Production process of shielding cover for electronic products

A production process and technology of electronic products, applied in the fields of magnetic/electric field shielding, local shielding, electrical components, etc., can solve the problems of difficulty in guaranteeing the curing effect of insulating paint, reducing the performance of metal shielding covers, affecting the service life of metal shielding covers, etc. Achieve the effect of reducing the possibility, prolonging the service life and ensuring the curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

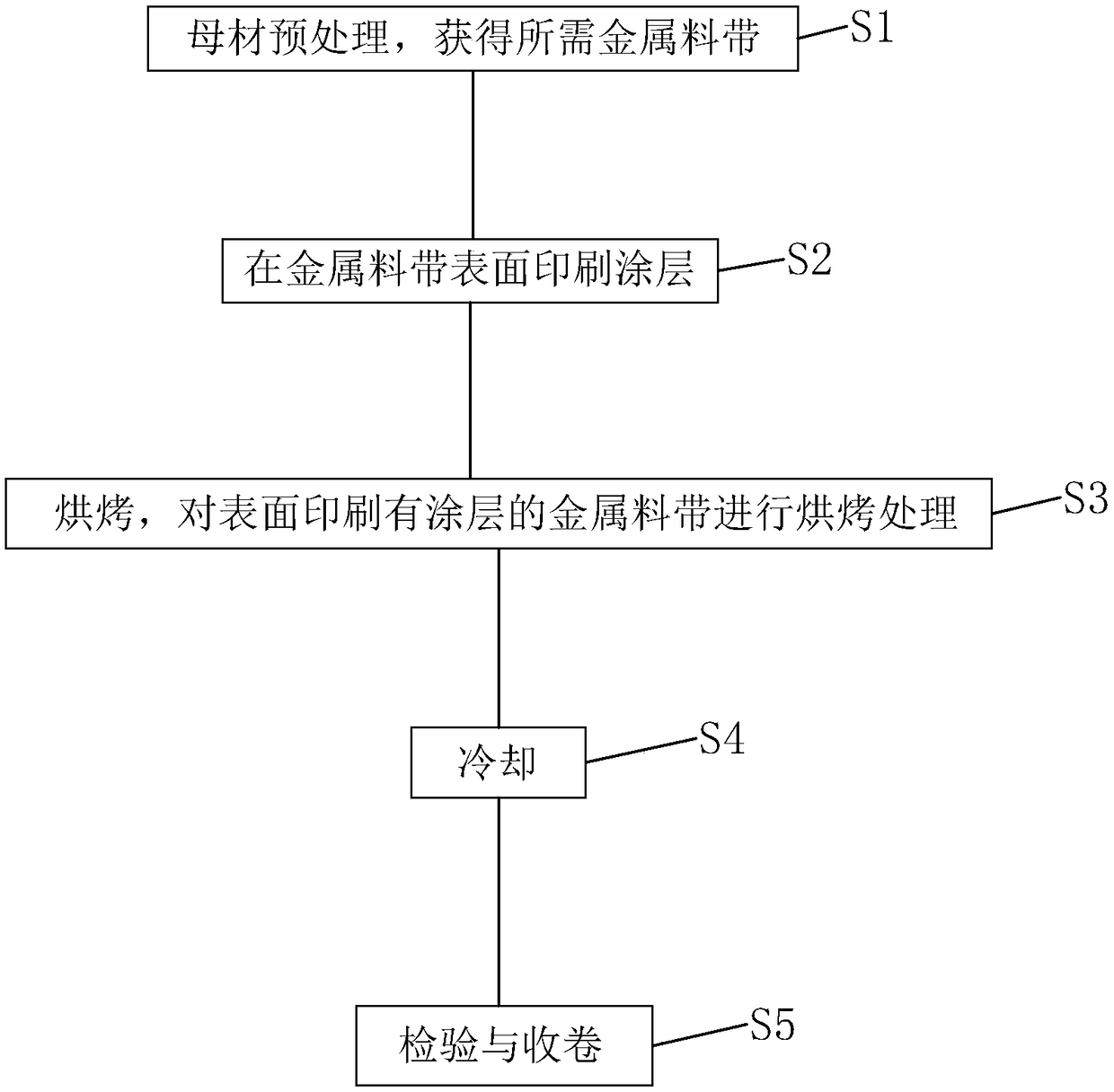

[0036] See attached figure 1 , a production process of a shielding cover for electronic products, comprising the following steps:

[0037] S1. Base material pretreatment to obtain the required metal strip. In actual production, the base material used can be SPCC cold-rolled steel strip or stainless steel strip. During the pretreatment process of the base material, the staff can first use the calender to perform rolling treatment on the base material steel strip, and roll the steel strip to the required thickness. Subsequently, the staff can use the steel strip slitting machine to cut the steel strip into the required width specifications, and form the required metal strips; in actual work, the commonly used widths of the metal strips are 30mm, 50mm and 100mm. After the steel strip is cut, the staff can clean the surface of the steel strip with a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com