Water-borne coating sofa leather and preparation method thereof

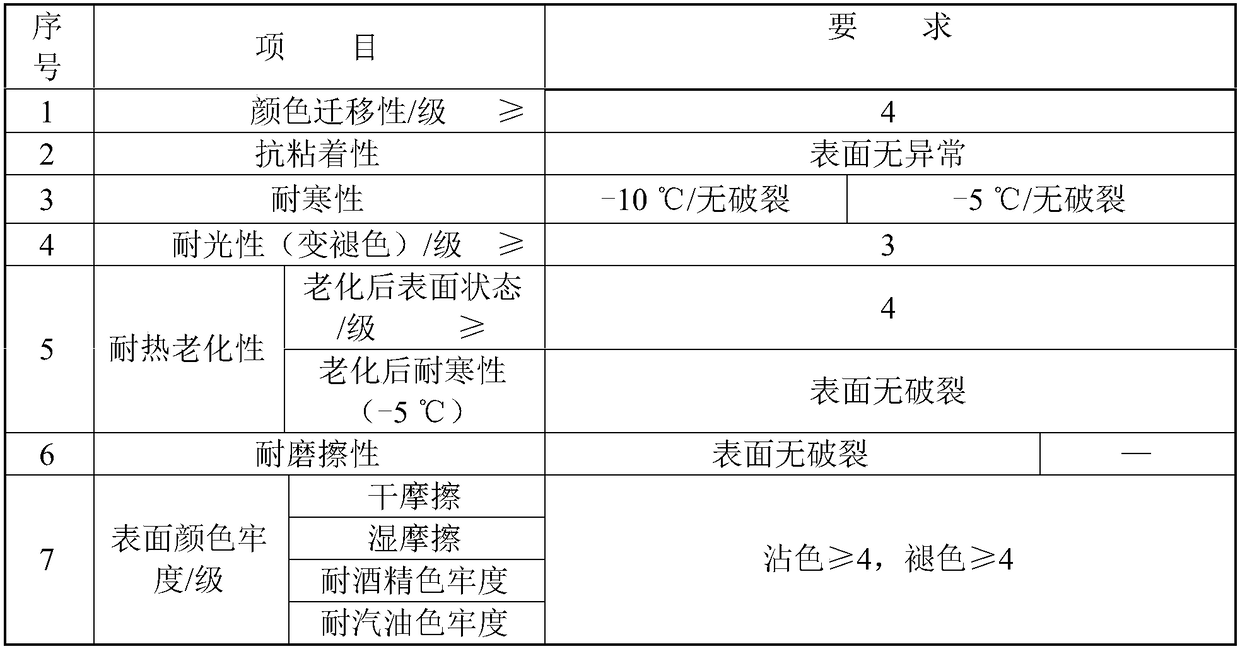

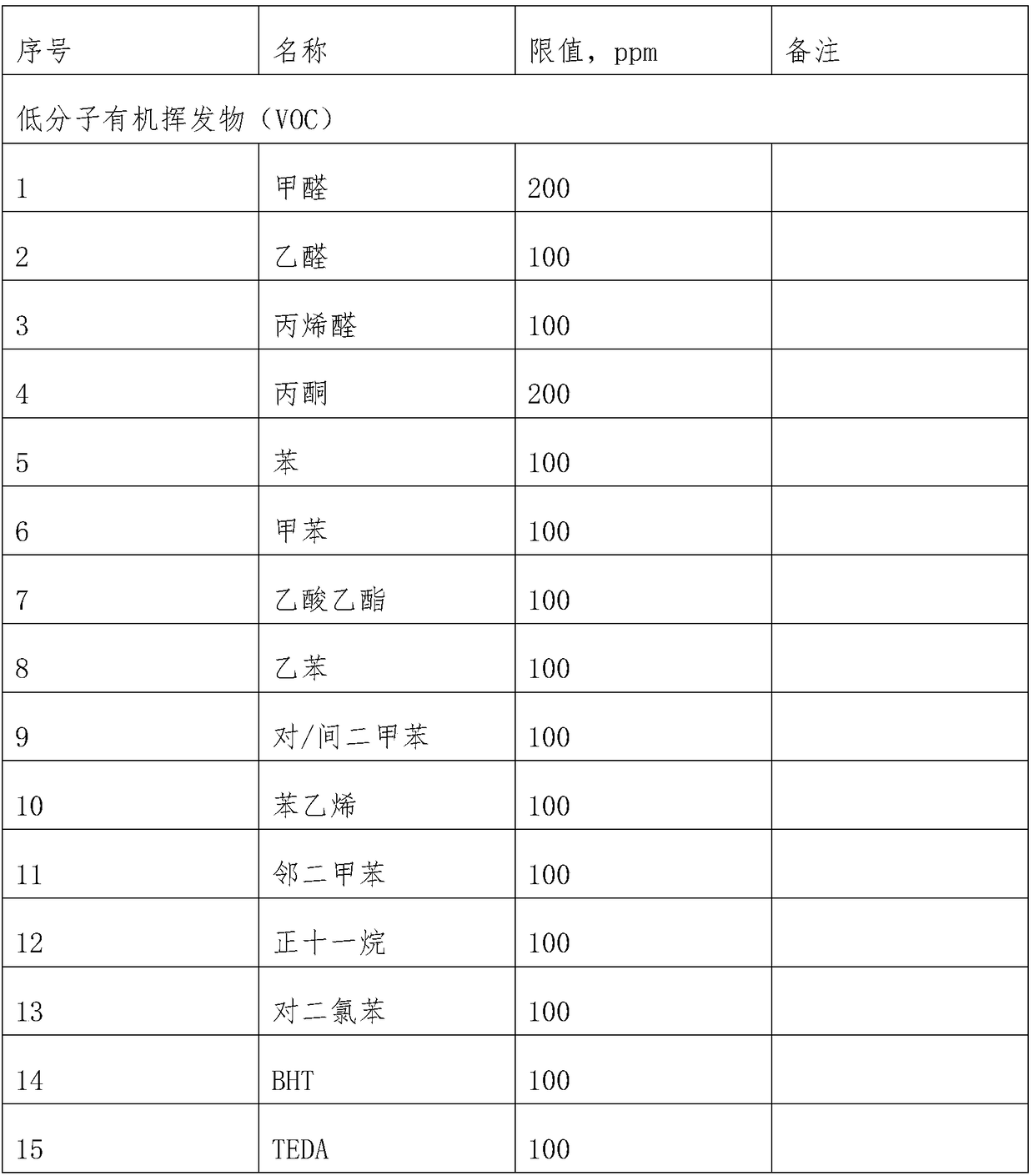

A water-based coating and sofa leather technology, applied in the field of sofa leather, can solve the problems of easy fading, aging, short service life, etc., achieve low VOC residue, good surface color fastness, and reduce VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

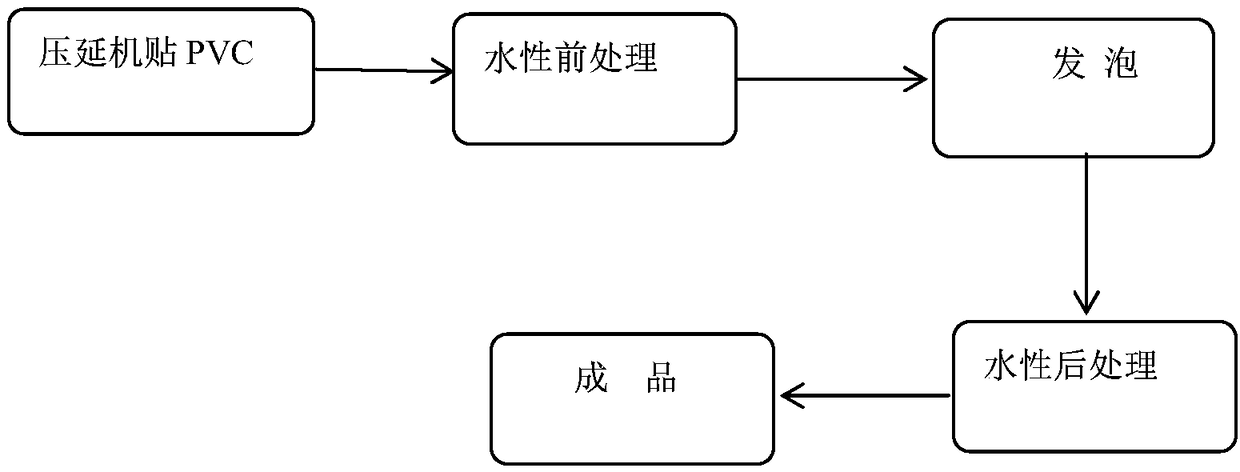

[0022] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0023] A water-based coated sofa leather, comprising a coating layer and an adhesive layer. According to the parts by mass, the coating raw materials include: water-based polyurethane 100, leveling agent 1, wetting agent 2, thickening agent 1.5, defoaming agent 0.5, hand feel Agent 1, Silica 5;

[0024] According to the mass fraction, the adhesive layer includes a foamed layer and a non-foamed layer, and the foamed layer includes: PVC resin SG-5 100, DOP80, stabilizer 4, AC foaming agent 5, foam stabilizer 1, calcium carbonate 80; ACR 1, stearic acid 0.4; non-foamed layer includes: PVC resin SG-3 100, DOP 80, ESPO 2, stabilizer 3, calcium carbonate 20, ACR 1, stearic acid 0.5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com