Power transmission line insulator cleaning robot and method

A technology for cleaning robots and transmission lines, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of easy damage to the surface of insulators, the inability to clean dirt, and unsatisfactory cleaning effects, etc., to achieve Stable crawling, simple structure, and the effect of preventing center shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

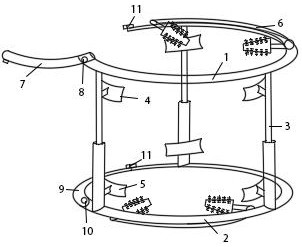

[0044] Such as Figure 1-3 As shown, this embodiment provides a transmission line insulator cleaning robot, including an upper support 1 and a lower support 2 connected to the upper support 1 through an electric push rod 3; the electric push rod 3 is close to the upper support 1 The position is provided with an upper clamping assembly 4 arranged around to clamp the insulator steel cap; the position of the electric push rod 3 close to the lower support 2 is provided with a lower clamping assembly 5 arranged around it to clamp the steel cap of the insulator; Both the upper bracket 1 and the lower bracket 2 are provided with a cleaning mechanism 6 for cleaning insulators.

[0045] The upper bracket 1 is an annular structure with a first notch, and the first notch is provided with an upper sealing member 7 having the same shape as the first notch, and the upper sealing member 7 is connected to the upper bracket 1 One end is provided with an upper seal motor 8 for driving the rota...

Embodiment 2

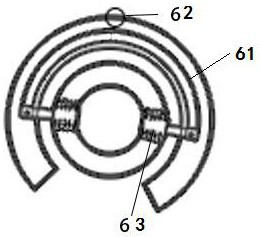

[0051] Such as Figure 4 As shown, this embodiment provides a transmission line insulator cleaning robot which is an improvement on the basis of Embodiment 1: a blowing module and a spraying module are installed at both ends of the arc track 61, and the blowing module includes The motor fan 64 that is arranged on the two ends of the arc track 61; the spray washing module includes nozzles arranged at the two ends of the arc track 61, a nozzle 65 connected to the nozzle, and the nozzle is connected to the liquid delivery unit. The liquid delivery unit includes a mobile tool trolley and a liquid storage barrel arranged on the mobile tool trolley, and the liquid storage barrel is connected to the spray pipe through a centrifugal pump.

[0052] Cleaning fluid or water can be stored in the liquid storage barrel. The steps of use are to clean with the brush roller 63 first, and then turn on the motor fan 64 to blow away the dust after cleaning to keep the surface of the insulator cle...

Embodiment 3

[0054] This embodiment provides a method for loading a power transmission line insulator cleaning robot described in Embodiment 2, and the decomposition steps are as follows:

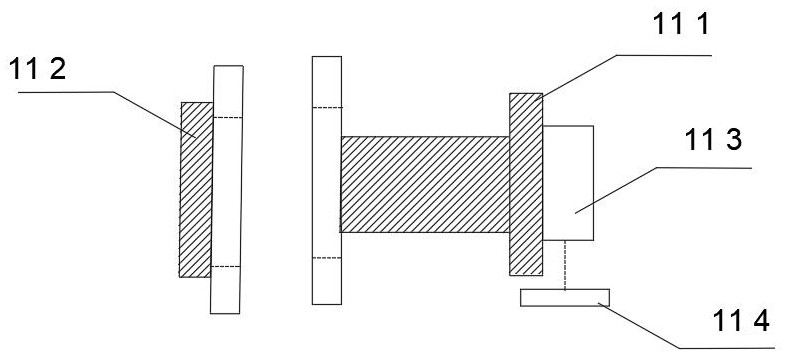

[0055] S1: First, the self-locking components 11 on the upper bracket 1 and the lower bracket 2 are unlocked, the rotation motor 113 is reversed, and the extension motor 114 is reversed to drive the self-locking bolt 111 to withdraw along the thread of the self-locking nut 112;

[0056] S2: When the self-locking bolt 111 is fully withdrawn, the upper sealing motor 8 reverses to drive the upper sealing member 7 to rotate, and the lower sealing motor 10 reverses to drive the lower sealing member 9 to rotate, so that the upper bracket 1 and the lower bracket 2 respectively open a gap;

[0057] S3: The staff uses the insulating rod to lift the robot to the bottom of the insulator string to be operated. The gaps of the upper bracket 1 and the lower bracket 2 correspond to the positions of the insulator steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com