Double-effect washing type spacer fluid for well cementation and preparation method of spacer fluid

A spacer fluid and cementing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that compatibility cannot meet the requirements of cementing quality, and achieve enhanced solubility and permeability, reduced The effect of cementing cost and reducing design dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

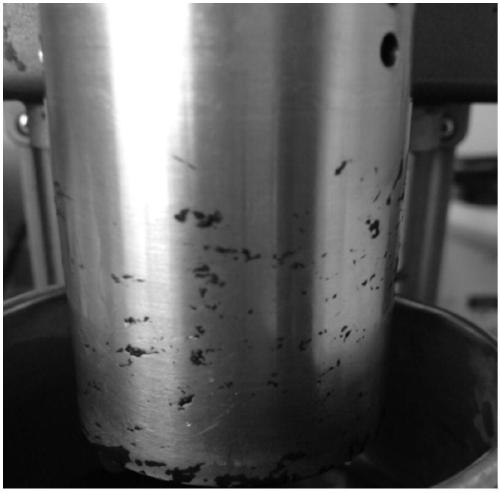

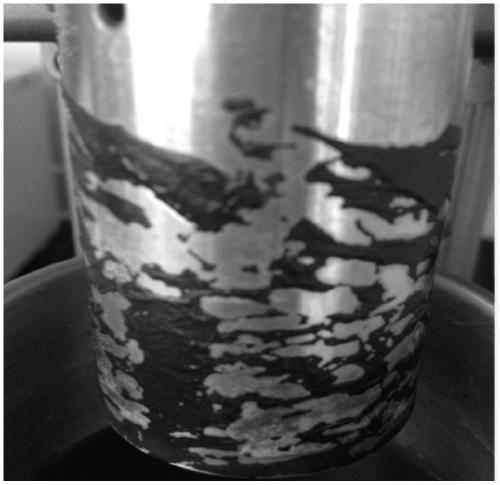

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a method for preparing a double-effect flushing spacer fluid for well cementing, including the preparation of flushing agent; the preparation of flushing agent includes: (1) according to the above weight parts, weigh water, AES and OP-10 , stir at 800-1200rpm for 20-30min until completely dissolved to obtain a mixed solution; (2) heat the mixed solution to 45-55°C, add cleaning aids according to the above weight parts, and continue stirring for 30-50min; (3) According to the above parts by weight, continue to add JFC and APG, stir at 800-1200rpm for 80-100min, and stir to obtain the above flushing agent.

[0032] The rinsing agent prepared by this method is used in the experiments of Example 1-Example 3 below.

Embodiment 1

[0035] This embodiment provides a double-effect flushing spacer fluid for well cementing, with a density of 1.80g / cm 3 : In parts by weight, the raw materials of the spacer fluid include: 100 parts of clear water, 20 parts of flushing agent, 1 part of suspending agent, 1 part of retarder, 155 parts of weighting agent and 0.1 part of defoamer. Wherein, in parts by weight, the raw materials of the flushing agent include: 80 parts of water, 20 parts of AES, 10 parts of OP-10, 10 parts of JFC, 10 parts of APG and 10 parts of butyl glycol ether.

[0036] A double-effect flushing spacer fluid for cementing. The preparation method is: add 1 part of suspending agent to 100 parts of clear water, stir well at low speed, then slowly add 1 part of retarder, and wait until the base fluid configuration is completed. Add 155 parts of weighting agent, stir evenly, add 20 parts of flushing agent and keep rotating at low speed. After the liquid is evenly distributed, finally add 0.1 part of def...

Embodiment 2

[0038] This embodiment provides a double-effect flushing spacer fluid for well cementing, with a density of 2.1g / cm 3 : In parts by weight, the raw materials of this spacer fluid include: 100 parts in clear water, 40 parts in flushing agents, 5 parts in suspending agents, 3 parts in retarders, 253 parts in weighting agents and 0.2 parts in defoamers; wherein, in parts by weight Counting, the raw materials of the flushing agent include: 80 parts of water, 30 parts of AES, 10 parts of OP-10, 10 parts of JFC, 20 parts of APG and 10 parts of ethylene glycol phenyl ether acetate.

[0039] A double-effect flushing type spacer fluid for cementing. The preparation method is: add 5 parts of suspending agent to 100 parts of clear water, stir well at low speed, then slowly add 3 parts of retarder, and wait until the base fluid is configured. Add 253 parts of weighting agent, stir evenly, add 40 parts of flushing agent and keep rotating at low speed. After the liquid is evenly distributed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com