Atomizing cleaning head for overhead transmission line

An overhead transmission line and atomization cleaning technology, which is applied to overhead line/cable equipment, chemical instruments and methods, cleaning methods and utensils, etc. Problems such as cleaning of lines and transmission lines, no design of closed and recycling loops, etc., to achieve the effect of easy replacement, low manufacturing cost, and avoid potential damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

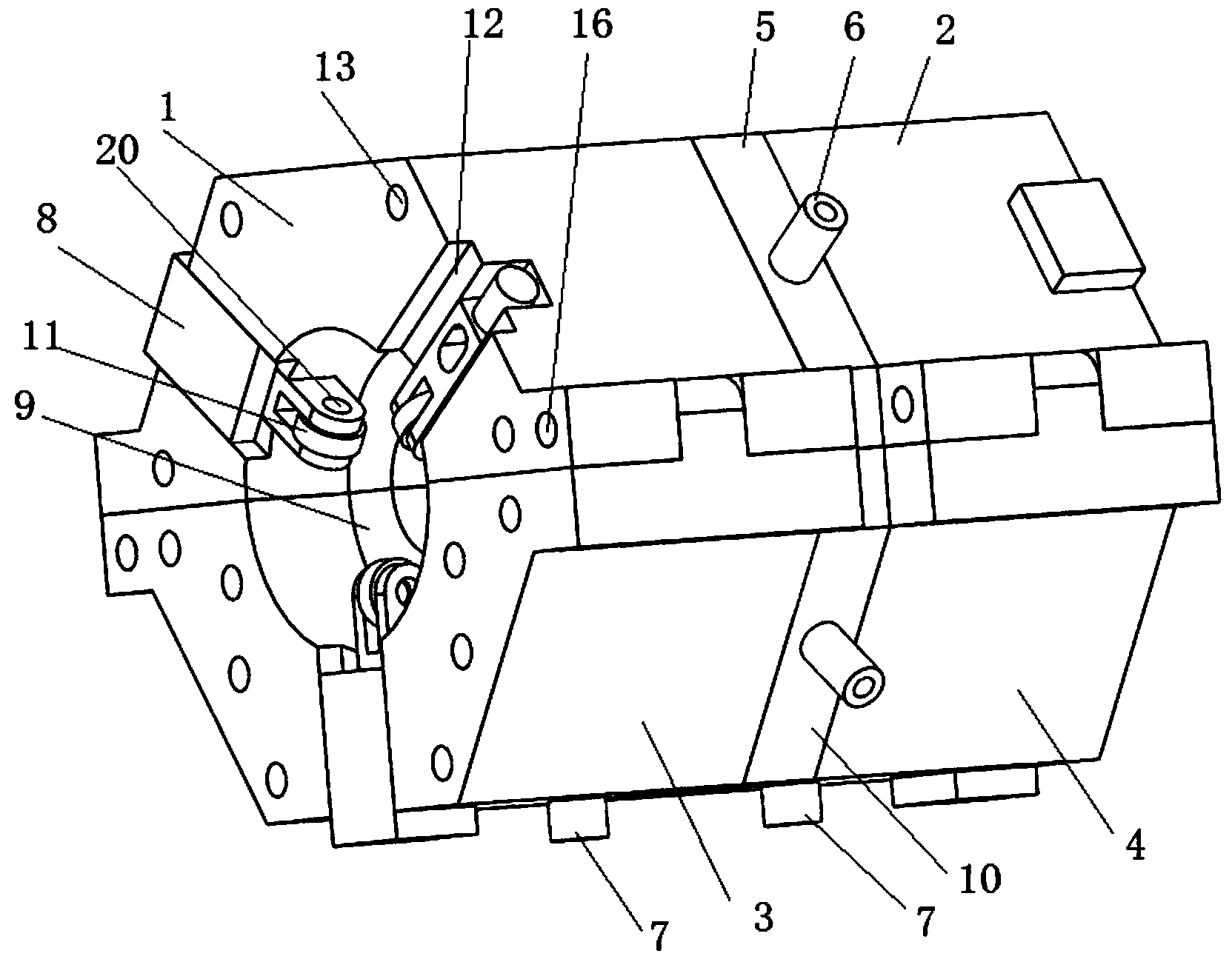

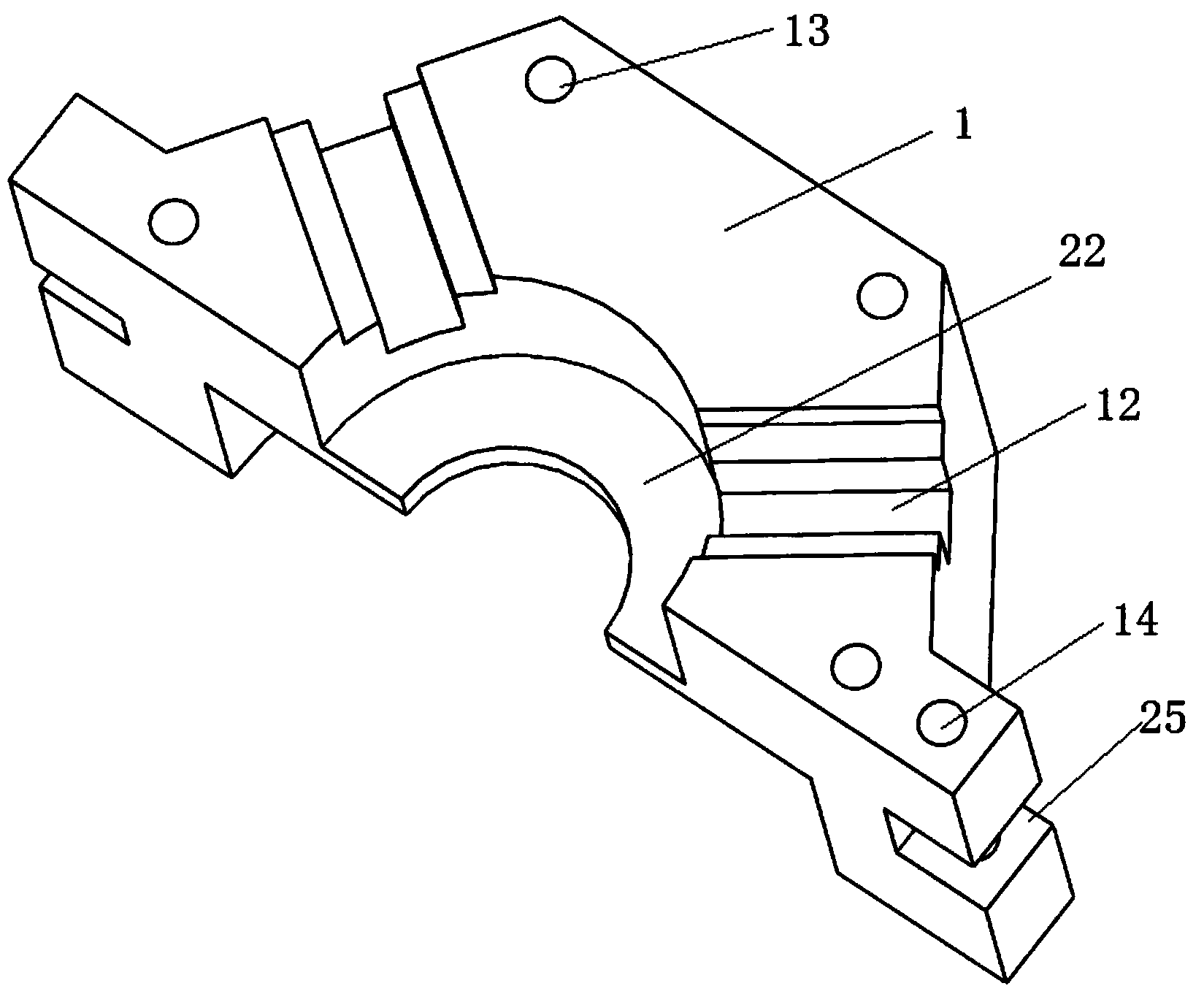

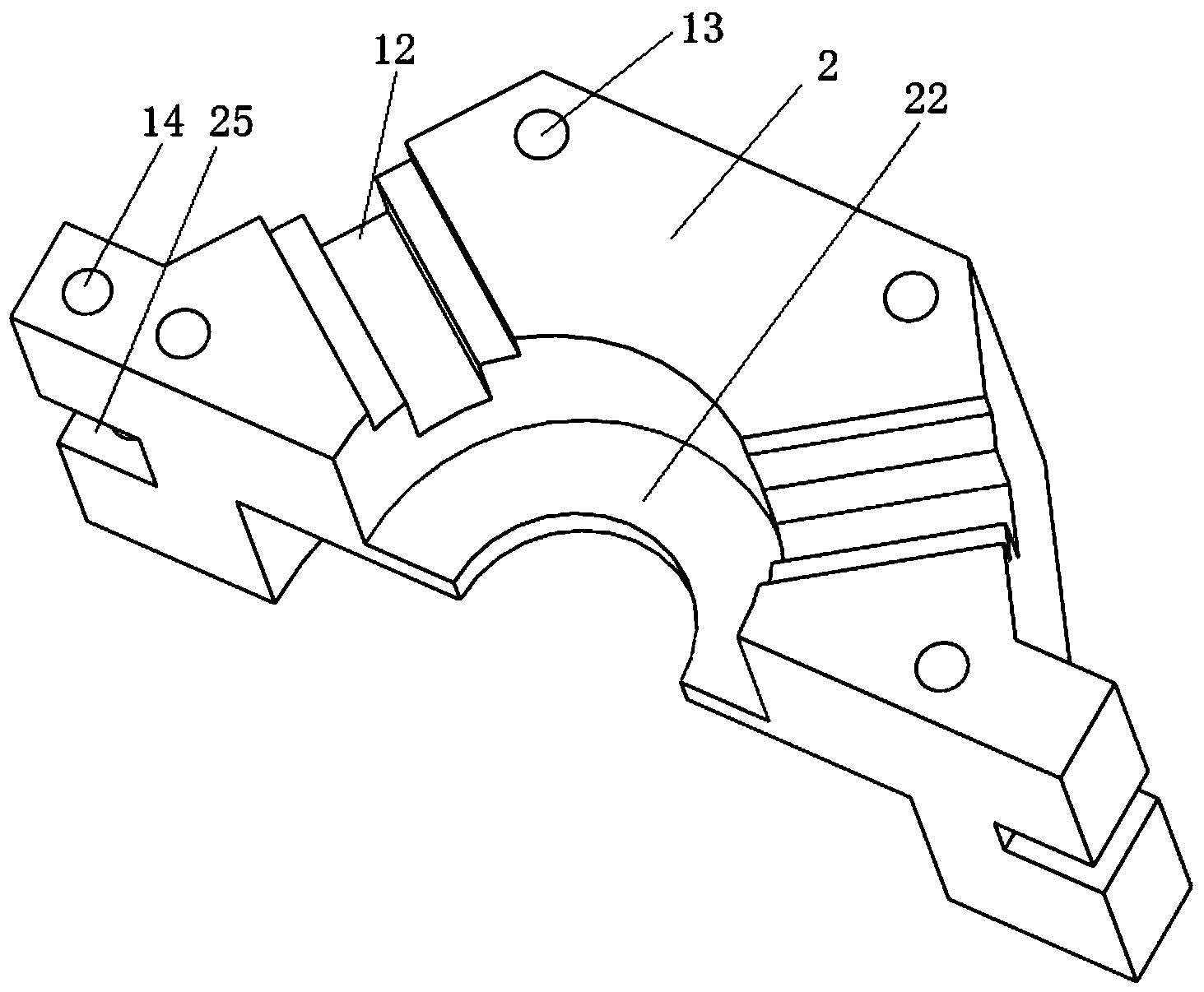

[0041] Such as figure 1 As shown, this embodiment includes: a cylindrical member composed of several modular structural connections, adopting a modular structural design form, the overall structure is simple, reliable, easy to replace, and low manufacturing cost. Two seals 9 arranged longitudinally in parallel are fixed in the middle of the inner cavity of the cylindrical member. There is a hole in the center of the seal 9 that only the power line for cleaning needs to pass through and the seal is sleeved on the power line. A seal is formed between the two seals 9. A cavity, the cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com