Cleaning and separating device for chemiluminescent analyser

A chemiluminescence and separation device technology, applied in the field of medical devices, can solve problems such as easy liquid splashing, long cleaning time, and poor cleaning effect, and achieve the effect of preventing hard contact from damaging the needle, occupying a small space, and having a compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

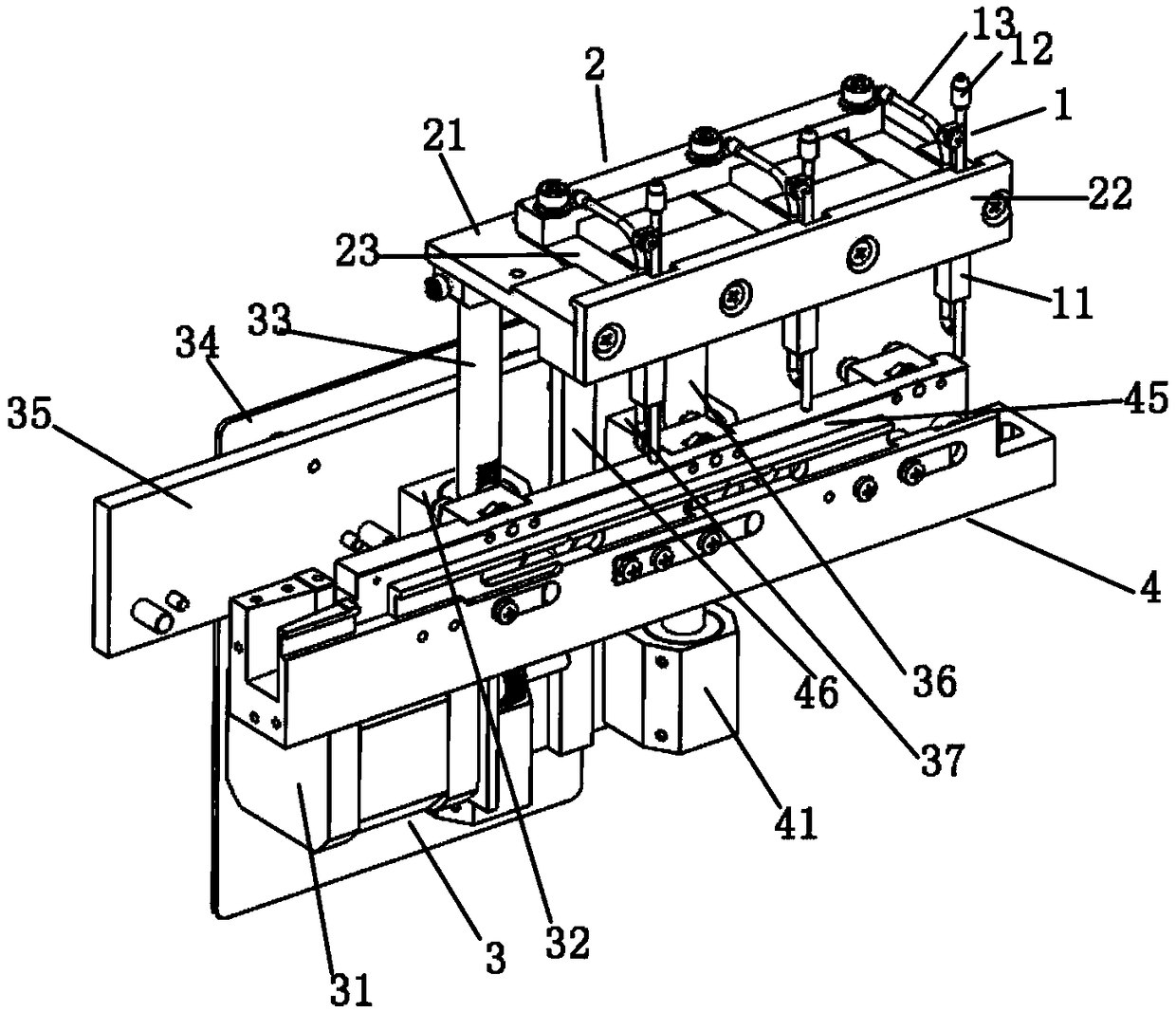

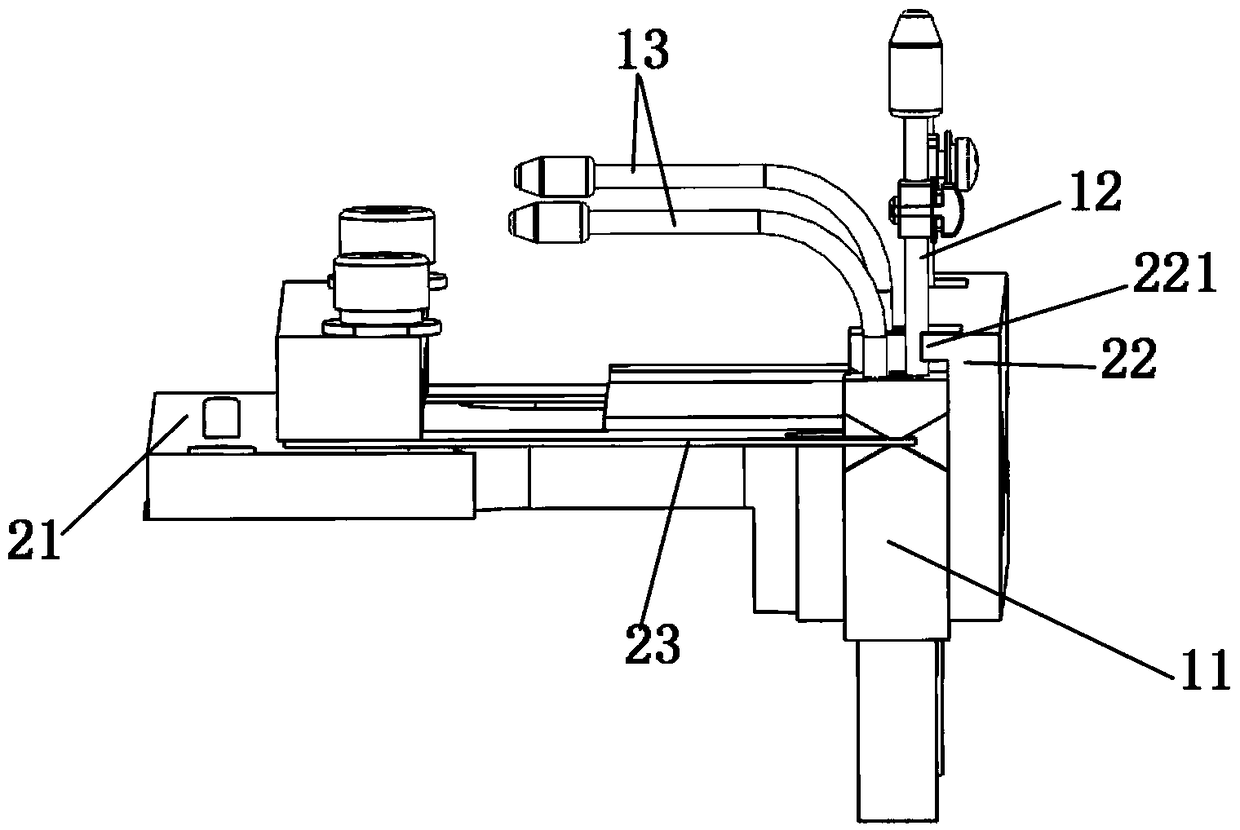

[0031] This embodiment provides a cleaning and separating device for a chemiluminescence analyzer, such as figure 1 As shown, it includes a cleaning needle assembly 1, a cleaning needle assembly mounting frame 2, a cleaning needle assembly driving structure 3, and a cuvette transport