Water-based environmentally friendly adhesive for inhibiting opp and vmpet composite film aluminizing transfer

A water-based adhesive and composite film technology, applied in the directions of adhesives, adhesive types, adhesive additives, etc., can solve problems such as transfer of aluminum plating, and achieve low additional cost, low VOC residue, and high interlayer composite strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

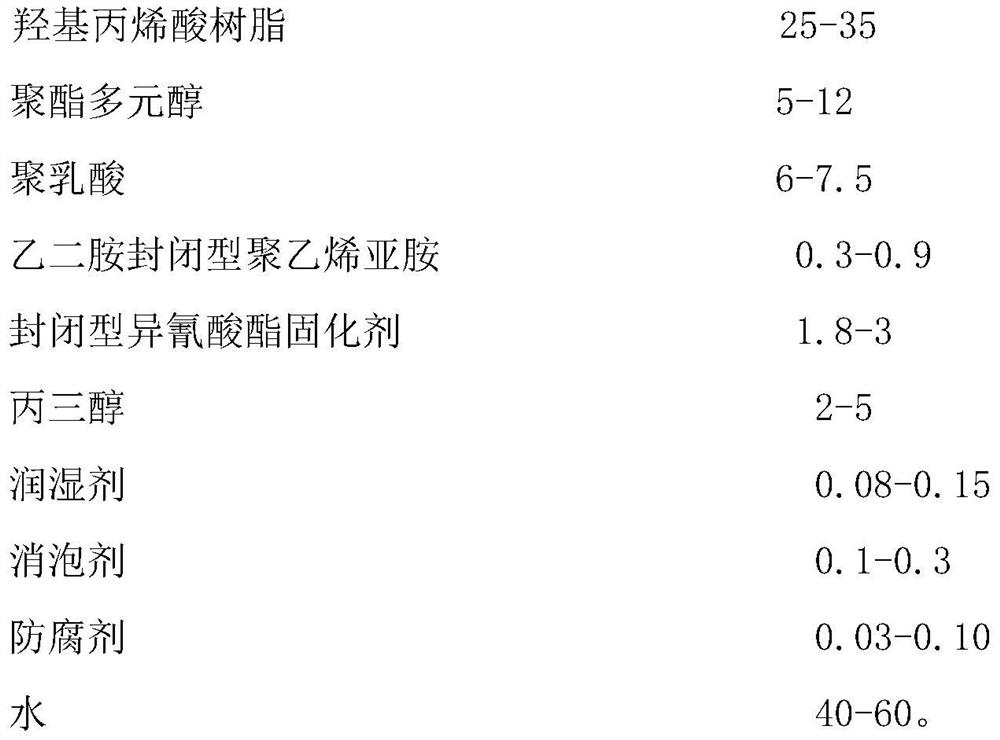

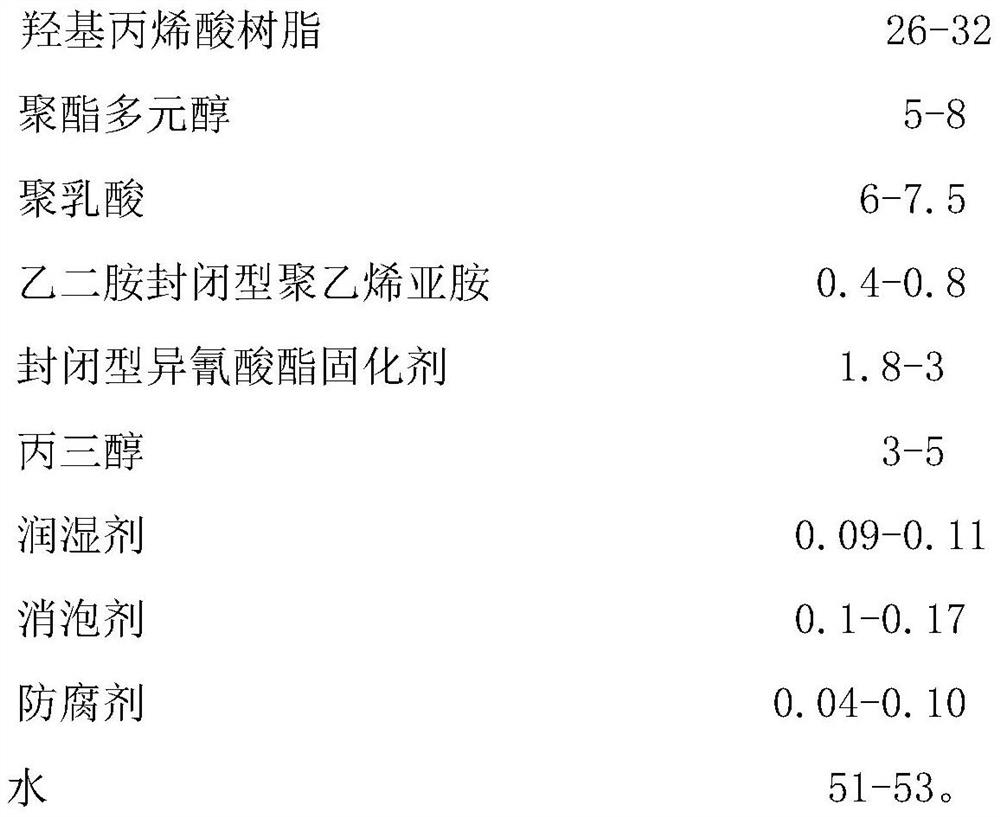

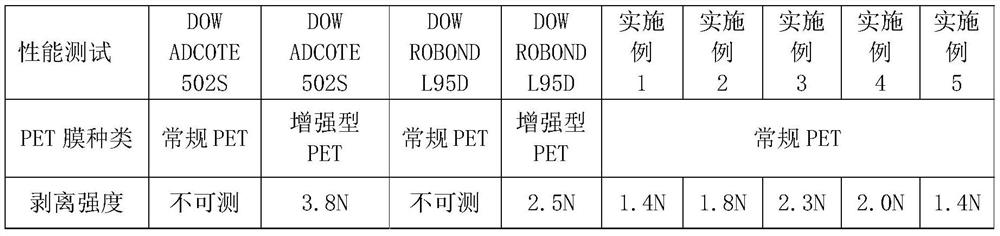

[0031] This embodiment 1-5 provides a water-based adhesive for inhibiting the transfer of OPP / VMPET composite film aluminum plating, and the components and parts by weight of the water-based adhesive are shown in Table 1.

[0032] The preparation method is specifically:

[0033] Table 1

[0034] components Example 1 Example 2 Example 3 Example 4 Example 5 hydroxyacrylic acid 26.0 26 30.0 27.0 32 Polyester polyol 8.0 10.0 5.0 7.0 5.0 polylactic acid 7.0 7.5 6.0 7.2 6.0 Ethylenediamine blocked polyethyleneimine 0.6 0.4 0.5 0.7 0.8 Blocked isocyanate curing agent 2.0 1.8 2.5 2.7 3 Glycerol 5.0 3.5 4.5 4.0 3.0 D 0.11 0.09 0.09 0.10 0.11 Defoamer 0.17 0.15 0.13 0.16 0.10 preservative 0.1 0.08 0.06 0.05 0.04 water 52 53 52 53 51

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com