Patents

Literature

211 results about "Oxygen inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen inhibition occurs when dissolved oxygen can act as a comonomer in a free-radical cure. Addition of oxygen to the growing polymer radical results in the formation of a relatively inactive peroxy radical. Oxygen inhibition is a potential problem of cures conducted in the open air.

Non-volatile dental compositions containing multifunctional acrylate compounds and lacking an oxygen-inhibited layer

Dental composite formulations containing an initiator and a multiacrylate compound are disclosed. The formulations lack methyl methacrylate, a volatile, irritating, and potentially hazardous material commonly found in dental formulations. The multiacrylate compound has at least three acrylate functionalities per molecule. The formulations cure to form a surface lacking an oxygen inhibition layer. The formulations can be used as dental sealants, dental coatings, and in fingernail / toenail repair applications.

Owner:BISCO

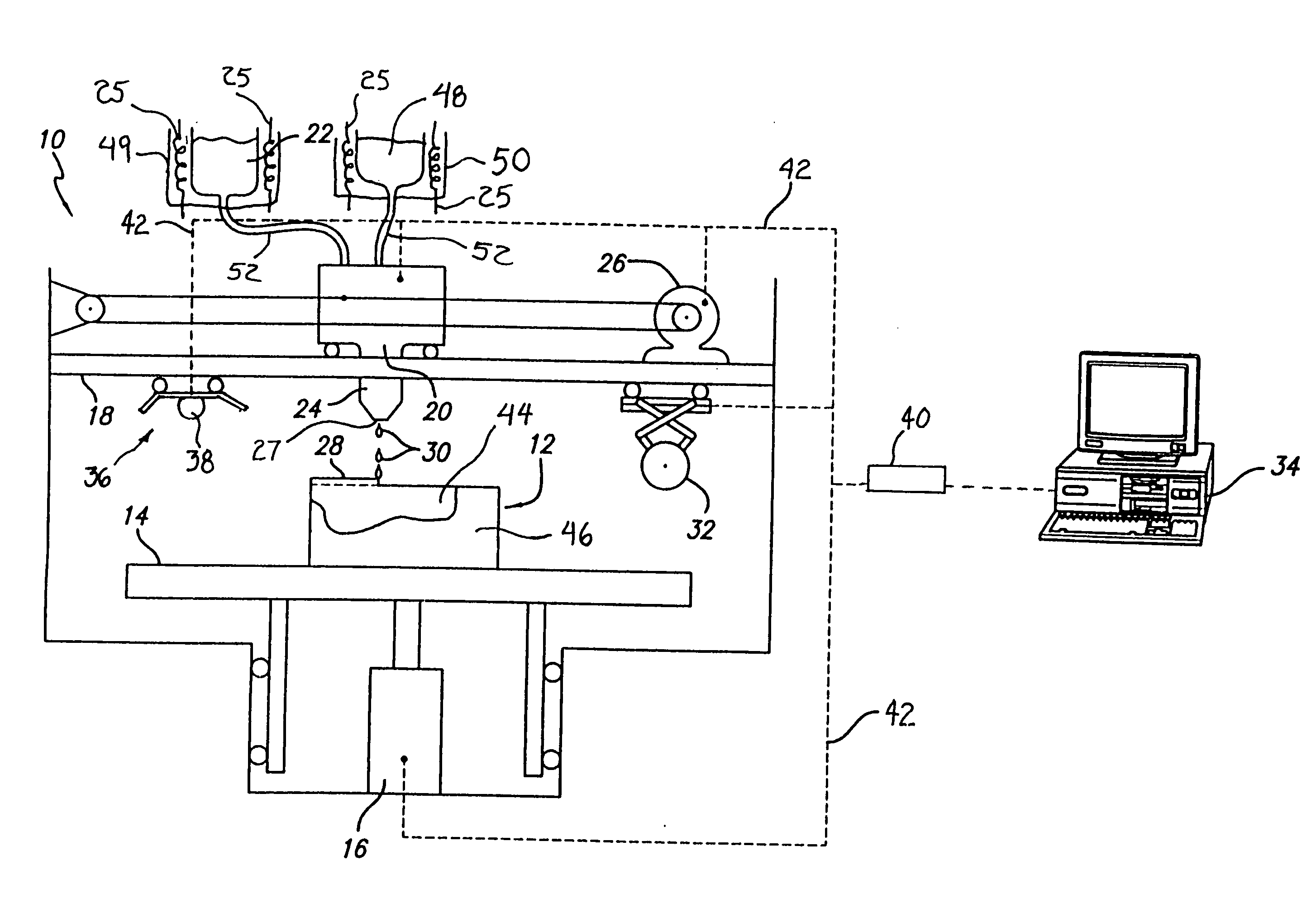

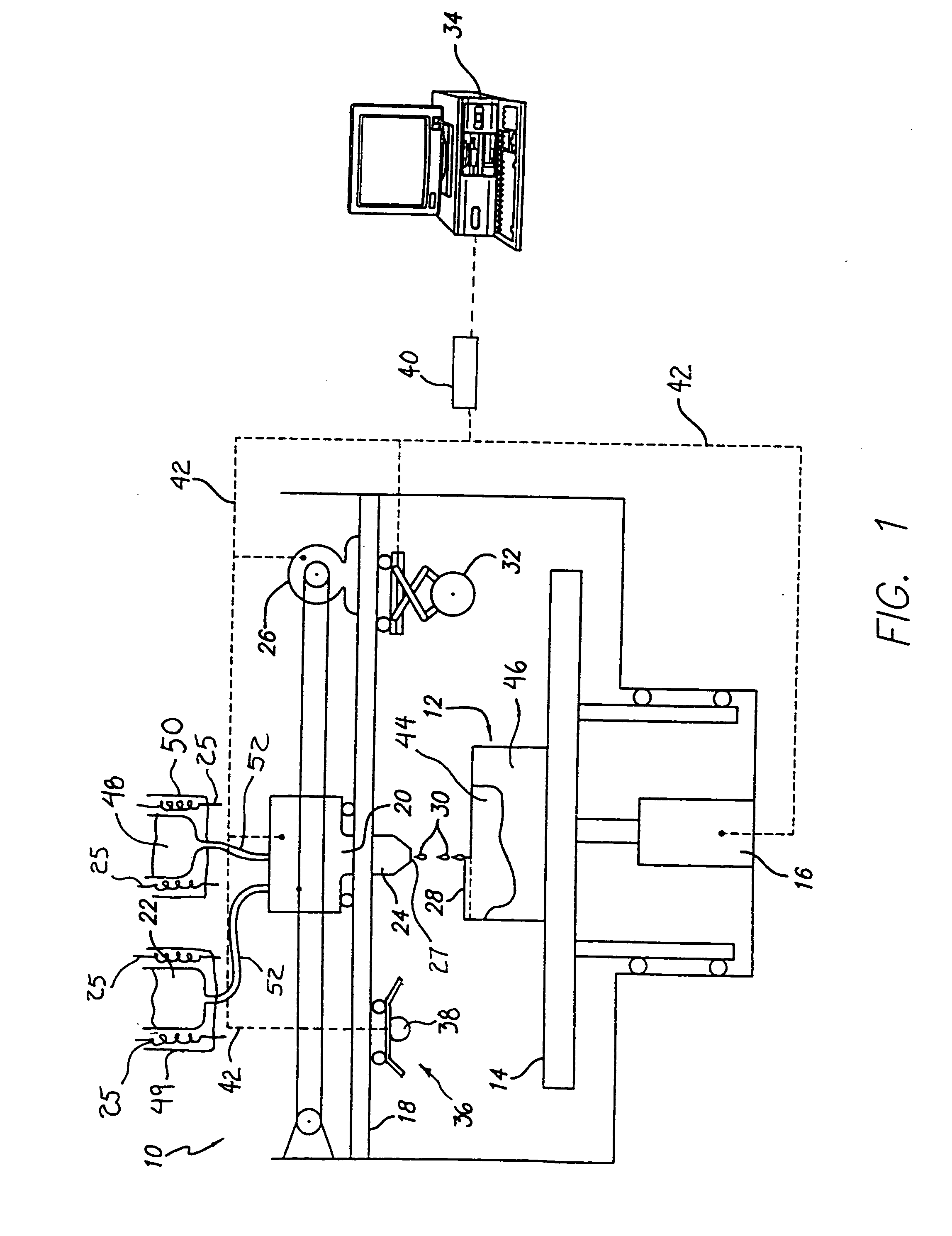

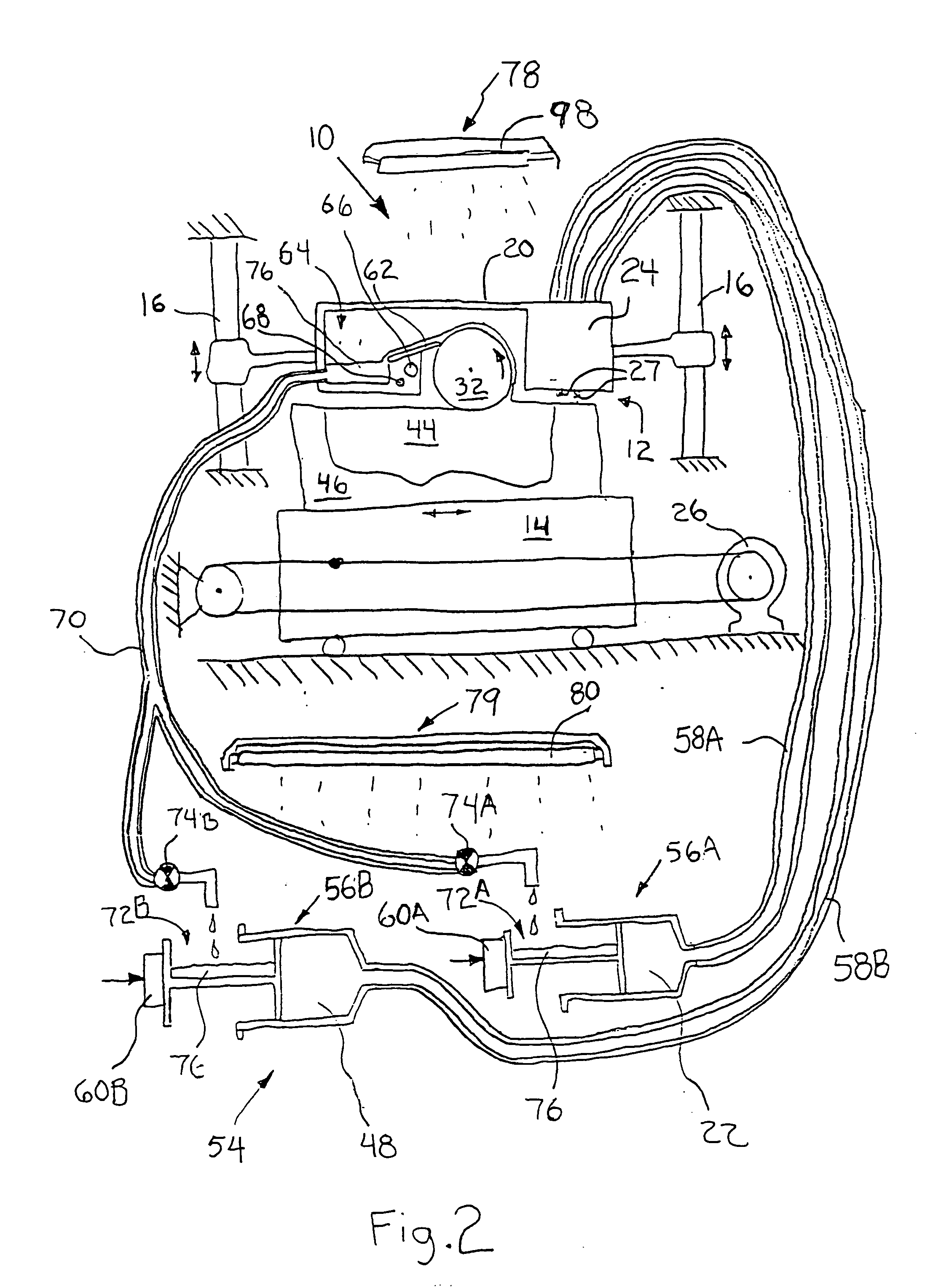

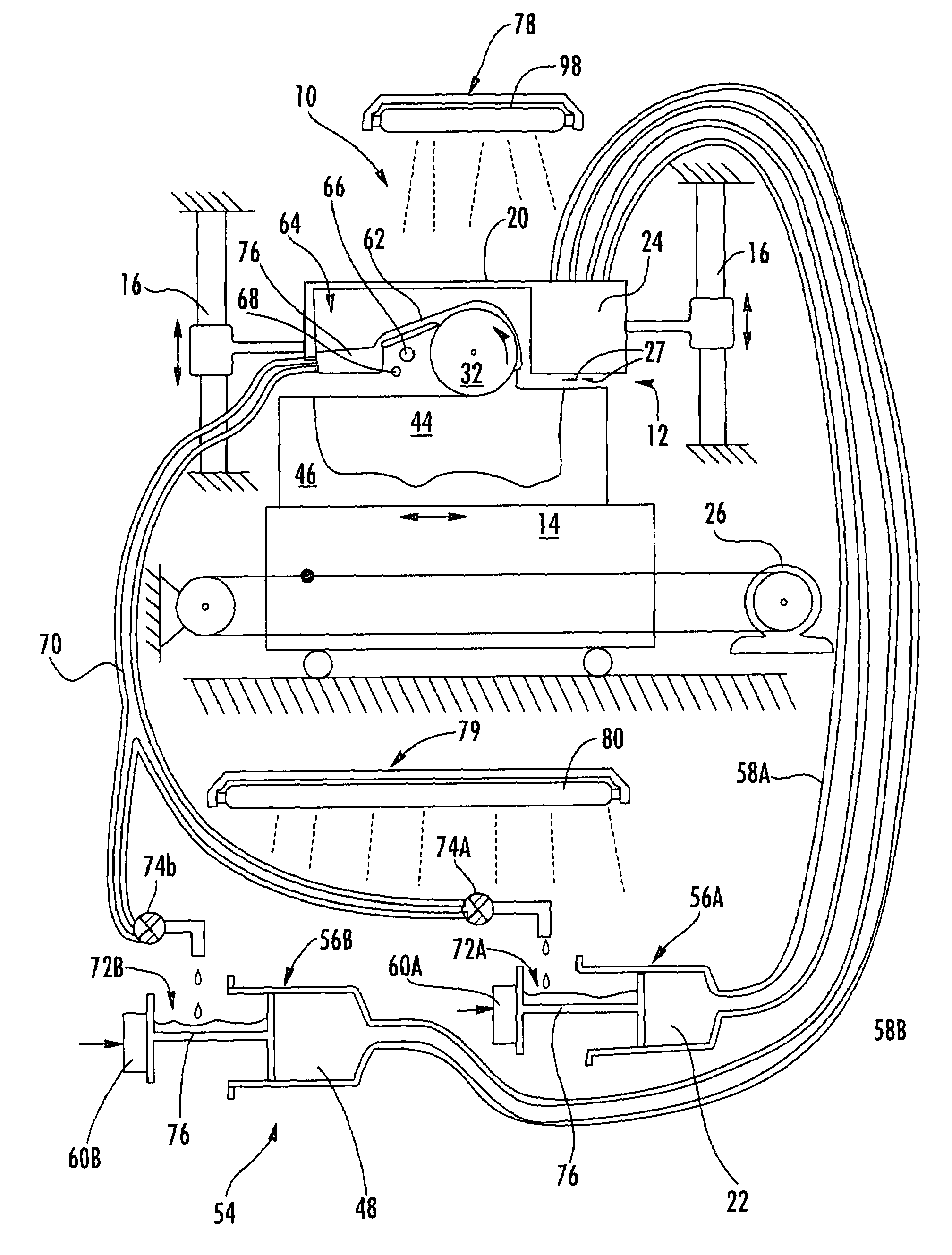

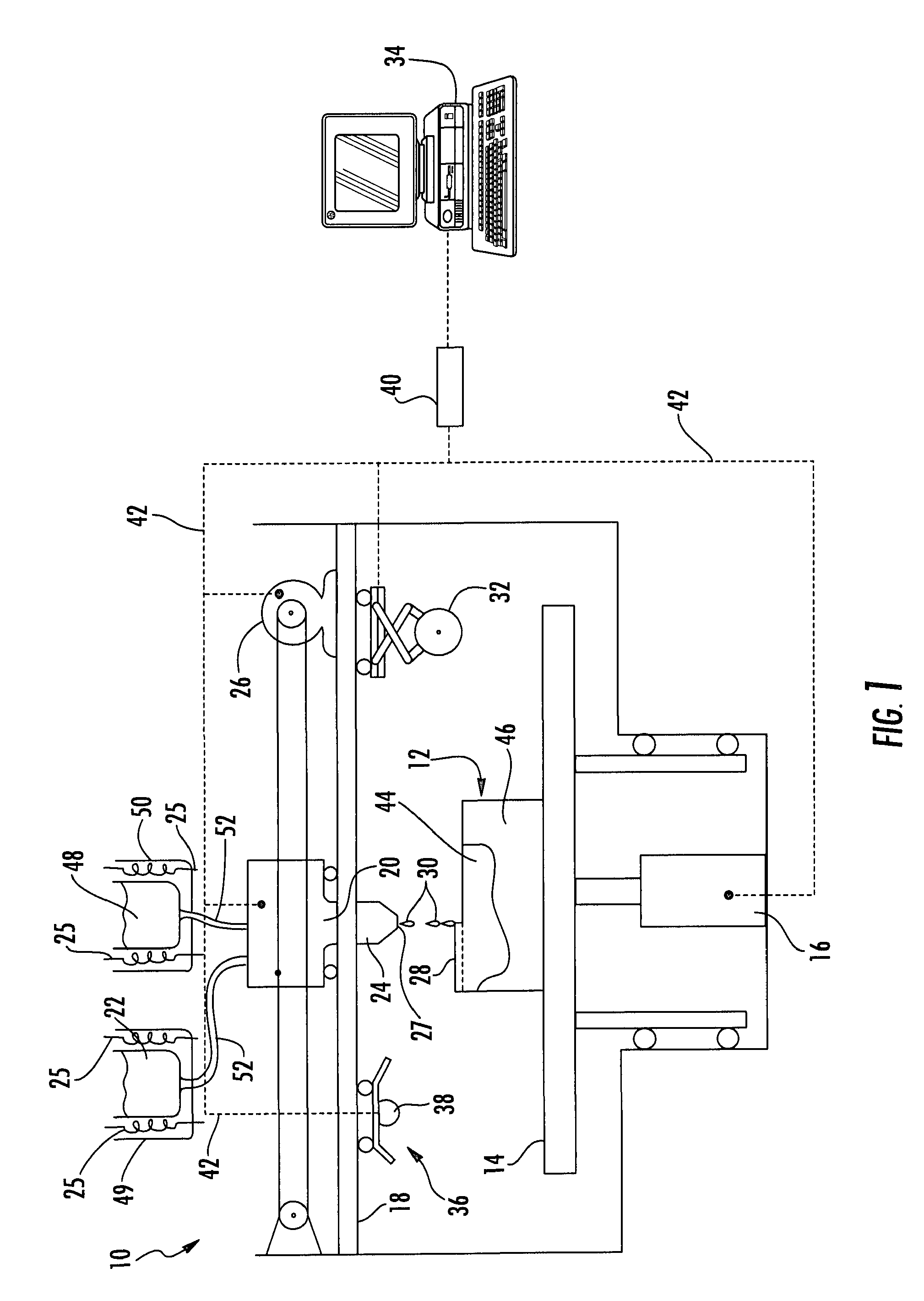

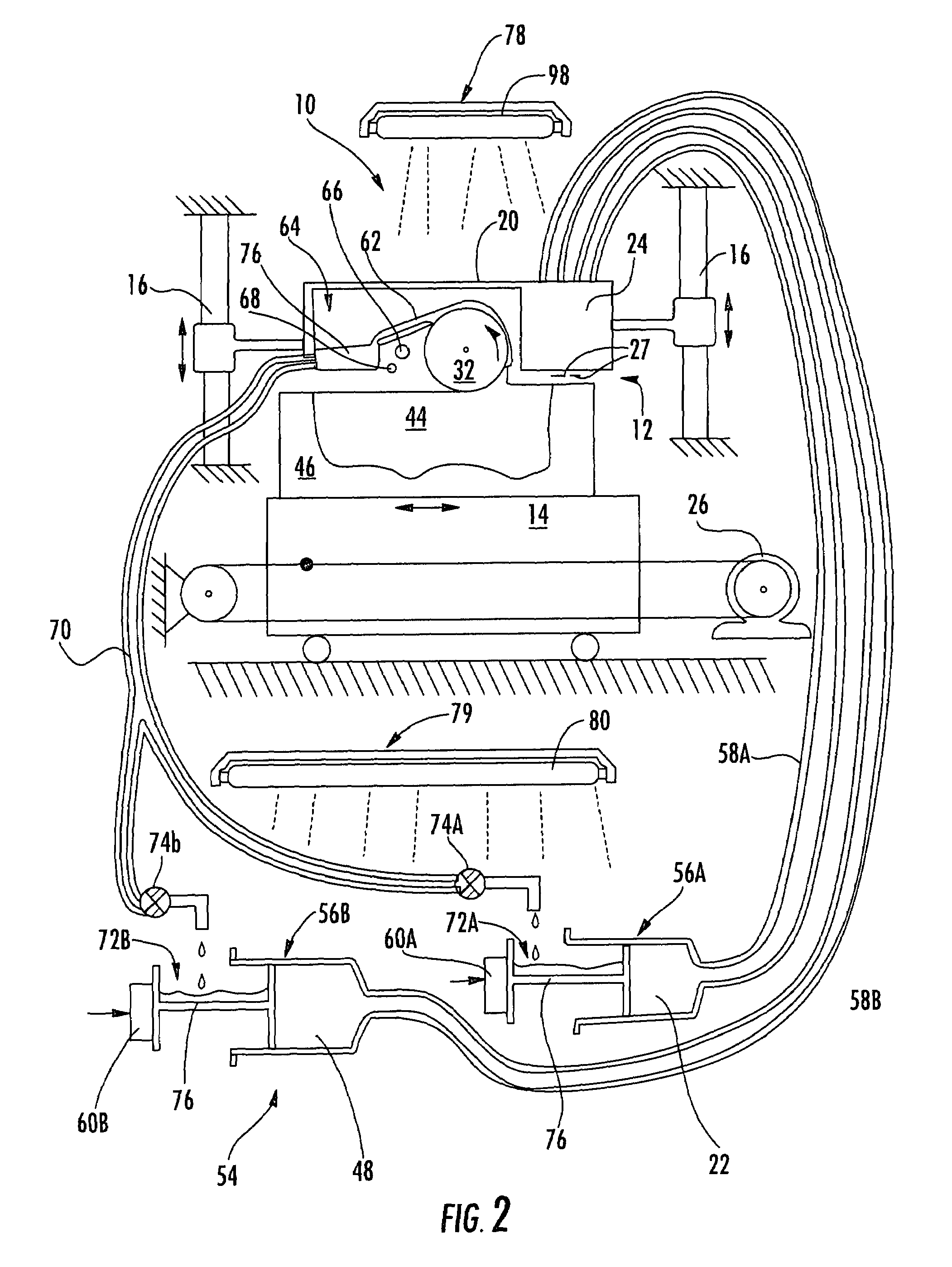

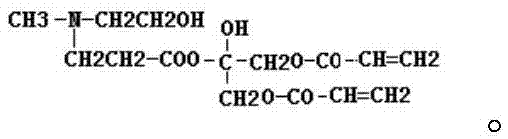

Flash curing in selective deposition modeling

InactiveUS20050253308A1Reduce heatReduce power consumptionAdditive manufacturing apparatusWood working apparatusSelective depositionOxygen

A flash curing system for solid freeform fabrication which generates a plurality of radiation emitting pulses that forms a planar flash. The planar flash initiates curing of a curable material dispensed by a solid freeform fabrication apparatus. The radiation emitting pulses have a high peak power value that releases a sufficient quantity of free radicals from the photoinitiator to initiate curing and overcome the problem of oxygen inhibition. Substantially less power is consumed and less heat generated by the flash curing system compared to conventional continuous emission curing systems.

Owner:3D SYST INC

Flash curing in selective deposition modeling

InactiveUS7270528B2Reduce heatReduce power consumptionAdditive manufacturing apparatusConfectionerySelective depositionPhotoinitiator

A flash curing system for solid freeform fabrication which generates a plurality of radiation emitting pulses that forms a planar flash. The planar flash initiates curing of a curable material dispensed by a solid freeform fabrication apparatus. The radiation emitting pulses have a high peak power value that releases a sufficient quantity of free radicals from the photoinitiator to initiate curing and overcome the problem of oxygen inhibition. Substantially less power is consumed and less heat generated by the flash curing system compared to conventional continuous emission curing systems.

Owner:3D SYST INC

Ultraviolet-thermal double curing coating composition with anti-oxygen inhibition effect and preparation thereof

InactiveCN101412860AEliminate oxygen barrier effectStrong adhesionPolyurea/polyurethane coatingsOligomerChain structure

The invention relates to an ultraviolet photo-thermal double curing paint with oxygen inhibition resistant effect and a manufacturing method thereof. The double paint comprise the following compositions in weight percentage: 3.0 to 57.0 percent of ultraviolet curing oligomer, 7.0 to 40.0 percent of thermal curing polyhydroxy oligomer, 10.0 to 41.0 percent of curing agent, 15.0 to 60.0 percent of active diluted monomer, 0.5 to 9.0 percent of light evocating agent and 0.5 to 5.2 percent of additive. The double curing paint composition is prepared without needing complicated equipment and has application period as long as 7 hours; the main chain structure of the oligomer is provided with a tertiary amine group which removes the influence of oxygen inhibition effect so as to greatly accelerate the curing speed and complete the light curing process in a short period of between 5 and 15 seconds; after the ultraviolet photo-thermal double curing, a thick paint film with thickness of between 60 and 120 mu m can be prepared; and the obtained paint film has good leveling, high hardness, good impact resistance, good toughness and strong adhesive force and is suitable for coating various substrates.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing ceramic body

The invention discloses a method for preparing a ceramic body. The method comprises the following steps: water is used as a solvent, and water-soluble polybutadiene vinyl polymer is added to the solvent to prepare ceramic slurry; the prepared ceramic slurry is injected into a forming mold, and self-gel in-situ solidification is conducted at the temperature of 15 DEG C-40 DEG C in the air; and demolding and drying are conducted after sufficient solidification. Due to the fact that the self-gel in-situ solidification is carried out on the water-soluble polybutadiene vinyl polymer which has the functions of a dispersing agent and a gel reagent at the same time, and is low in toxicity, low in cost and easy to obtain to prepare the ceramic body, preparation cost is greatly reduced and pollution is reduced. Moreover, the method is simple in preparation technology, free of oxygen inhibition, capable of being operated in the air and free of harsh operating conditions and equipment requirements. Besides, the prepared ceramic body is high in intensity, good in toughness, bright and clean in surface, free of exfoliation and suitable for preparation of various oxide ceramics, oxide ceramics, composite ceramics and ceramics with complex shapes, and thus the method for preparing the ceramic body has industrial application prospects.

Owner:PINGXIANG SHUNPENG NEW MATERIALS

Actinic radiation and moisture dual curable composition

A dual curable, liquid adhesive composition capable of polymerization by exposure to actinic radiation and moisture. The composition is particularly useful for liquid adhesives for electronic applications. The composition comprises an alkoxysilane functional polyurethane acrylate oligomer; a free radical polymerizable reactive diluent; a free radical photoinitiator; a catalyst for moisture curing of silane groups; and an optional alkoxysilane functional oligomer having a polyolefin group; an optional acrylate or methacrylate functional polyurethane acrylate oligomer; an optional hydroxyl terminated monoacrylate or monomethacrylate functional reactive diluent; an optional UV-absorber and hindered amine light stabilizer antioxidant; an optional wax capable of reducing oxygen inhibition; an optional 1,3 dicarbonyl compound chelating agent; an optional thixotropic agent; and an optional adhesion promoter. optional adhesion promoter.

