Environment-friendly UV gloss oil for food packaging and printing

A technology for food packaging and environmental protection, applied in epoxy resin coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor curing effect, singleness, and migration of photoinitiators, so as to deepen the photocuring effect and improve Good printing performance and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Environmentally friendly UV varnish for food packaging and printing, including the following components by weight: 30% prepolymer, 20% active monomer, 10% photoinitiator, 1% defoamer, 1% leveling agent, thickener 8%, 25% solvent and 5% slow-drying water; wherein, the prepolymer is polyurethane acrylic resin and epoxy ester acrylic resin with a mass ratio of 3:2, and the active monomer is neopentyl acrylic resin with a mass ratio of 1:1 Alcohol diacrylate and trimethylolpropane triacrylate, the photoinitiator is bisbenzoylphenyl phosphine oxide and triaryl silicone ether with a mass ratio of 3:2, the defoamer is emulsified silicone oil, leveling agent It is an acrylic resin, the thickener is sodium carboxymethyl cellulose, the solvent is ethanol, and the slow-drying water is 783 slow-drying water.

Embodiment 2

[0025] Embodiment 2: the preparation method of the environment-friendly UV varnish for food packaging and printing

[0026] ①Preparation of prepolymers, active monomers, photoinitiators, defoamers, leveling agents, thickeners, solvents and slow-drying water for later use; polyurethane acrylate and epoxy ester acrylic resin prepolymers for later use, among which photo The initiator is a mixture of a free radical photoinitiator and a cationic photoinitiator;

