Automatically cleaning suction nozzle

A technology of self-cleaning and cleaning needles, which is applied in the direction of single-grain planters and planter parts, etc. It can solve the problems of suction nozzle failure, affecting adsorption capacity, suction nozzle hole blockage, etc., and achieve the effect of simple structure and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

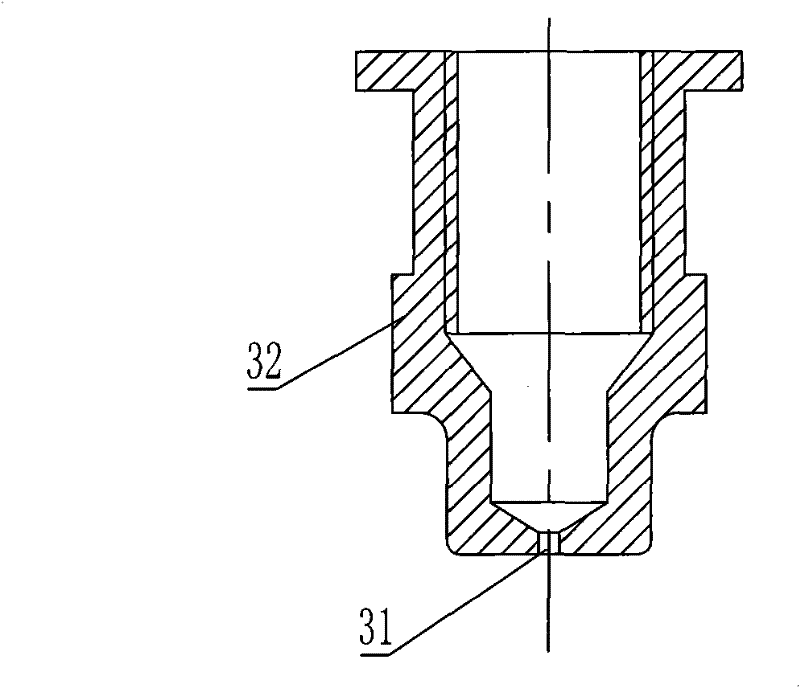

[0021] Figure 4 The structural composition diagram of the self-cleaning suction nozzle of the present invention is given. As shown in the figure, a cleaning needle 42 driven by a piston 44 is installed inside the suction nozzle housing 41. The cleaning needle 42 is a rod-shaped round rod. The outer diameter corresponds to the inner diameter of the nozzle hole of the nozzle housing 41 and is slightly smaller. When it goes down, it can penetrate into the nozzle hole; the bottom of the piston 44 is equipped with a return spring 43, and there is a The gap 45 for gas circulation.

[0022] Its action principle is as follows: when the suction nozzle is under negative pressure, under the action of the return spring 43 elastic force, etc., the piston 44 is in a floating state, and the side gap 45 ensures the smooth flow of the seed suction channel, exposing the suction nozzle hole to complete the seed adsorption; During this process, when the vacuum generator is converted from negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com