Owner:DYMAX

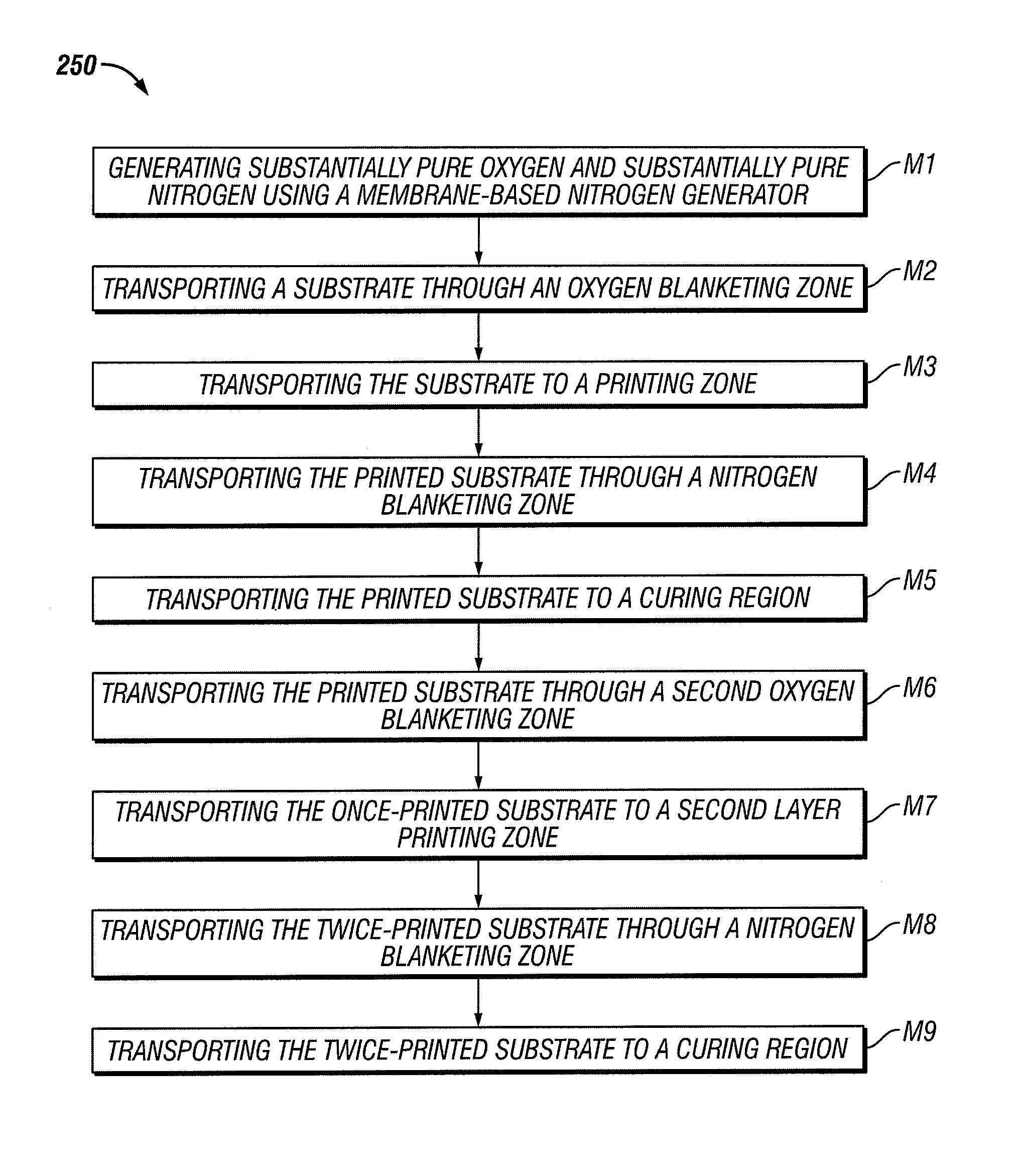

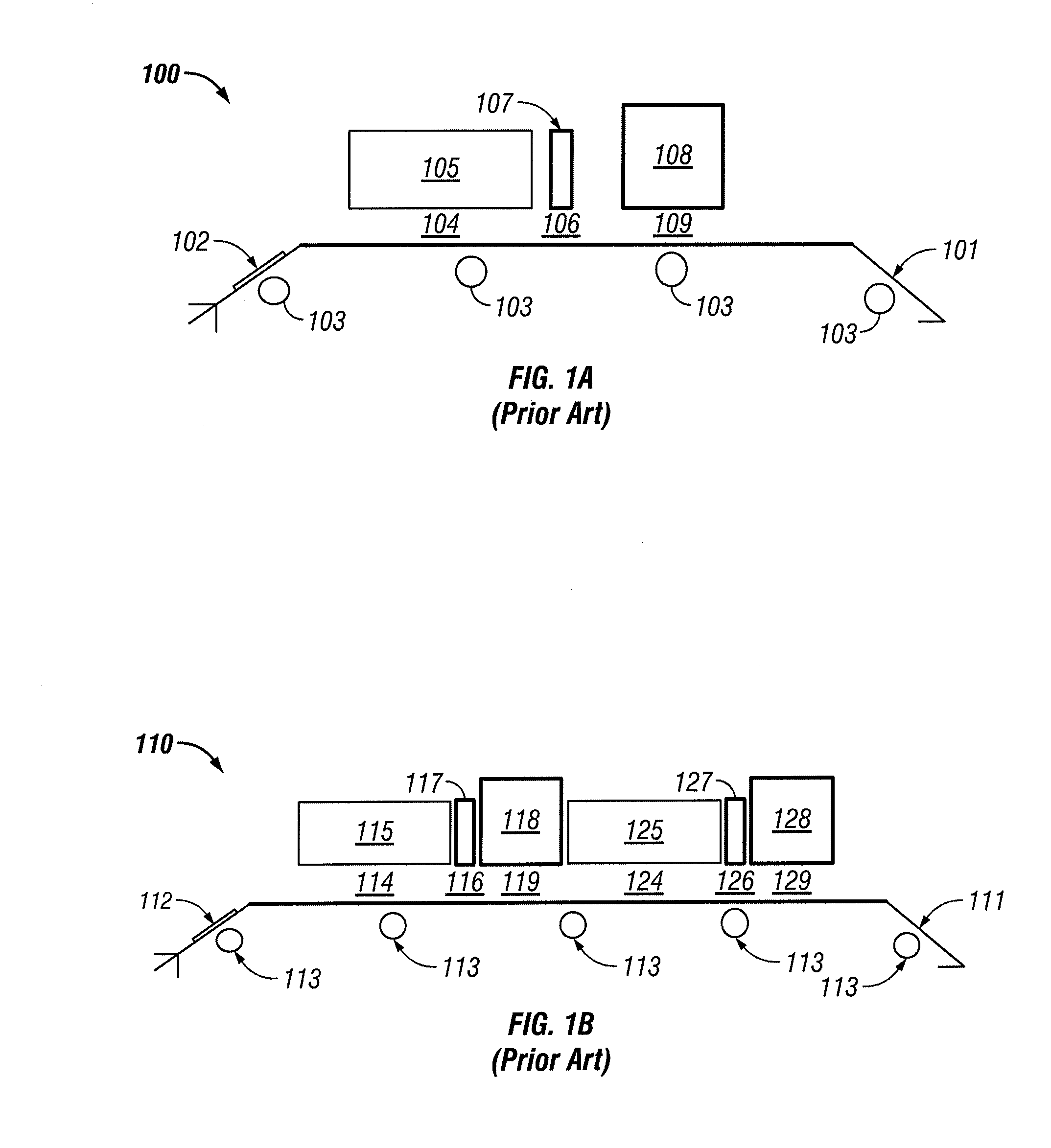

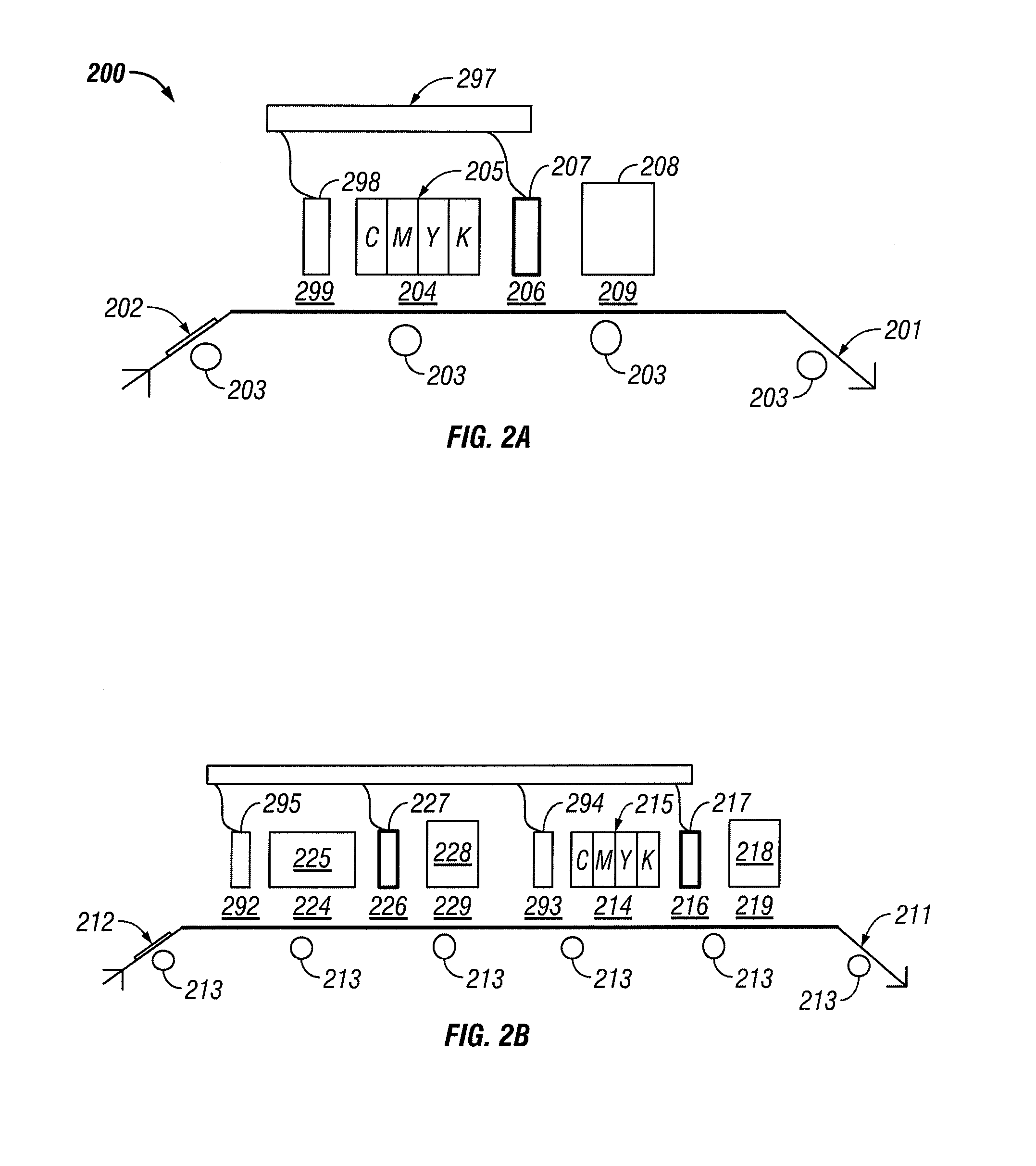

Oxygen Inhibition for Print-Head Reliability

ActiveUS20120154495A1Duplicating/marking methodsOther printing apparatusStray lightOxygen inhibition

Systems and methods of applying a gaseous inhibitor into a printing region to hinder the curing process of ink on the print heads caused by the presence of stray light in the printing environment.

Owner:ELECTRONICS FOR IMAGING INC

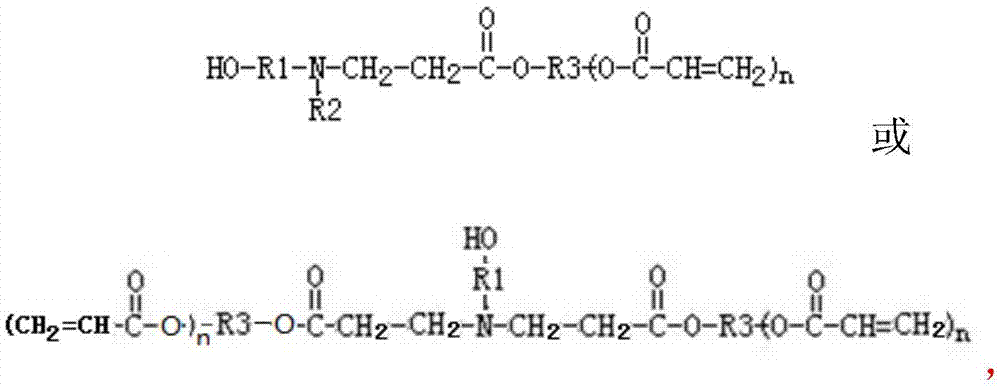

Radiation-cured water-based coating resin, and preparation method thereof

ActiveCN106854432AImprove stabilityEasy to storePolyurea/polyurethane coatingsWater basedWater dispersible

The invention relates to a radiation-cured water-based coating resin, and a preparation method thereof. The radiation-cured water-based coating resin comprises water dispersible polyurethane acrylate and an optionally selected polyfunctional acrylate. In emulsification dispersion of the radiation-cured water-based coating resin, neutralization of the acid hydrophilic functional groups of the water dispersible polyurethane acrylate is realized via taking amino-acrylate as a neutralizer, so that the stability of pH value of viscosity of obtained resin and coating can be maintained at a relatively high storage temperature; the neutralizer takes part in curing reaction in coating curing, so that volatilization and residual of the neutralizer are avoided; the main chain structure of the polyurethane acrylate contains a tertiary amine structure, oxygen inhibition effect in curing process is eliminated because of the existence of the tertiary amine structure in the main structure and the amino-acrylate neutralizer, double bond conversion rate and curing construction speed are increased, and coating performance is improved.

Owner:WANHUA CHEM GRP CO LTD

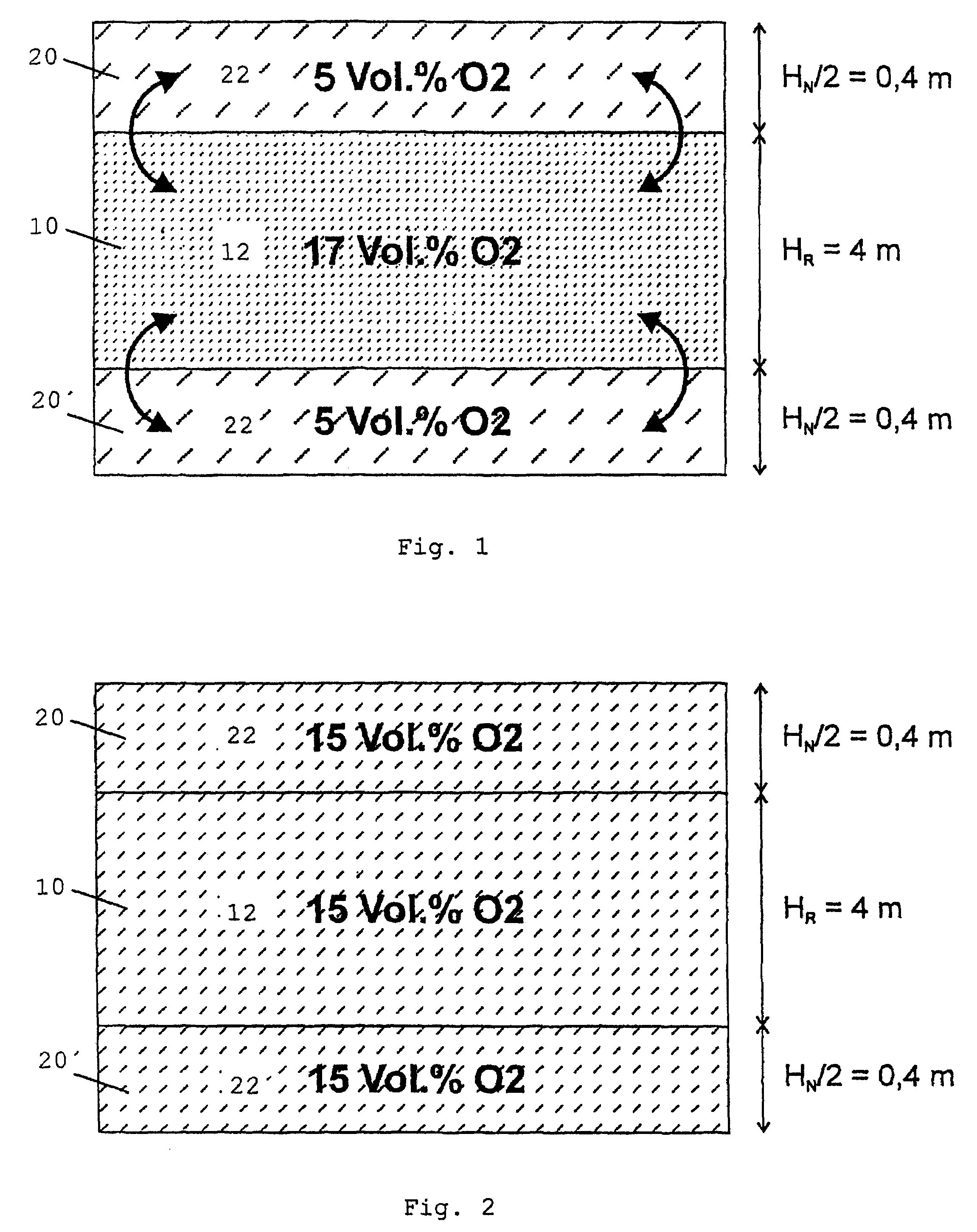

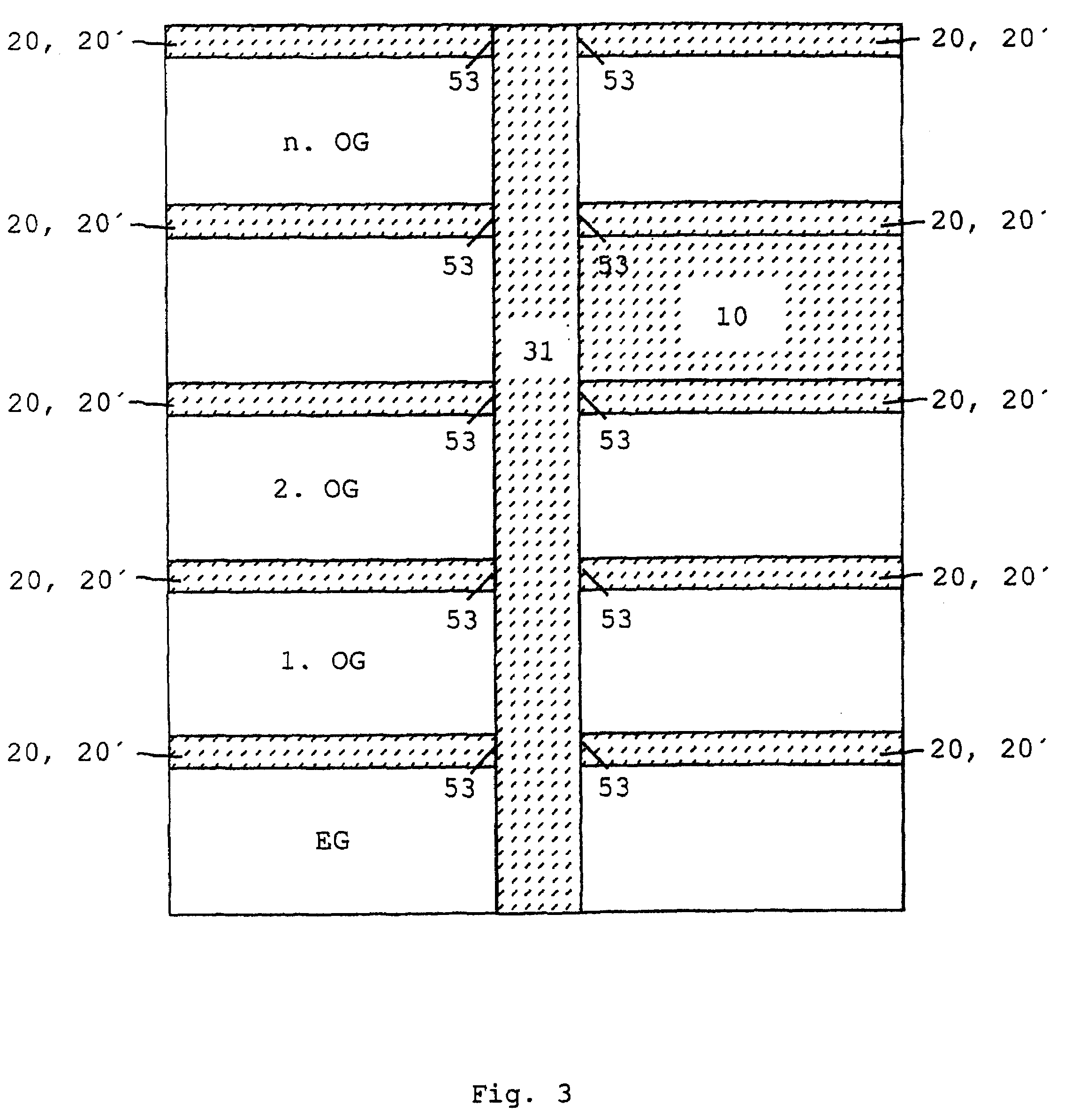

Inert rendering method with a nitrogen buffer

The invention relates to an inert rendering method for preventing and / or extinguishing fires in enclosed spaces, wherein an oxygen-inhibiting gas is introduced into the target area in order to adjust a first basic level of inertion with a reduced oxygen content in comparison with natural conditions, and wherein an oxygen-inhibiting gas is further introduced in a gradual or sudden manner (in the case of a fire) into the target area in order to adjust one or more levels of inertion with a similarly reduced oxygen content. The invention also relates to a device for carrying out the method, comprising an oxygen-measuring device in the target area and a source of an oxygen-inhibiting gas. The aim of the invention is to provide an inert rendering method and device for carrying out said method enabling the storage of extinguishing gas needed to extinguish a fire in a simple, economical manner without having to resort to premises which are normally specially provided therefor.

Owner:WAGNER GROUP

Nanowire-based flexible transparent conducting electrode and preparation method thereof

InactiveCN104882190ALow costSave energyNon-conductive material with dispersed conductive materialCable/conductor manufactureNanowireSurface-active agents

The invention discloses a nanowire-based flexible transparent conducting electrode and a preparation method thereof. The preparation method includes dispersing nanowires in a mixed liquid composed of monomer, photo-initiator and a surface active agent uniformly and then disposing the mixed liquid in a mold and placing the mold under a light source. After being subjected to light, the mixed liquid undergoes polymerization reaction which induces the gathering of the nanowires and then the flexible transparent electrode is formed through solidification. According to the invention, by utilizing a principle that in situ photopolymerization induces the gathering of the nanowires, the flexible transparent electrode can be formed quickly and conveniently without a solvent, an oxygen inhibition preventing agent and inert gas shielding at a low production cost. Therefore, the method facilitates the construction of a complicated electrode structure and can be applied to flexible transparent conducting electrode manufacturing field widely.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Anti-ultraviolet transparent hard coating film for in-mold decoration (IMD)

ActiveCN101955699AGuaranteed normal formationMeet the molding tensile performance requirementsSynthetic resin layered productsCoatingsPolyesterUltraviolet

The invention relates to an anti-ultraviolet transparent hard coating film for in-mold decoration (IMD), which is formed by coating a transparent hard coating on a transparent substrate. The transparent hard coating comprises the following components in part by weight: 20 to 40 parts of polyester acrylate oligomer, 10 to 30 parts of organic-inorganic hybrid oligomer, 0.5 to 5 parts of ultraviolet absorption precursor, 1.0 to 10 parts of hydrogen proton donor, 0.5 to 7 parts of photoinitiator, 0.5 to 7 parts of active amine, 0.05 to 2 parts of leveling agent and 30 to 70 parts of solvent, wherein the thickness of the hard coating is 2 to 6mu m. The anti-ultraviolet transparent hard coating film solves the problems of ageing, yellowing, embrittlement and the like of a product irradiated by ultraviolet rays, solves the problems of oxygen inhibition and hydrogen proton consumption and ensures the formation of an ultraviolet absorbent; and the film meets the requirements of the IMD on forming and stretching by combining raw materials and controlling the thickness of the hard coating, and the stretching and forming height of the film can be 7 to 8mm at most but the film cannot be embrittled.

