Producing system of internally-heating curing glass fibre reinforced plastic controlled by programm

A technology of manufacturing system and control system, applied in the direction of program control, general control system, control/regulation system, etc., can solve the problems of unstable control and control of glass fiber reinforced plastic pipe wall, and improve the appearance quality and strength consistency. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention is further described below in conjunction with embodiment. The scope of the present invention is not limited by these examples, and the scope of the present invention is set forth in the claims.

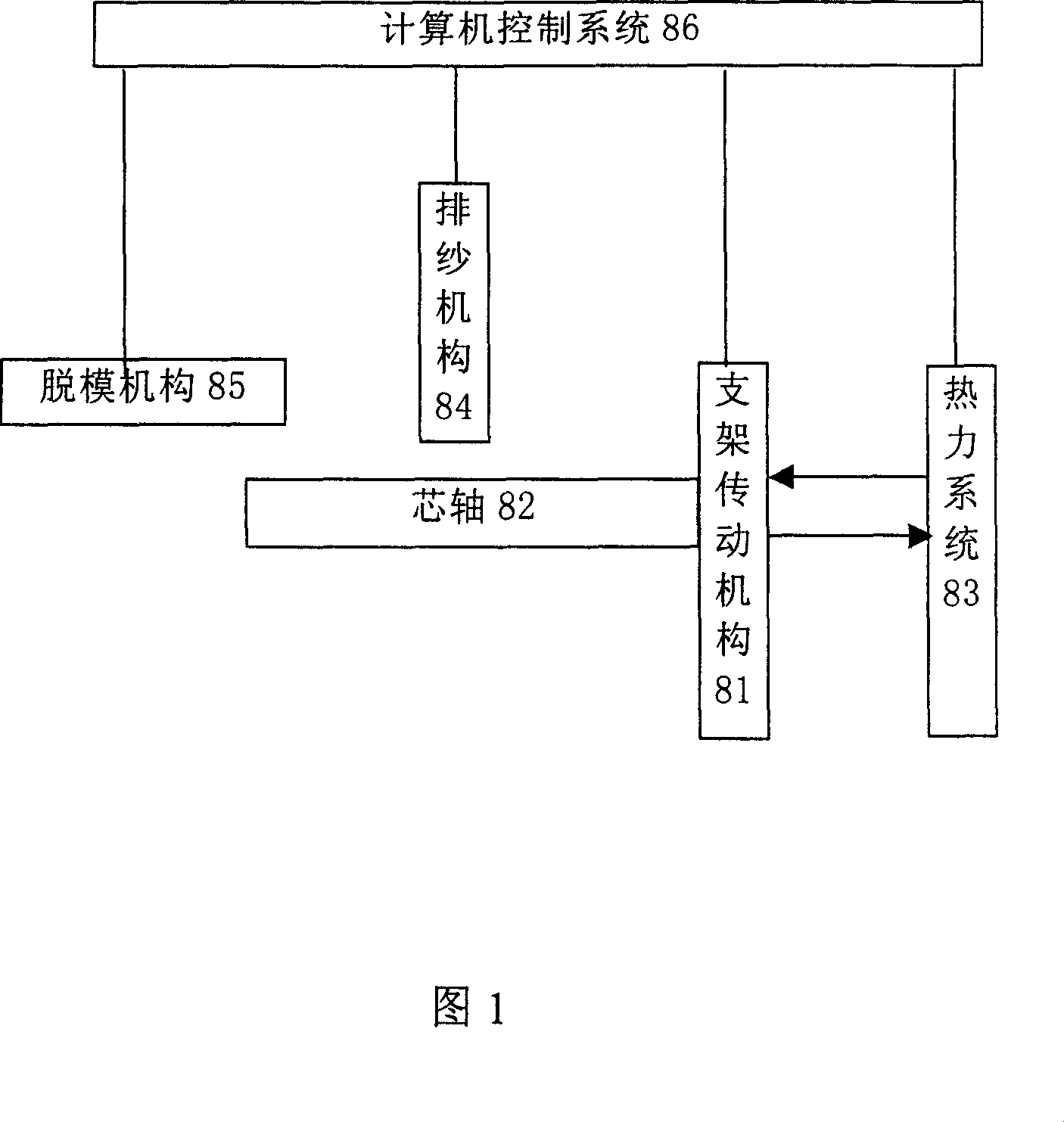

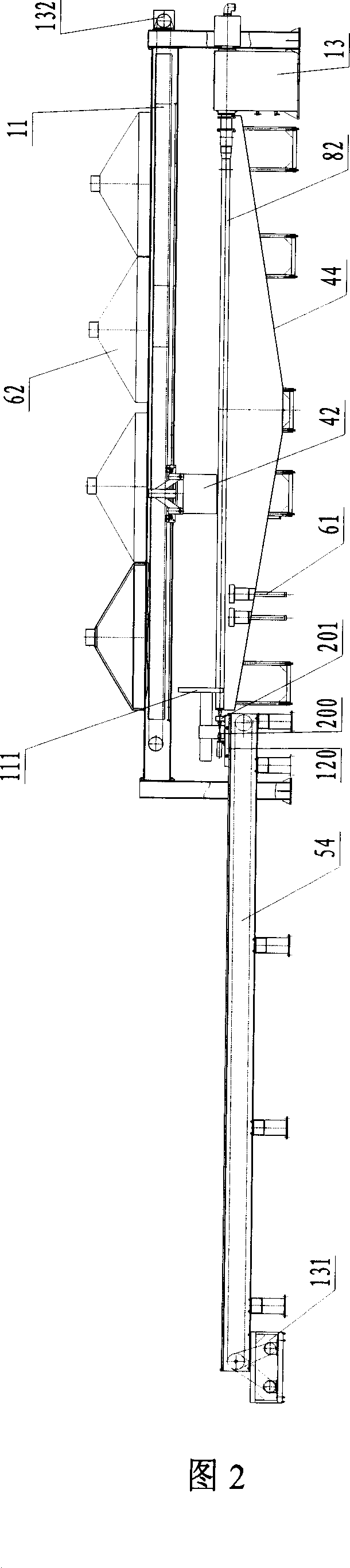

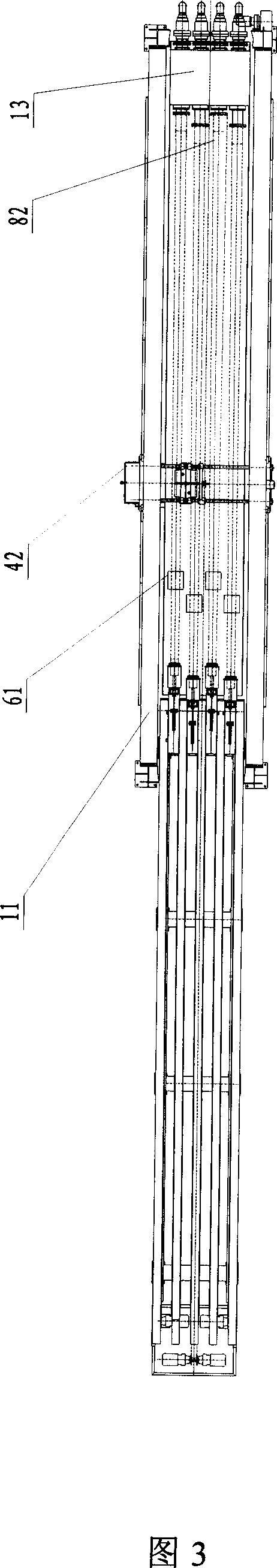

[0072] A program-controlled internal heating and curing FRP pipeline manufacturing system, including: a bracket transmission mechanism 81, a mandrel 82, a thermal system 83, a yarn arrangement mechanism 84, a demoulding mechanism 85, and a computer control system 86; the bracket transmission mechanism 81 It includes a bracket 11, a motor, a gear transmission mechanism 13, and a bearing 14; the mandrel 82 is erected on the bearing placed on the bracket, and the motor drives the mandrel 82 to rotate through the gear transmission mechanism; the glass fiber tape 41 is wound on the mandrel 82 to form FRP pipeline 10; the mandrel 82 is a double-layer metal pipe, and the steam from the thermal system 83 passes into the inner pipe from one end of the mandrel 82 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com