Neodymium iron boron waste material screening device and using method

A screening device, NdFeB technology, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problem that impurities and waste cannot be separated quickly, waste cannot be separated from impurities, and impurities stick to waste and other problems, to achieve the effect of shortening the cleaning time, reducing the number of cleanings, and preventing secondary cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

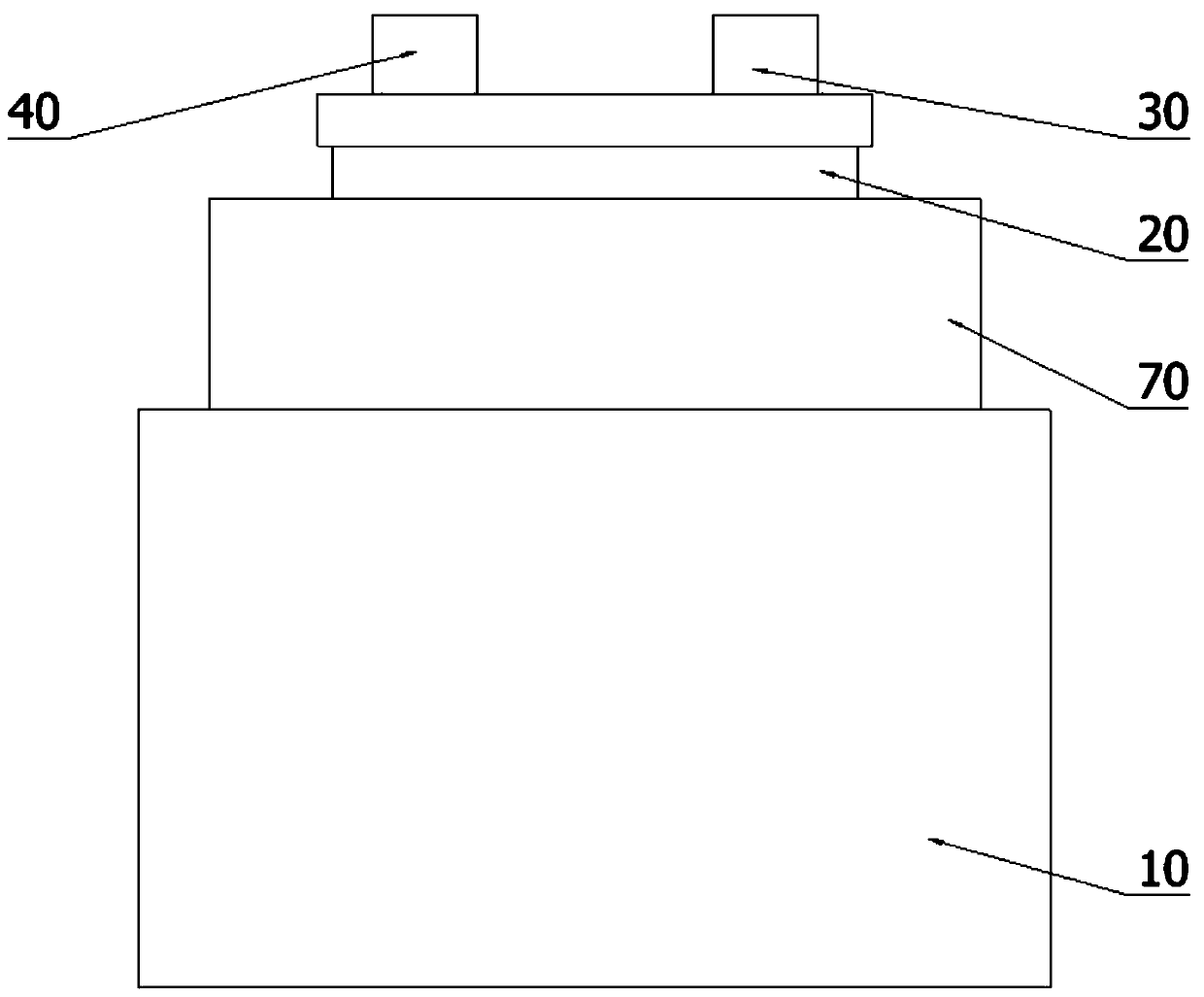

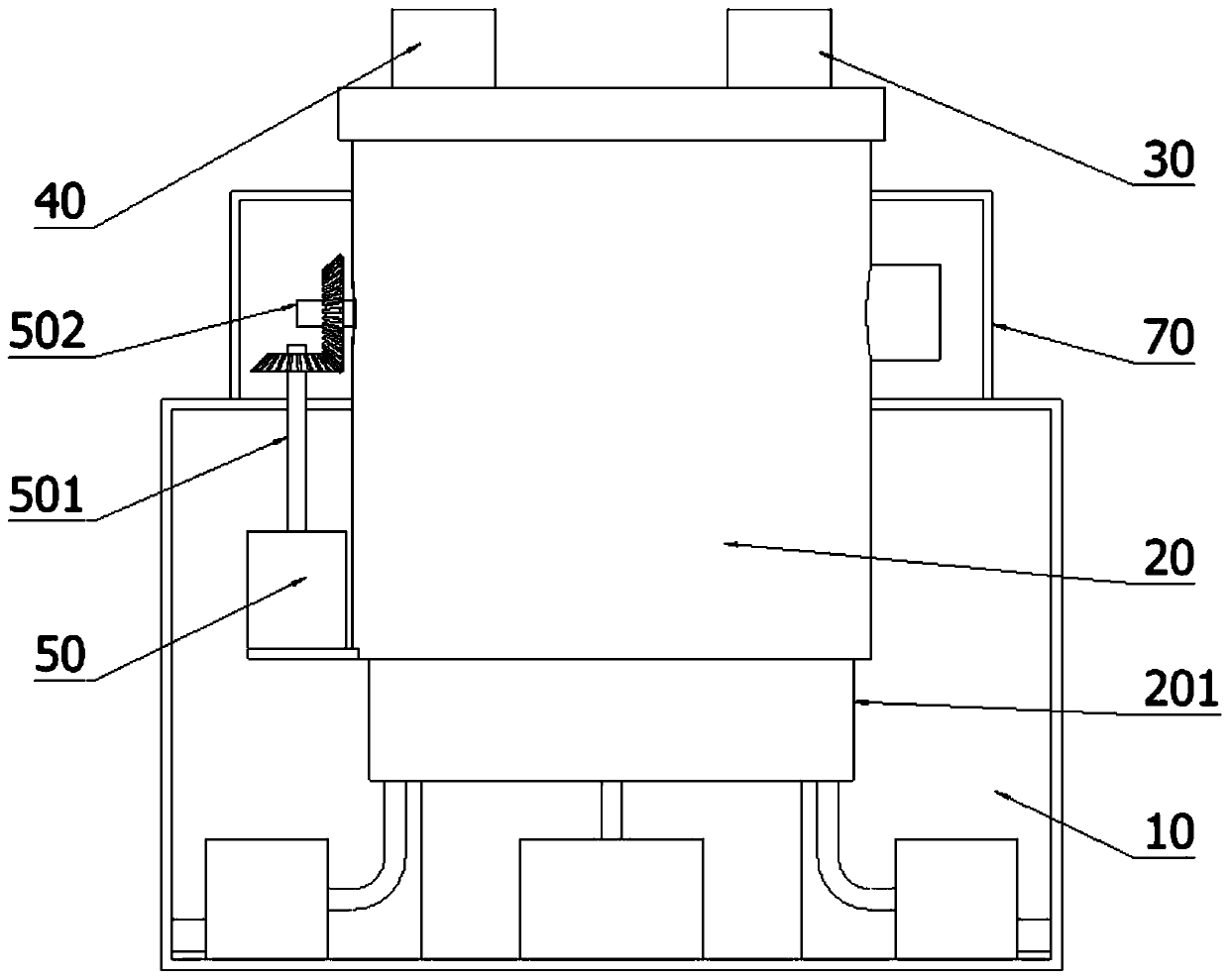