Owner:CHINA LUCKY FILM CORP

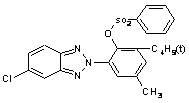

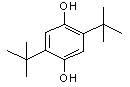

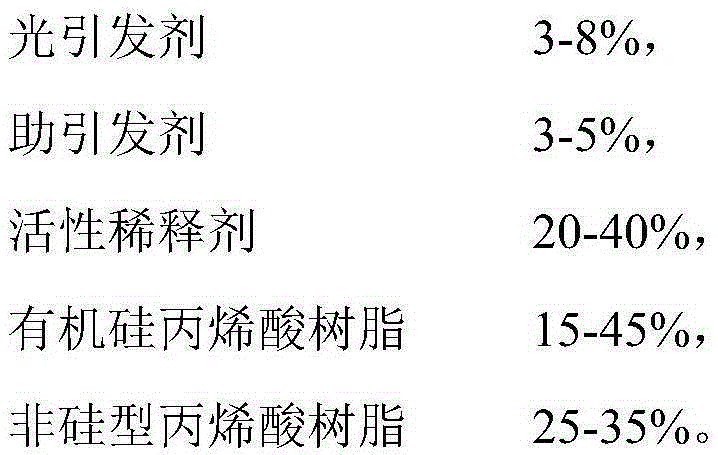

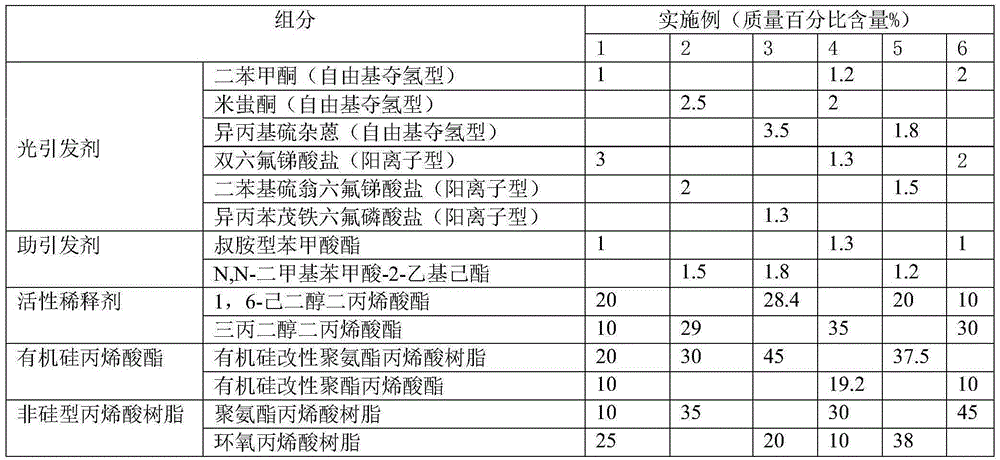

Efficient anti-sticking UV release paint applied to pressure-sensitive adhesive as well as preparation and application of efficient anti-sticking UV release paint

ActiveCN105315881ANo releaseOvercome polymerization inhibitionPolyurea/polyurethane coatingsEpoxy resin coatingsSolubilityAcrylic resin

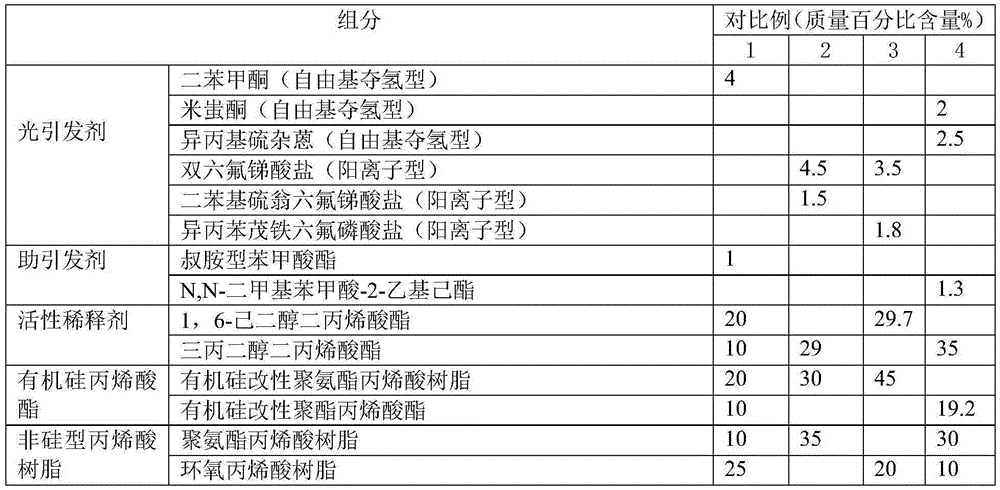

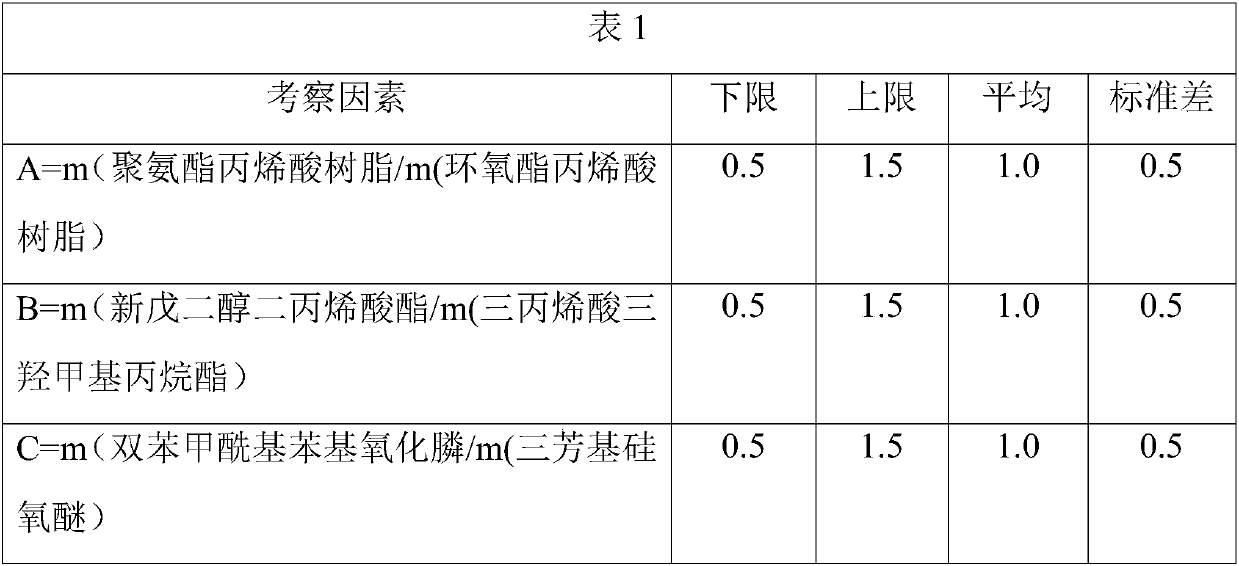

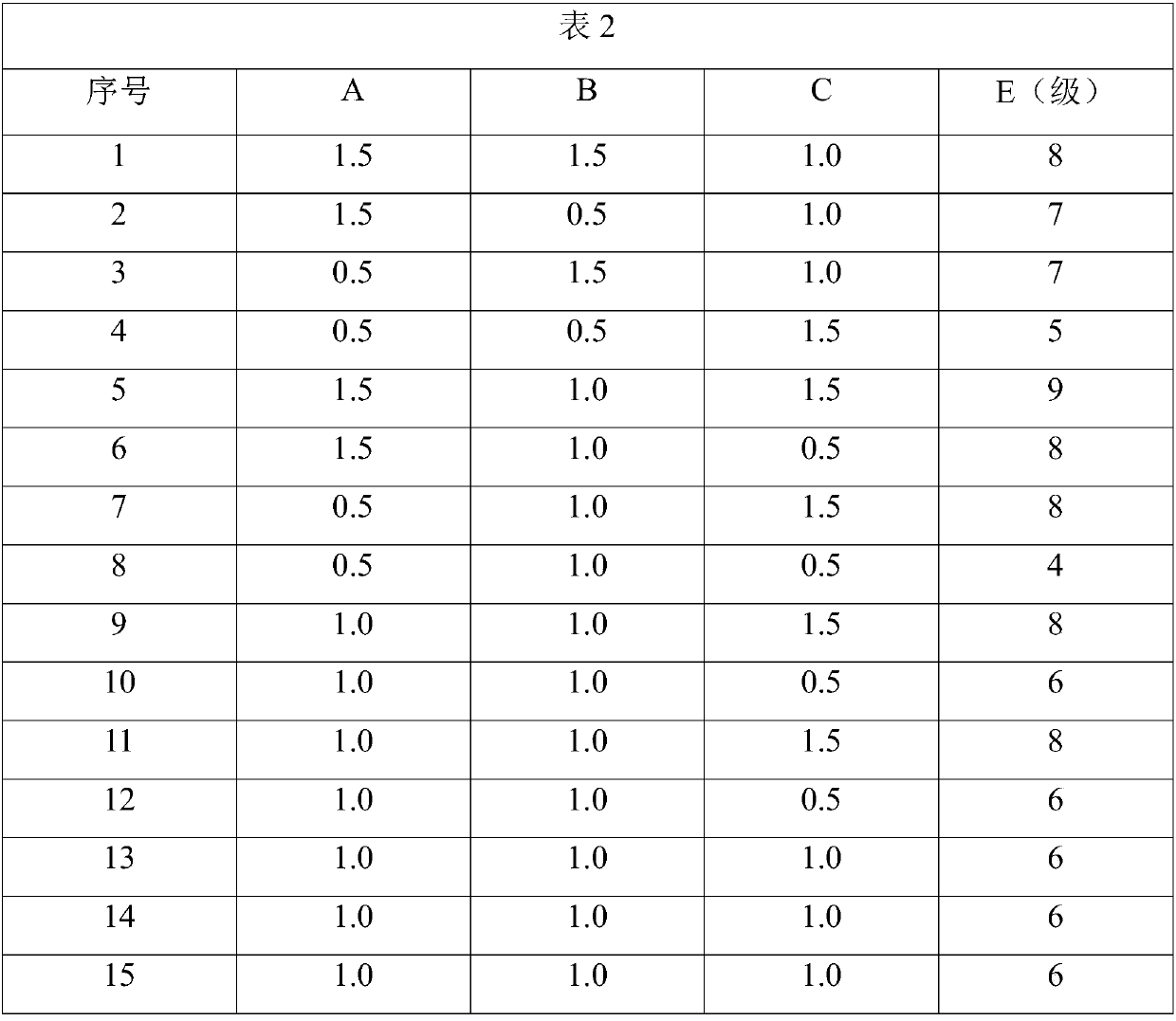

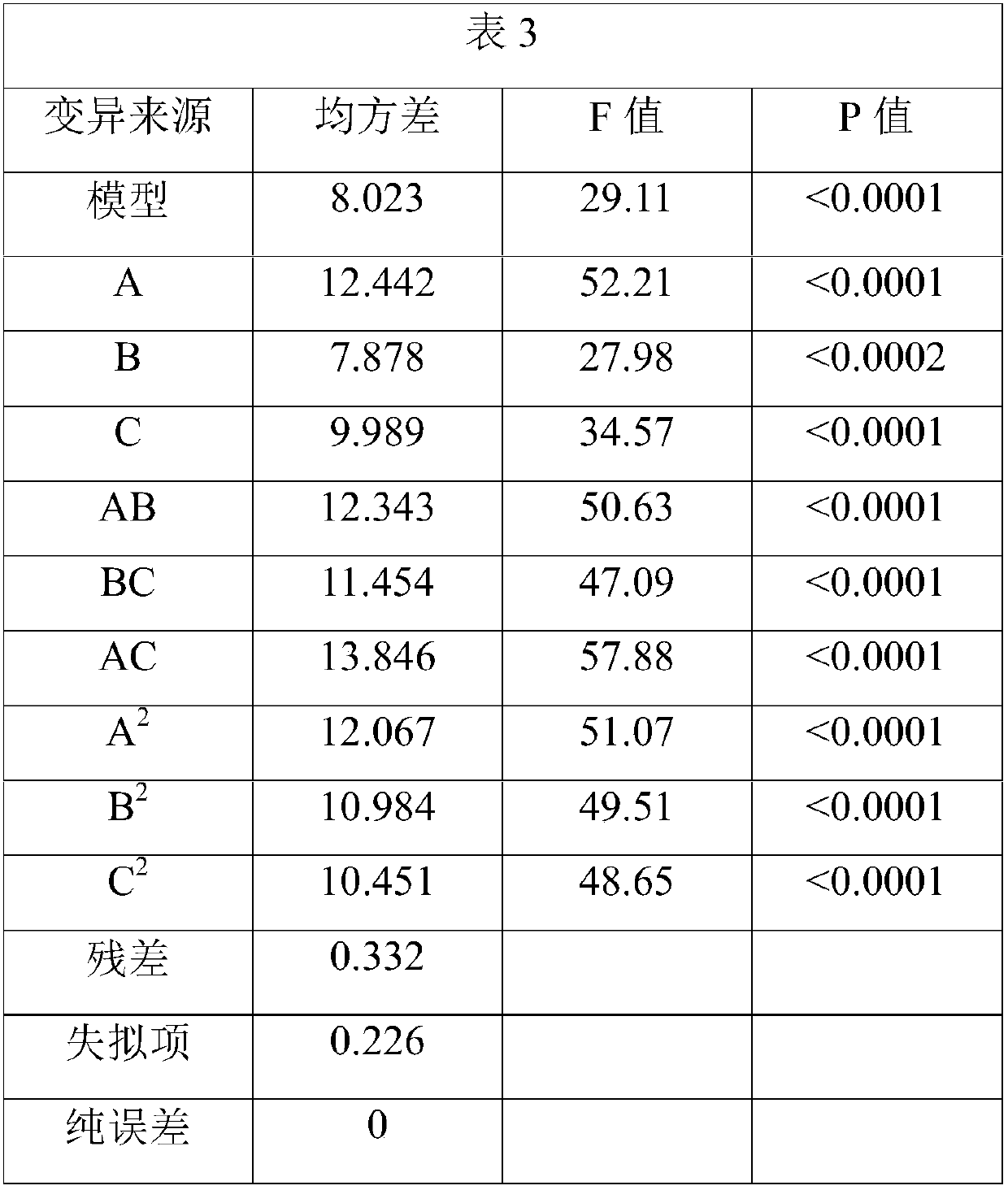

The invention provides an efficient anti-sticking UV release paint applied to a pressure-sensitive adhesive as well as preparation and application of the efficient anti-sticking UV release paint. The paint comprises the following ingredients in percentage by weight: 3-8% of a photoinitiator, 3-5% of an auxiliary initiator, 20-40% of an active diluent, 15-45% of organic silicon-acrylic resin and 25-45% of non-silicon acrylic resin. The system of free radicals and the cationic composite initiator is adopted, a sensitization effect realized through the synergistic effect of the free radicals and the cationic composite initiator better solves the problems of oxygen inhibition and slow curing caused by the single initiator, meanwhile, the photo-curing speed is high, the solubility is good, the absorption wavelength reaches 390 nm and the paint is an efficient, energy-saving and environment-friendly photo-cured release paint.

Owner:SHANGHAI CHENGYING NEW MATERIALS

Environment-friendly UV gloss oil for food packaging and printing

InactiveCN107652873ALow VOC residualLess volatile organicPolyurea/polyurethane coatingsEpoxy resin coatingsIsophoroneHardness

The invention relates to the field of UV gloss oil, in particular to environment-friendly UV gloss oil for food packaging and printing. The environment-friendly UV gloss oil comprises, by weight, 8-45% of prepolymer, 8-65% of active monomer, 1-15% photoinitiator, 0.05-2% of defoamer, 0.05-2% of flatting agent, 5-10% of thickener, 5-35% of solvent and 5-10% of isophorone. Free radical photoinitiator and cationic photoinitiator are added at the same time; through oxygen inhibition resisting and post-curing effects of cations, photocuring effect is enhanced, migration of the photoinitiators is reduced, and the environment-friendly UV gloss oil has the advantages of high solution resistance, good glossiness, high hardness and environment friendliness.

Owner:DONGGUAN POLYTECHNIC

Macromolecule photoinitiator for gradient polymerization as well as synthesis method and application thereof

The invention discloses a macromolecule photoinitiator for gradient polymerization as well as performance research thereof, which is characterized in that organosilicon-polymer is adopted to react with reactive micromolecule photoinitiator to prepare organosilicon macromolecule photoinitiator; the photoinitiator is applied to gradient polymerization to obtain a polymer with the molecular weight varying in a gradient way by a primary polymerization; and the gradient variation along vertical direction is uniform and has no obvious component interface. In addition, the initiator not only overcomes the defects of easy yellowing, evaporation and migration, great toxicity, poor thermal resistance and the like, but also is endowed with capability of spontaneous ascending by characteristics of organosilicon surface energy and low surface tensile force, thus effectively avoiding oxygen inhibition.

Owner:BEIJING UNIV OF CHEM TECH

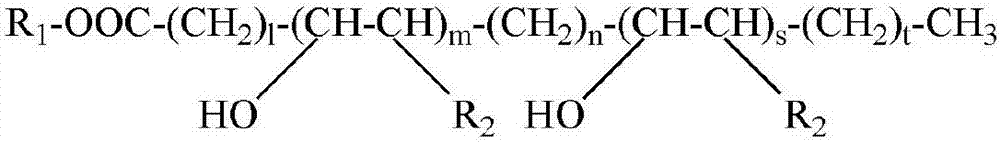

Multifunctional UV cured polyurethane vegetable oleate prepolymer, and preparation method and application thereof

ActiveCN107189032AReduce usageImprove mechanical propertiesPolyureas/polyurethane adhesivesInksVegetable oilAlcohol

The invention discloses a multifunctional UV cured polyurethane vegetable oleate prepolymer, and a preparation method and application thereof. According to the method, trifunctional UV cured polyurethane prepolymer is prepared from trifunctional castor oil, and a photosensitive monomer adopted by prepared UV cured polyurethane adopts vegetable oleate alcohol to replace traditional acrylic ester, so that the prepared UV polyurethane initiates polymerization and film formation in a UV light irradiation condition, in an aerobic condition without a photoinitiator or a cationic photoinitiator and radical photoinitiator compound initiating condition, and effectively overcomes the problem of oxygen inhibition. As vegetable oil is taken as a raw material, the prepared prepolymer has excellent biodegradability. The multifunctional UV cured polyurethane vegetable oleate prepolymer can be widely applied to various fields, such as UV cured paint, UV cured ink and UV cured adhesives.

