High-speed wire drawing device for optical fiber production process and high-speed wire drawing method thereof

A medium-to-high-speed production process technology, applied in glass production, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of shortened residence time, insufficient cooling, poor appearance of the coating, etc., to ensure the curing effect and operability Strong, superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

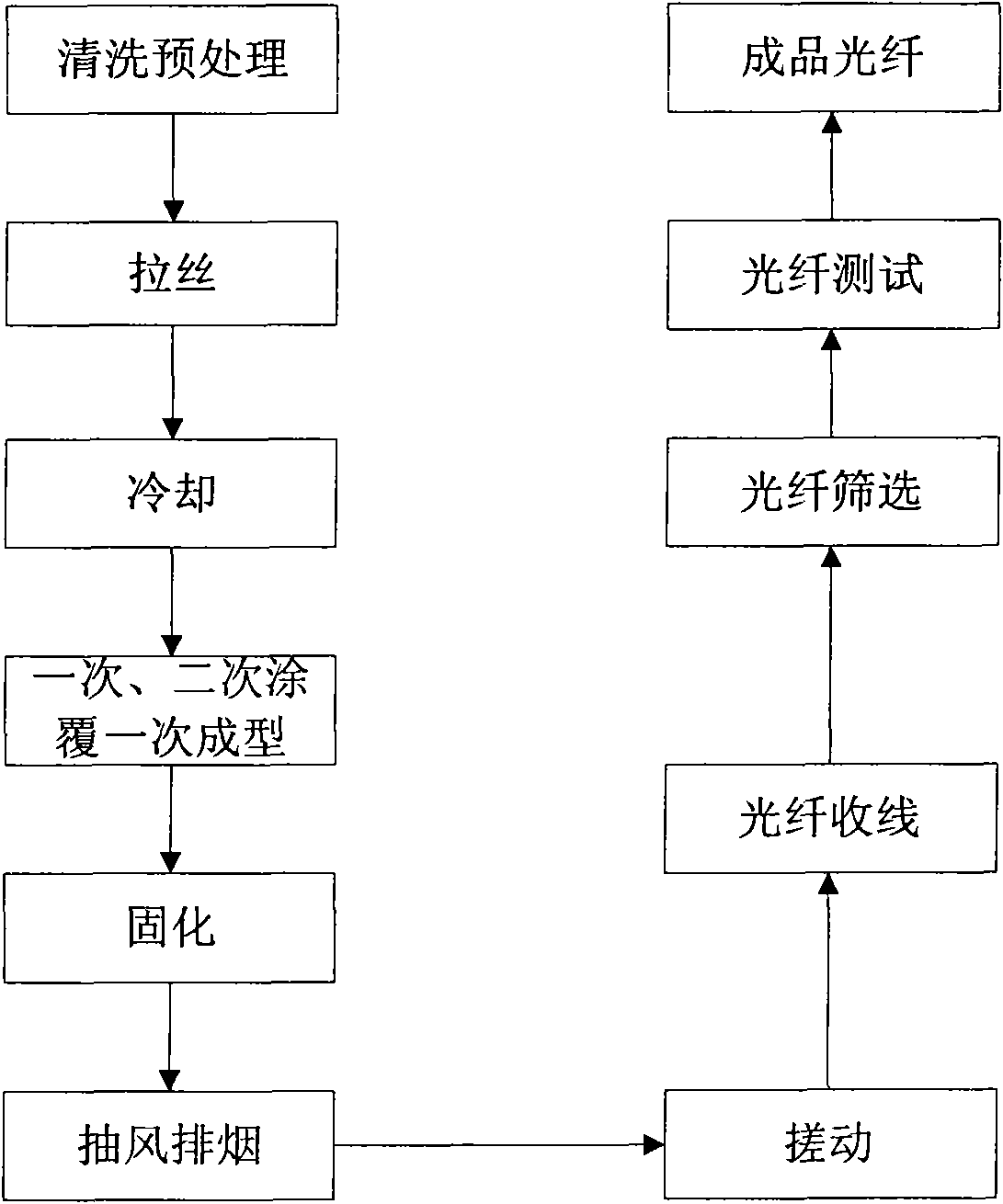

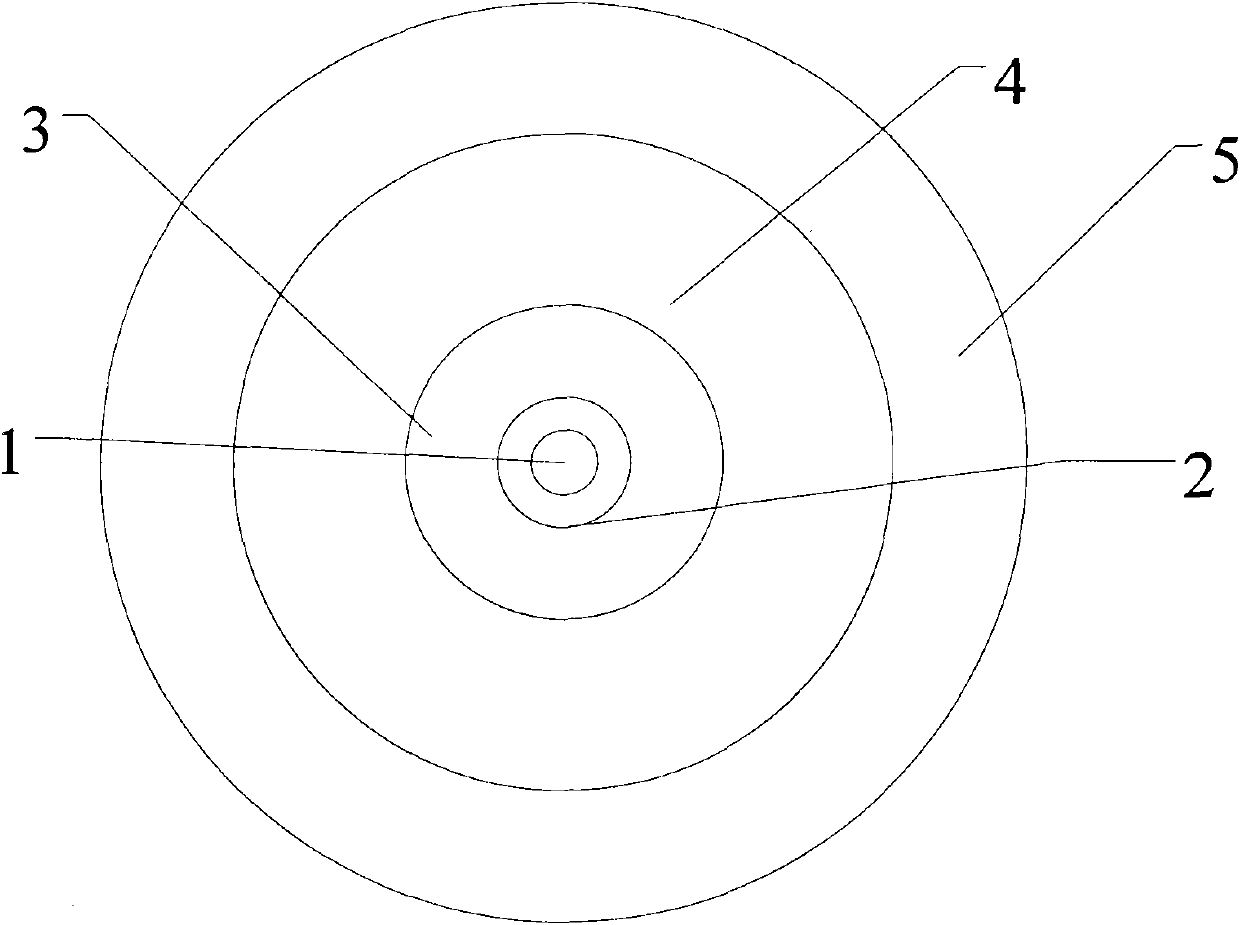

[0027] Refer to attached Figure 1-2 , the single-mode optical fiber produced by the high-speed wire drawing method includes a core 1 , an inner cladding 2 , an outer cladding 3 , a primary UV-curable coating 4 , and a secondary UV-curable coating 5 . The core 1 is wrapped with an inner cladding 2 and an outer cladding 3. There are two layers of UV-curable coatings on the outside of the outer cladding 3, which are the primary UV-curable coating 4 and the secondary UV-curable coating 5. The outer cladding is coated once. , Two-layer coating is formed at one time, and UV-cured coating is used. UV-cured coatings feature low modulus and low refractive index. The index of this optical fiber is basically equivalent to the index of conventional G.652: the zero dispersion wavelength of this optical fiber is between 1300-1324nm, and the zero dispersion slope is not greater than 0.092ps / (nm 2 km). The attenuation of the optical fiber at 1310nm is not greater than 0.34dB / km, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com