Stepping all-directional valve cleaner

An all-round cleaning machine technology, applied in the direction of dryers, conveyors, drying gas arrangement, etc., can solve the problems that the workpiece cannot be cleaned thoroughly, unfavorable for the use of the workpiece, and cannot guarantee the cleaning efficiency and cleaning effect of the workpiece, so as to achieve easy cleaning , reduce the dosage, and avoid the effect of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

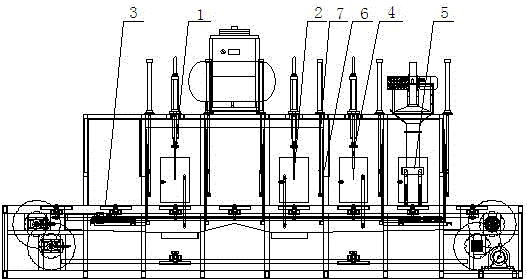

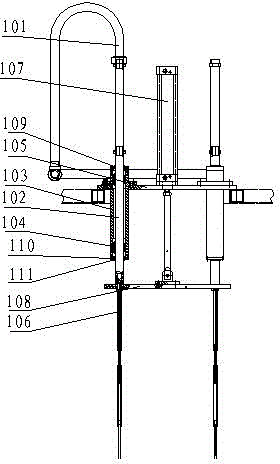

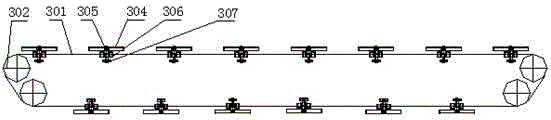

[0043] Such as figure 1 As shown, this embodiment provides a step-by-step omni-directional valve body cleaning machine, including a conveying mechanism 3 for moving workpieces, a cleaning device 1 for removing surface impurities from workpieces, and rinsing for removing oil stains on the surface of workpieces. Device 2, a drying device 4 for removing moisture from the workpiece surface after rinsing, a drying device 5 for removing surface moisture from the workpiece, the cleaning device 1, the rinsing device 2, the drying device 4 and the drying device 5 Arranged in sequence, the cleaning device 1 and the rinsing device 2 both include a spraying device. The cleaning device 1, the rinsing device 2, the drying device 4 and the drying device 5 are respectively arranged in a single operation room, and a lifting door 6 for separation is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com