Microcrystalline domestic ceramic prepared by talcum

A technology of microcrystalline ceramics and talc, which is applied in the field of microcrystalline daily-use ceramics to achieve various performance and appearance quality requirements, solve supply bottlenecks, and stabilize quality and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

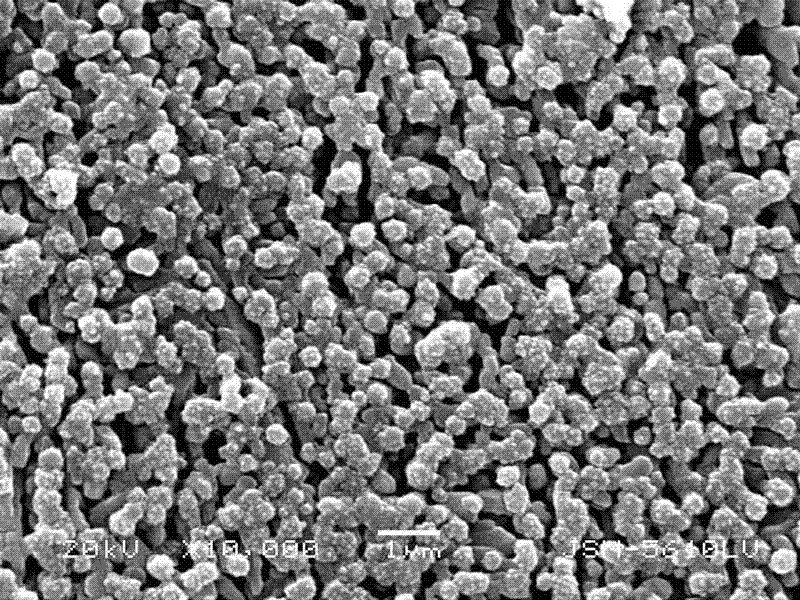

Image

Examples

Embodiment 1

[0018] Take 62 grams of talc, 56 grams of albite, 4 grams of potassium feldspar, and 1.5 grams of barium carbonate, put them into a grinder for grinding and mixing, and pass through a 60-mesh sieve to obtain powder. Put the mixed powder into the electric melting furnace for melting, and keep it warm at 1520°C for 3 hours. After it is completely melted into a uniform liquid, it is fed into the mold of the centrifugal molding machine with a liquid extractor for molding. The microcrystalline ceramic matrix is obtained by annealing in the furnace, and the chemical composition of the obtained microcrystalline ceramic matrix is (in terms of moles): 0.06K 2 O, 0.92Na 2 O, 0.43CaO, 1.0Al 2 o 3 , 11.3SiO2 2 , 3.9MgO, 0.07BaO, put it on the imitation refractory kiln furniture coated with quartz coating, and then place the microcrystalline ceramic matrix and imitation refractory kiln furniture in the automatic control gradient electric furnace as a whole to keep the temperature ri...

Embodiment 2

[0022] Get 60 grams of talc, 56 grams of albite, 7 grams of potassium feldspar, and 0.3 grams of barium carbonate. Other conditions are the same as in Example 1. The chemical composition of the obtained microcrystalline ceramic matrix is (in moles): 0.1K 2 O, 1.0Na 2 O, 0.45 CaO, 1.0 Al 2 o 3 , 12.3SiO2 2 .

[0023] .

Embodiment 3

[0025] The chemical composition of the microcrystalline ceramic matrix is the same as in Example 1, and it is placed on the imitation refractory kiln furniture coated with quartz coating, and then the microcrystalline ceramic matrix and the imitation refractory kiln furniture are placed in an automatic control In a gradient electric furnace, heat treatment is carried out. The heat treatment parameters are as follows: heating up to 900°C at 5°C / min, holding for 2 hours, then raising the temperature to 1000°C at 1°C / min, holding for 2 hours, taking it out and quenching to 650°C, and then cooling naturally to room temperature to obtain Microcrystalline ceramic products for daily use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com