Quick plate washing machine for microporous reaction plate and plate washing method

A technology of microporous reaction plate and plate washer, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of large volume, low biological safety level, long cleaning time, etc., and achieve The effect of small size, short cleaning time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

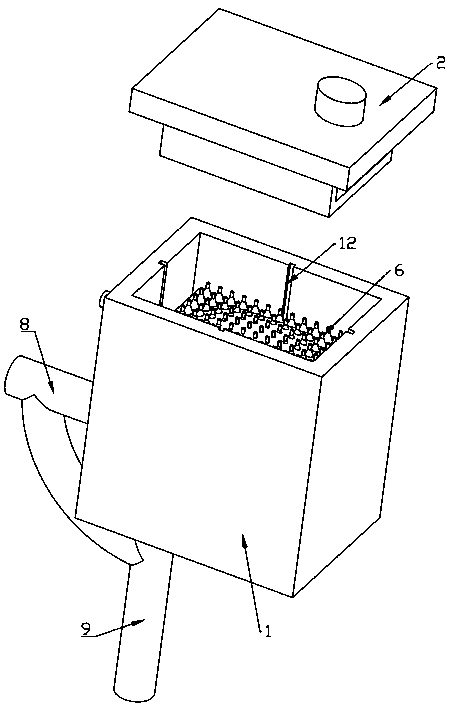

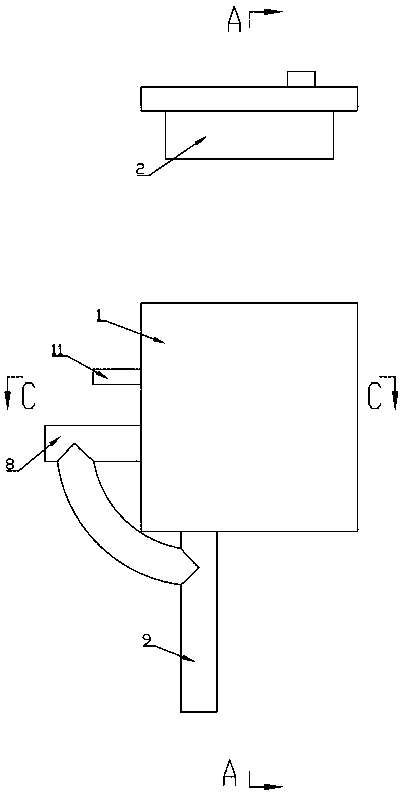

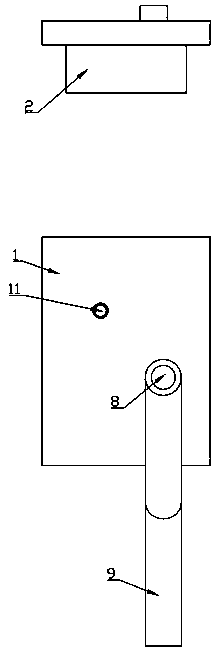

[0040] Embodiment 1: A kind of microporous reaction plate fast washing machine, see Figure 1 to Figure 10 , including a box body 1 and a cover body 2 that are sealed and connected, the cover body 2 is provided with a microplate plate placement cavity 3, and the plate holes corresponding to the microplate plate 4 are provided with through holes 5 corresponding in number and size, and the box body 1 is provided with There are enzyme label plate cleaning system and enzyme label plate drying system; the enzyme label plate cleaning system includes the cleaning nozzle corresponding to each through hole and the liquid source of the cleaning liquid connected with the cleaning nozzle, specifically, including cleaning plate 7, cleaning The upper surface of the plate 7 is provided with a cleaning needle 6 corresponding to the number and size of the plate holes of the microplate 4. The cleaning needle 6 is hollow inside, connected to the bottom cavity of the cleaning plate 7, and then ext...

Embodiment 2

[0049] Embodiment 2: The working method is the same as that of Embodiment 1, the specific difference is that, as Figure 11 , 12 , the box body 1 and the cover body 2 are hingedly connected, and the microplate plate 4 is installed into the microplate plate placement chamber 3 in a horizontal plug-in installation manner.

Embodiment 3

[0050]Embodiment 3: The working method is the same as that of Embodiment 1, the specific difference is that, as Figure 13 , the microplate plate 4 can be installed into the microplate plate placement cavity 3 in a vertical plug-in installation mode, further reducing the difficulty of installation:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com