Method, system and device for eliminating influence on photocuring by oxygen and photocuring equipment

A light-curing and oxygen technology, applied in the field of additive manufacturing, can solve the problems of increasing the cost of light-curing equipment, curing the bottom layer of the cured layer, and uncured surface, and achieve the effect of ensuring the light-curing effect, saving the amount of use, and ensuring the curing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

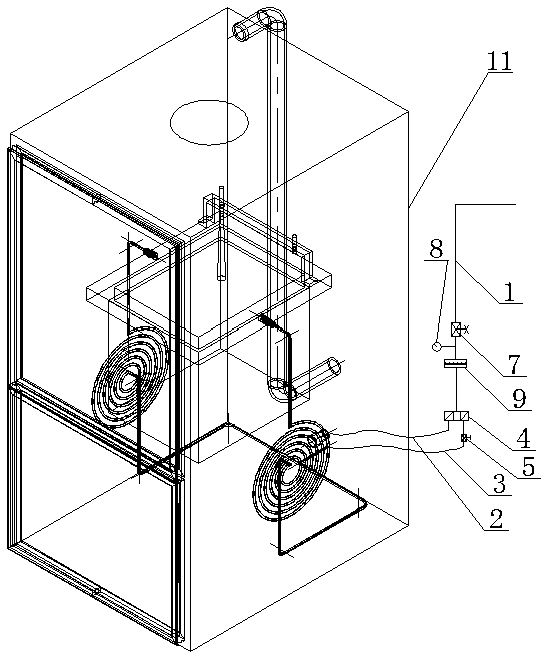

[0033] In order to allow those skilled in the art to better understand and realize the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

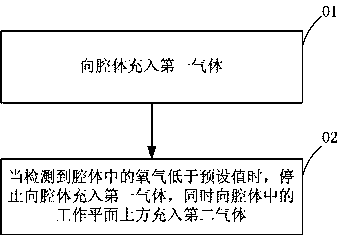

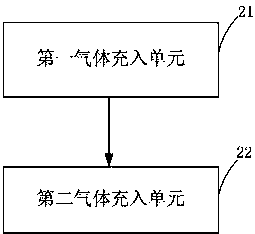

[0034] Such as figure 1 As shown, a method to eliminate the influence of oxygen on photocuring, including:

[0035] Step 01, filling the cavity with the first gas;

[0036] Step 02, when it is detected that the oxygen in the cavity is lower than the preset value, stop filling the cavity with the first gas, and at the same time fill the cavity with the second gas above the working plane;

[0037] Wherein, both the first gas and the second gas are gases capable of eliminating the influence of oxygen on the photocuring reaction process, and the filling flow value of the second gas is smaller than that of the first gas.

[0038]In specific implementation, the first gas and the second gas can be nitrogen, argon, and of course any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com