Owner:SOUTH CHINA AGRI UNIV

Method for preventing oxygen inhibition in injection moulding process

The invention belongs to the technical field of the preparation of the ceramic material and relates to a method for preventing oxygen inhibition in the gel injection moulding process. The invention provides a method which can be operated under air condition and prevent the oxygen inhibition of slurry in the gel injection moulding process. In the method in the invention, a layer of alcohol type organic solvent which can not affect the gelation of slurry is covered on the surface of the part of slurry contacting with the air before the gelation so as to separate slurry and air; and the organic solvent on the surface is poured away after the gelation of slurry, thus complete gel can be obtained without any surface treatment. The technology comprises the following steps: proportioning, mixingthrough ball milling, defoaming, adding catalyst and initiator, pouring, covering a layer of alcohol type antioxidation polymerization inhibitor on the surface of slurry, performing gelation, pouringaway the antioxidation polymerization inhibitor on the surface, demoulding and drying. The method in the invention is convenient to operate, is simple and practical, and can be used to effectively solve the oxygen inhibition problem in the gel injection moulding process of ceramic slurry and obtain a ceramic blank with bright surface and fully consistent internal structure.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

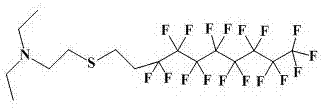

LED-UV phototherapy glue scrubbing-free sealing layer glue and preparation method thereof

ActiveCN105878054AImprove curing efficiencyAvoid oxygen inhibitionCosmetic preparationsToilet preparationsOligomerReaction rate

The invention discloses LED-UV phototherapy glue scrubbing-free sealing layer glue. The LED-UV phototherapy glue scrubbing-free sealing layer glue is prepared from, by weight concentration, 7-90% of oligomer, 7-90% of active monomers, 1-10% of photoinitiator, 1-10% of a mercaptan compound and 0.1-1% of stabilizer. The invention further discloses a preparation method of the LED-UV phototherapy glue scrubbing-free sealing layer glue. The scrubbing-free sealing layer glue can basically overcome the oxygen inhibition phenomenon, has a very high curing reaction rate and can be completely cured under an LED-UV weak light source, the situations that floating glue exists and the surface is not dry do not exist, and the curing time is shortened to about 60 s from general 120 s. Therefore, in the nail beautifying process, the scrubbing process is omitted, the nail beautifying process becomes simple, and manpower, material resources and time cost are saved.

