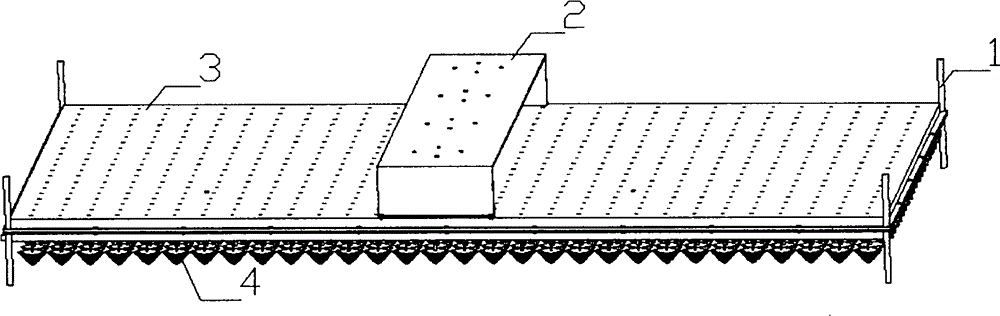

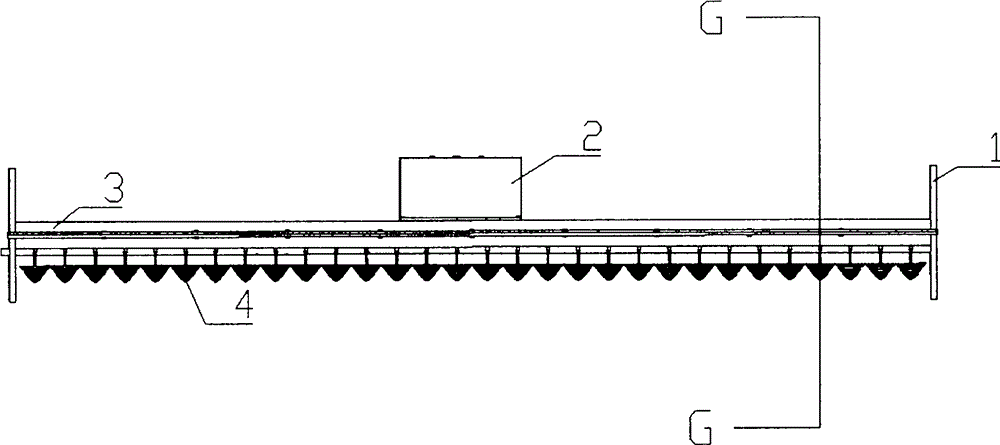

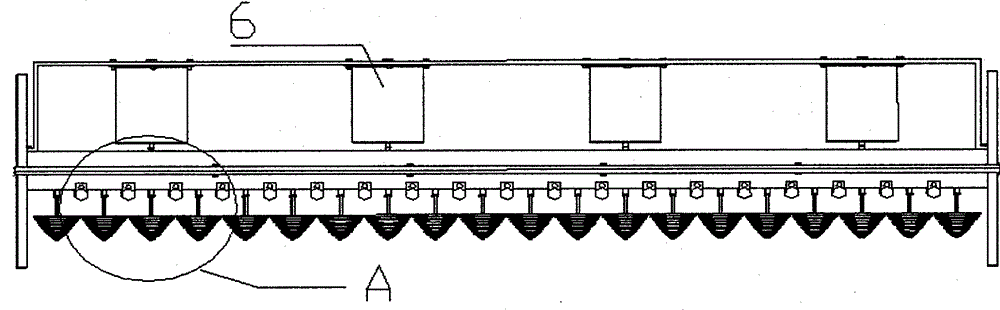

Rotary cleaning equipment for floating seedling trays

A technology for cleaning equipment and floating seedlings, which is applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc. Slow speed and other problems, to achieve the effect of reducing the labor intensity of cleaning, shortening the seedling cycle, and rotating efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment, a kind of cleaning method of floating seedling tray rotary cleaning equipment, its steps are as follows:

[0024] (1) lifting rod 1 raises the cleaning equipment until the bottom of the cleaning brush 4 is slightly greater than the height of the seedling tray when the height of the bottom of the cleaning brush 4 is slightly greater than the height of the seedling tray.

[0025] (2) After the seedling raising tray is in place, open the nozzle 7 to allow the cleaning solution to wet the seedling raising tray. Bottom arrives seedling hole bottom and stops elevating bar 1 to descend.

[0026] (3) Wait for the cleaning brush 4 to rotate and clean the seedling hole.

[0027] (4) After cleaning, the elevating rod 1 rises, and when the cleaning brush retreats from the seedling raising tray completely, it stops rising and waits for the next seedling raising tray to be in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com