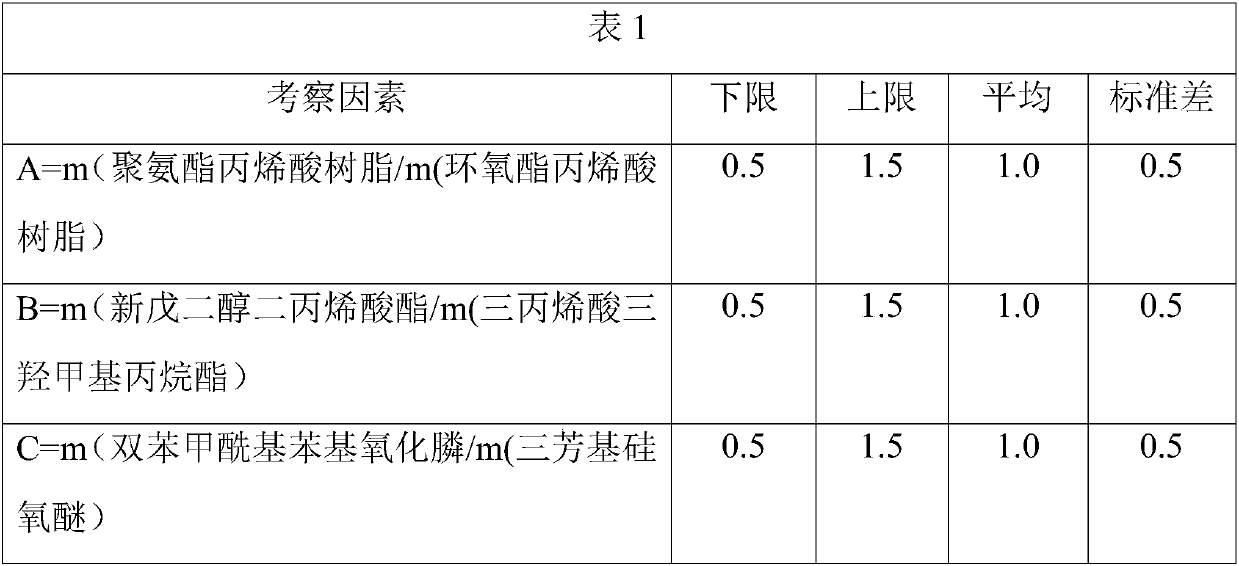

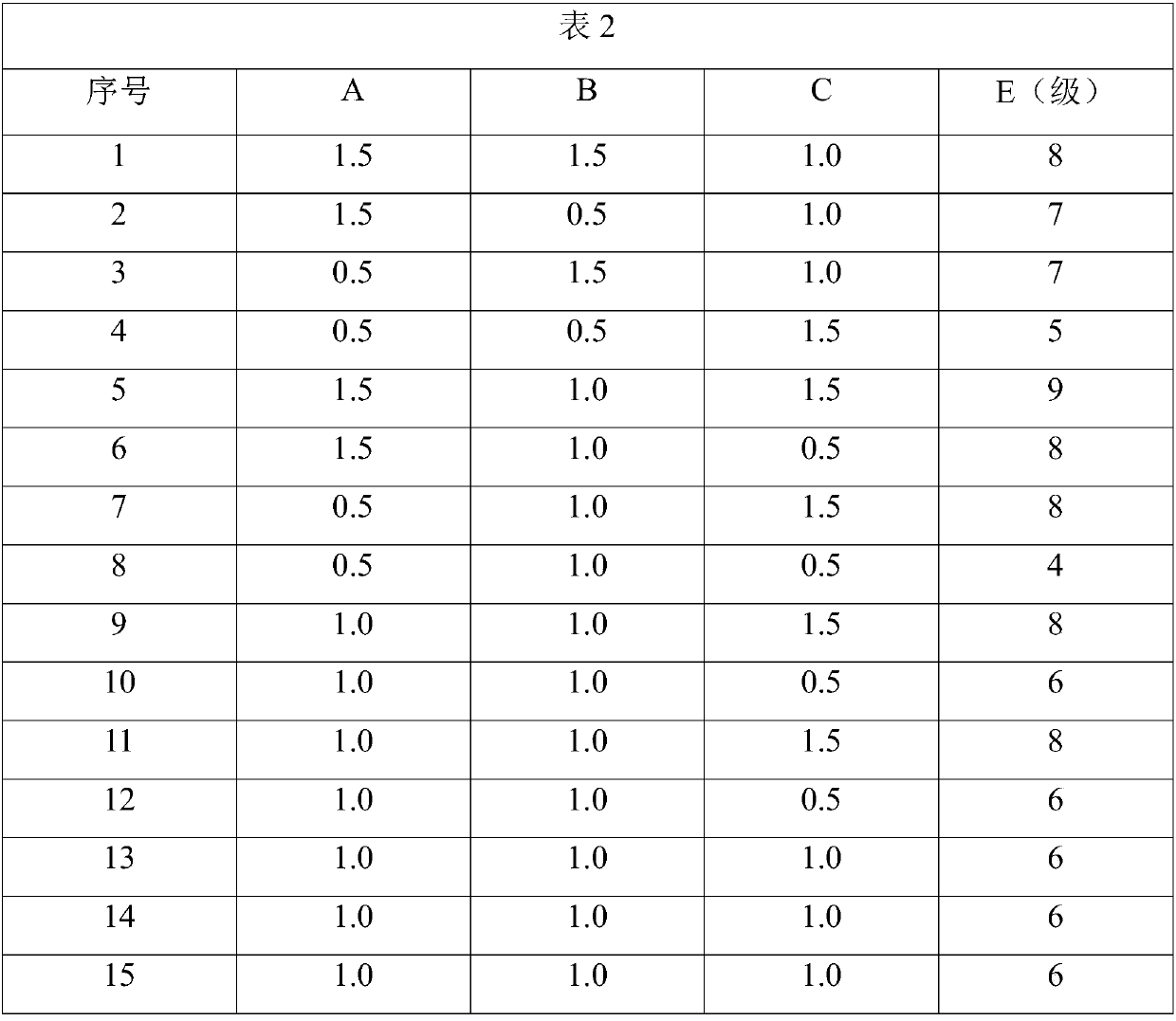

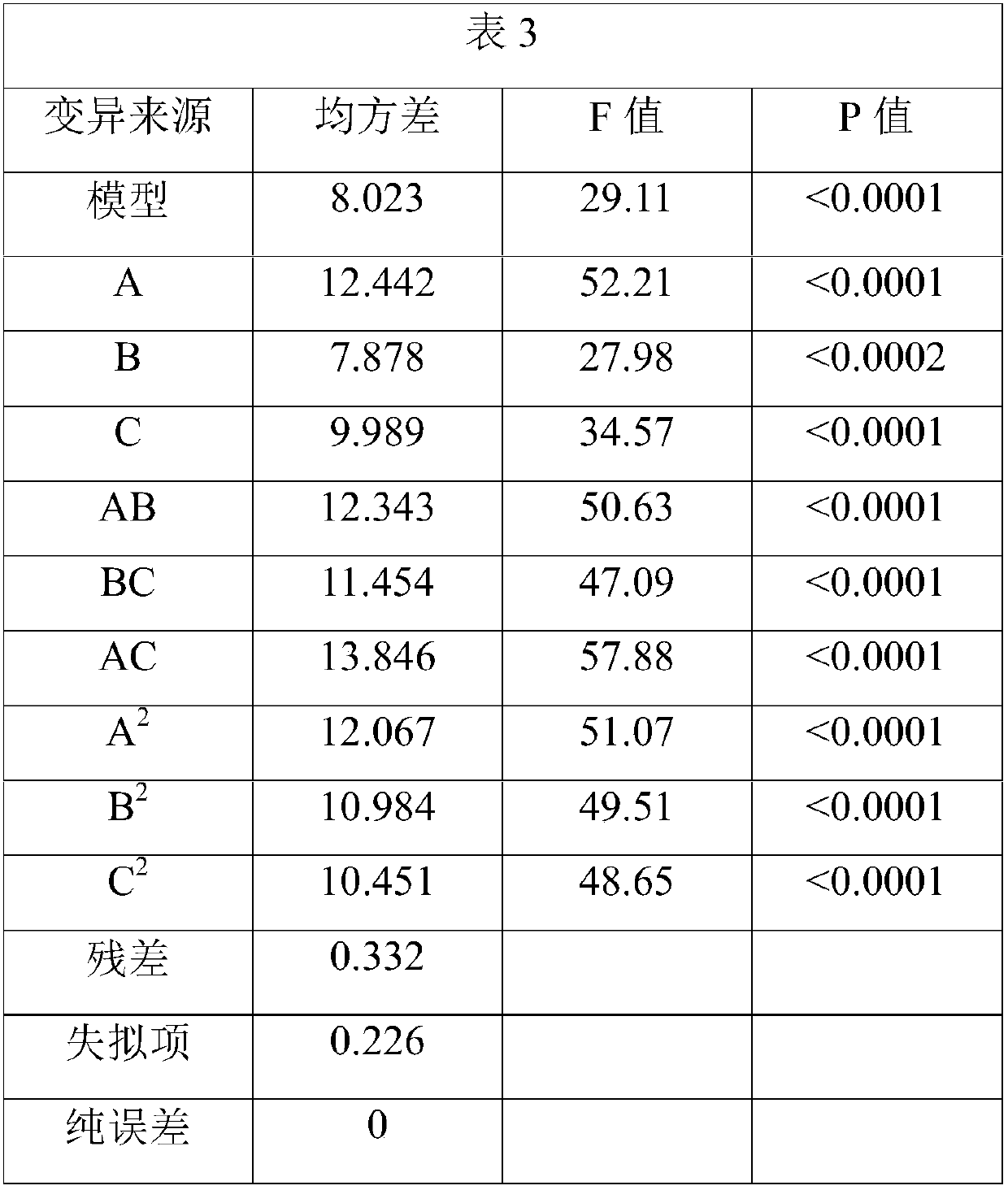

[0027] ② Determine the formula of UV varnish through the design method of response surface experiment;

[0028] ③According to the UV varnish formula in step ②, weigh the prepolymer, active monomer, photoinitiator, defoamer, leveling agent, thickener, solvent and slow-drying water to fully mix, and stir at high speed , the stirring speed is 500-2000 rev / min, and the temperature is controlled below 60°C to fully dissolve completely until transparent to obtain environmentally friendly UV varnish for food packaging and printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com