Owner:广州市尤特新材料有限公司

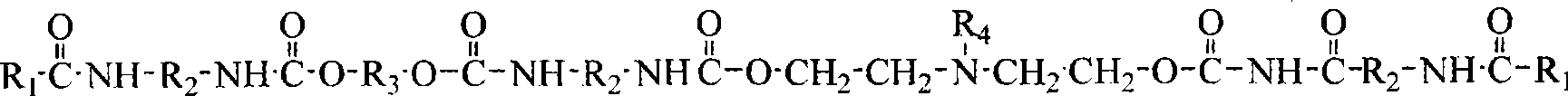

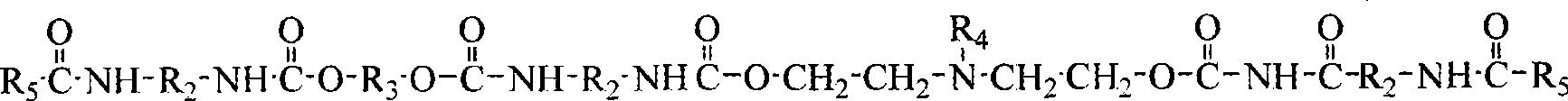

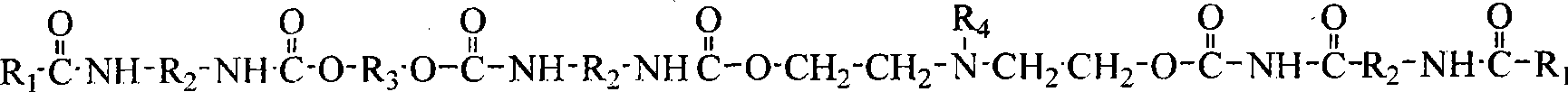

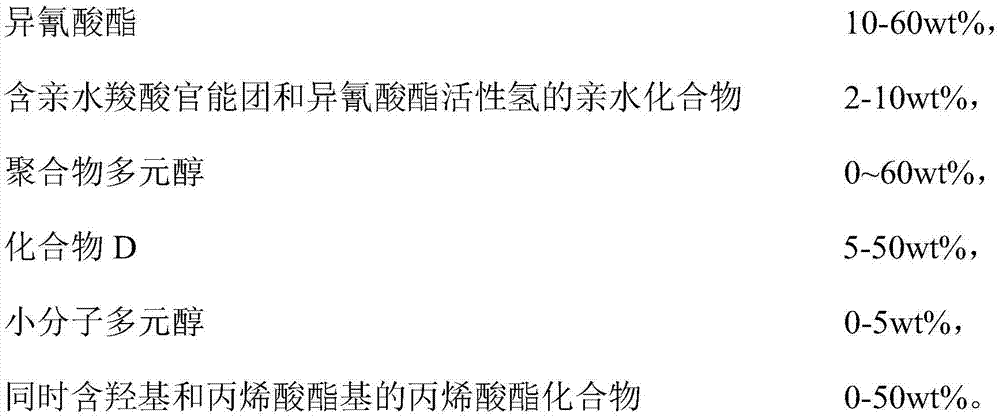

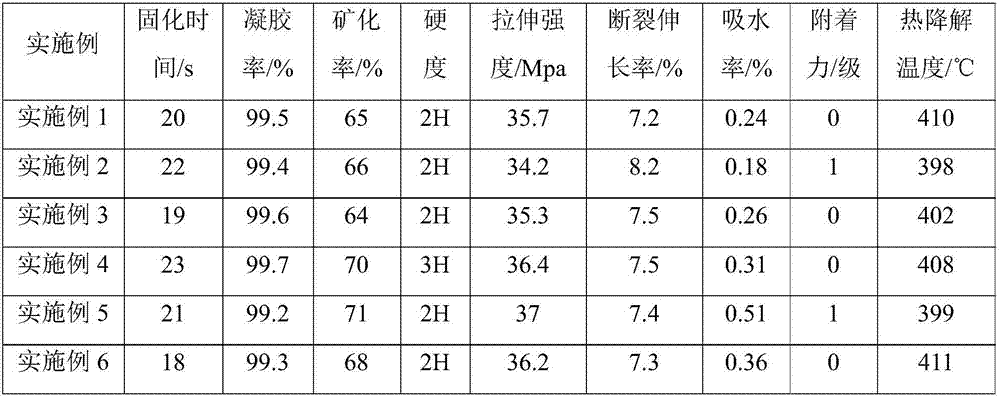

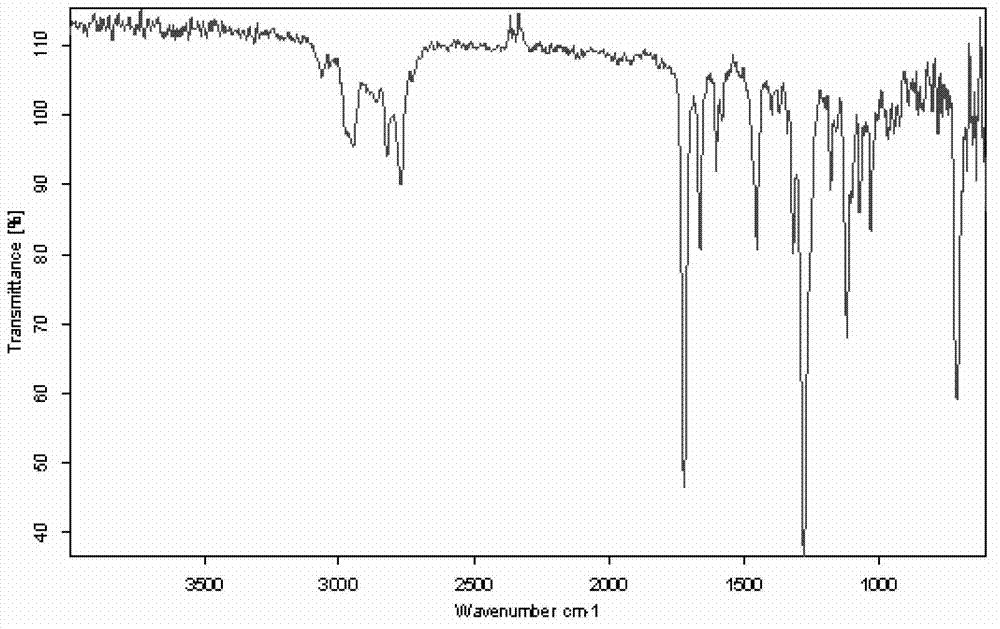

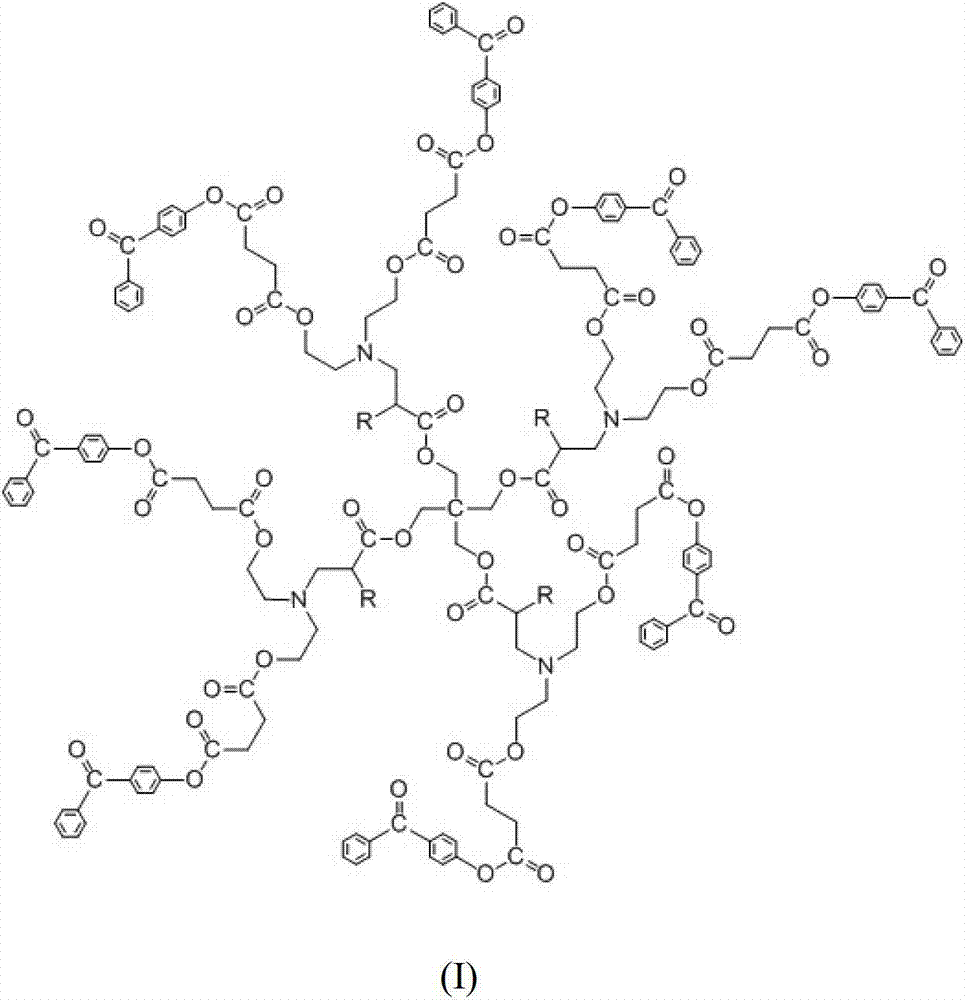

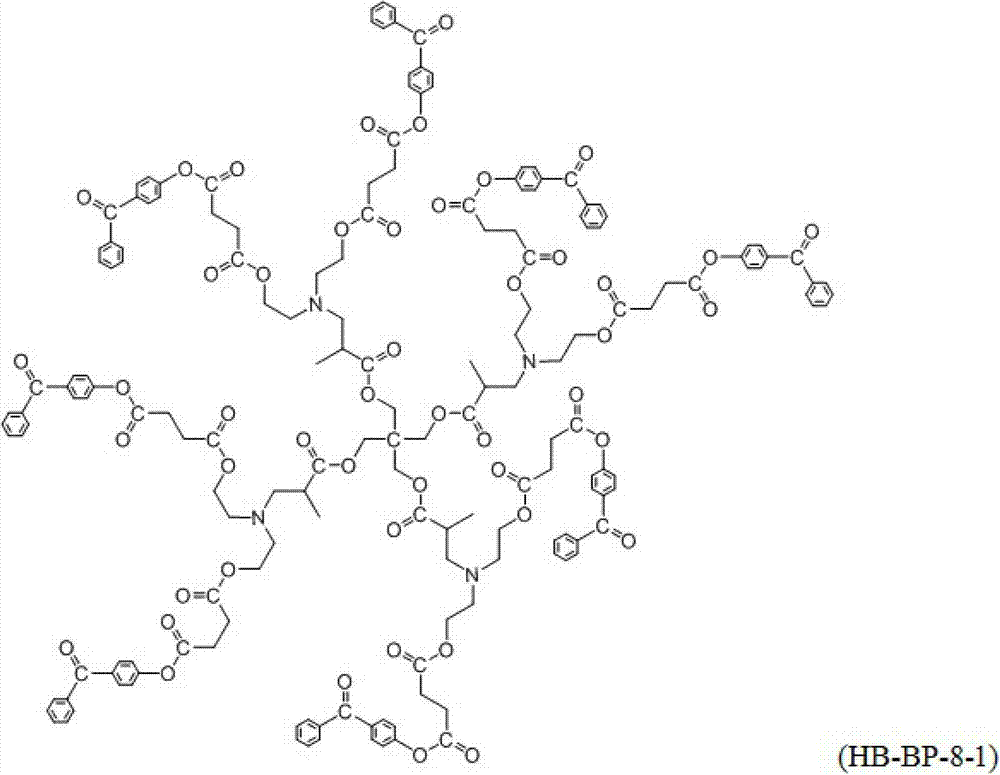

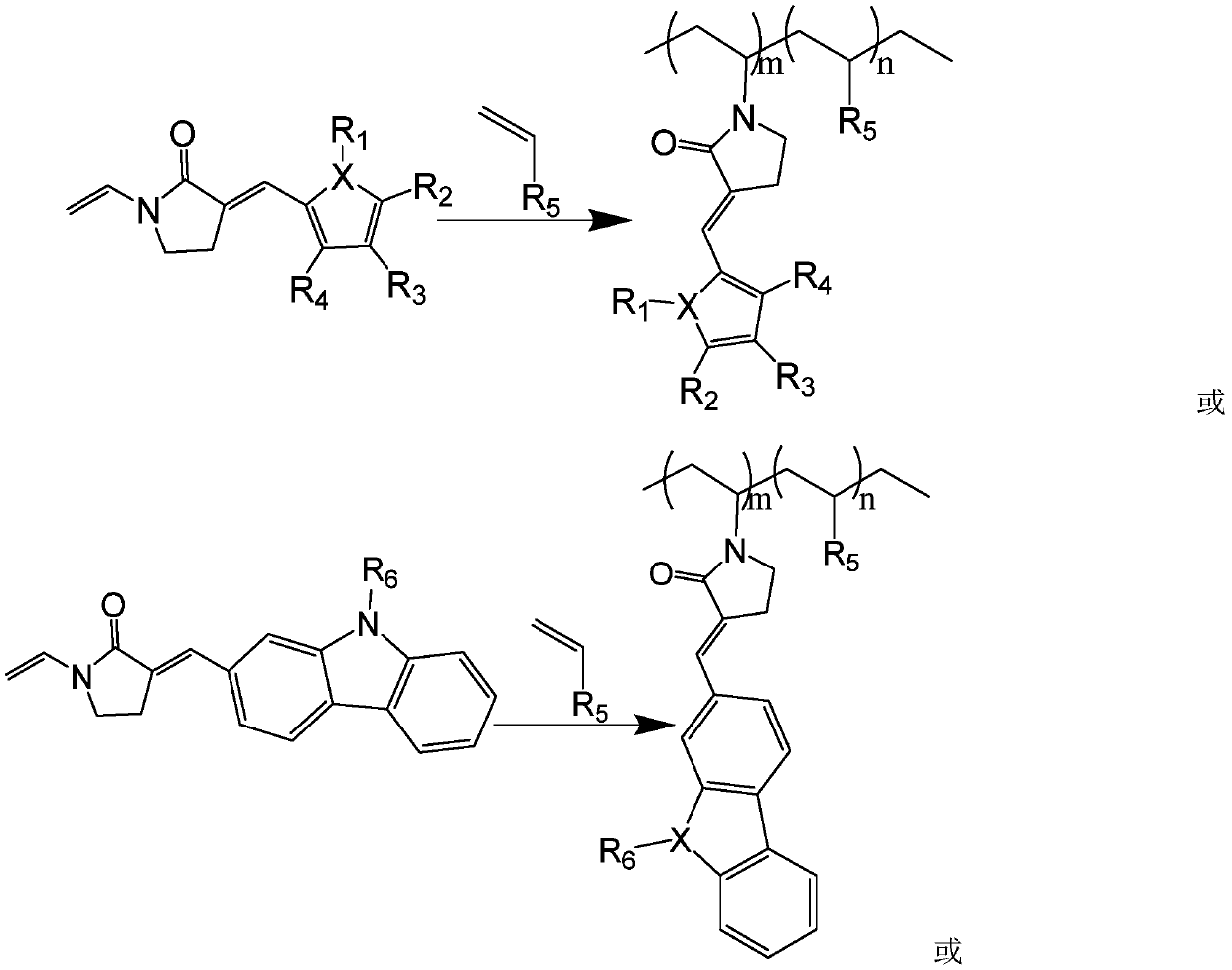

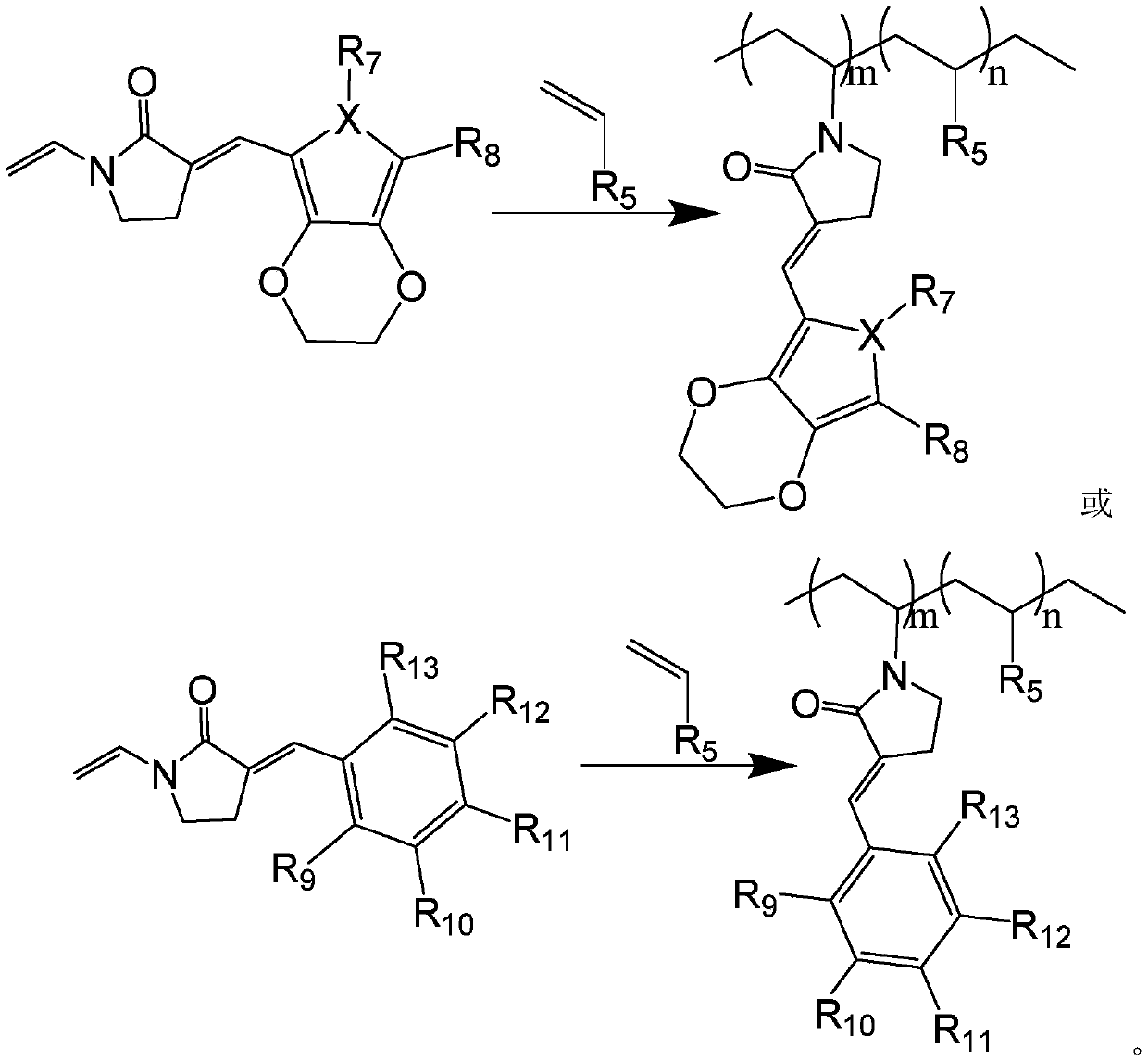

Highly branched macro-molecule photoinitiator and preparation method thereof

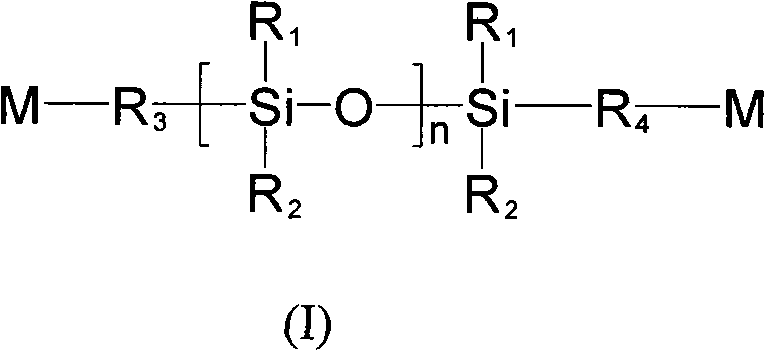

The invention discloses a highly branched macro-molecule photoinitiator of formula (I). The novel photoinitiator has eight branched chains having exactly same structure and the end group of each chain contains a photoactive group. Highly-branched macro-molecule numerous photoactive groups allow the photoinitiator disclosed herein to have high initiation efficiency and simultaneously let the photoinitiator disclosed herein can effectively overcome the disadvantages of bad intermiscibility, easy migration, strong smell, oxygen inhibition, etc. of micro-molecule photoinitiators. According to the invention, a highly-branched compound can be effectively constructed by the reaction of polyhydric alcohols and trifunctional monomers, and then the photoinitiator with excellent comprehensive performance is prepared by introducing the photoactive groups into the end groups of the branched chains; based on the excellent performances of the highly branched macro-molecule photoinitiators, the highly branched macro-molecule photoinitiator disclosed herein will be the main research and development direction of future photoinitiators.

Owner:CHANGSHANG NEWSUN CHEM IND

UV curable epoxy system organic packaging composition, preparation method and use method thereof

The invention discloses a UV curable epoxy system organic packaging composition, a preparation method and a use method thereof, wherein the organic packaging composition comprises, by weight, 10-90% of silicon-based epoxy, 10-90% of non-silicon-based epoxy, 5-40% of a diluent, 0.5-10% of a photoinitiator, and 0.5-10% of a photosensitizer, wherein the non-silicon-based epoxy is a one or a mixture comprising two selected from bifunctional epoxy and polyfunctional epoxy, and the diluent is aromatic or aliphatic non-silicon-based monoepoxy. According to the present invention, the UV curable epoxysystem organic packaging composition can achieve the organic packaging film with advantages of high light transmittance, high curing rate, high adhesion, small volume yield, no oxygen inhibition and dark reaction.

Owner:XIAN SMART MATERIALS CO LTD

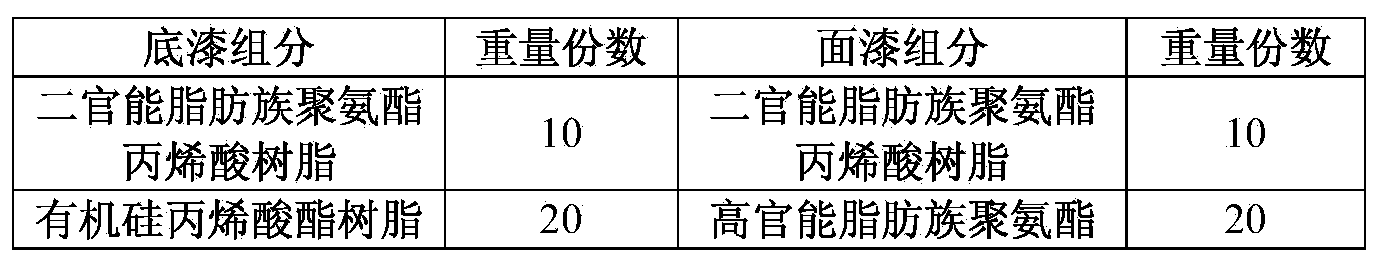

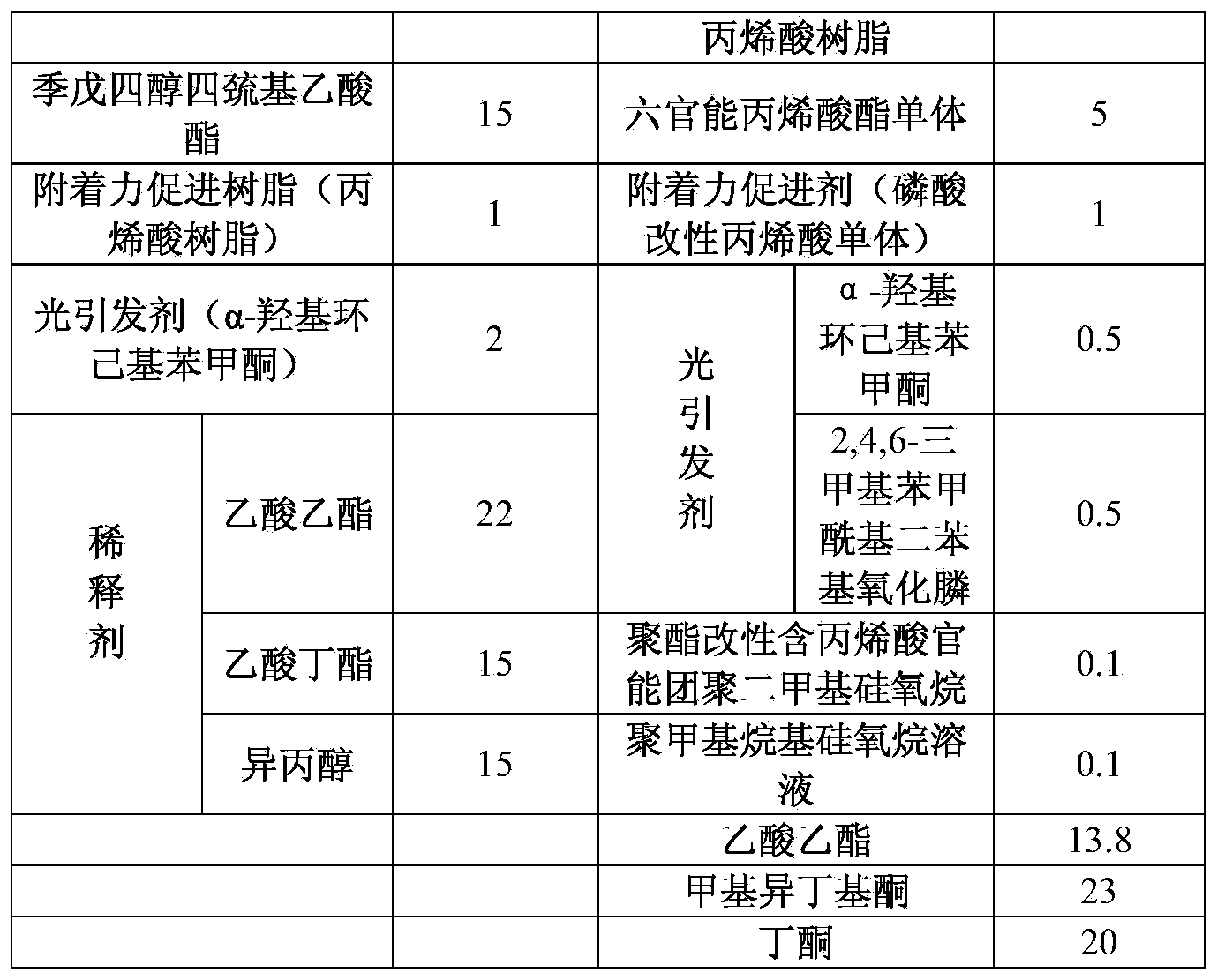

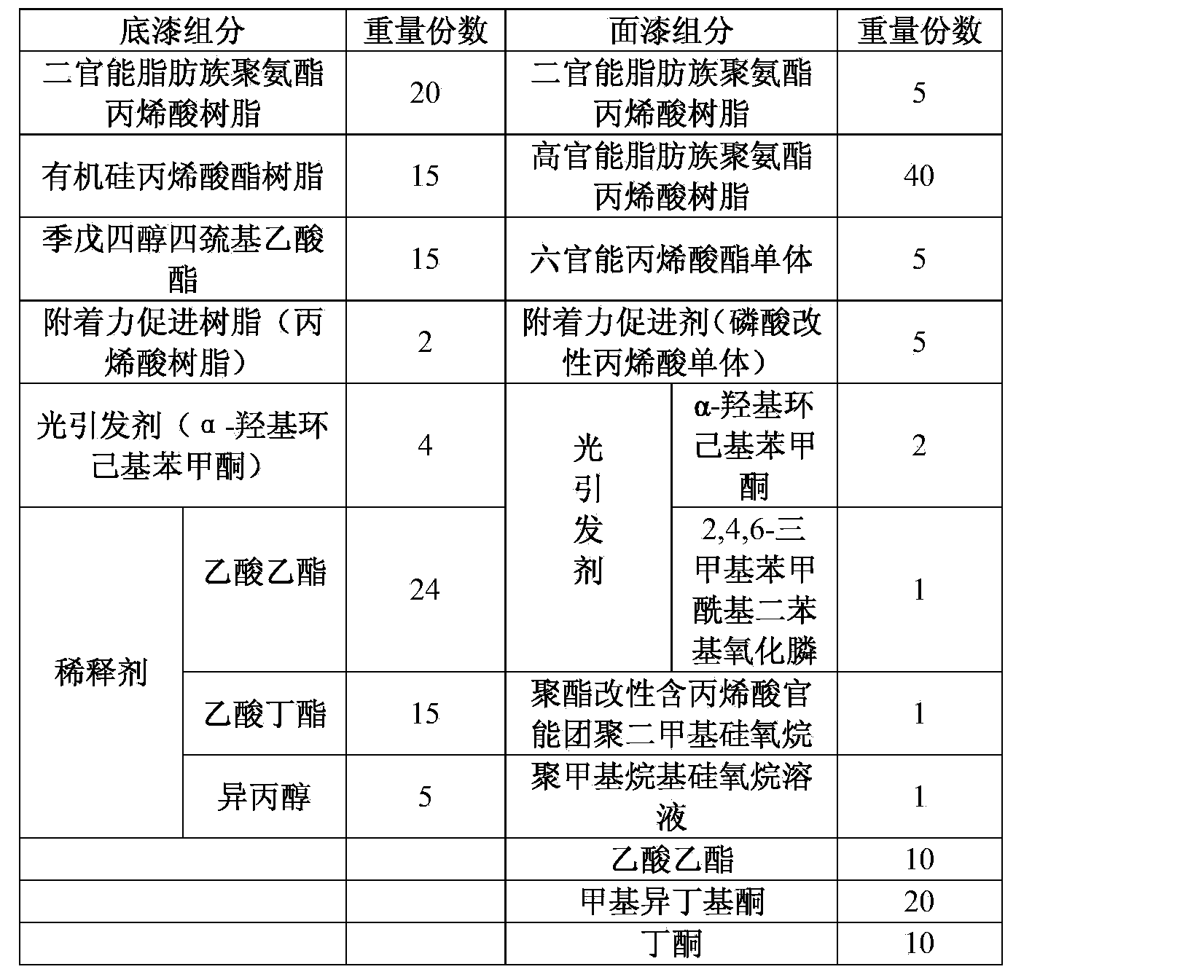

