Fully-automatic cleaning device and method for spinneret plate micro-holes

A technology for cleaning devices and spinnerets, which is applied to spinneret assemblies, textiles, and papermaking, and can solve the problems of high polymer residues, carbide impurities that cannot be completely removed, high labor intensity, and low work efficiency. Achieve the effect of automatic cleaning, improve production efficiency, and increase the probability of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

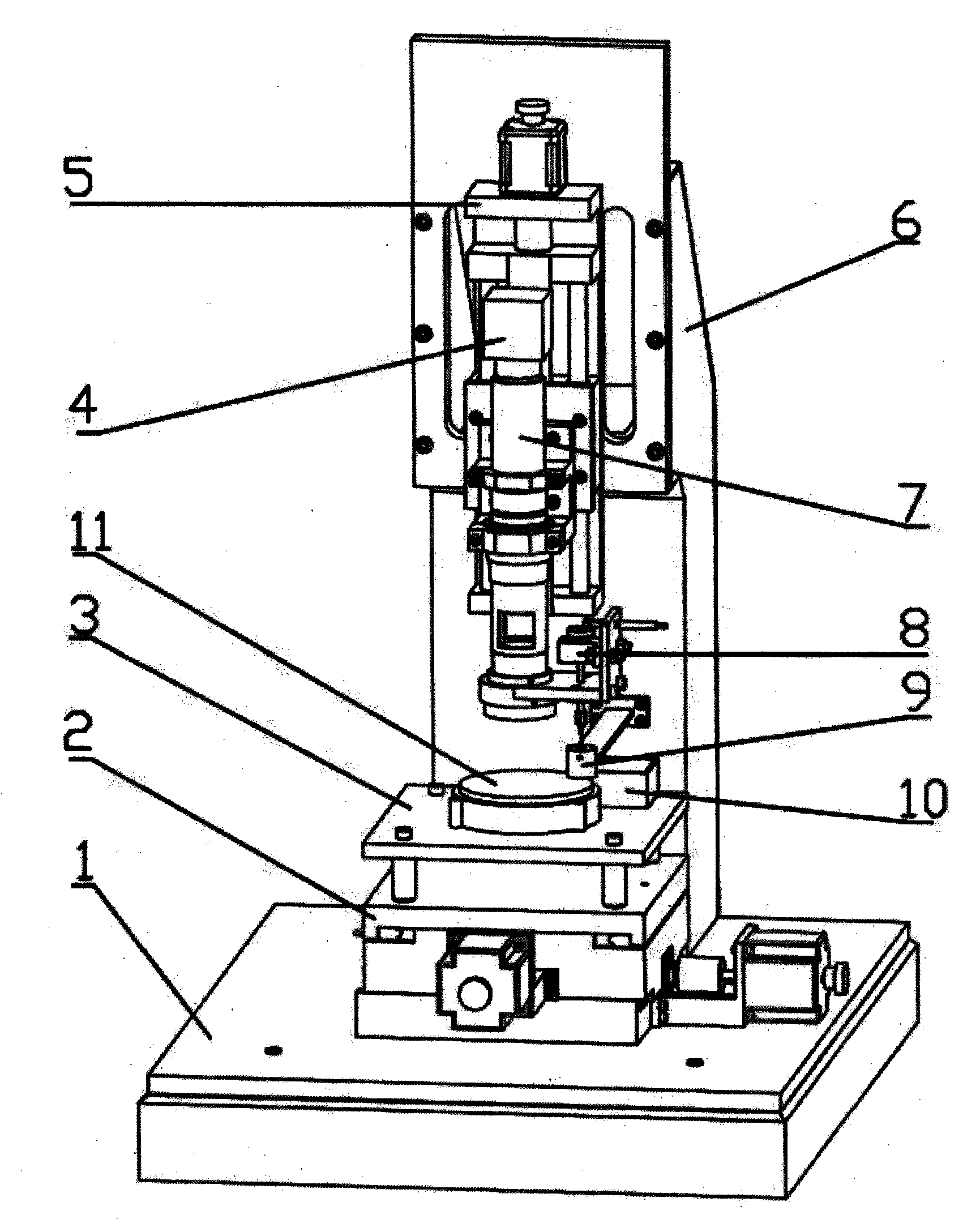

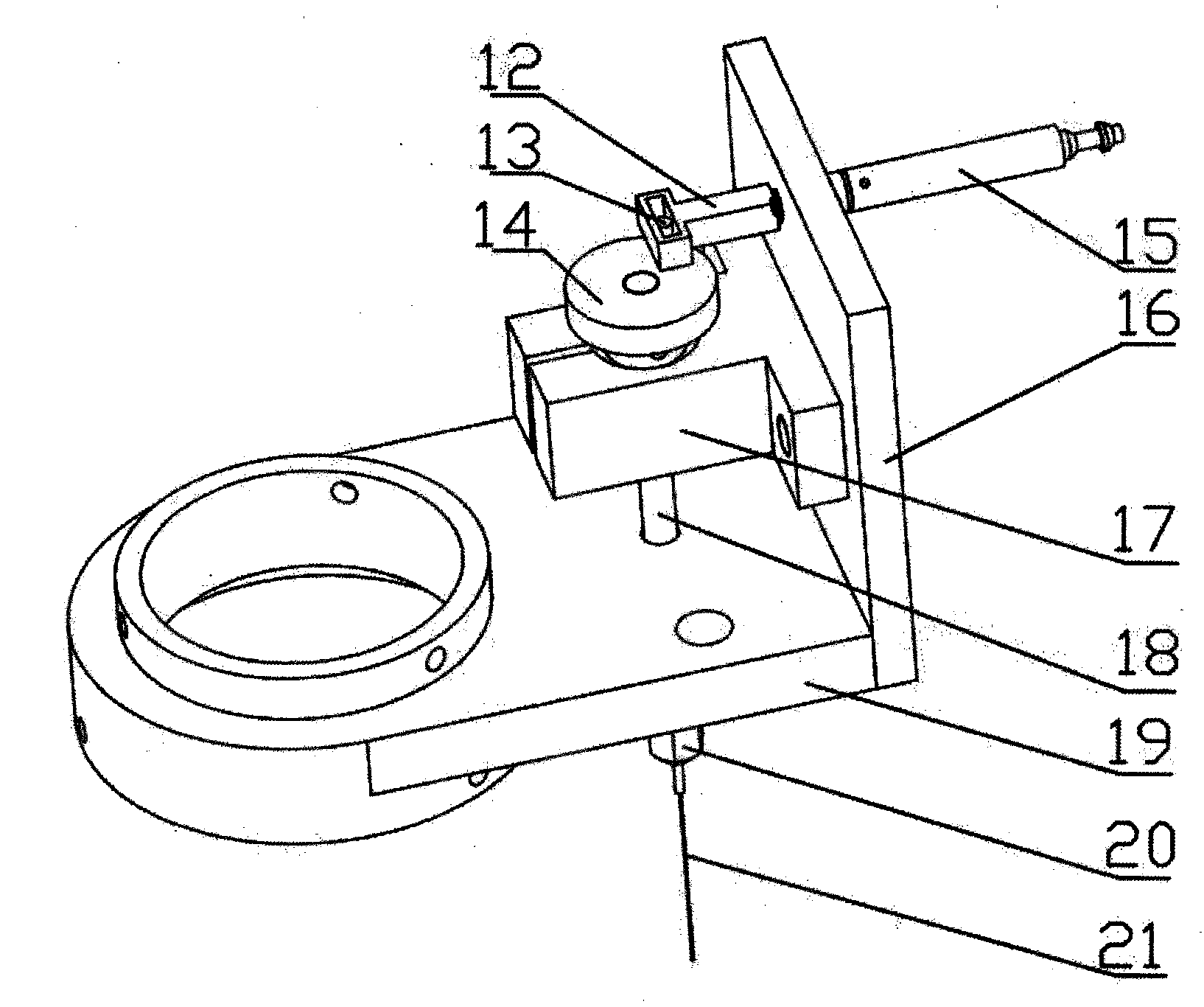

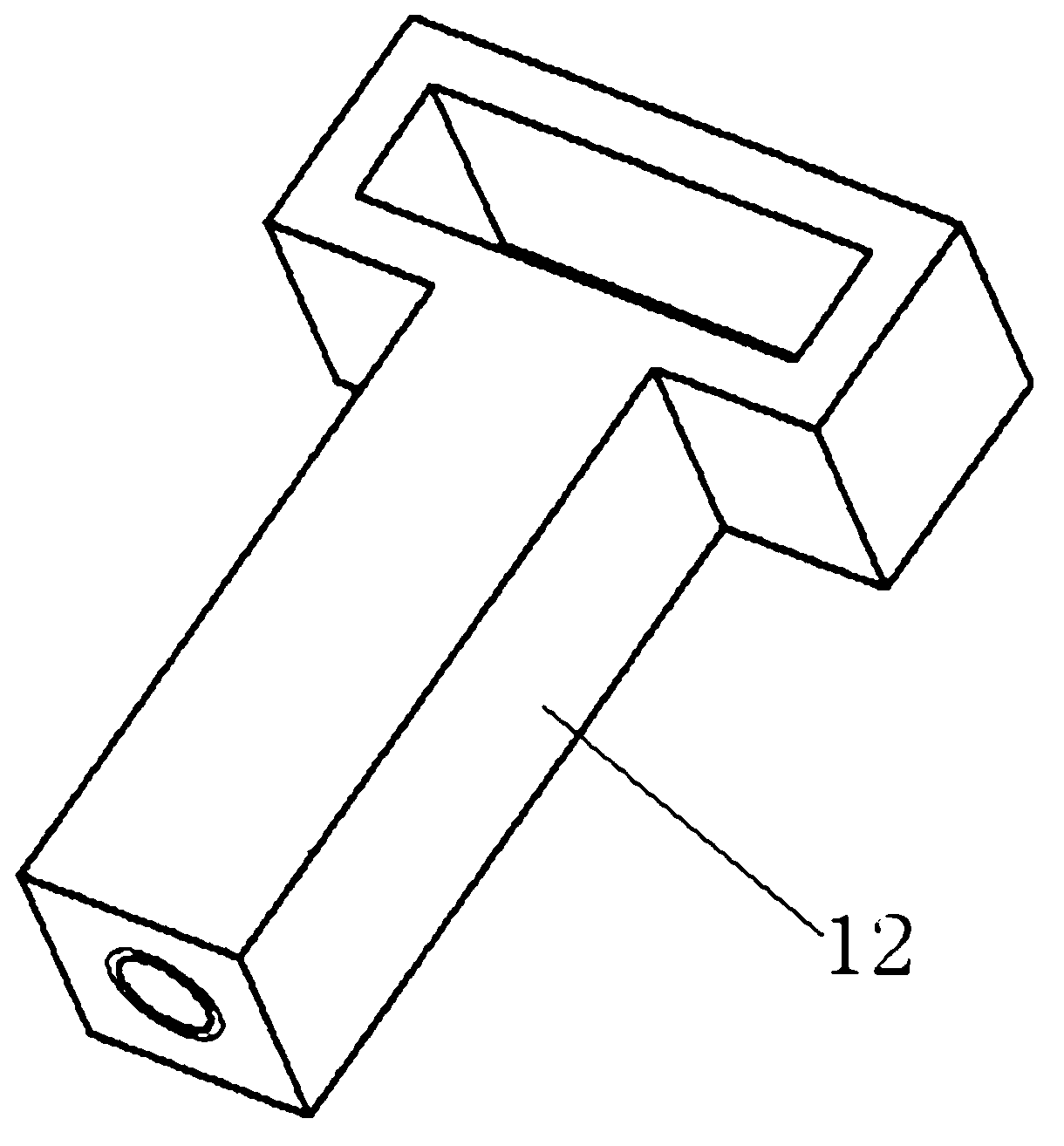

[0032] like figure 1 As shown, a kind of spinneret microhole automatic cleaning device provided by the present invention includes a base 1, on which an XY precision motion platform 2 that can move back and forth and left and right in the horizontal direction