Boiler based on internet and method for operating boiler

An Internet and boiler technology, applied in the field of boilers, can solve problems such as single steam control structure, difficult equipment cleaning, poor adjustment performance, etc., achieve efficient steam discharge process, facilitate cleaning, and realize the effect of structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

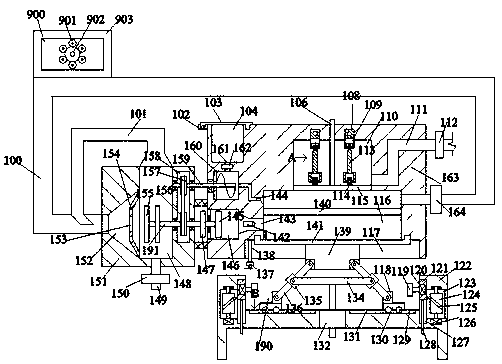

[0018] Combine below Figure 1-3 The present invention will be described in detail.

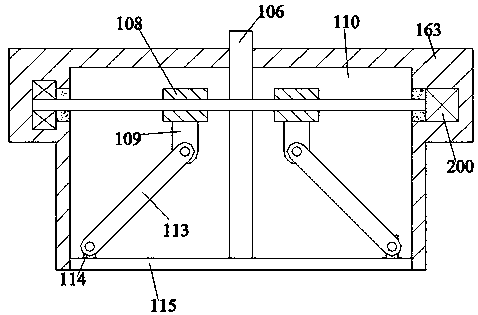

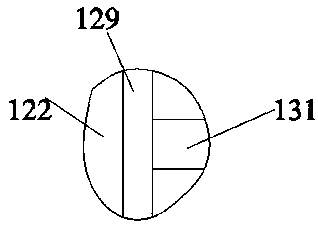

[0019]According to a boiler device according to an embodiment, the boiler device includes a main box 163, and a card installation cavity 110 is fixed inside the main box 163, and a communication channel extending out of the external space is provided in communication with the right end wall of the card installation cavity 110. Pipe 111, the communication pipe 111 is connected with a valve 112, and the rear end wall of the clamping chamber 110 is fixed with a left-right symmetrical driving motor 200, and the output shaft of the driving motor 200 is connected to the clamping chamber 110. The end wall is rotated and connected, and the outer surface of the output shaft of the drive motor 200 is threaded and connected with a symmetrical slider 108. The lower end of the slider 108 is fixed with a bottom block 109, and the bottom block 109 rotates A swing rod 113 is provided, and a closing plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com