Ultrasonic vibration cleaning tank and cleaning method utilizing same

A technology of ultrasonic wave and cleaning tank, applied in the field of immunochemical analysis, achieves the effect of simple structure, unique design and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

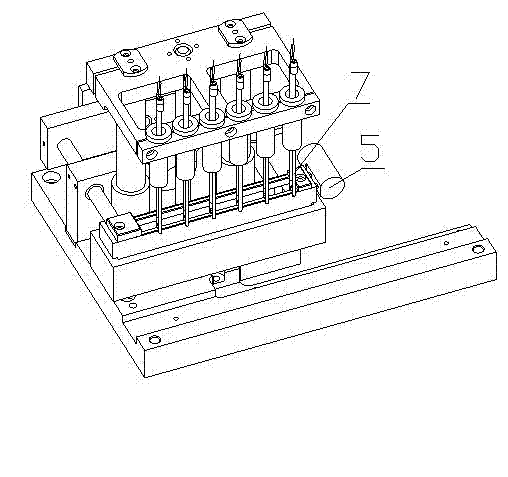

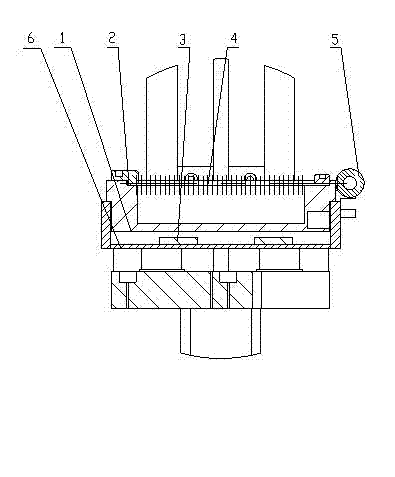

[0016] The following describes the present invention in detail with reference to the drawings. The present invention discloses an ultrasonic vibration cleaning tank, which is dedicated to a fully automatic tubular chemical analyzer and is used to thoroughly clean the needle set to be cleaned. The present invention includes an ultrasonic cleaning system and a liquid spray system. The ultrasonic cleaning system includes a cleaning tank 1 where the needle group 7 to be cleaned is placed during cleaning and an ultrasonic vibrator 3 that generates ultrasonic vibration. In order to achieve a good ultrasonic cleaning effect, the ultrasonic cleaning system The vibrator 3 is fixed in the ultrasonic vibration chamber 6, and the side wall of the ultrasonic vibration chamber 6 is installed in the bottom tank of the cleaning tank 1. In this way, when the ultrasonic vibrator 3 vibrates, its vibration will be transmitted to the cleaning tank 1 through the ultrasonic vibration chamber 6. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com