Nano-carbon low-carbon magnesia carbon brick for ladle slag line and preparation method

A carbon magnesia carbon brick and ladle slag wire technology, applied in the field of refractory materials, can solve the problems of high cost of metal powder and antioxidant, difficulty in carbon mass percentage ≥ 98%, difficulty in industrialization implementation, etc. area, reducing heat dissipation losses, and improving the effect of erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

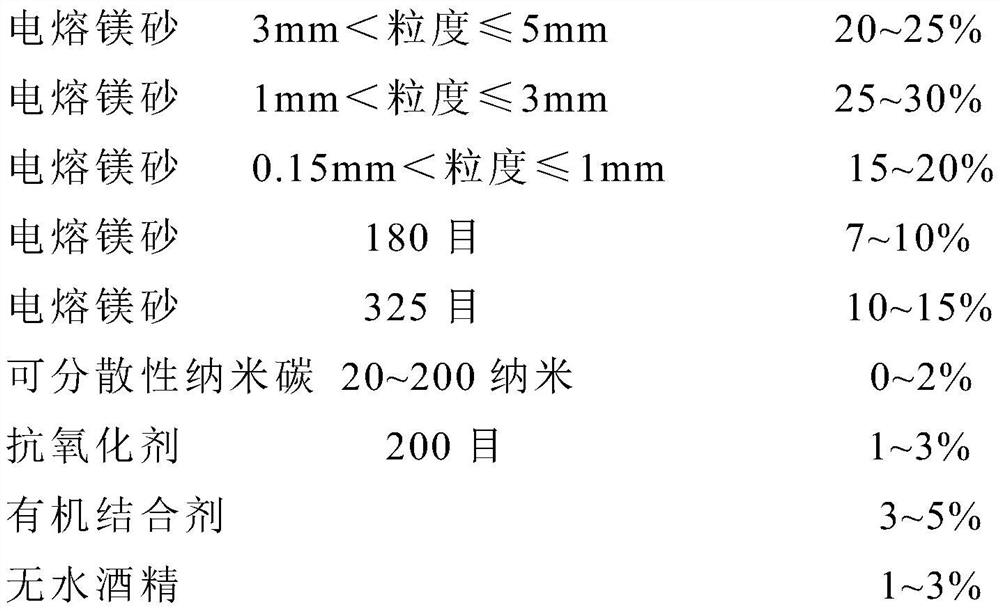

[0040] The raw materials of nano-carbon low-carbon magnesia-carbon bricks for ladle slag line include main raw materials and auxiliary raw materials. The main raw materials include by weight percentage:

[0041]

[0042]

[0043] The auxiliary raw materials include steel fiber, polyvinyl alcohol fiber and chopped carbon fiber. The weight of steel fiber accounts for 1% of the total weight of the main raw material, the weight of polyvinyl alcohol fiber accounts for 0.05% of the total weight of the main raw material, and the weight of chopped carbon fiber accounts for the total weight of the main raw material. 0.02% of;

[0044] The preparation method comprises the following steps:

[0045] 1) Crushing and grading the fused magnesia into raw materials with three specifications of 5-3mm, 3-1mm, and 1-0.15mm, further grinding the fused magnesia and grading it into raw materials with two specifications of 180 mesh and 325 mesh , forming five kinds of raw materials in total; ...