assembly 4. The needle cleaning assembly mounting frame 2 is used for fixedly installing the cleaning needle assembly 1, and the cleaning needle assembly The assembly driving structure 3 is used to move the cleaning needle assembly 1 up or down, and the cuvette conveying assembly 4 is used to move the cuvette to the bottom of the cleaning needle assembly 1;

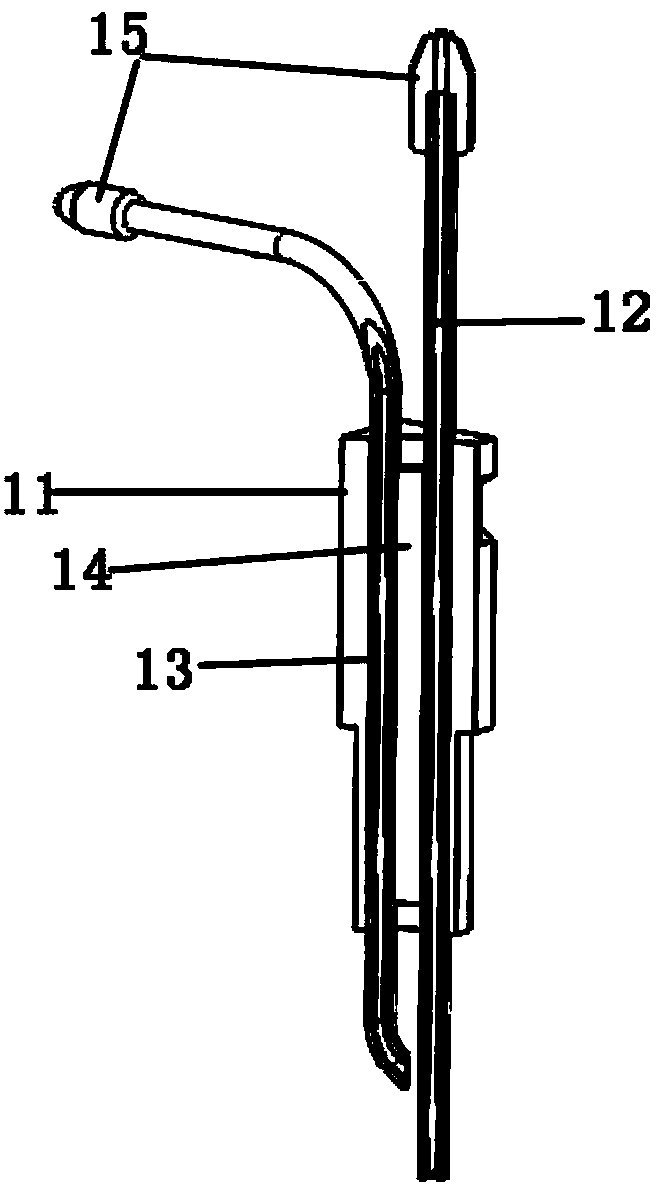

[0032] Such as figure 1 , figure 2 and image 3 As shown, the cleaning needle assembly 1 includes a needle tube fixing base 11, a waste liquid needle 12 and a flushing needle 13 fixed on the needle tube fixing base 11, and the bottom of the flushing needle 13 is bent and the bottom opening faces the waste liquid needle 12. outer wall;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com