OPP aluminized film back-coated coating with good fastness to water-based glue and preparation method thereof

A technology of aluminized film and glue, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor fastness and no fastness with water-based glue, and achieve convenient use, excellent pull fastness, VOC low residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

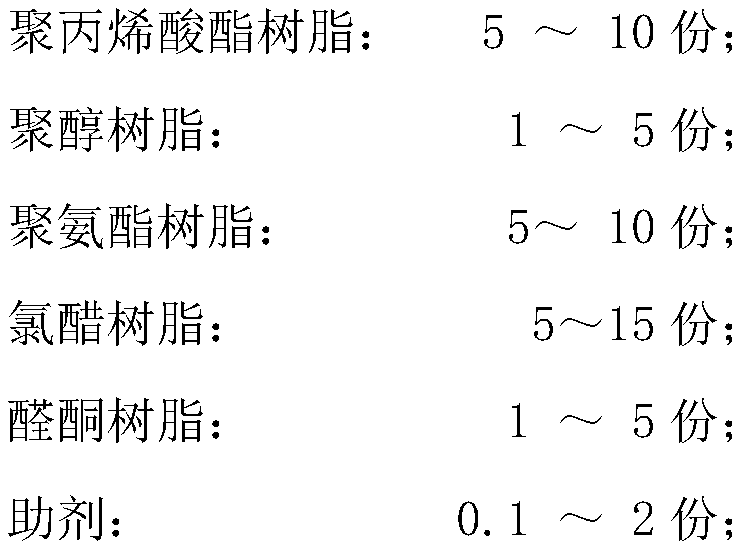

[0031] Examples 1-5 provide an OPP aluminized film back coating with good fastness to water-based glue, and its components and parts by weight are shown in Table 1.

[0032] Its preparation method is specifically:

[0033] (1) Put all the solvents into the reaction kettle, and heat to 30-60°C for stirring;

[0034] (2) Keep stirring and put the resins and additives into the reaction kettle in turn, and stir for 0.5 to 2.5 hours;

[0035] (3) Measure the solid content and adjust to the theoretical value;

[0036] (4) Slowly stir again for 0.5-2.5 hours, cool down, weigh and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com