Cleaning agent for aircraft pipelines and preparation method thereof

A cleaning agent and pipeline technology, used in the aviation field, can solve the problems of pipeline corrosion and irritation, low pH buffer capacity, low corrosion of pipeline system materials, high pH buffer capacity, etc., to achieve low corrosion, prevent coarsening, and improve cleaning efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

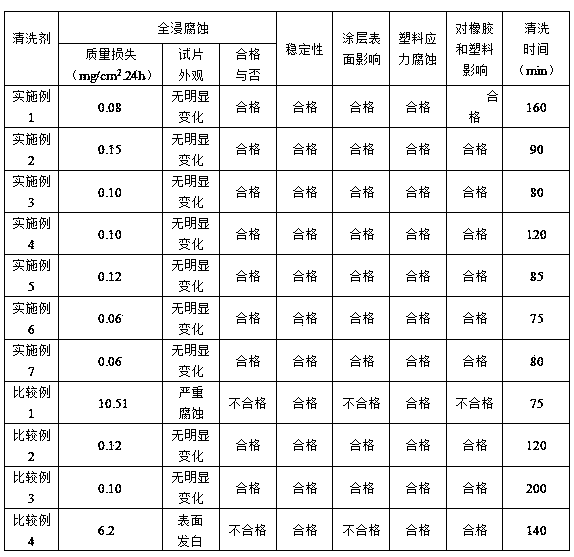

Examples

Embodiment 1

[0033] Sulfamic acid 8%

[0034] Tartaric acid 8%

[0035] Organic phosphoric acid 0.5%

[0036] Alkylamine 0.2%

[0037] Low molecular weight polycarboxylic acid 0.4%

[0038] Fatty alcohol polyoxyethylene ether 2%

[0039] Flavor and color 0.05%

[0040] Deionized water balance

[0041] The total weight of the above components is 100%.

Embodiment 2

[0043] Sulfamic acid 10%

[0044] Citric acid 6%

[0045] Organic phosphoric acid 0.7%

[0046] Alkylamine 0.3%

[0047] Low molecular weight polycarboxylic acid 0.2%

[0048] Diethanolamide Stearate 1%

[0049] Flavor and color 0.05%

[0050] Deionized water balance

[0051] The total weight of the above components is 100%.

Embodiment 3

[0053] Sulfamic acid 9%

[0054] Glycolic Acid 7%

[0055] Organic phosphoric acid 0.9%

[0056] Alkylamine 0.2%

[0057] Imidazoline quaternary ammonium salt 0.1%

[0058] Cocamidopropylamine Oxide 0.5%

[0059] Flavor and color 0.05%

[0060] Deionized water balance

[0061] The total weight of the above components is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com