Grinding and powdering device for synthesis essence production

A powder and flavoring technology, used in cocoa, grain processing, food science, etc., can solve problems such as clogging of grinding discs and barrel walls, grinding of difficult materials into powder, overloading of motors, etc., to improve grinding effect and fully grind , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

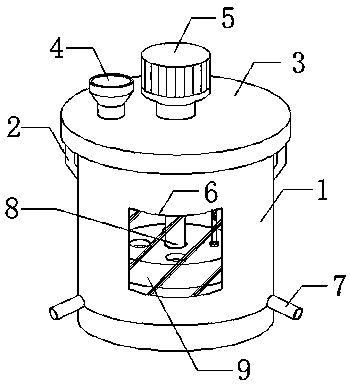

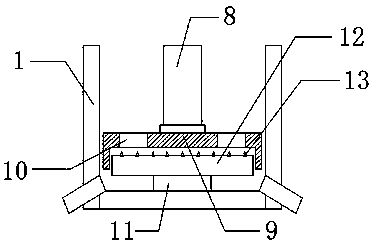

[0024] see Figure 1-5 As shown, a grinding and powdering device for the production of synthetic flavors includes a grinding barrel 1, an upper grinding disc 9 and a lower grinding disc 12, buckles 2 are arranged on both sides of the top of the grinding barrel 1, and a top cover 3 is arranged on the top of the buckle 2, The buckle 2 is used to fix the top cover 3, the top of the top cover 3 is equipped with a motor 5, one side of the motor 5 is provided with a feeding port 4, one side of the grinding bucket 1 is provided with a glass window 6, and both sides of the bottom of the grinding bucket 1 are provided with Material port 7, rotating rod 8 is installed inside the grinding barrel 1, several stirring blades 14 are arranged on the outer wall of the rotating rod 8, the motor 5 is connected to an external power supply, and the motor 5 can drive the stirring blade 14 to mix and spread the materials in the grinding barrel 1 Evenly, the upper grinding disc 9 is installed under t...

Embodiment 2

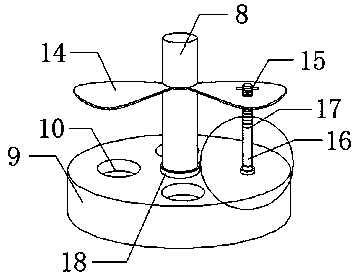

[0026] In addition, refer to Figure 1-5 The difference with the above-mentioned embodiment is that a turntable 18 is set between the upper grinding disc 9 and the rotating rod 8, and the upper grinding disc 9 is rotationally connected with the rotating rod 8 through the rotating disc 18, so that the rotating rod 8 drives the rotating disc 18 to rotate when rotating. The upper millstone 9 is not controlled by the rotating rod 8, the base 20 is arranged on the top of the upper millstone 9, and the stirring blade 14 is connected with the upper millstone 9 through the connecting rod 16, so that the stirring blade 14 can drive the upper millstone 9 to rotate through the connecting rod 16 , the threaded rod 17 is arranged on the side close to the stirring blade 14, and the threaded rod 17 is movably connected with the stirring blade 14 through the adjusting bolt 15, so that the adjusting bolt 15 can adjust the pressure that the connecting rod 16 presses down on the fixed ball 19, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com