Glass with two film-coated surfaces, preparation method thereof, and hollow glass using same

A double-membrane and glass technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., to achieve excellent thermal performance, save target positions, and overcome the effects of easy target drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

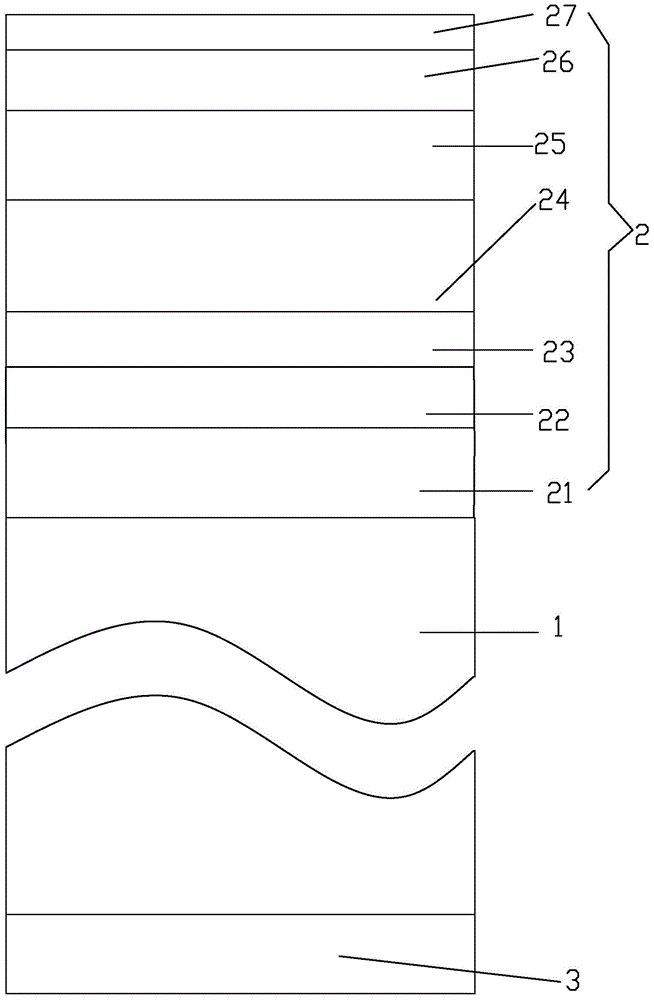

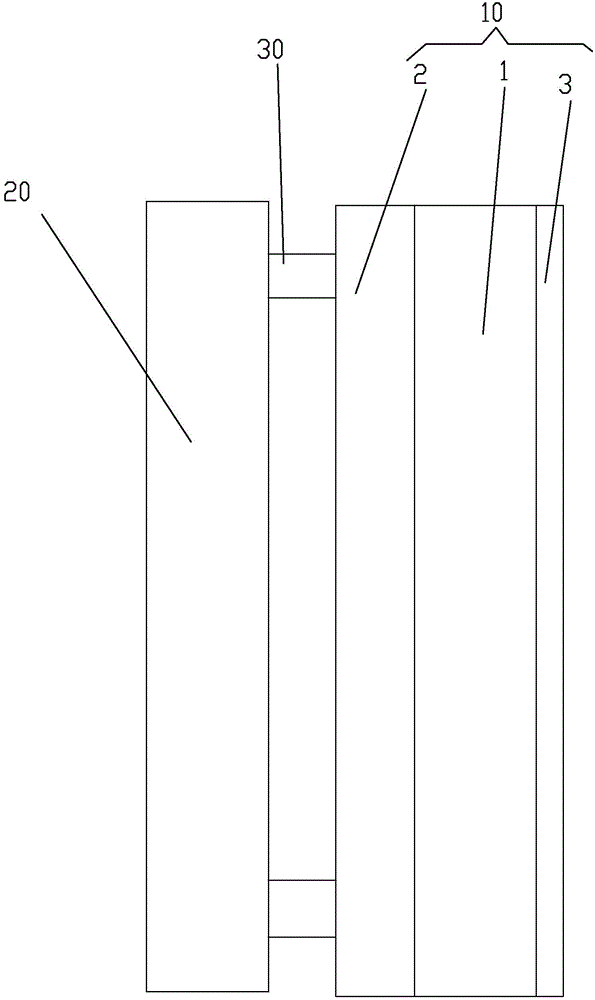

[0032] Such as figure 1 As shown, the double-coated glass includes a glass substrate 1, a double-silver LOW-E film layer 2 is compounded on the reverse side of the glass substrate 1, and a self-cleaning film layer 3 is compounded on the front side.

[0033] The self-cleaning film layer 3 is a nanoscale titanium dioxide coating.

[0034] The double-silver LOW-E film layer 2 includes seven film layers that are sequentially compounded adjacently from the inside to the outside on the reverse side of the glass substrate 1, wherein the first film layer, the innermost layer, is Si 3 N 4 layer 21, the second layer is AZO layer 22, the third layer is Ag layer 23, the fourth layer is AZO layer 24, the fifth layer is Ag layer 25, the sixth layer is AZO layer 26, and the outermost layer is Si 3 N 4 Layer 27.

[0035] The Si of the first film layer 3 N 4 Layer 21, the sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com