Ultraviolet-curing primer for vacuum coating and ultraviolet-curing paint for vacuum coating

ActiveCN104031546AAvoid the negative effects of oxygen inhibitionFully curedPolyurea/polyurethane coatingsPentaerythritolAcrylic resin

The invention provides an ultraviolet-curing primer for vacuum coating and an ultraviolet-curing paint for vacuum coating. The primer comprises the following components in parts by weight: 10-20 parts of a bifunctional aliphatic polyurethane acrylic resin, 15-25 parts of an organic silicone acrylate resin, 10-15 parts of pentaerythritol tetrakis(2-mercaptoacetate), 1-2 parts of an adhesion promoting resin, 2-5 parts of a photoinitiator, and 25-60 parts of a diluting agent. According to the ultraviolet-curing primer for vacuum coating provided by the invention, Due to the addition of the pentaerythritol tetrakis(2-mercaptoacetate), a primer layer with a thickness of 0.5-3 microns is just formed by the ultraviolet-curing primer on the surface of a material, and an oxygen inhibition negative effect of the primer in the process of ultraviolet-curing also can be avoided, thereby guaranteeing that the surface of a primer coating is fully cured, and a good working plane is provided for subsequent vacuum coating.

Owner:HUNAN SOKAN NEW MATERIAL

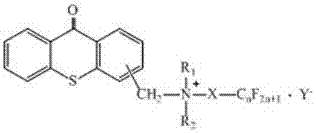

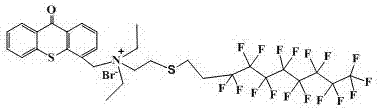

Photoinitiator and preparation method thereof

ActiveCN107400112AHas photolytic propertiesStrong absorption capacityOrganic chemistryHigh concentrationCarbon chain

The invention relates to fields of photosensitive materials and photocuring and particularly relates to a photoinitiator and a preparation method thereof. The photoinitiator can absorb long waves based on a thioxanthone mother nucleus and can strongly absorb a 395nm UV LED light source. By introducing fluorine carbon chain so as to endow the photoinitiator with a low surface tension, the photoinitiator can float to the surface of a coating layer / ink layer in a formula system, namely that the photoinitiator can be enriched in the surface; and after light is absorbed, high-concentration free radicals are generated on the surface so as to confront against surface oxygen inhibition. The novel photoinitiator contains a quaternary ammonium group and is connected with a thioxanthone aromatic ring through a methylene, so that the structure has a photosensitive cracking property, is capable of generating tertiary amine with an oxygen inhibition prevention function through photolysis and can be simultaneously used as an initiation aid of thioxanthone for generating free radicals. All behaviors are generated on the surface of the coating layer / ink layer, so that the photoinitiator has the characteristic of being capable of efficiently confronting against surface oxygen inhibition.

