Silver residue washing machine

A cleaning machine and residual silver technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of low efficiency of cleaning residual silver, high production costs, and high labor intensity of workers , to achieve the effect of increasing factory income, saving cleaning costs, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

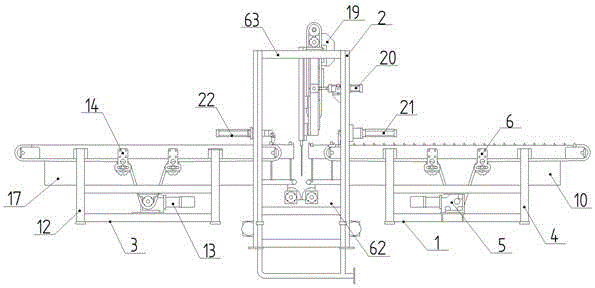

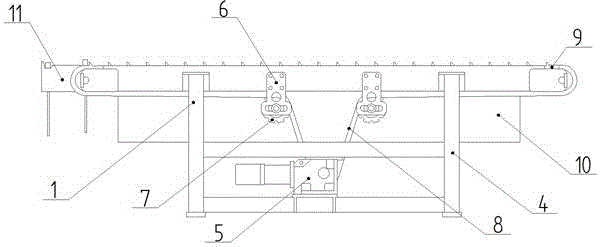

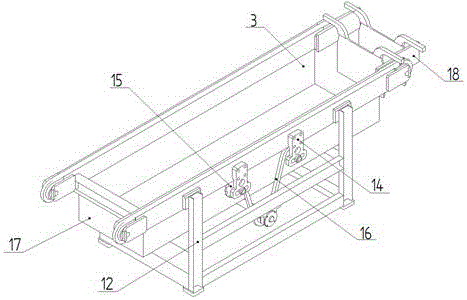

Embodiment 1

[0025] Embodiment 1: as Figure 1-10 As shown, a residual silver cleaning machine includes a plate granting device 1, a cleaning device 2, and a discharge conveying device 3; the plate granting device 1 and the discharge conveying device 3 are respectively installed on both sides of the cleaning device 2, and the plate granting device 1 includes Trigger granting chassis 4, plate granting motor 5, tensioning mounting plate 6. First sprocket 7. Plate granting chain 8. Waste liquid collection tank 10. Transition plate 11; The trigger-granting base frame 4 is installed on the foundation, the plate-granting motor 5 is installed on the inner side of the bottom of the trigger-granting base frame 4, and the mounting plate is tensioned 6 is symmetrically installed on the outer side of the upper part of the plate granting machine chassis 4, the first sprocket 7 Mounted on tensioned mounting plate 6, there is a protrusion 9 on the board-granting chain 8, and the board-granting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com