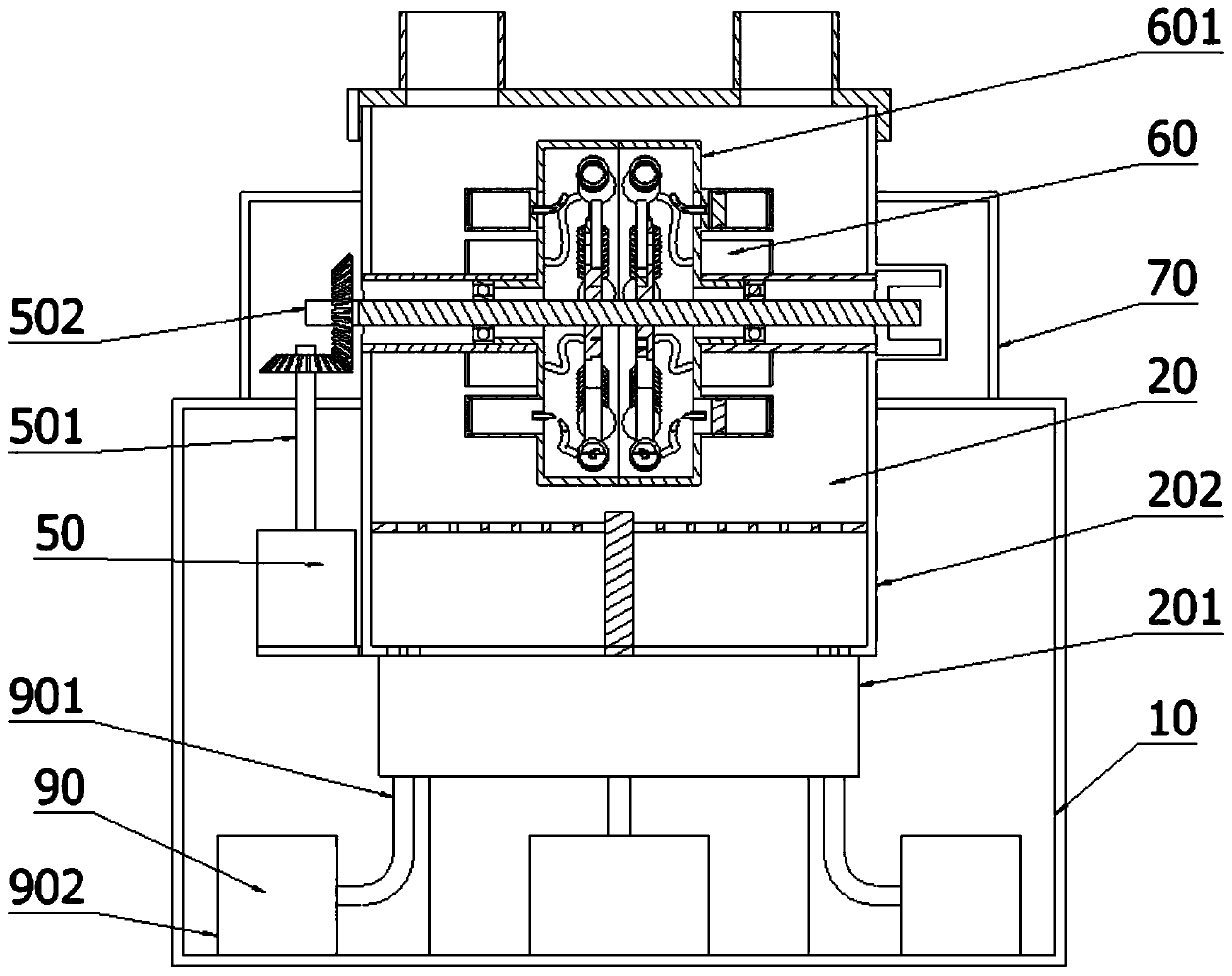

[0038] Such as figure 1 , 2 , 3, this embodiment discloses a screening device, including: a base 10, a placement part 20, a protective cover 70, a rotating part 60, and a control part 50. The interior of the base 10 is hollow, and the placement part 20 and the base 10 Connection, the placing part 20 is arranged in the center of the base body 10, and the inside of the placing part 20 is hollow. The placement part 20 includes: a connecting body 202 and a receiving body 201. The connecting body 202 is arranged inside the base body 10, and one end of the connecting body 202 is higher than the top of the base body 10 On the surface, the connecting body 202 and the ladder are on the same axis, the inside of the connecting body 202 is hollow, the receiving body 201 is arranged inside the base body 10, the receiving body 201 is connected with the connecting body 202, and the receiving body 201 is arranged under the connecting body 202 to accept The inside of the body 201 is hollow, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com