Owner:SUN YAT SEN UNIV

Catalyst capable of removing N2O, NO and NO2 simultaneously and preparation method

InactiveCN106423184AWide temperature windowImprove denitrification effectNitrous oxide captureHeterogenous catalyst chemical elementsWater vaporOxygen inhibition

The invention relates to the field of industrial catalysis and environmental governance, in particular to a catalyst capable of removing N2O, NO and NO2 simultaneously and a preparation method of the catalyst. After tail gas containing N2O, NO and NO2 is subjected to the action of the catalyst, on one hand, N2O gas is decomposed directly, on the other hand, NO gas and NO2 gas are subjected to an SCR (selective catalytic reduction) denitration reaction, and simultaneous removal of N2O, NO and NO2 is realized. The plate catalyst capable of removing N2O, NO and NO2 simultaneously is prepared from V2O5 and a Co-based composite metal oxide as active components, TiO2 as a supporter and one or two of WO3 and MoO3 as a metal additive through mixing, rolling coating, pleating, drying and roasting. The N2O decomposing efficiency of the catalyst in the temperature range of 300-450 DEG C can reach 80% or higher, the NO removal rate and the NO2 removal rate can reach 85% or higher, and the catalyst has excellent oxygen inhibition resistance and water vapor poisoning resistance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

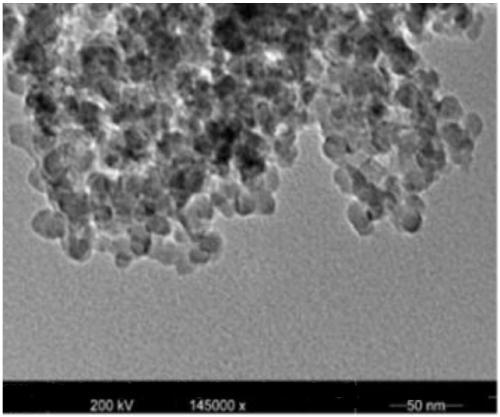

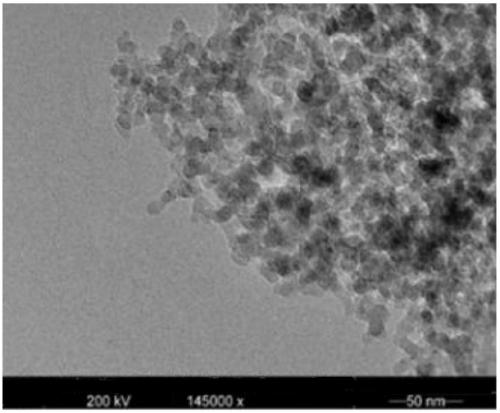

Preparation method of fluorine-containing nano-SiO2 microspheres with photo-initiating activity and nano-SiO2

ActiveCN109337410AOxygen and polymerization resistanceHydrophobicEpoxy resin coatingsPigment treatment with non-polymer organic compoundsMicrosphereHigh surface

The invention discloses a preparation method of fluorine-containing nano-SiO2 microspheres with photo-initiating activity and nano-SiO2, relates to the field of high polymer material synthesis and aims to solve the problems that existing nano-SiO2 is prone to oxygen inhibition when applied to a photo-cured coating by direct filling and surface performance of the photo-cured coating is required tobe improved. The preparation method comprises following steps: fluorocarbon modified nano-SiO2 with active sites is prepared; acrylic ester with an initiator structure is added to a prepared fluorocarbon modified nano-SiO2 solution, and the silica surface is grafted with a photoinitiator structure by a Michael addition reaction. The preparation method has beneficial effects as follows: the preparation method is simple, stability of the prepared nano-SiO2 microspheres can be improved, and when the nano-SiO2 microspheres are added to a formula of the photo-cured coating, a coating with high surface hardness, scratch resistance, good glossiness, good weather fastness and oxygen inhibition resistance can be obtained and the coating surface can further has hydrophobic performance.

Owner:安庆北化大科技园有限公司

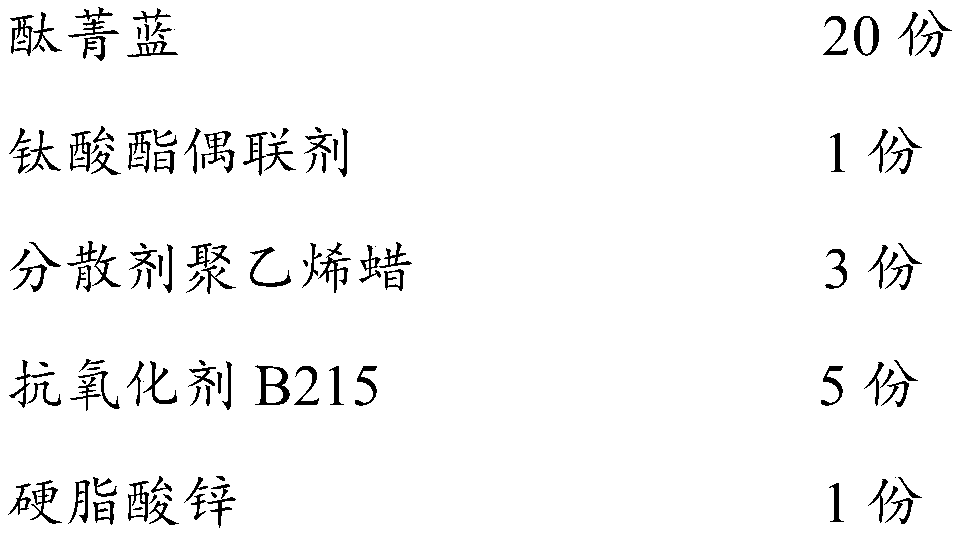

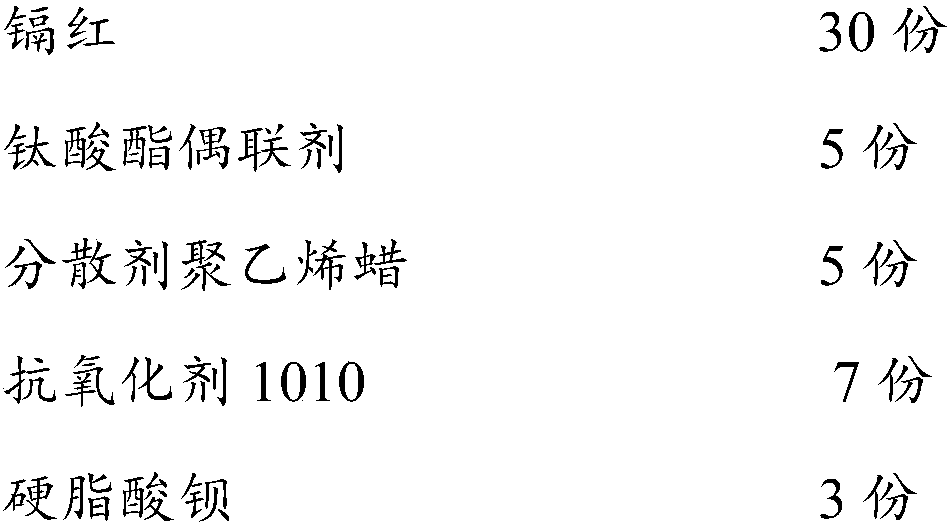

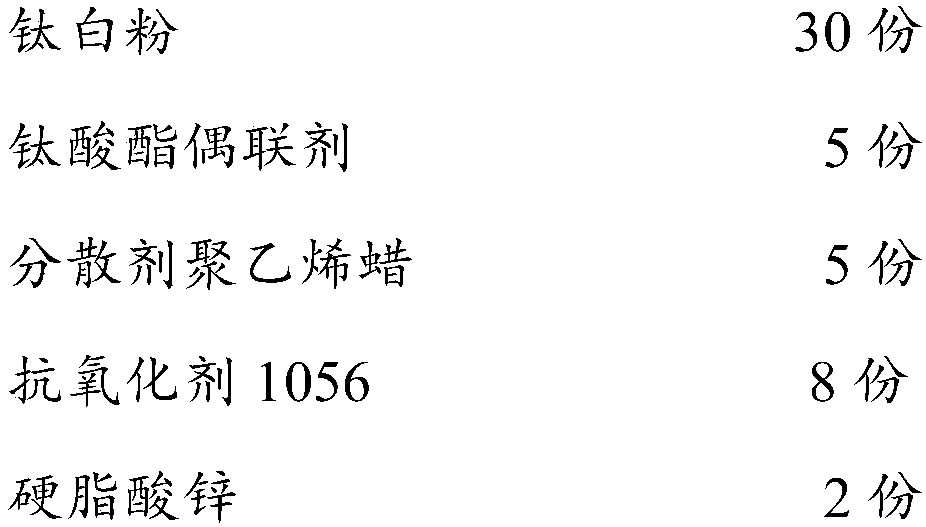

Coupling anti-oxidation special color master batch for barrier bottle and preparation method of coupling anti-oxidation special color master batch

The invention provides a coupling anti-oxidation special color master batch for a barrier bottle and a preparation method of the coupling anti-oxidation special color master batch. The coupling anti-oxidation special color master batch comprises, by weight, 10-50 parts of high-density polyethylene, 10-20 parts of low-density polyethylene, 3-6 parts of low-density linear polyethylene, 10-40 parts of pigment toners, 1-5 parts of titanate coupling agents, 3-10 parts of dispersant polyethylene wax, 5-10 parts of antioxidants and 1-3 parts of stearate. The coupling anti-oxidation special color master batch is modified by adding the coupling agents and the antioxidants. The color master batch has the advantages that the color master batch has high concentration and dispersity and has coupling, oxygen inhibition and anti-oxidation functions, and the barrier effect of the barrier bottle is further enhanced.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

Photo-cured printing ink for ink-jet printer

The invention discloses photo-cured printing ink for an ink-jet printer, relates to a preparation method of the photo-cured printing ink, and belongs to the technical field of ink-jet printing. The photo-cured printing ink comprises 30-90wt% of epoxy monomer, 5-50wt% of diluents, 0.1-20% of coloring agents, 0-20wt% of dispersing agents, 0.5-40wt% of auxiliaries and the like which are grinded and scattered to obtain color paste, 0.1-20% of photo-initiators and sensitizers are added into the mixture, the mixture is sufficiently dissolved and scattered in ink by stirring and ultrasound, and the ink is filtered at multiple stages and then degassed to obtain the photo-cured printing ink. The photo-cured printing ink can be used for the ink-jet printer and has the advantages that the ink is completely cured, the curing degree is also increased, the size is reduced, oxygen inhibition is avoided, zero VOC (volatile organic compounds) emission is avoided, environmental pollution is decreased, cured wavelengths move towards visible light, and the application range is extended.

Owner:CHANGSHU RES INST OF DALIAN UNIV OF TECH CO LTD

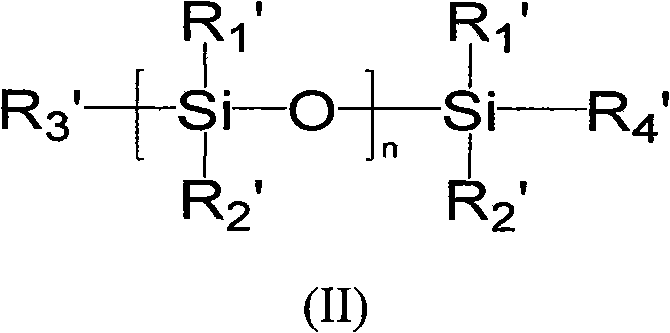

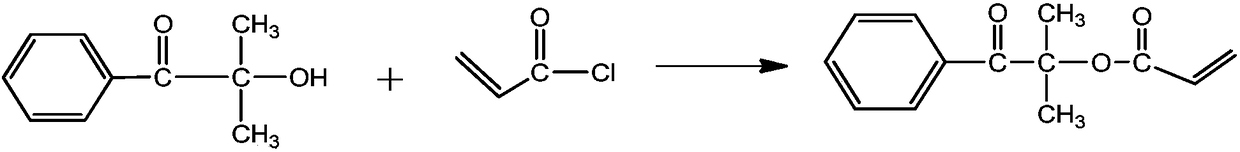

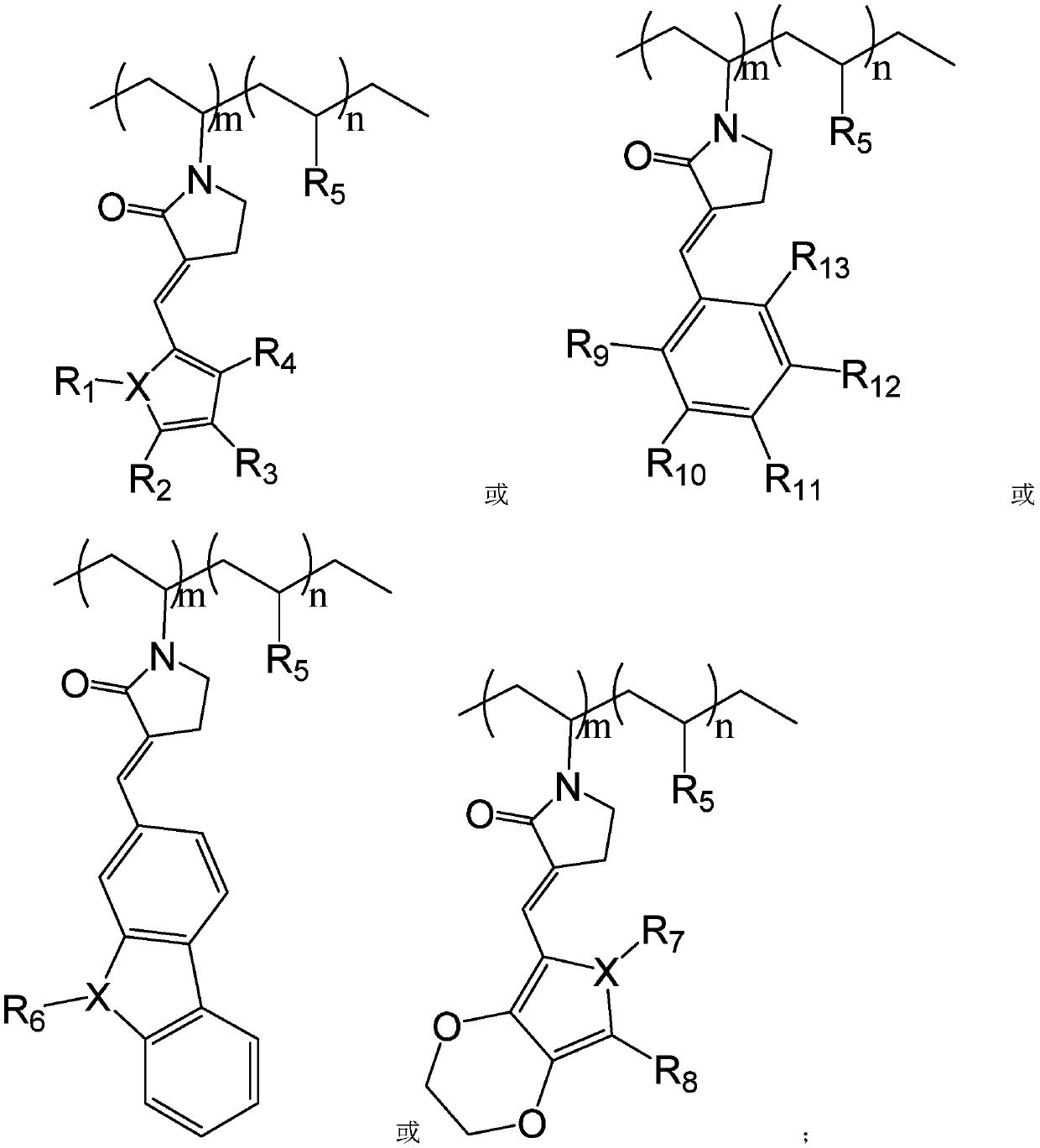

Copolymerized macromolecular photoinitiator and preparation method thereof

The invention discloses a copolymerized macromolecular photoinitiator, and relates to the technical field of synthesizing photoinitiators in the field of photopolymerization. and the photoinitiator has a structural formula shown in the specification. The present invention also provides a preparation method for preparing the above photoinitiator. The beneficial effect is that the prepared copolymerized macromolecular photoinitiator of the invention can be copolymerized with different comonomers to improve the oxygen inhibition problem, and can provide a hydrogen donor as a one-component multi-faceted photoinitiator.

