Microspheres prepared from composition containing zirconium oxide and preparation method of microspheres

A technology of zirconium oxide and composition, which is applied in the field of composite zirconia microspheres and its preparation, can solve the problems of large market constraints of zirconia powder, low strength of zirconia balls, uneven distribution of material components, etc., and achieve energy saving And labor consumption, avoid secondary high temperature sintering, the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Using traditional techniques, add 5wt% of the third component of silicon dioxide and 0.1mol% of yttrium oxide to the commercialized zirconia powder;

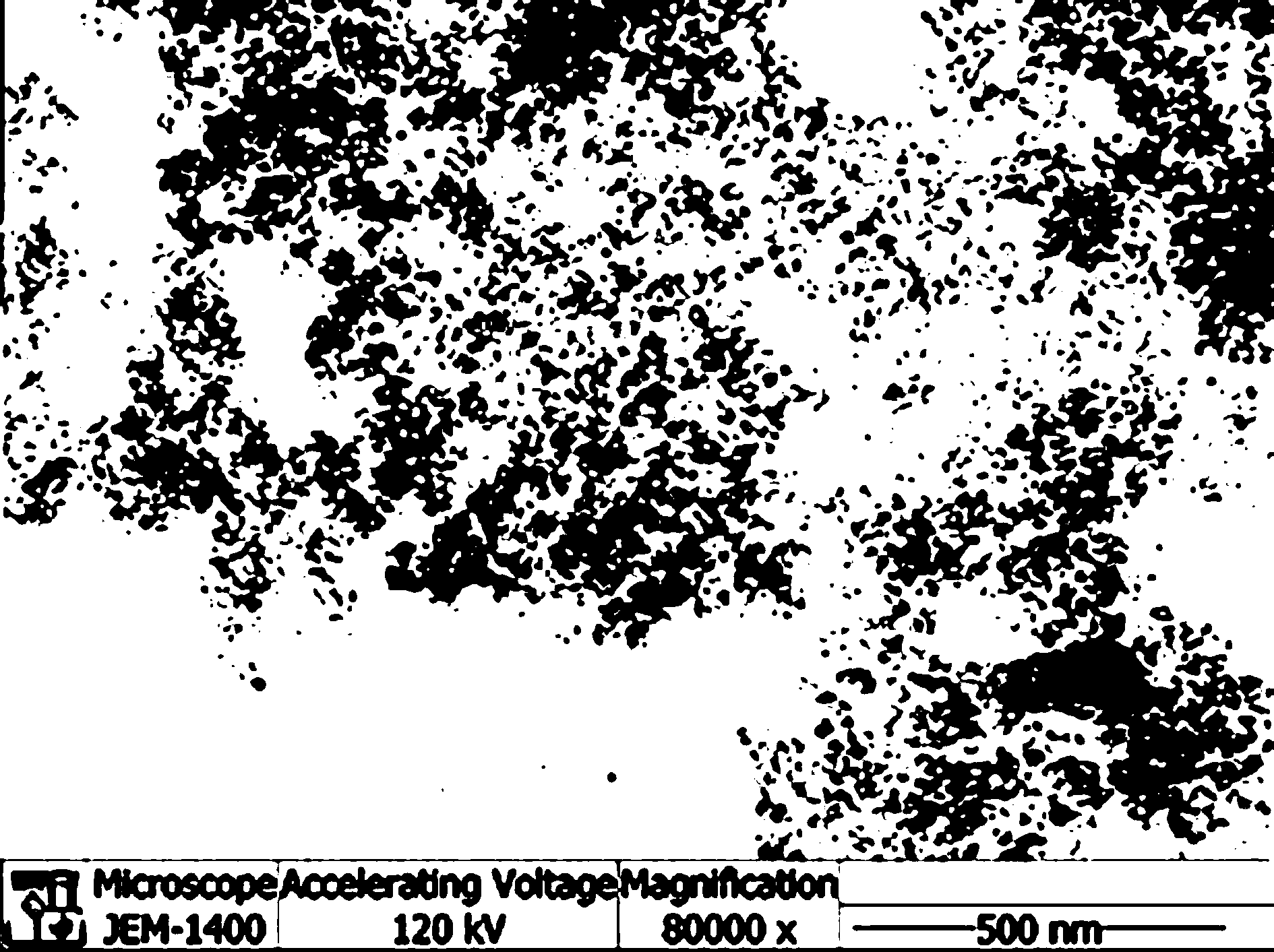

[0032] (2) After that, pour into the stirring mill and wet ball mill until the particle size D 50 Less than 0.6 microns;

[0033] (3) Add spray drying or oven drying. Moisture is less than 6% after drying;

[0034] (4) Slowly add the prepared powder into the rolling ball machine, and while rolling the powder, spray the composite binder solution containing PVA at a concentration of 0.1-0.8% by spraying until the obtained diameter is 0.1-5mm Zirconia composite ball seeds;

[0035] (5) Put the ball seeds into the ball rolling machine, while rolling the seeds and adding powder slowly, while spraying the composite binder solution with a concentration of 0.5-1.2% PVA in the form of spray, until the diameter reaches the required size. Zirconia composite ball blank. Then spray a small amount of water and continue rolling...

