Large-pore-path plugging compound water shutoff agent for sandstone reservoir and preparation method of large-pore-path plugging compound water shutoff agent

A technology for sandstone oil reservoirs and large pore channels, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of small water blocking range, small water blocking radius, and pipeline and other equipment blockage, etc., and achieves simple construction technology, The effect of increasing the compressive strength and expanding the radius of water blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

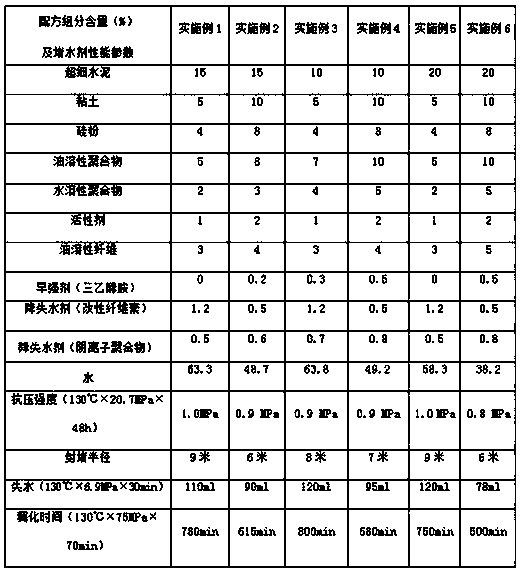

[0037] The formulations of Examples 1-6 are shown in Table 1.

[0038] The performance parameters of the composite water shutoff agent for large pore plugging in sandstone reservoirs are shown in Table 1.

[0039] Table 1

[0040]

[0041] In Example 1, the modified cellulose is hydroxyethyl cellulose, and the anionic polymer is 2-acrylamido-2-methylpropanesulfonic acid;

[0042] In Example 2, the modified cellulose is hydroxyethyl cellulose and carboxymethyl hydroxyethyl cellulose, which are mixed in equal weight; the anionic polymer is 2-acrylamido-2-methylpropanesulfonic acid and ethylene sulfonate, mixed in equal weight;

[0043] In embodiment 3, the modified cellulose is carboxymethyl cellulose, and the anionic polymer is 2-acrylamido-2-methylpropanesulfonic acid, propylene sulfonate and styrene sulfonate, the three The weight ratio is 2:1:1;

[0044] In embodiment 4, the modified cellulose is carboxymethyl hydroxyethyl cellulose, and the anionic polymer is styrene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com