Owner:BEIJING UNIV OF CHEM TECH +1

Preparation method of high-wear-resistance UV matte paint and preparation method of high-wear-resistance UV matte coating

The invention discloses a preparation method of high-wear-resistance UV matte paint, comprising the steps of S1, mixing well a photosensitive monomer, a photoinitiator, a dispersant and a defoaming agent, allowing standing until foam completely disappears to obtain mixed liquid A; S2, adding matte powder and matte wax into the mixed liquid A of step S1, fully wetting the powder, adding a photosensitive prepolymer and a leveling slipping agent, and mixing well at a high speed to obtain mixed liquid B; S3, mechanically grinding the mixed liquid B of step S2, and dispersing to obtain mixed liquidC; S4, stirring well the mixed liquid C of step S3 at a high speed to obtain the high-wear-resistance UV matte paint. Stirring and pre-dispersing are performed under low viscosity, low speed and lowfoam before high-speed stirring and grinding, and high-speed stirring is finally performed; the dispersing mode above helps effectively solve the problems that, for instance, powder easily thickens again after dispersing and the power has a large distribution range of particle size. Preparation of the coating herein employs a high-energy high-speed curing process under nitrogen protection; the insufficient surface scratch resistance due to oxygen inhibition during light coating can be effectively improved.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

Ultraviolet curing adhesive capable of being quickly cured at low energy and preparation method of ultraviolet curing adhesive

InactiveCN106753183ASave energyOvercome the effects of oxygen inhibitionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdjuvantAdhesive

The invention discloses an ultraviolet curing adhesive capable of being quickly cured at low energy and a preparation method of the ultraviolet curing adhesive. The adhesive is prepared from the following raw materials by weight: 30 to 60 percent of an acrylate oligomer, 20 to 50 percent of an active diluent, 2 to 5 percent of a photoinitiator, 1 to 4 percent of an adjuvant and 2 to 5 percent of a low-polyamine synergist. Compared with the prior art, the ultraviolet curing adhesive disclosed by the invention has the advantages that by optimal screening of the acrylate oligomer and the active diluent, particularly by adding of the low-polyamine synergist, the influence of oxygen inhibition is effectively avoided; furthermore, the crosslinking curing efficiency is improved, and the energy to be absorbed for curing of the ultraviolet curing adhesive is greatly reduced, so that the portion which cannot be irradiated by ultraviolet rays can be cured through low energy reflection light rays, and the application field of the ultraviolet curing adhesive is expanded; the energy required by complete curing of the adhesive is less than or equal to 30 mj / cm<2>; meanwhile, after being cured, the ultraviolet curing adhesive is high in strength, high in surface dryness, high in toughness, excellent in damp-heat resistance and high temperature resistance, and the like.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Light resistance composition as well as preparation method and display device thereof

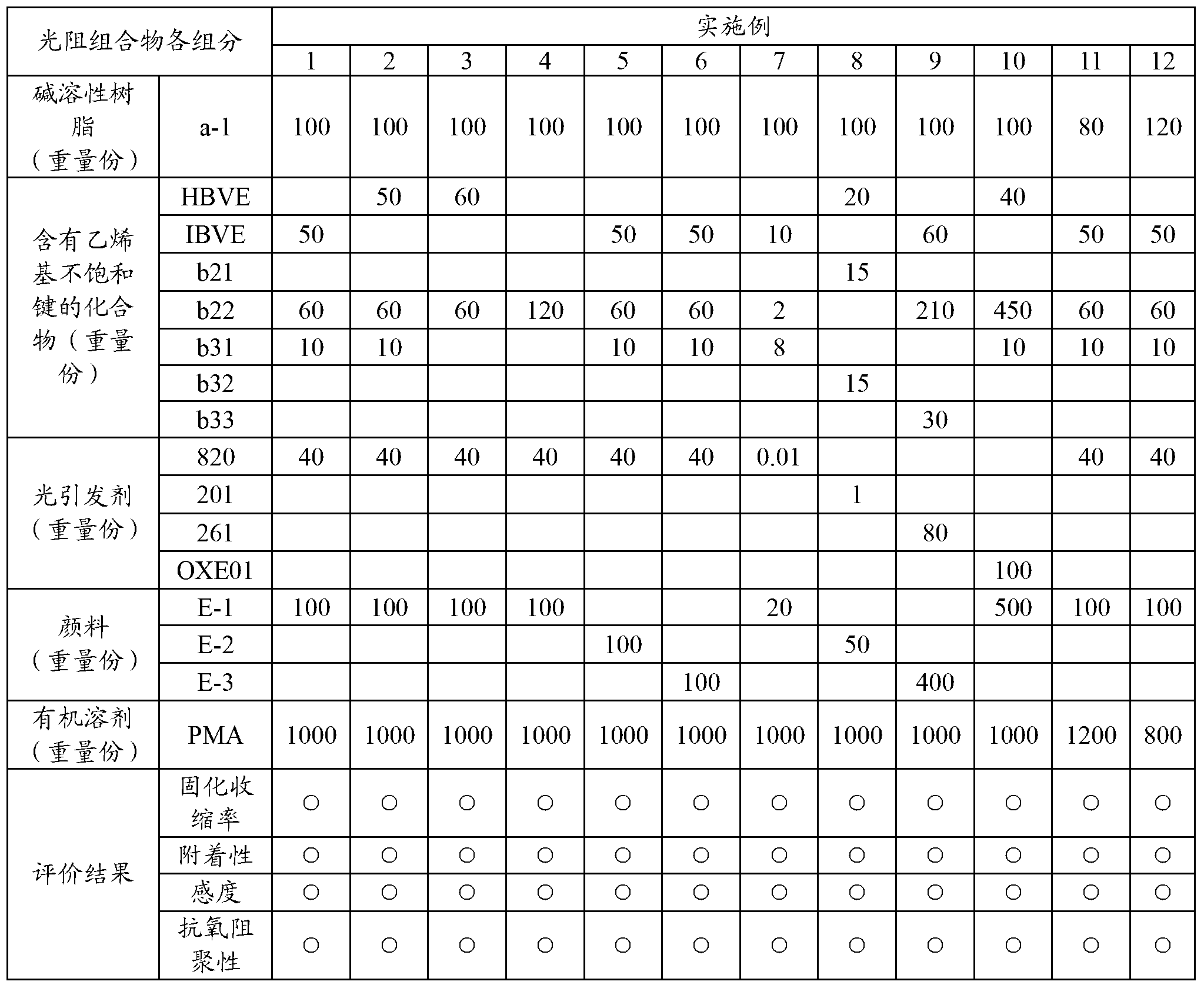

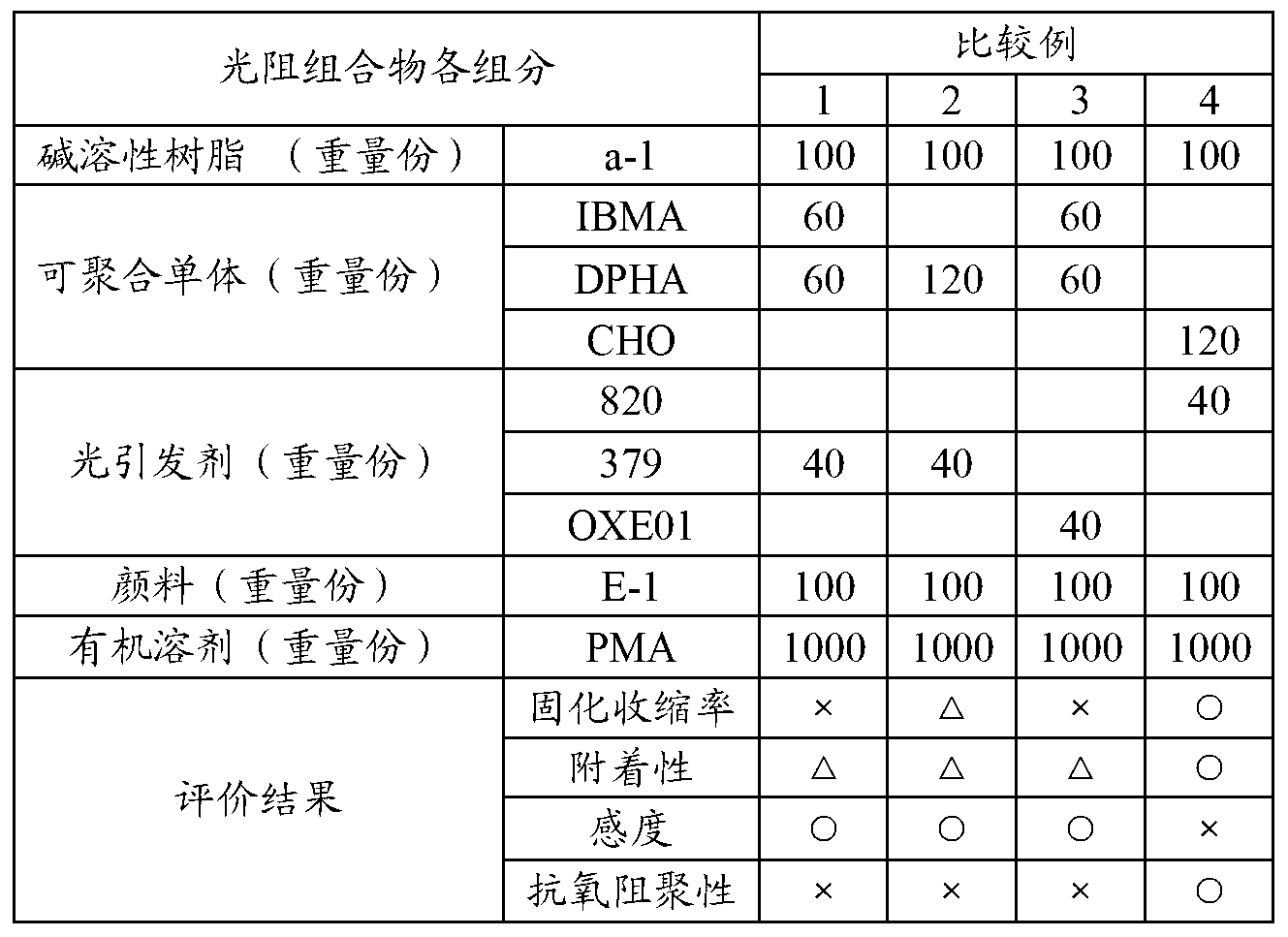

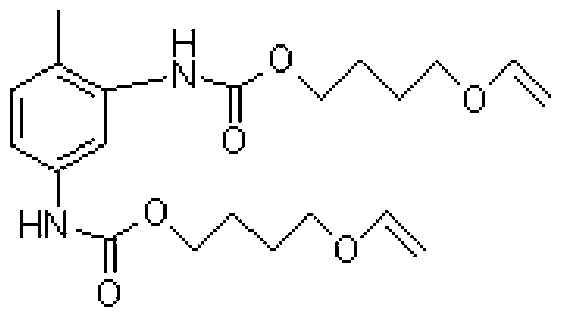

ActiveCN103235484AShorten production timeImprove adhesionOptical filtersPhotosensitive materials for photomechanical apparatusOrganic solventCationic polymerization

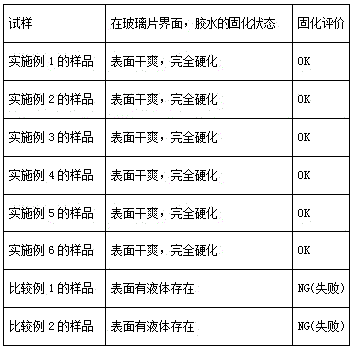

The invention relates to the technical field of display and in particular relates to a light resistance composition as well as a preparation method and a display device thereof. The light resistance composition comprises the following components: 80-120 parts of alkali soluble resin, 20-500 parts of compound containing a vinyl unsaturated bond, 0.01-100 parts of photoinitiator, 20-500 parts of pigment and 800-1200 parts of organic solvent, wherein the compound containing the vinyl unsaturated bond can participate in a cationic polymerization reaction. The light resistance composition can not be influenced by oxygen inhibition when carrying out ultraviolet irradiation and a polymerization reaction, so that oxygen blocking equipment is not required, and reduction of production cost of a product can be facilitated.

Owner:BOE TECH GRP CO LTD

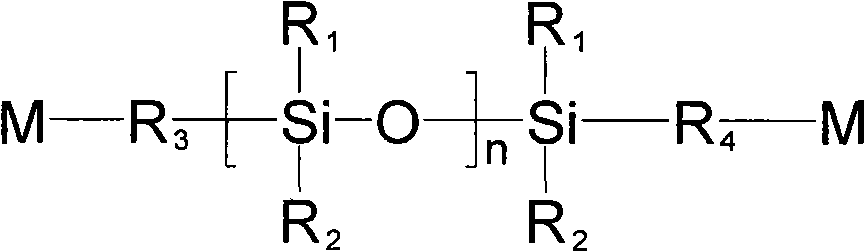

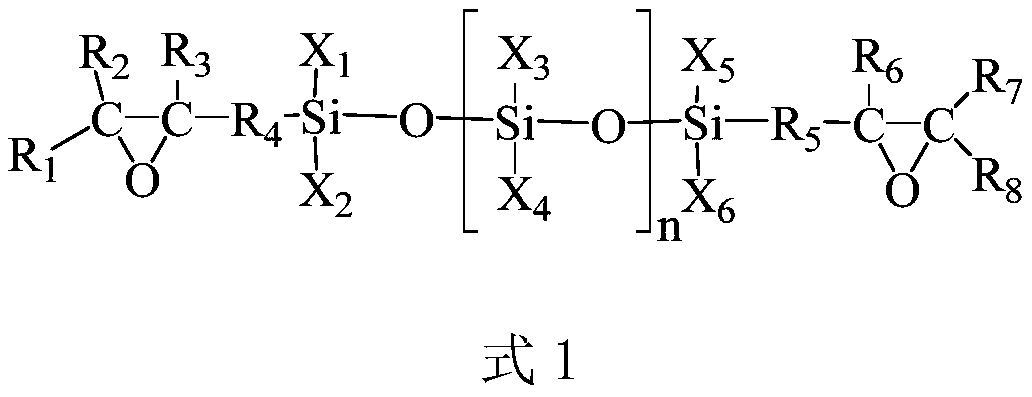

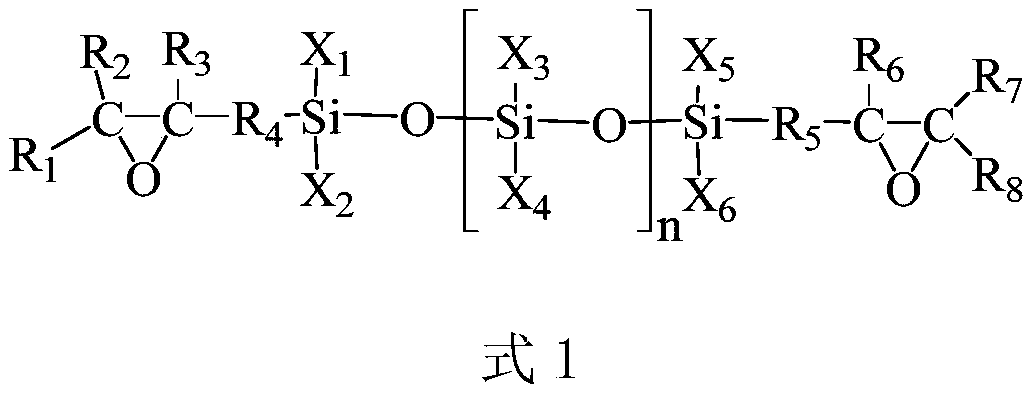

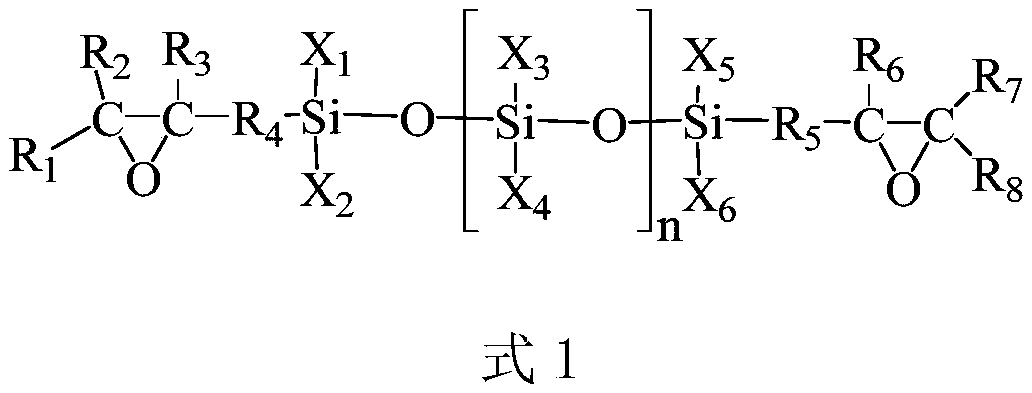

Ink composition, packaging structure and semiconductor device

PendingCN111826024AImprove light curing rateCuring shrinkage is smallSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

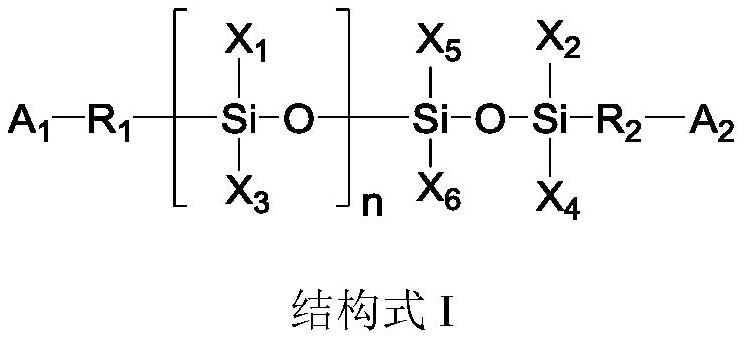

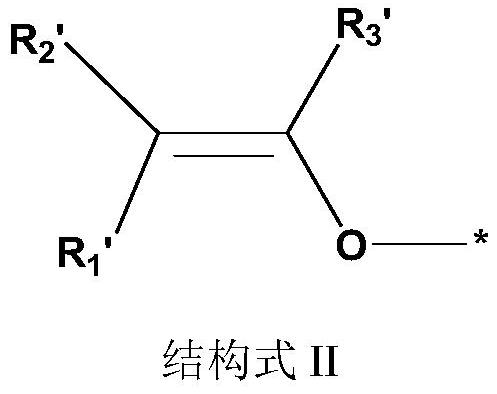

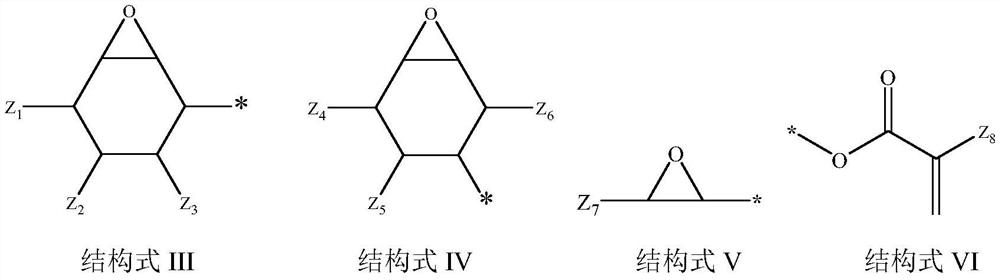

The invention provides an ink composition, a packaging structure and a semiconductor device. The ink composition comprises a photocurable silicon-containing monomer component, an active diluent component and a photoinitiator component, wherein the photocurable silicon-containing monomer component is a photocurable silicon-containing monomer or a combination of a plurality of photocurable silicon-containing monomers, and each photocurable silicon-containing monomer has the following structural formula I: at least one of A1 and A2 in the photocurable silicon-containing monomer component is represented by any one of structural formulas II. According to the invention, when the silicon-containing monomer containing the alkenyl ether bond and the component containing the reactive diluent are matched for use, the free radical-cation hybrid curing system can be formed, and the free radical-cation hybrid curing system can reduce oxygen inhibition, improve the curing speed and reduce the curingshrinkage rate, so that the photocuring rate of the system can be improved, and the curing shrinkage rate of the system can be reduced; and thus, the organic barrier layer with relatively high photocuring rate and relatively low curing shrinkage rate is obtained.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com