Multifunctional automatic sample injector

An automatic sampling and multi-functional technology, applied in the direction of instruments, analytical materials, etc., can solve the problems of unfavorable automatic control and programming, poor anti-interference ability, single function of automatic sampler, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

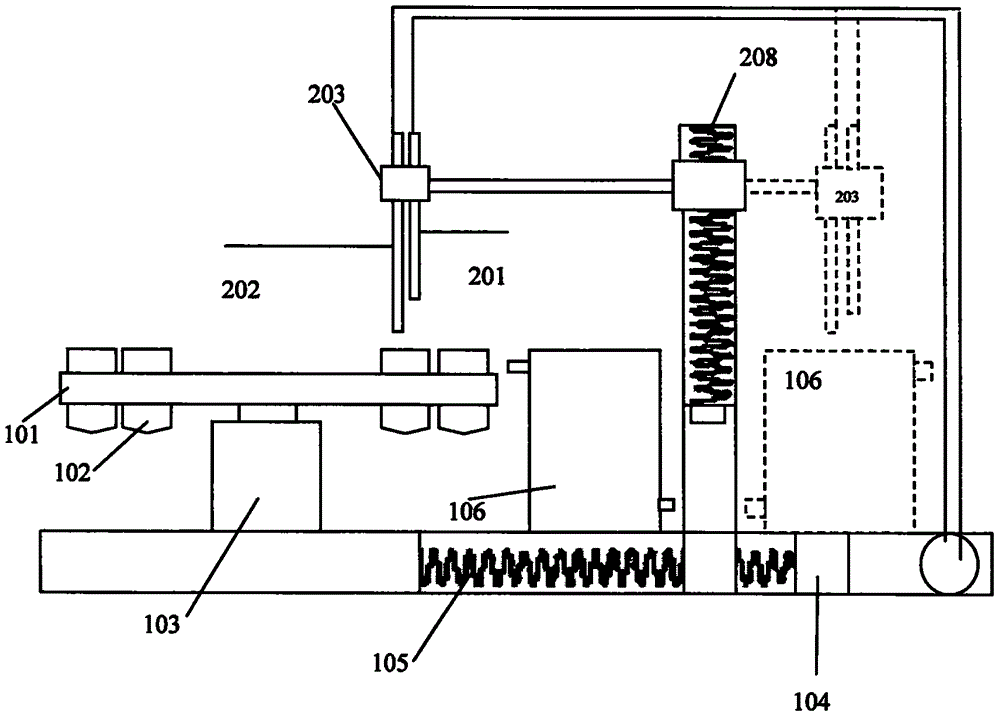

[0031] Embodiment 1: centrifugation and sampling process

[0032] The sample 102-sample bottle to be tested is placed in the 101-sample tray (horizontal rotor). When it is necessary to separate the supernatant and precipitate, or, for example, after the titration method is used to determine the concentration of chloride ions, the supernatant is used to continue to measure the total organic carbon ( TOC) concentration, 103-sample disc drive motor drives 101-sample disc (horizontal rotor) to rotate at high speed for centrifugation. The position gradually tends to the parallel position, standing still.

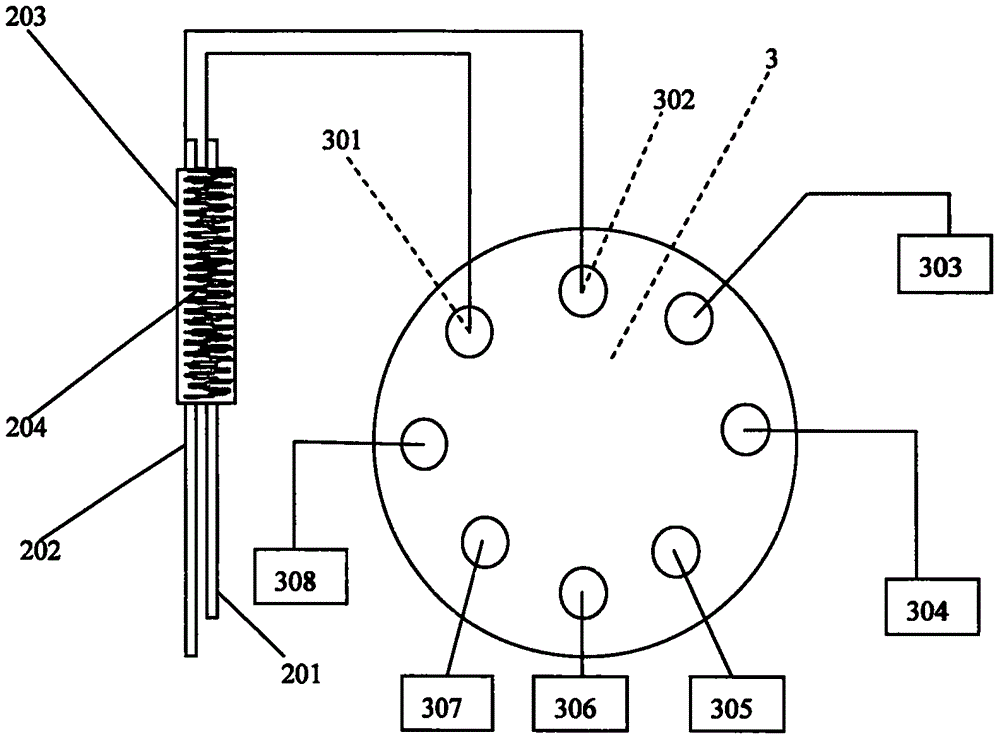

[0033] According to the sampling sequence, sampling times, 201-sampling needle cleaning program set by the host computer, 205-slider moves horizontally, when reaching the corresponding position, 207-slider moves vertically, when reaching the corresponding position, 201 -The sampling needle carries out quantitative sampling, passes through the 307-mixing reactor of the 3-multipor...

Embodiment 2

[0038] Example 2, such as image 3 Shown: different from embodiment 1, its features, such as image 3 As shown by the dotted line, the 106-cleaning solution pool can also be placed on the other side of the sample tray, for example, if the sample tray is on the left side of the vertical slider, the 106-cleaning solution pool can be set on the right side of the vertical slider; when 201 -sample injection needle; 202-cleaning needle rotates 180 degrees when 106-cleaning solution pool takes water for cleaning. It should be noted that 207-slider is not reversed 180 degrees, namely: 201-injection needle; 202-cleaning needle in the original direction downwards, 207-slider rotated 180 degrees, 201-injection needle; 202-cleaning The needle is still pointing downwards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com