All-glass injector ultraclean brushing machine

A syringe and all-glass technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of not having separate tank cleaning conditions, failing to reach 120°C, and failing to meet cleanliness requirements etc. to achieve the effect of convenient use and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

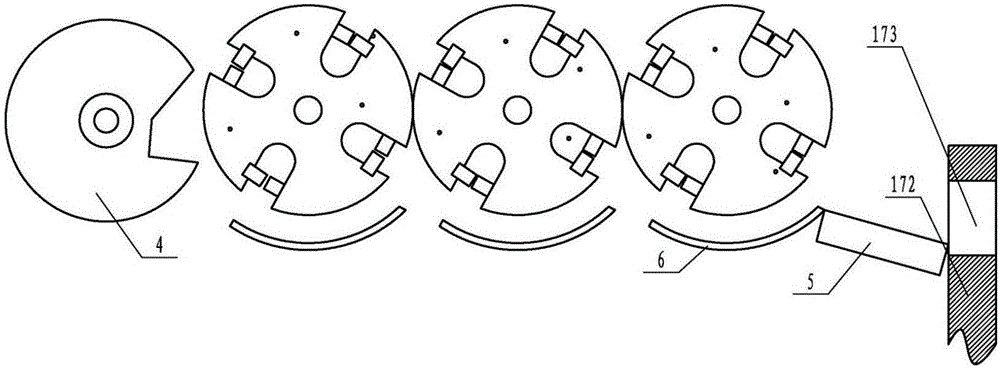

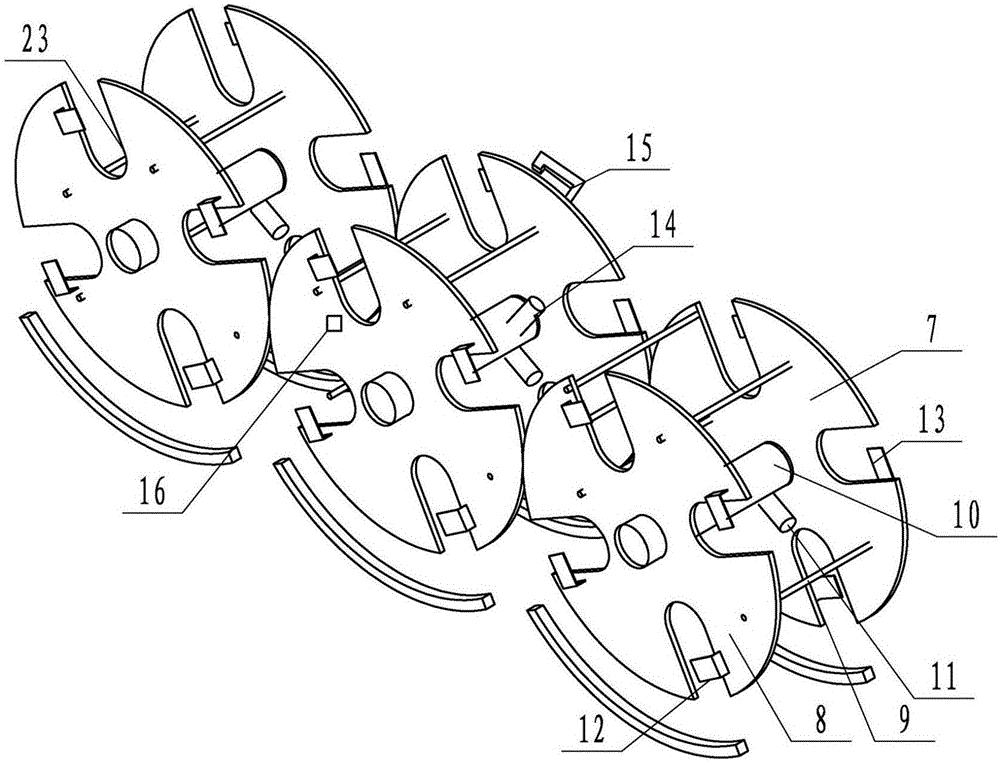

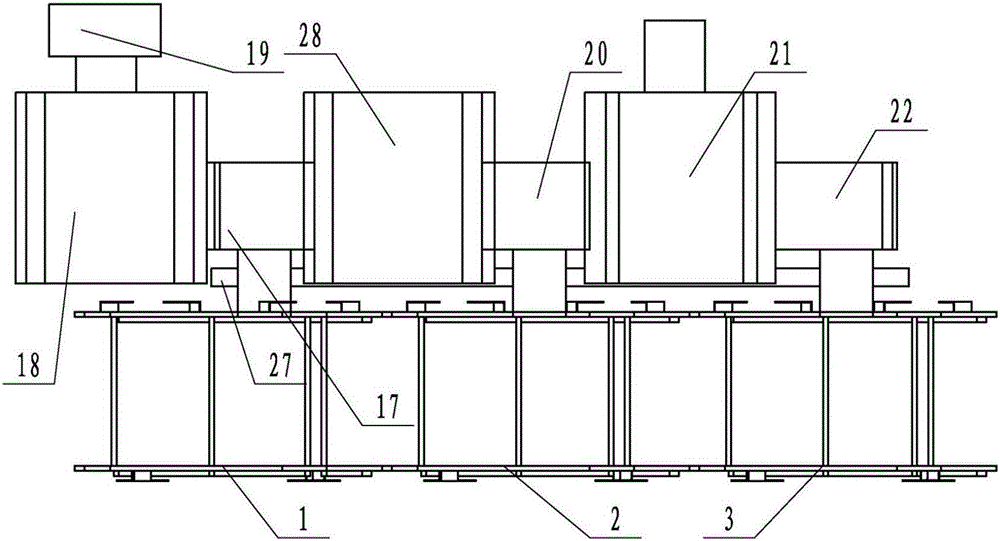

[0016] Such as Figure 1-15 As shown, this embodiment includes a feeding device 101 for storing the needle core 139 and the needle cover 140, a detection and identification frame 102 for distinguishing and identifying the needle core 139 and the needle cover 140, and a detection frame 102 for identifying the needle core 139 and the needle cover 140. The indexing transmission device 103 for loading and transporting, the cleaning pool 100 for cleaning the needle core 139 and the needle cover 140, the washing tool 118 arranged in the cleaning pool 100, and the tool for controlling the rotation of the indexing transmission device 103 The indexing transmission control device 104 and the discharge device 105 for storing the cleaned needle core 139 and needle sheath 140;

[0017] The feeding device 101 , the detection and identification frame 102 , the indexing transmission device 103 and the discharge device 105 are arranged in sequence from left to right, and the cleaning tank 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com