Washing device

A technology of cleaning device and valve device, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. The effect is that the rate is not affected, the direction is easy to adjust, and the temperature is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

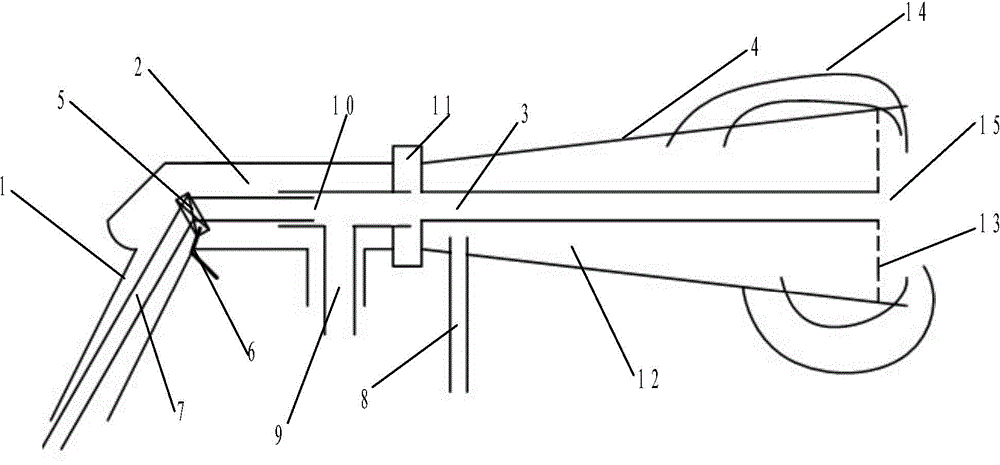

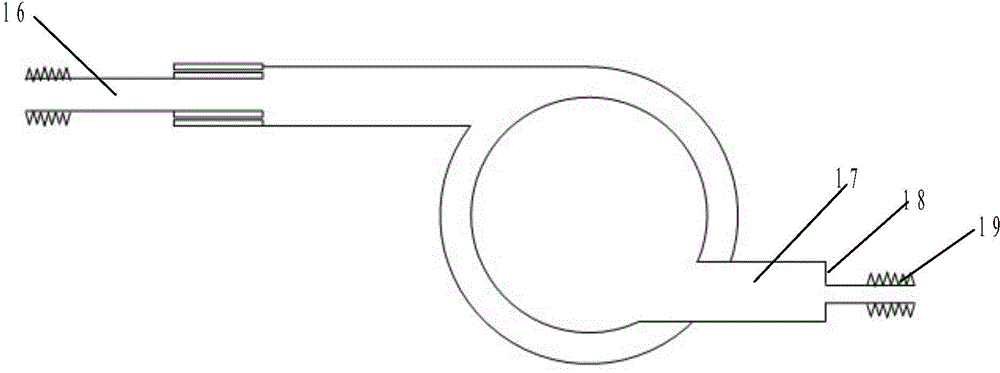

[0039] like figure 1 and figure 2 Shown, the present invention provides a kind of cleaning device, it is characterized in that, comprises:

[0040] The gun body, which includes a hollow gun handle 1 and a gun barrel section communicating with the gun handle, said gun barrel section includes a first gun barrel section 2, a second gun barrel section 3 and a third gun barrel section 4, said One end of the first barrel section 2 communicates with one end of the gun handle 1, and the other end of the first barrel section 2 is connected to the second barrel section 3 through a universal joint 11 having a hollow cavity. One end communicates, the third gun barrel segment 4 is sleeved on the outside of the second gun barrel segment 3 and one end is connected to the universal joint 11, the third gun barrel segment 4 is connected to the second gun barrel An annular space 12 is formed between the sections 3, and the other end of the third barrel section 4 extends to the front side of t...

Embodiment 2

[0055] like figure 1 and figure 2 Shown, the present invention provides a kind of cleaning device, it is characterized in that, comprises:

[0056] The gun body, which includes a hollow gun handle 1 and a gun barrel section communicating with the gun handle, said gun barrel section includes a first gun barrel section 2, a second gun barrel section 3 and a third gun barrel section 4, said One end of the first barrel section 2 communicates with one end of the gun handle 1, and the other end of the first barrel section 2 is connected to the second barrel section 3 through a universal joint 11 having a hollow cavity. One end communicates, the third gun barrel segment 4 is sleeved on the outside of the second gun barrel segment 3 and one end is connected to the universal joint 11, the third gun barrel segment 4 is connected to the second gun barrel An annular space 12 is formed between the sections 3, and the other end of the third barrel section 4 extends to the front side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com