Anti-ultraviolet transparent hard coating film for in-mold decoration (IMD)

A technology of anti-ultraviolet and in-mold decoration, which is applied in the direction of chemical instruments and methods, coatings, instruments, etc., can solve the problem of embrittlement, high-hardness hardened film brittleness that is difficult to meet the tensile performance requirements of IMD molding, and IMD products aging and yellowing and other issues to achieve the effect of solving the consumption problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] HM-234 40.0 parts

[0090] 601A-35 10.0 parts

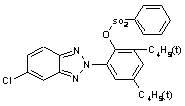

[0091] UV-absorbing precursor UVP-1 2.0 parts

[0092] Hydrogen proton donor H-1 5.0 parts

[0093] Photoinitiator 184 7.0 parts

[0094] Tertiary amine 7.0 parts

[0095] Levaslip 432 1.0 servings

[0096] Butanone 14.0 parts

[0097] Ethyl cellosolve 14.0 parts

[0098]To 40.0 parts by weight polyester acrylate prepolymer HM-234 (manufactured by Jiangxi Kunlong New Material Co., Ltd., functionality 3, average molecular weight 1500) and 10.0 parts by weight organic-inorganic hybrid oligomer 601A-35 (Changxing Chemical Manufactured by Industrial Co., Ltd., functionality 2, average molecular weight 550), add 2.0 parts by weight of UV-absorbing precursor UVP-1 (developed by China Lucky Film Group Corporation) and 4.0 parts by weight of hydrogen proton donor H-1 (developed by China Lucky Film Group Corporation), and 1.0 parts by weight of leveling agent Levaslip 432 [manufactured by Deqian (Shanghai) Chemical Co., Ltd....

Embodiment 2

[0101] B-530 UV 20.0 copies;

[0102] 601B-35 30.0 copies;

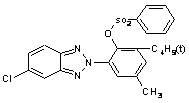

[0103] UV-absorbing precursor UVP-2 2.0 parts;

[0104] 4.0 parts of hydrogen proton donor H-2;

[0105] Photoinitiator 1173 3.2 parts;

[0106] 4.0 parts of secondary amine;

[0107] Levaslip 410 2.0 parts;

[0108] Butanone 34.8 parts;

[0109] To 20.0 parts by weight polyester acrylate prepolymer B-530 UV (manufactured by Guangzhou Boxing Chemical Technology Co., Ltd., functionality 4, average molecular weight 2500) and 30.0 parts by weight organic-inorganic hybrid oligomer 601B-35 ( Manufactured by Changxing Chemical Industry Co., Ltd. (functionality 2, average molecular weight 600), 2.0 parts by weight of UV-absorbing precursor UVP-2 (developed by China Lucky Film Group Corporation) and 4.0 parts by weight of hydrogen proton donor H -2 (developed by China Lucky Film Group Corporation), add 2.0 parts by weight of leveling agent Levaslip 410 [manufactured by Deqian (Shanghai) Chemical Co., Ltd.] with polydim...

Embodiment 3

[0112] CN2262 28.0 copies;

[0113] 601C-35 17.0 copies;

[0114] UV-absorbing precursor UVP-3 5.0 parts;

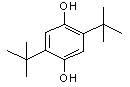

[0115] 10.0 parts of hydrogen proton donor H-3;

[0116] 2.8 parts of photoinitiator 184;

[0117] 4.0 parts of tertiary amine;

[0118] BYK 377 1.2 copies;

[0119] 15.5 parts of ethanol;

[0120] 15.5 parts of isopropanol;

[0121] To 28.0 parts by weight of polyester acrylate prepolymer CN2262 (manufactured by Shanghai Juncai Chemical Technology Co., Ltd., functionality 5, average molecular weight of 1000) and 17.0 parts by weight of organic-inorganic hybrid oligomer 601C-35 (Changxing Chemical Industry Co., Ltd. Co., Ltd., functionality 2, average molecular weight 800), while adding 5.0 parts by weight of UV-absorbing precursor UVP-3 (developed by China Lucky Film Group Corporation) and 10.0 parts by weight of hydrogen proton donor H-3 (China Lucky Film Group Co., Ltd.), and 1.2 parts by weight of leveling agent BYK 377 (manufactured by BYK Chemicals) and 2.8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com