Preparation method of suspended particle controllable light valve

A suspended particle and light valve technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of shortening the service life of the suspended particle light valve, attenuation of the light transmittance of the suspended particle light valve, and low light transmittance, and achieves Improve curing effect, increase UV penetration performance, reduce light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

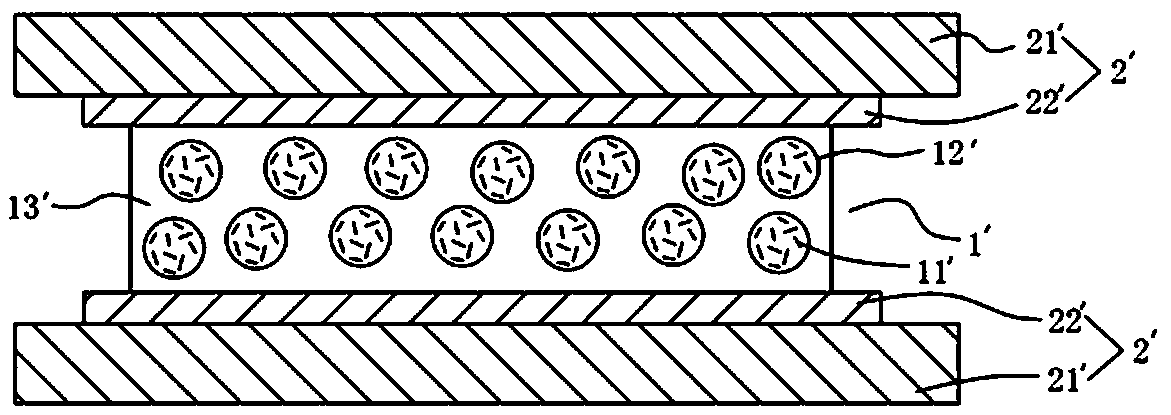

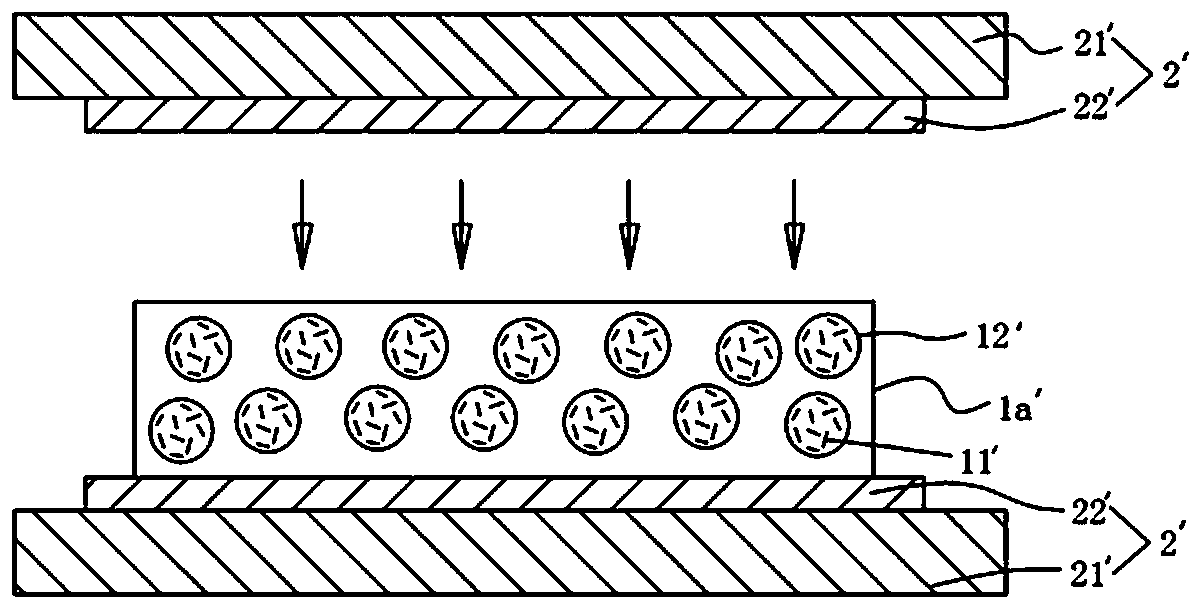

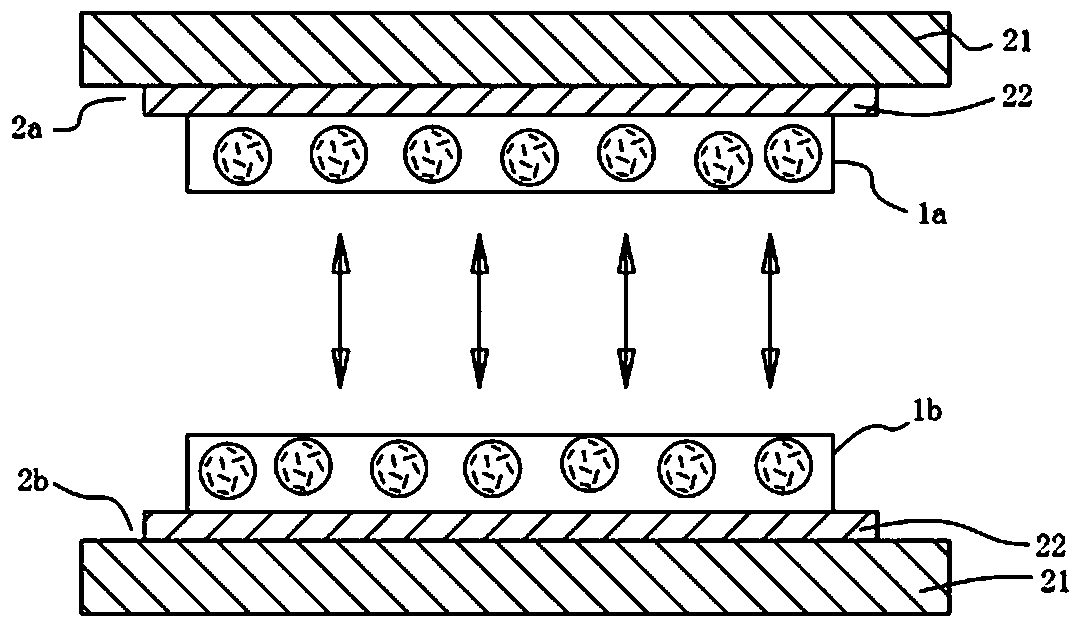

[0026] like image 3 and 4 As shown, a method for preparing a suspended particle controllable light valve includes an upper transparent electrode 2a and a lower transparent electrode 2b, both of which are composed of a transparent substrate 21 and a layer of transparent conductive film 22 thereon.

[0027] The light valve matrix emulsion containing the polymerization precursor PPM, the suspension medium SM, the light control particles LCP and the photoinitiator PI is divided into two parts, and then respectively coated on the transparent conductive film 22 inside the two transparent electrodes to form a light valve matrix emulsion layer. The light valve matrix emulsion layer on the electrode 2 is respectively cured by ultraviolet radiation to form the light control upper layer 1a and the light control lower layer 1b; after curing, the upper transparent electrode 2a and the light control upper layer 1a integrally form the upper stack assembly A, and the lower transparent electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com