is provided, and the XY precision motion platform 2 is provided with a spinneret fixture 3 for placing the spinneret 11 to be inspected, the support arm 6 fixedly connected to the base 1 is located on the side of the XY precision motion platform 2, and the Z-axis precision electric control console 5 is fixed on the support arm 6 On the top, the cleaning part 8 is driven by the Z-axis precision electric control console 5 to move up and down in the vertical direction. The lens 7 is connected on the Z-axis precision electric control console 5 through a screw mandrel, and the lens 7 faces the spinneret 11 directly. The cleaning part 8 is fixed on the bottom of the lens 7, and the lens 7 is connected with the camera 4. The bo...

Embodiment 2

[0040] like Figure 8 As mentioned, in the present embodiment, the cleaning part 8 includes a fixed panel 22 fixed on the Z-axis precision electric control console 5, a motor fixing frame 23 is arranged on the fixing panel 22, and a small motor fixing frame 23 is provided. Motor 24, the output shaft of the small motor 24 is connected with the collet 18 through the coupling 25, the collet 19 is driven to rotate by the small motor 24, there is at least one bearing on the jacket of the collet 18, the bearing is fixed on the bearing holder, and the bearing is fixed The seat is connected and fixed with the fixed panel 22 , and the cleaning needle 21 is connected and fixed with the chuck 18 through the locking nut 20 .

[0041] When performing automatic cleaning, the small motor 24 drives the chuck 18 to rotate, thereby driving the cleaning needle 21 to rotate, and completes the cleaning of the spinneret 11 microporous impurities.

[0042] Other structures and working methods of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com