Chemical scrubbing method of the flat-plate film

A technology for chemical cleaning and flat membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inappropriateness, different operating conditions, and no cleaning of flat membranes, to improve effectiveness and easy operation. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described by examples below, but the following examples do not represent the limited scope of protection of the present invention.

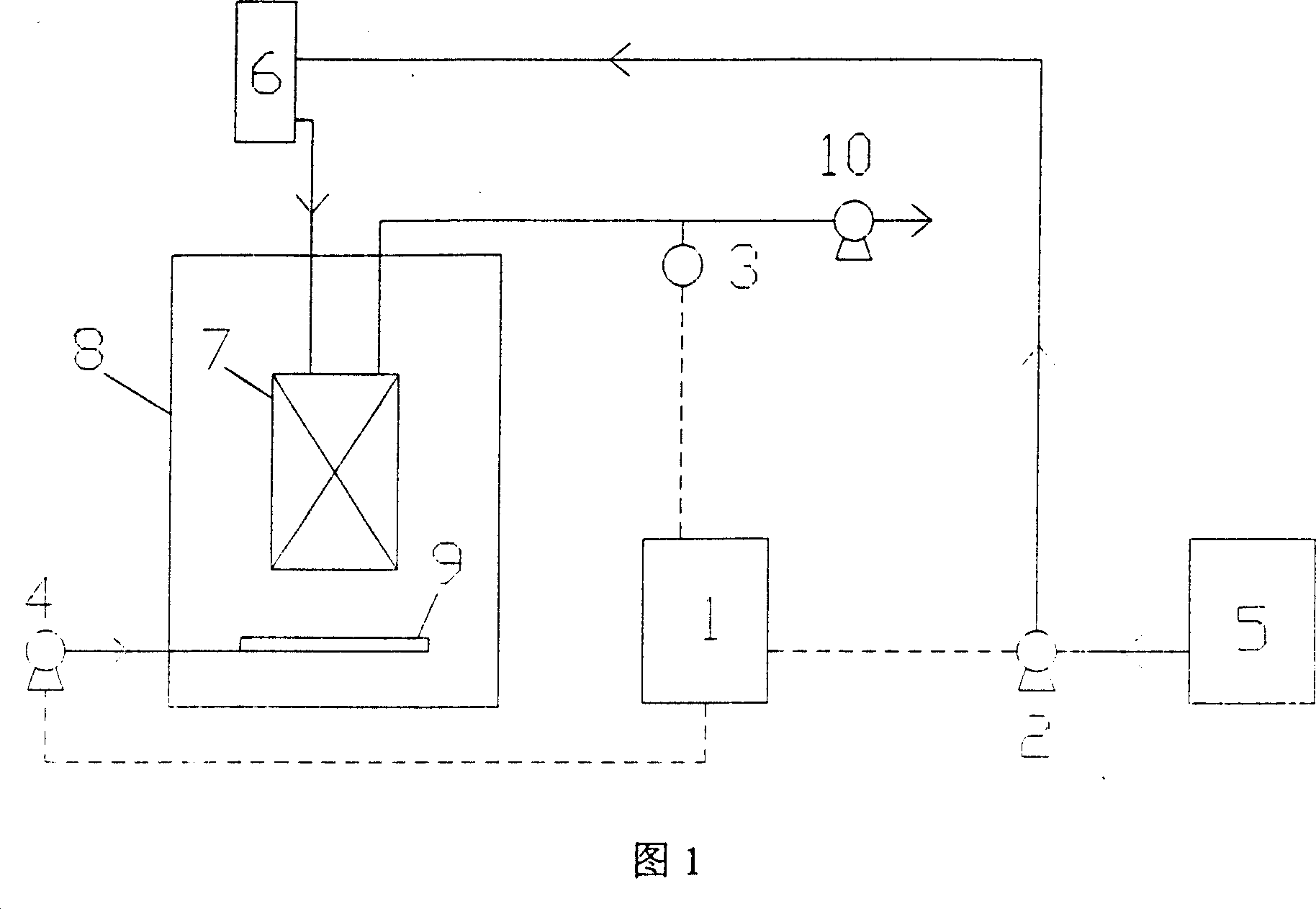

[0021] As shown in FIG. 1 , it is a principle diagram of online cleaning of the present invention, wherein a PLC automatic control system 1 is connected with a dosing pump 2 , a pressure detection 3 , and a blower 4 . When the pressure detector 3 detects an excessively high pressure value, a signal is sent to the PLC automatic control system 1, and the PLC automatic control system 1 reduces the blowing volume of the blower 4, and starts the dosing pump 2 at the same time; the dosing pump 2 will feed the dosing box The NaClO solution (4%) in 5 is injected into the high-position dosing box 6; the high-position dosing box 6 is connected with the flat membrane assembly 7, and the injected NaClO solution (4%) is poured into the flat membrane; the flat membrane assembly 7 is placed in the membrane In the bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com