Embodiment 2

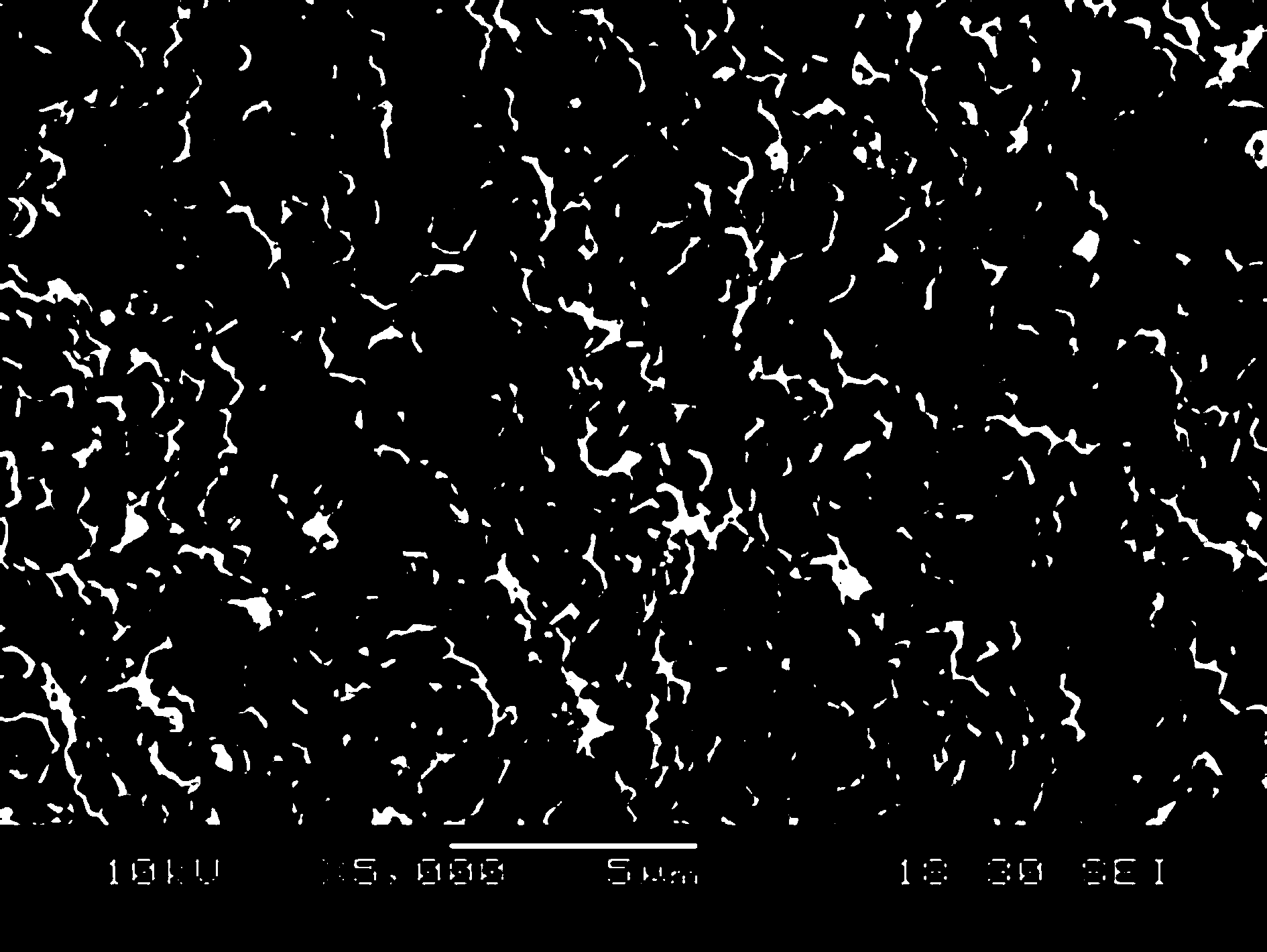

[0041] (1) Pre-place a certain amount of zirconia balls in the stirring mill, and prepare Zr 4+ Zirconium oxychloride solution with a concentration of 2mol / L, including the third component doping system of 5wt% alumina, 2wt% cerium oxide, 1wt% magnesium oxide, 5wt% calcium oxide, 2wt% silicon dioxide, and yttrium oxide 8mol%, heating and stirring to dissolve;

[0042] (2) Then add 2.5% polyethylene glycol relative to the mass of zirconia, and stir evenly;

[0043] (3) Finally, slowly add a solid-phase precipitant to the uniformly stirred solution. The precipitant is ammonium bicarbonate and urea, and mix with ball milling for 4 hours;

[0044] (4) up to Zr 4+ ion and Y 3+ The ions are completely precipitated, the reaction is completed, and the final pH value is controlled at about 7-8;

[0045] (5) The final prepared colloid is stored and aged for 8 hours;

[0046](6) After that, wash and filter with water;

[0047] (7) Mix the filtered filter cake with distilled water a...

Embodiment 3

[0055] The process flow of Example 2 is adopted, except that the third component added is 1 wt% of silicon dioxide.

[0056] The nano-ceramic ball green body prepared by this method was calcined at 1400°C, and the holding time was 2 hours. The microspheres of 0.8-1mm were selected, and the density of the ceramic tool was determined to be 6.02g / cm by the Azimiade drainage method. 3 , the theoretical density reaches 98.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com