Embodiment 2

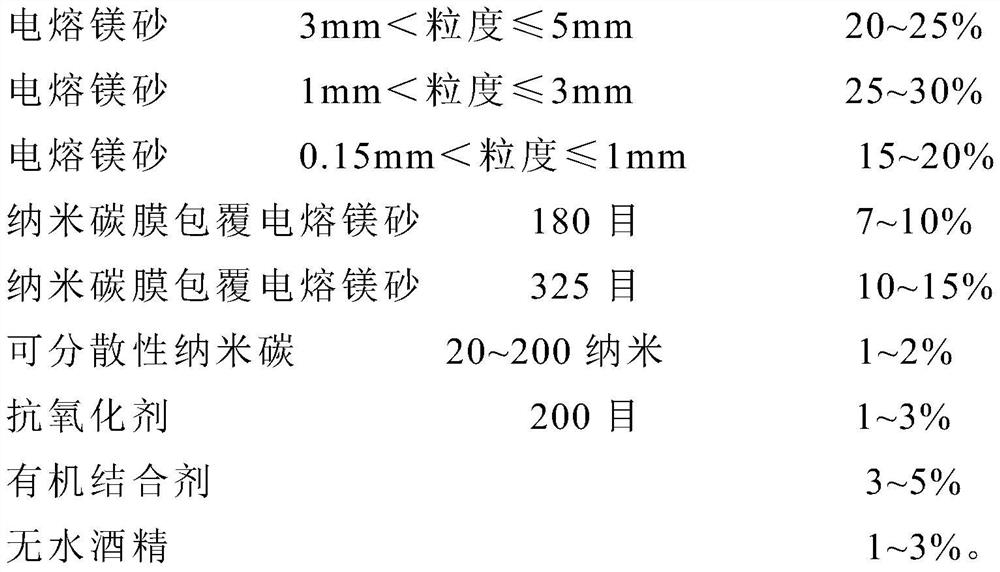

[0052] The raw materials of nano-carbon low-carbon magnesia-carbon bricks for ladle slag line include main raw materials and auxiliary raw materials. The main raw materials include by weight percentage:

[0053]

[0054] The auxiliary raw materials include steel fiber, polyvinyl alcohol fiber and chopped carbon fiber. The weight of steel fiber accounts for 0.5% of the total weight of the main raw material, the weight of polyvinyl alcohol fiber accounts for 0.10% of the total weight of the main raw material, and the weight of chopped carbon fiber accounts for the total weight of the main raw material. 0.10%.

[0055] The preparation method is the same as in Example 1.

Embodiment 3

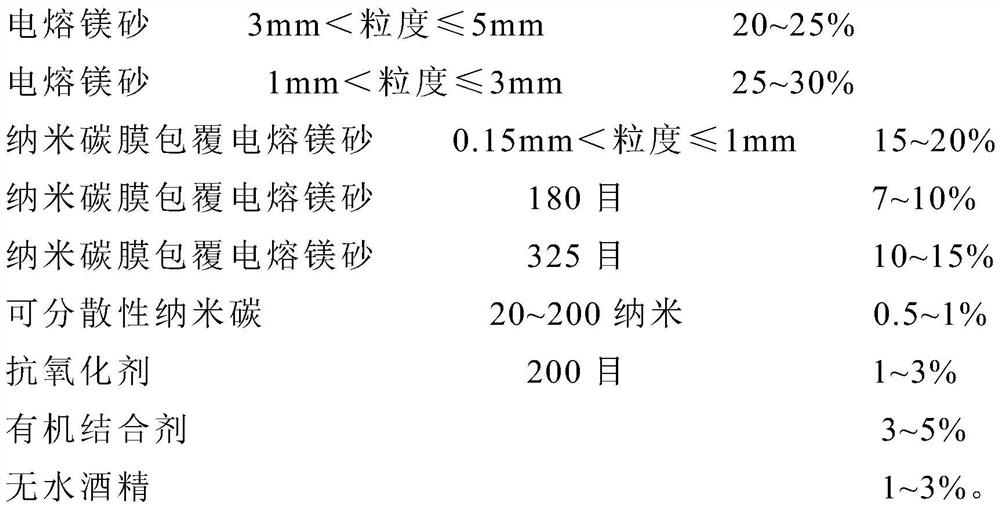

[0057] The raw materials of nano-carbon low-carbon magnesia-carbon bricks for ladle slag line include main raw materials and auxiliary raw materials. The main raw materials include by weight percentage:

[0058]

[0059]

[0060] The auxiliary raw materials include steel fiber, polyvinyl alcohol fiber and chopped carbon fiber. The weight of steel fiber accounts for 0.5% of the total weight of the main raw material, the weight of polyvinyl alcohol fiber accounts for 0.15% of the total weight of the main raw material, and the weight of chopped carbon fiber accounts for the total weight of the main raw material. 0.20%.

[0061] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com