Crystal growth tank used for freezing and concentration

A freeze-concentration and crystallization tank technology, applied in the direction of solution crystallization, can solve the problems of increased operation pollution, high equipment costs, and many procedures, and achieve the effect of reducing operation pollution, saving equipment costs, and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

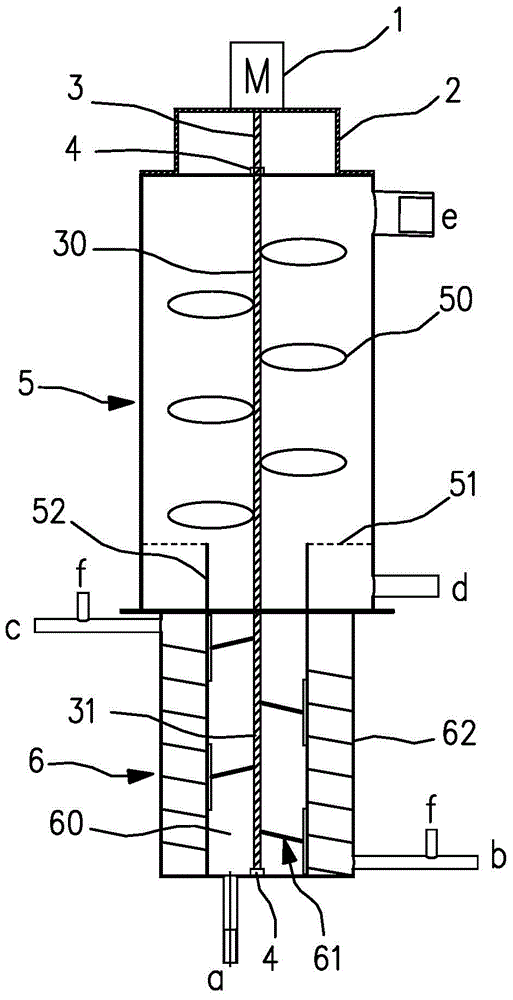

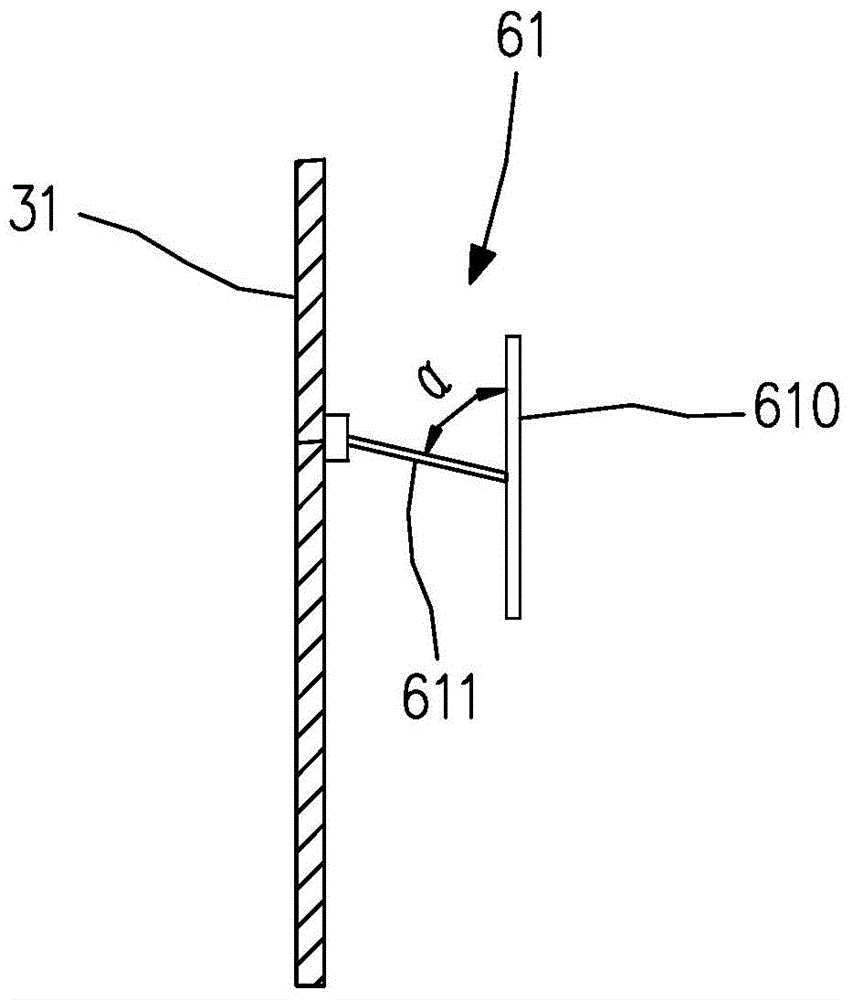

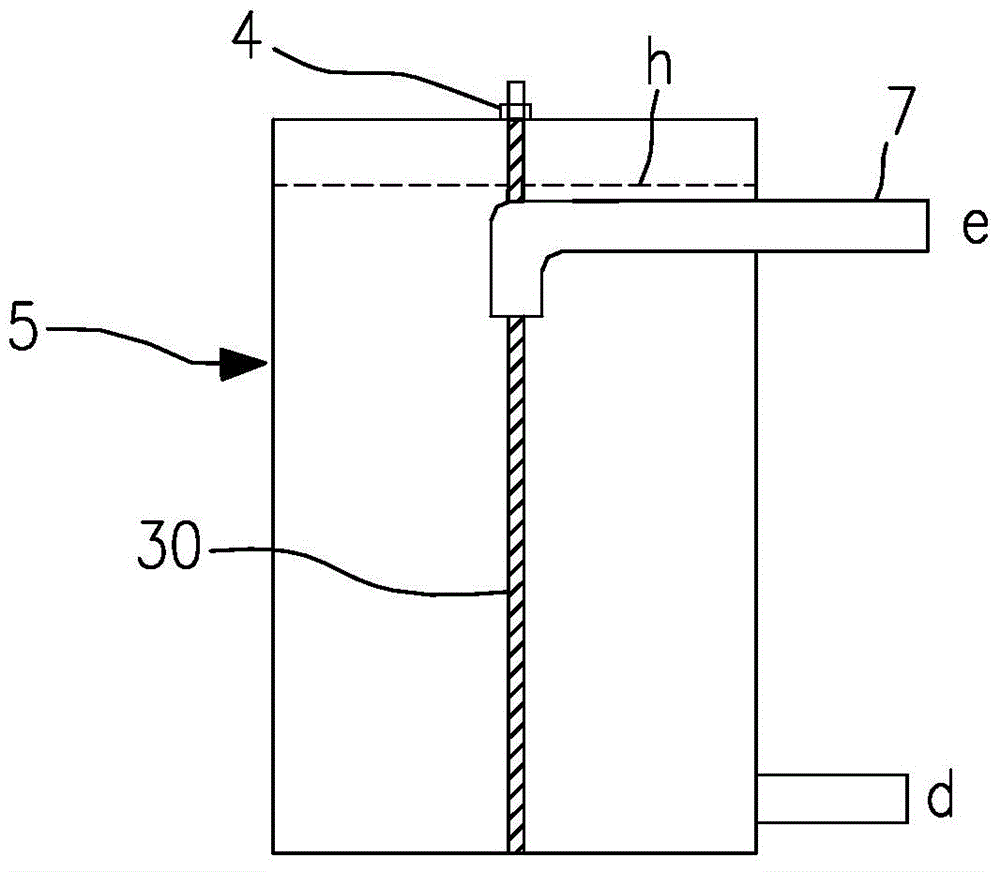

[0039] Such as figure 1 As shown, the figure is a crystal growth tank for freeze concentration, including a cylindrical crystallization tank 6 and a growth tank 5, the crystallization tank 6 is arranged on the lower side of the growth tank 5, and the two are coaxially arranged And communicate with each other as a whole; this crystal growth tank is provided with a rotating shaft 3 at the central axis of the crystallization tank body 6 and the growth tank body 5, and the rotation shaft 3 is rotatably fixed and sealed on the top of the growth tank body 5 and the crystallization tank body 6 Between the bottom of the bottom; the rotating shaft 3 is driven by the ice scraping motor 1, the ice scraping motor 1 is fixed on the ice scraping motor base 2, and the ice scrapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com