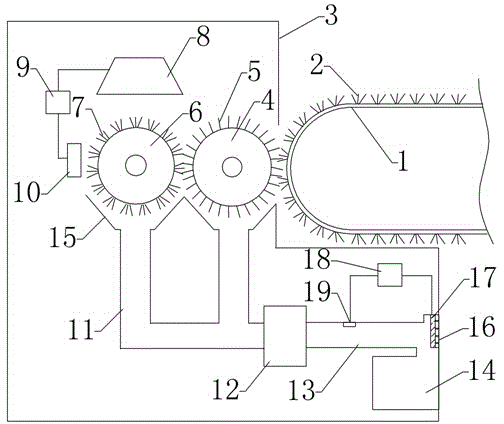

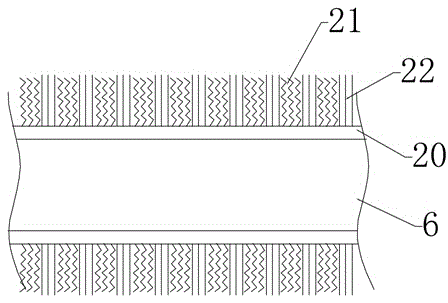

[0027] An automatic cleaning device for pile brushes of pile machines, see figure 1 , the velvet brush 2 is located on the surface of the rotary crawler belt 1 of the pile machine, the automatic cleaning device includes a housing 3, and a needle roller 4 whose surface is covered with cleaning needles 5 inside the housing 3 and a needle roller 4 whose surface is covered with A brush roller 6 for cleaning the bristles 7; the needle roller 4 is arranged on the side of the end of the rotating crawler belt 1, and its cleaning needle 5 extends into the pile brush 2, and the brush roller 6 is arranged on the needle roller 4 side, and its cleaning bristles 7 extend into the cleaning needle 5; the automatic cleaning device also includes a static removal device and a vacuum receiving device; the static removal device includes an electrically connected ion blower 8 and a surface potential sensor 10. The ion fan 8 is arranged on the top of the brush roller 6, the surface potential sensor...

Embodiment 2

[0032] An automatic cleaning device for pile brushes of pile machines, see figure 1, the velvet brush 2 is located on the surface of the rotary crawler belt 1 of the pile machine, the automatic cleaning device includes a housing 3, and a needle roller 4 whose surface is covered with cleaning needles 5 inside the housing 3 and a needle roller 4 whose surface is covered with A brush roller 6 for cleaning the bristles 7; the needle roller 4 is arranged on the side of the end of the rotating crawler belt 1, and its cleaning needle 5 extends into the pile brush 2, and the brush roller 6 is arranged on the needle roller 4 side, and its cleaning bristles 7 extend into the cleaning needle 5; the automatic cleaning device also includes a static removal device and a vacuum receiving device; the static removal device includes an electrically connected ion blower 8 and a surface potential sensor 10. The ion fan 8 is arranged on the top of the brush roller 6, the surface potential sensor ...

Embodiment 3

[0037] An automatic cleaning device for the pile brush of a pile machine, the pile brush 2 is located on the surface of the rotary crawler belt 1 of the pile machine, the automatic cleaning device includes a shell 3, and a surface inside the shell 3 is covered with cleaning needles 5 needle roller 4 and a brush roller 6 whose surface is covered with cleaning bristles 7; The brush roller 6 is located on the side of the needle roller 4, and its cleaning bristles 7 extend into the cleaning needle 5; the automatic cleaning device also includes a static removal device and a vacuum receiving device; the static removal device includes Electrically connected ion fan 8 and surface potential sensor 10, the ion fan 8 is arranged on the top of the brush roller 6, the surface potential sensor 10 is arranged on the side of the brush roller 6, between the ion fan 8 and the surface potential sensor 10 There is also a control system 9 (PLC) between them, which can control the opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com