Universal wheel hub cleaning equipment

A cleaning equipment, a general-purpose technology, applied in lighting and heating equipment, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of inability to clean the wheel hub, reduce work efficiency, and cumbersome procedures, and improve cleaning. Efficiency and quality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

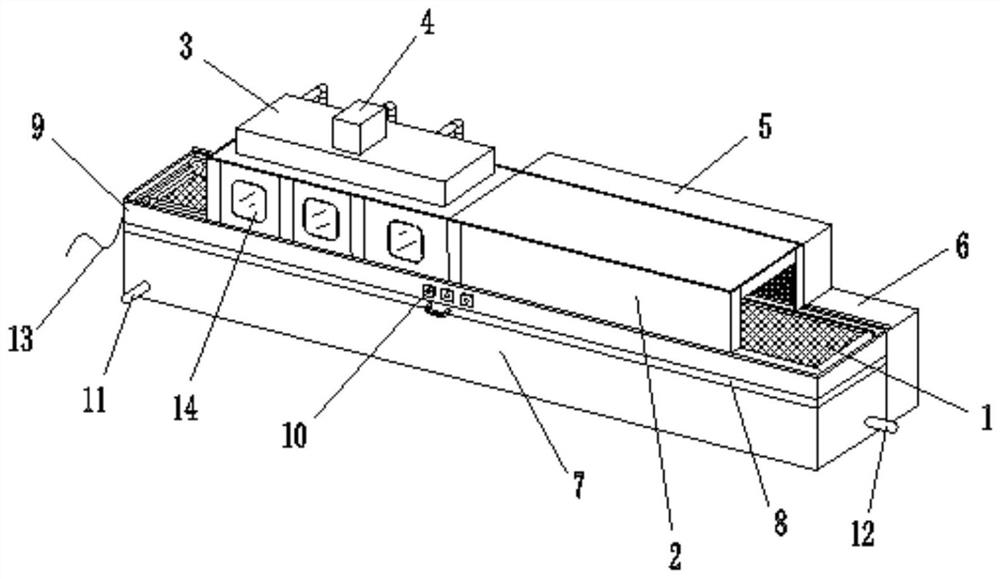

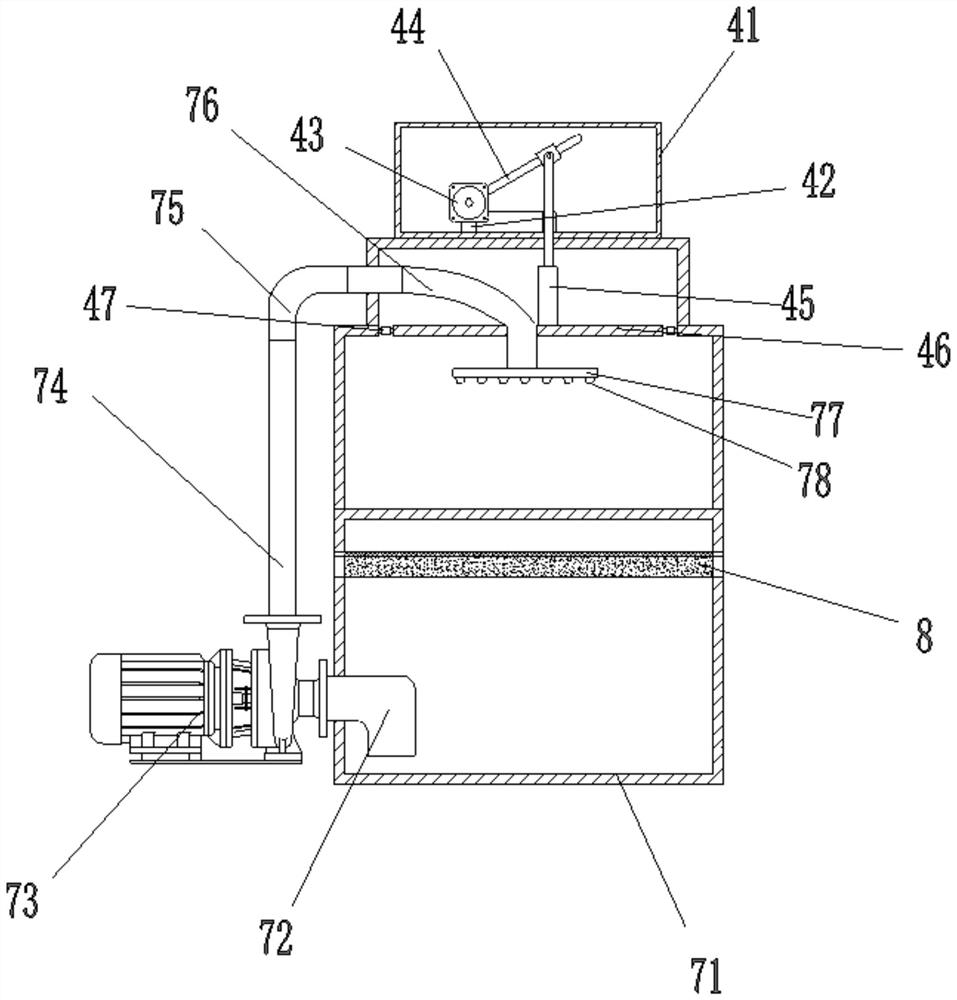

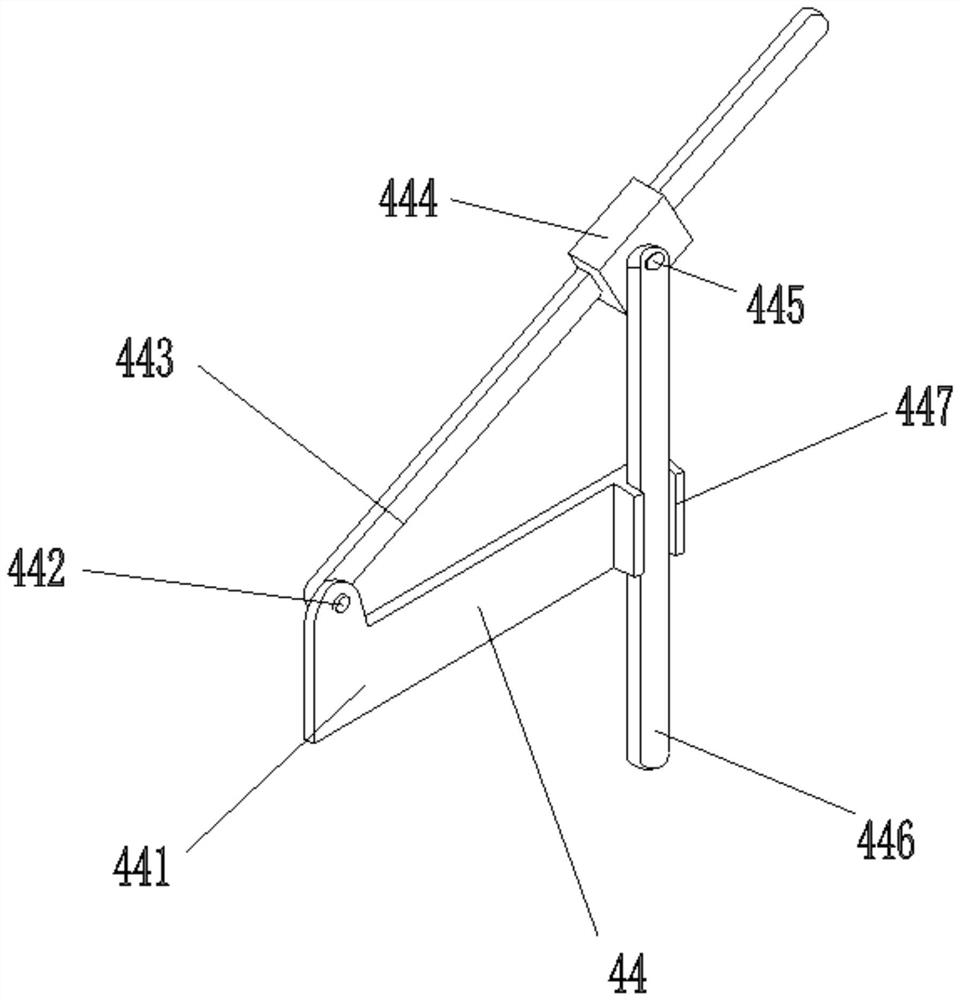

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a general-purpose wheel hub cleaning equipment: including a conveyor belt 1, a casing 2, a protective box 3, an auxiliary device 4, a hot air drying device 5, a first fixed block 6, a circulation device 7, a filter device 8, Body 9, switch 10, water inlet 11, drain 12, power cord 13 and observation window 14, conveyor belt 1 is arranged on the top of body 9, the bottom of casing 2 is welded to the left and right sides of the top of body 9, and the protective box

[0035]3. The bottom is welded to the left end of the top of the casing 2. The middle part of the top of the protective box 3 is provided with an auxiliary device 4. The front side of the hot air drying device 5 is fixedly connected to the right end of the back of the casing 2. The top of the first fixing block 6 is connected to the bottom of the hot air drying device 5. Fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com